1933 Ford Coupe/Roadster Stroker Build

#1

TECH Enthusiast

Thread Starter

iTrader: (10)

Join Date: Jun 2010

Location: Boston

Posts: 728

Likes: 0

Received 0 Likes

on

0 Posts

I've been saying im going to post up a build thread, so here it is. Lately i have been a little disappointed in my progress, since things keep coming up. So hopefully this thread will motivate me to get my a$$ moving again.

Background on the project:

When i started the project, all i knew was i wanted to build a hot rod. But the thing was it had to be for as little money as possible. I had just started working since i've graduated college, and am saving to buy a house. So the majority of my budget had to come from whatever i sold my last project car for. Last summer about a week after i graduated college i set out on a journey! Most kids head off to Europe, some start looking for a job right away, well i knew the economy sucked, so why kill myself looking for a job, when i knew i could find one easily once the time was right. So what did i do, a week after my last class i bought a 1972 buick skylark. Ran ok, body was decent, interior was rotty, but it was my first real project car. Not one of those things where i had it have it running by the end of the night so i could drive it to school or work the next day. So i spent the summer restoring it. Learned alot about alot! But when i could finally take it out on the road, i thought i was a bit unique driving an old muscle car, till i saw a chevelle and skylark on every corner of my town, WTF! Well so i decided i needed to stand out a little bit more. Well that resulted in a louder exhaust and a louder paint job. Flame Orange! w/ buick gsx stripes. That was fun for a while, but i had some slight motor problems, so only drove it around town. The only engine experience i had at the time was installing a supercharger on my brothers 2.8l v6 passat. So i decided it was time to let her go, and build something i can be more creative with, and actual fabricate.

The guy down the street from me has what i think is a '32 lowboy. Never really had the chance to get a good look at it. But after seeing it thats when i realized its what i had to build, a hotrod.

So i get it in my head i want to build one, but which? I didn't care, anything pre '35 was good for me, but i wanted to have a sick frame under it, so if i wanted i could swap the body for something nicer. So now im dieing to sell the buick to start this project, luckly someone finally buys it, a little less than i wanted but it was still a profit on what i spent on it and put into it. So now i have 6k to build a hot rod, sure why not. The next day i was off to pick up parts. While waiting to sell it i decided it would be cheapest to pick up a idepended rear suspension from a vette and retrofit it. So a day after the buick sells i pick up the vette irs. Got a nice dana 44 for a steal, and the day after that i pick up enough steel to give me enough work for a few weeks. Thats when i cam across a great deal for the body.

Body/Frame:

The body of the car is a fiberglass replica of a 1933 ford roadster, but it has a removable hard top. I bought it from someone who thought it was going to be an easy project, and never got to it. And from what i was told, be got it from someone who did the same. The seller told me he got it exactly as it was the day i picked it up from him. His father-in-law, who lived down the street had a 36/37 coupe that was built from a kit, and he wanted to do the same. The only difference was, the kit his father-in-law had came complete minus the motor and trans. This car, that he bought for about 13k less than the kit[ he supposedly only paid 6.5k] came sitting on an original chevy top-hat frame from the lat 30's to early 40's. It had a parallel leaf spring front end, with a gm 10bolt from an 80's camaro. This took the whole easyness out of it, since everything had to be fabricated. This is where i come in. He had it for sale on ebay for 6.5k obo. I only wanted the body, since i had already started building a frame from scratch to accommodate any pre-'35 body. After going back and forth a bit he accepted 3.7k for it and the next day off i was to pick it up. The only wrench in the mix was the fact it was a 10hr drive w/ only stops for gas. And to borrow my parents van to pick it up i had to take my mom along. So off my brother, my mom and i go to pick up a hot rod. The drive down took 11 hours, since we stopped for food and gas a few times. Stayed at a hotel. picked the car up bright and early the next morning, and back on the road by 10ish am. The rid back took about 10 hours with quicker stops and eating while driving. I also drove slower on the way down since it was the first time i've ever driven towing a trailer.

Here are a few pics of when we picked up the car.

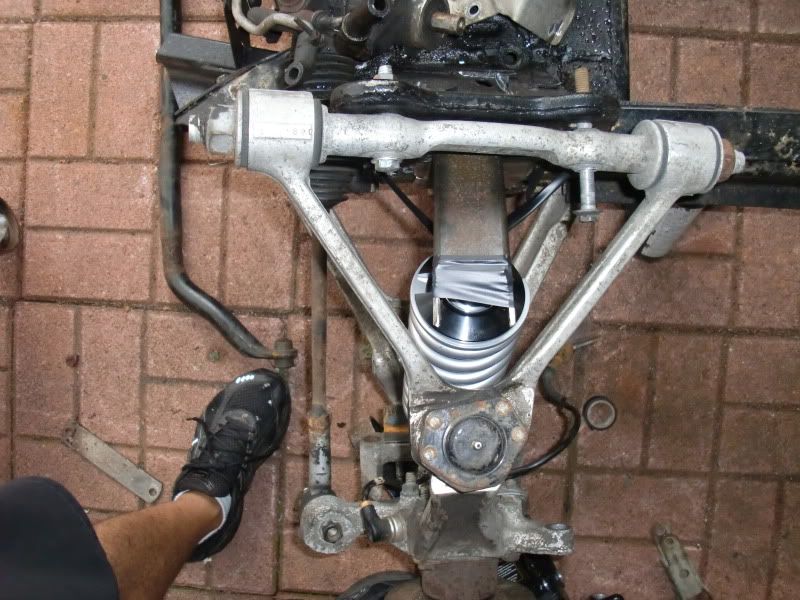

Suspension/Steering/Breaks/[modified frame]:

So as mentioned before the suspension is from a c4 vette. The plan was for a vette irs, and dropped ibeam front for the traditional look, but my body had fenders so it would be hidden anyways. Plus a vette ifs was alot cheaper than the dropped axle setup.both suspension came with disc breaks, and the front cam with the steering rack, so that was all taken car of. The only problem was once i had the frame semi finished and the body mounted, the front leaf spring held the body up way too high. With the motor my car is probably half the weight of the vette, and the motor isn't directly over the front wheels its set back. So i had to go with a coilover set up. So qa1 adjustables it is.

Background on the project:

When i started the project, all i knew was i wanted to build a hot rod. But the thing was it had to be for as little money as possible. I had just started working since i've graduated college, and am saving to buy a house. So the majority of my budget had to come from whatever i sold my last project car for. Last summer about a week after i graduated college i set out on a journey! Most kids head off to Europe, some start looking for a job right away, well i knew the economy sucked, so why kill myself looking for a job, when i knew i could find one easily once the time was right. So what did i do, a week after my last class i bought a 1972 buick skylark. Ran ok, body was decent, interior was rotty, but it was my first real project car. Not one of those things where i had it have it running by the end of the night so i could drive it to school or work the next day. So i spent the summer restoring it. Learned alot about alot! But when i could finally take it out on the road, i thought i was a bit unique driving an old muscle car, till i saw a chevelle and skylark on every corner of my town, WTF! Well so i decided i needed to stand out a little bit more. Well that resulted in a louder exhaust and a louder paint job. Flame Orange! w/ buick gsx stripes. That was fun for a while, but i had some slight motor problems, so only drove it around town. The only engine experience i had at the time was installing a supercharger on my brothers 2.8l v6 passat. So i decided it was time to let her go, and build something i can be more creative with, and actual fabricate.

The guy down the street from me has what i think is a '32 lowboy. Never really had the chance to get a good look at it. But after seeing it thats when i realized its what i had to build, a hotrod.

So i get it in my head i want to build one, but which? I didn't care, anything pre '35 was good for me, but i wanted to have a sick frame under it, so if i wanted i could swap the body for something nicer. So now im dieing to sell the buick to start this project, luckly someone finally buys it, a little less than i wanted but it was still a profit on what i spent on it and put into it. So now i have 6k to build a hot rod, sure why not. The next day i was off to pick up parts. While waiting to sell it i decided it would be cheapest to pick up a idepended rear suspension from a vette and retrofit it. So a day after the buick sells i pick up the vette irs. Got a nice dana 44 for a steal, and the day after that i pick up enough steel to give me enough work for a few weeks. Thats when i cam across a great deal for the body.

Body/Frame:

The body of the car is a fiberglass replica of a 1933 ford roadster, but it has a removable hard top. I bought it from someone who thought it was going to be an easy project, and never got to it. And from what i was told, be got it from someone who did the same. The seller told me he got it exactly as it was the day i picked it up from him. His father-in-law, who lived down the street had a 36/37 coupe that was built from a kit, and he wanted to do the same. The only difference was, the kit his father-in-law had came complete minus the motor and trans. This car, that he bought for about 13k less than the kit[ he supposedly only paid 6.5k] came sitting on an original chevy top-hat frame from the lat 30's to early 40's. It had a parallel leaf spring front end, with a gm 10bolt from an 80's camaro. This took the whole easyness out of it, since everything had to be fabricated. This is where i come in. He had it for sale on ebay for 6.5k obo. I only wanted the body, since i had already started building a frame from scratch to accommodate any pre-'35 body. After going back and forth a bit he accepted 3.7k for it and the next day off i was to pick it up. The only wrench in the mix was the fact it was a 10hr drive w/ only stops for gas. And to borrow my parents van to pick it up i had to take my mom along. So off my brother, my mom and i go to pick up a hot rod. The drive down took 11 hours, since we stopped for food and gas a few times. Stayed at a hotel. picked the car up bright and early the next morning, and back on the road by 10ish am. The rid back took about 10 hours with quicker stops and eating while driving. I also drove slower on the way down since it was the first time i've ever driven towing a trailer.

Here are a few pics of when we picked up the car.

Suspension/Steering/Breaks/[modified frame]:

So as mentioned before the suspension is from a c4 vette. The plan was for a vette irs, and dropped ibeam front for the traditional look, but my body had fenders so it would be hidden anyways. Plus a vette ifs was alot cheaper than the dropped axle setup.both suspension came with disc breaks, and the front cam with the steering rack, so that was all taken car of. The only problem was once i had the frame semi finished and the body mounted, the front leaf spring held the body up way too high. With the motor my car is probably half the weight of the vette, and the motor isn't directly over the front wheels its set back. So i had to go with a coilover set up. So qa1 adjustables it is.

Last edited by Marcello7x; 03-19-2011 at 09:44 PM.

#2

TECH Enthusiast

Thread Starter

iTrader: (10)

Join Date: Jun 2010

Location: Boston

Posts: 728

Likes: 0

Received 0 Likes

on

0 Posts

Motor/trans:

So this is why im here. I originally planned on a simple ls1 t56 pullout. Then once i started reading on this website, i realized i could build a tt 5.3l with a t56 for about the same cost. This is all very budget minded. Then i realized there was no way i was going to stay under budget. So i picked up my 5.3, mocked up mounts and such bolted it to the t56 and sat it on the frame. Then when i go to pull off the truck mani to install my ls1 mani i find water in the heads. There is a thread on it here:https://ls1tech.com/forums/generatio...vice-asap.html

Long story short i got a new motor, and thats where i stand.

I'll put more details on the fuel and turbo system im planning later on. I just wanted to get a thread together.

So this is why im here. I originally planned on a simple ls1 t56 pullout. Then once i started reading on this website, i realized i could build a tt 5.3l with a t56 for about the same cost. This is all very budget minded. Then i realized there was no way i was going to stay under budget. So i picked up my 5.3, mocked up mounts and such bolted it to the t56 and sat it on the frame. Then when i go to pull off the truck mani to install my ls1 mani i find water in the heads. There is a thread on it here:https://ls1tech.com/forums/generatio...vice-asap.html

Long story short i got a new motor, and thats where i stand.

I'll put more details on the fuel and turbo system im planning later on. I just wanted to get a thread together.

#3

TECH Enthusiast

Thread Starter

iTrader: (10)

Join Date: Jun 2010

Location: Boston

Posts: 728

Likes: 0

Received 0 Likes

on

0 Posts

Finally got her started! Huge milestone for me, so figured i would post a quick update/link.

Didn't read where i left off, but frame is complete, new'er 5.3 is in, driveshaft custom cut and installed.....so on.

All i need is to make brakets for the seats, install my brake lines, clutch master, brake master, and route me steering linkage and i can drive it.

http://www.youtube.com/watch?v=t-bFUtRdn4U

Didn't read where i left off, but frame is complete, new'er 5.3 is in, driveshaft custom cut and installed.....so on.

All i need is to make brakets for the seats, install my brake lines, clutch master, brake master, and route me steering linkage and i can drive it.

http://www.youtube.com/watch?v=t-bFUtRdn4U

#4

Awesome build. You're doing a great job with that frame, it's coming along real nice.

What part of Boston do you live in?

Just moved to NC from MA last year, did a lot of work in Boston, lived in Waltham.

What part of Boston do you live in?

Just moved to NC from MA last year, did a lot of work in Boston, lived in Waltham.

#5

TECH Enthusiast

Thread Starter

iTrader: (10)

Join Date: Jun 2010

Location: Boston

Posts: 728

Likes: 0

Received 0 Likes

on

0 Posts

Sry for the lat response, im in medford. I actually have a knee surgery in Walther tomorrow.

Anyways, i wanted to post an update. I've been rallying to get my first drive in before my surgery tomorrow. I don't know how long im going to be out of commission of working on the car. My only hold up was my order from jegs isn't coming till tommorrow. Out off all things in it, it has my steering wheel. So im almost done mounting the seat securely and finished my steering linkage, and one of the older hot rod guys stops by. His buddy lives down the street and is turning his 31 coupe to a pickup. So i figured i would stop by and check it out on my way to home depot for some bolts i was missing. Well guess who had a spare steering wheel just sitting there.

So i made my bolt run and ran home to get the little things buttoned up. Anyways by the time i was done it was almost dark. I wait for my dad to get home from work to check it out. He got out at 5 and was home by 5:10. Then my mother decided to call my uncle and grandma to come see. They live two houses over but still took like 20 min to get everyone there.

So there i am, ready to go. Im not registered, its dark, i have no headlights, and my doors arn't on either so i was worried about cops. My mom doesn't know how to use a cam so she didn't hit record, so no video for now. I start it up, and start to let off the clutch to get a feel for it. i pull out and can feel the body shaking a little. Get to the stop sign and slowly set off. First feels ok, didn't go over 2k or so, shift to second and i gave it a light blip and sideways i go. first thought is holysh*t. let off quickly and start to brake. First car i own or driven with manual breaks so its a workout. Reach the end of the street with less parked cars and i blip[ever so slightly] in first and the back end kicked out good. Thats when i scared myself a little and baby it around the block and home.

This is the first time i've scared myself with the power of a car. Not that a stock 5.3 is fast, but between how light my car is and it feeling alot more raw it scared me. I've topped out the new v8 bmw M3 from a 20mph roll to 150 and didn't flinch.

Going to go for a quick spin tomorrow before my surgery and actually video it.

Anyways, i wanted to post an update. I've been rallying to get my first drive in before my surgery tomorrow. I don't know how long im going to be out of commission of working on the car. My only hold up was my order from jegs isn't coming till tommorrow. Out off all things in it, it has my steering wheel. So im almost done mounting the seat securely and finished my steering linkage, and one of the older hot rod guys stops by. His buddy lives down the street and is turning his 31 coupe to a pickup. So i figured i would stop by and check it out on my way to home depot for some bolts i was missing. Well guess who had a spare steering wheel just sitting there.

So i made my bolt run and ran home to get the little things buttoned up. Anyways by the time i was done it was almost dark. I wait for my dad to get home from work to check it out. He got out at 5 and was home by 5:10. Then my mother decided to call my uncle and grandma to come see. They live two houses over but still took like 20 min to get everyone there.

So there i am, ready to go. Im not registered, its dark, i have no headlights, and my doors arn't on either so i was worried about cops. My mom doesn't know how to use a cam so she didn't hit record, so no video for now. I start it up, and start to let off the clutch to get a feel for it. i pull out and can feel the body shaking a little. Get to the stop sign and slowly set off. First feels ok, didn't go over 2k or so, shift to second and i gave it a light blip and sideways i go. first thought is holysh*t. let off quickly and start to brake. First car i own or driven with manual breaks so its a workout. Reach the end of the street with less parked cars and i blip[ever so slightly] in first and the back end kicked out good. Thats when i scared myself a little and baby it around the block and home.

This is the first time i've scared myself with the power of a car. Not that a stock 5.3 is fast, but between how light my car is and it feeling alot more raw it scared me. I've topped out the new v8 bmw M3 from a 20mph roll to 150 and didn't flinch.

Going to go for a quick spin tomorrow before my surgery and actually video it.

#7

TECH Enthusiast

Thread Starter

iTrader: (10)

Join Date: Jun 2010

Location: Boston

Posts: 728

Likes: 0

Received 0 Likes

on

0 Posts

Yes i am, im going crazy stuck in bed because of my knee. Now im sitting here planning my attach on what to get done next. I need to brace the body much better, it shakes like hell when the tires let loose. Plus i have some weight to spare. I've never broken traction as easily in any car before, and it has the widest tires of any car i've driven [295's]. I'm already planing some spacers and 305/45 dr's.

Trending Topics

#8

TECH Enthusiast

Thread Starter

iTrader: (10)

Join Date: Jun 2010

Location: Boston

Posts: 728

Likes: 0

Received 0 Likes

on

0 Posts

Today was the first day i really made progress on it. A few weeks ago i pulled and sold the motor so there is something else i need to add to the timeframe. Basically what happened was i over sized my boltons and cam. So once i talked to my tuner, slowhawk, he told me everything was mismatched and to either sell the parts or motor and get a 6.0. So i had sold the motor since i figured selling one thing would be easier than a bunch. Then i found a great deal on everything to assemble a 404ci shortblock which included a machined block and all. So i sold the rest of the parts in 2 weeks and picked up the stroker parts. So now i picked up some afr's and all the rest of the parts to assemble the longblock. Its getting dropped off at the machineshop to be built next week once my pat g cam comes in.

In the meanwhile i decided to rebuild the center of my frame. It flexed during the first drive so it needed some work. Today i tore the whole car apart. Pulled out the seats, pedals, wire harness, ecu, steering xolumb, floor. Then leveled out the frame on jackstands and cut out the center section. The plan is tubular steel for the center k member. I ordered a bender from jd2 and assmebled the bender tonight.

Thats all i really got done today. Tomorrow im going to attempt to convert the bender to use the hydraulic ram from my engine crane.

In the meanwhile i decided to rebuild the center of my frame. It flexed during the first drive so it needed some work. Today i tore the whole car apart. Pulled out the seats, pedals, wire harness, ecu, steering xolumb, floor. Then leveled out the frame on jackstands and cut out the center section. The plan is tubular steel for the center k member. I ordered a bender from jd2 and assmebled the bender tonight.

Thats all i really got done today. Tomorrow im going to attempt to convert the bender to use the hydraulic ram from my engine crane.

#9

TECH Senior Member

iTrader: (12)

Great build going, Light car and any amount of power is a great combination.

Frame build can be problematic if not done correctly. 1/4 of a degree, .100" and you can be fighting it forever.

You need to make sure everything is square and level. Your rear Alignment was most likely out and caused the rearend to come around when you mashed the go pedal.

Good Luck and keep the post coming.

BC

Frame build can be problematic if not done correctly. 1/4 of a degree, .100" and you can be fighting it forever.

You need to make sure everything is square and level. Your rear Alignment was most likely out and caused the rearend to come around when you mashed the go pedal.

Good Luck and keep the post coming.

BC

#11

TECH Enthusiast

Thread Starter

iTrader: (10)

Join Date: Jun 2010

Location: Boston

Posts: 728

Likes: 0

Received 0 Likes

on

0 Posts

Ill pit up some engine parts pics tonight, shiny new pistons and such. Theres not much left of the frame, the center is all removed, i have some pics of that as well.

I didnt touch the car at all, but did get my jd2 tube bender mounted to my engine stand and welded on some mounts to convert it to hydraulic with parts from my hoist. Ill take pics when its done. Pumping a hydraulic ram sure beats manual tube bendeing.

The alignment def caused it now that i think about it! It will het sorted out once i make new tie rod bars with hiems. Current setup is rusted and wont unbind to adjust it.

#13

TECH Enthusiast

Thread Starter

iTrader: (10)

Join Date: Jun 2010

Location: Boston

Posts: 728

Likes: 0

Received 0 Likes

on

0 Posts

Here is a post while i was accumulating all my parts with part numbers. This was posted in Gen III internal, if you see the thread i pretty much had a conversation with myself, but at-least i was able to search out part numbers and save them so when i went home from work i had access!

So im trying to get a full list of stuff I need to complete my motor. I have a rotating stroker assembly, block and heads. Im listing off everything I have, then what I need, please chime in with something im forgetting. I have never pieced together a motor before, so I know I WILL forget something. Most important things are the ones the machine shop will need to complete the shortblock. I want to have this thing in the car so I can start work on my subframe. Chassis easily flexed with a stock 5.3l on its maiden voyage, so it needs serious reinforcement. I want to to be able to remove the oil pan, and tranny w/o pulling the motor, but still have the most structural support as possible. A roll bar with the possibility of a roll cage will help with the stiffening.

Details on the build are as follows: 6.0 iron block bored to 4.010. precision stroker crank, TSP diamond -15cc dished pistons, lunati rods, arkly and childs xtreme rings. For heads I have a set of afr 225ís that will be milled down to around 59-60cc chambers. The block was specíed out for a twin turbo build, I purchased it and have no need for more than 500rwhp on a regular basis, so im going to mill the heads to make up for the large piston dishes.

I had a fully running setup, then pulled the longblock w/o intake or pan. So I have all the acc and everything else needed to run.

Once its all up and running, i may merge this thread into my car's build thread, and add dyno sheets. Car will be tuned by Don Slowhawk Performance, and motor assembled by Jim Reid, at Reids automotive.

What I have:

Heads [complete no rockers]

Block Machined already!

Crank

pistons

rings

Rods

Rod bearings [clevite 77]

Cam bearings installed in block

Oil pan

Front and back covers

That little white barbell thing for oiling system[what is this by the way?]

What I need for short block assembly:

Front cover gasket _______GM Part# 12633904

Rear cover gasket _______GM Part# 12633578

front cover bolts _________GM Part# 11515758 M8x1.25x30

rear cover bolts _________GM Part# 11515758 M8x1.25x30

Ls7 Lifters ______________GM Part# 12499225 all 16

Cam

Lifter retainers __________GM Part#12551162 uses 4 of them.

Main bearings

TSP ls6 ported oil pump ___TSP part# 25-12586665M

timing set with chain _____TSP part#11-1160 Rollmaster heat treated double roller

LS6 valley pan __________GM Part# 12568002 [According to ls1howto.com this includes the gasket and the bolts!]

Valley pan gasket _______GM Part# 12558178

Vally pan bolts __________GM Part# 11515758 M8x1.25x30

Oil pan gaskets _________GM Part# 12612350

What I need to complete the entire motor:

Head gaskets___________GM Part# 12589227

Rockers

prís Don't know the length i need, so i will have to purchase post assembly.

Head bolts/studs _______TSP Part# 46-134-3609

valve covers Prob get through the classifieds.

Sensor list

Knock sensors[Qty 2] ___GM Part# 12589867 Part#'s Delco # 213-362, BWD #S8696 , Duralast #SU1282

Kock sensor wire _______GM Part# 12601822

Cam sensor ___________GM Part# 12561211 Part#'s Delco # 213-363, BWD #CS1531, Duralast #SU1277

Crank sensor __________GM Part# 12560228 Part#'s Delco # 213-354, BWD # CSS142, Duralast # SU1178

Coolang Temp sensor ___Part#'s 2 pin design- .Delco # 213-953, Duralast #SU112, Everco # 36419, BWD , #WT5132

Air intake temp ________Part#'s Delco # 213-243, BWD # W3036Z, Duralast # SU176

If you have part numbers for the generic stuff I can get strait from a dealer please list them. If you have part numbers from stuff not from a dealer, please list only if they are a sponsor!!!! Im going to update this post with numbers, im sure someone else could benefit from this.

Details on the build are as follows: 6.0 iron block bored to 4.010. precision stroker crank, TSP diamond -15cc dished pistons, lunati rods, arkly and childs xtreme rings. For heads I have a set of afr 225ís that will be milled down to around 59-60cc chambers. The block was specíed out for a twin turbo build, I purchased it and have no need for more than 500rwhp on a regular basis, so im going to mill the heads to make up for the large piston dishes.

I had a fully running setup, then pulled the longblock w/o intake or pan. So I have all the acc and everything else needed to run.

Once its all up and running, i may merge this thread into my car's build thread, and add dyno sheets. Car will be tuned by Don Slowhawk Performance, and motor assembled by Jim Reid, at Reids automotive.

What I have:

Heads [complete no rockers]

Block Machined already!

Crank

pistons

rings

Rods

Rod bearings [clevite 77]

Cam bearings installed in block

Oil pan

Front and back covers

That little white barbell thing for oiling system[what is this by the way?]

What I need for short block assembly:

Front cover gasket _______GM Part# 12633904

Rear cover gasket _______GM Part# 12633578

front cover bolts _________GM Part# 11515758 M8x1.25x30

rear cover bolts _________GM Part# 11515758 M8x1.25x30

Ls7 Lifters ______________GM Part# 12499225 all 16

Cam

Lifter retainers __________GM Part#12551162 uses 4 of them.

Main bearings

TSP ls6 ported oil pump ___TSP part# 25-12586665M

timing set with chain _____TSP part#11-1160 Rollmaster heat treated double roller

LS6 valley pan __________GM Part# 12568002 [According to ls1howto.com this includes the gasket and the bolts!]

Valley pan gasket _______GM Part# 12558178

Vally pan bolts __________GM Part# 11515758 M8x1.25x30

Oil pan gaskets _________GM Part# 12612350

What I need to complete the entire motor:

Head gaskets___________GM Part# 12589227

Rockers

prís Don't know the length i need, so i will have to purchase post assembly.

Head bolts/studs _______TSP Part# 46-134-3609

valve covers Prob get through the classifieds.

Sensor list

Knock sensors[Qty 2] ___GM Part# 12589867 Part#'s Delco # 213-362, BWD #S8696 , Duralast #SU1282

Kock sensor wire _______GM Part# 12601822

Cam sensor ___________GM Part# 12561211 Part#'s Delco # 213-363, BWD #CS1531, Duralast #SU1277

Crank sensor __________GM Part# 12560228 Part#'s Delco # 213-354, BWD # CSS142, Duralast # SU1178

Coolang Temp sensor ___Part#'s 2 pin design- .Delco # 213-953, Duralast #SU112, Everco # 36419, BWD , #WT5132

Air intake temp ________Part#'s Delco # 213-243, BWD # W3036Z, Duralast # SU176

If you have part numbers for the generic stuff I can get strait from a dealer please list them. If you have part numbers from stuff not from a dealer, please list only if they are a sponsor!!!! Im going to update this post with numbers, im sure someone else could benefit from this.

#14

TECH Enthusiast

Thread Starter

iTrader: (10)

Join Date: Jun 2010

Location: Boston

Posts: 728

Likes: 0

Received 0 Likes

on

0 Posts

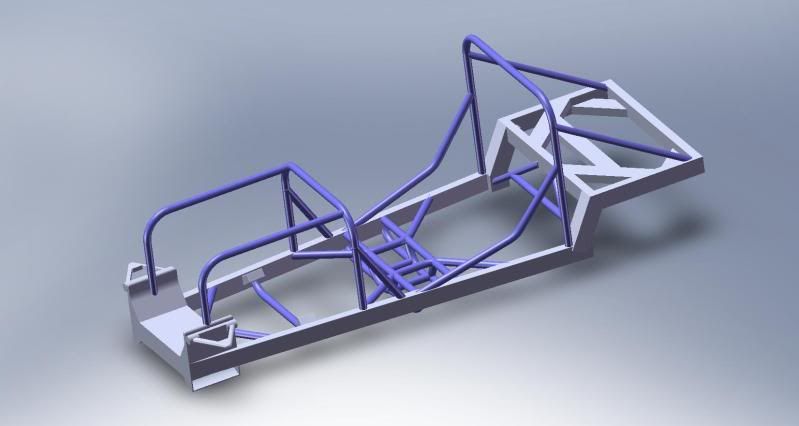

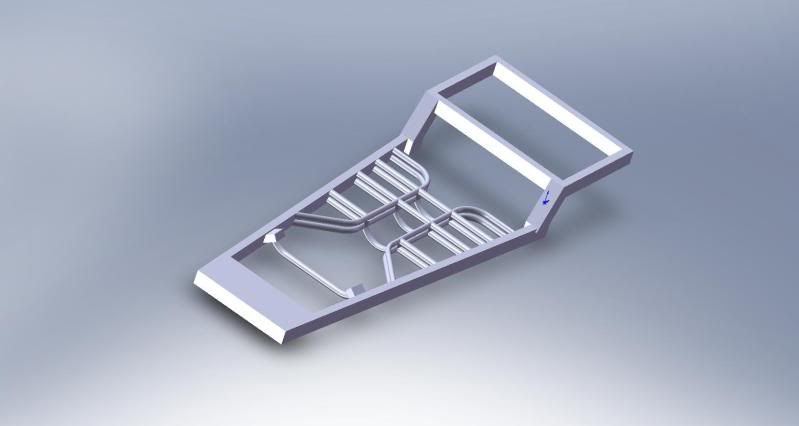

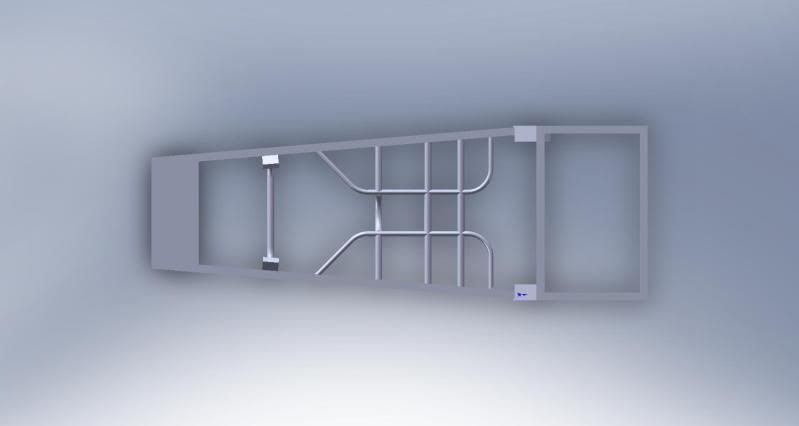

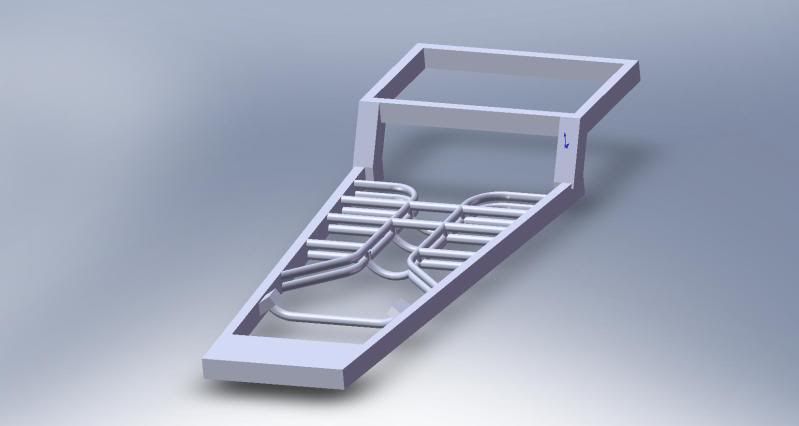

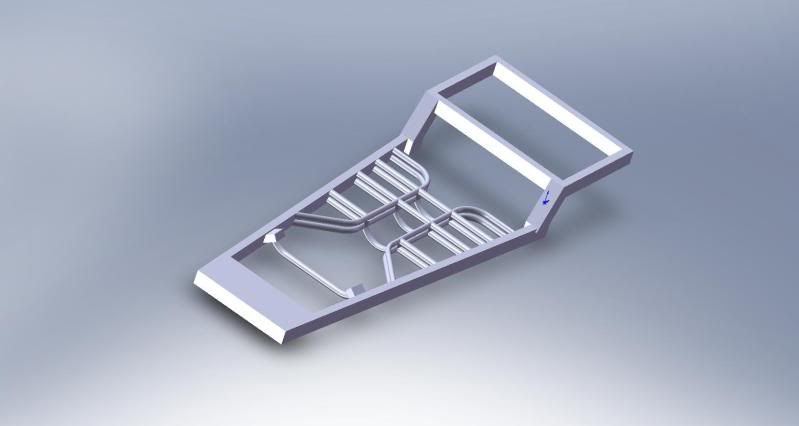

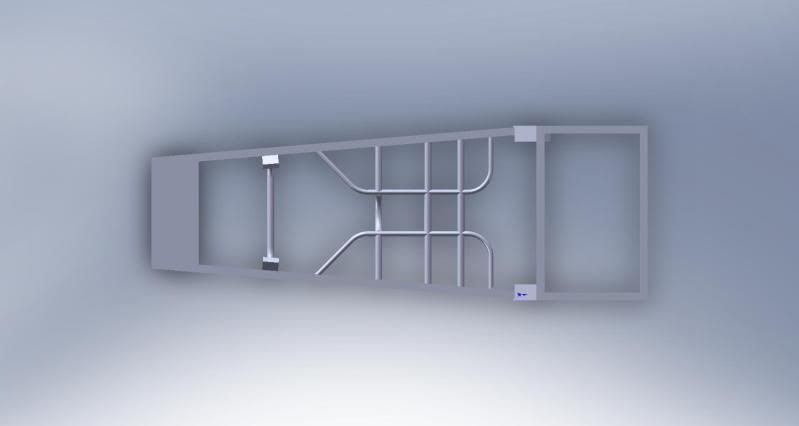

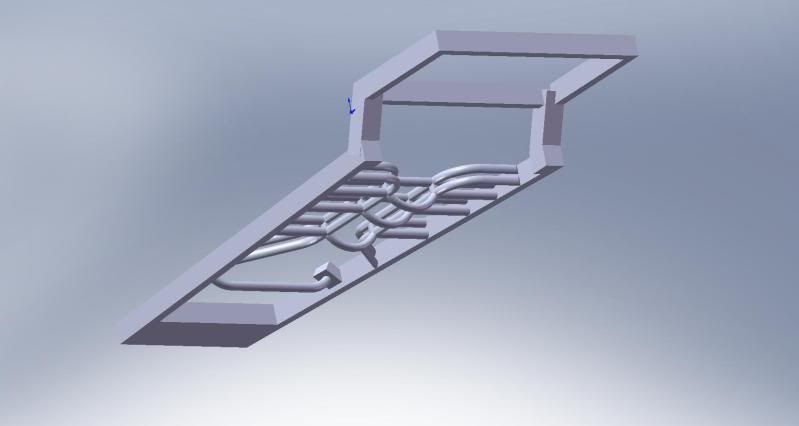

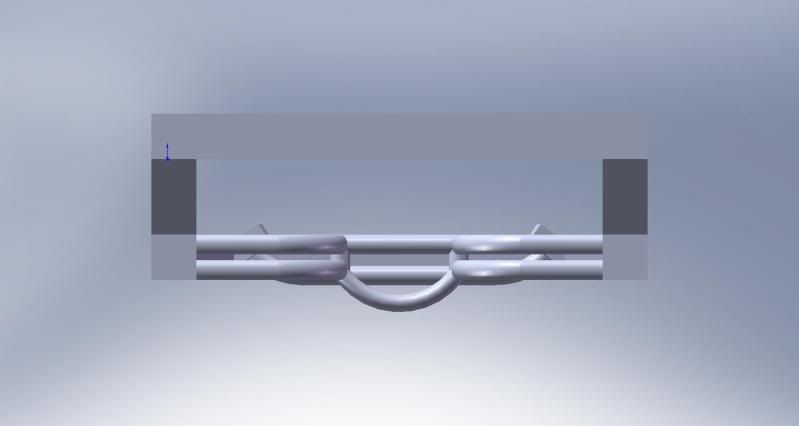

So i finished up playing with solidworks and getting my frame designed. I needed an excuse to learn it at work and what better than my new center section! Got a little tricky, and its a bit rough but its a good frame of reference.

The only difference so far is that after i started drawing it friday and got most of it done, i decided to bank down the lower half of the tubing in order to route my exhaust through it. Too much work to go back an modify, i think it would have been easier to start over so i left it as is.

The only difference so far is that after i started drawing it friday and got most of it done, i decided to bank down the lower half of the tubing in order to route my exhaust through it. Too much work to go back an modify, i think it would have been easier to start over so i left it as is.

#15

TECH Enthusiast

Thread Starter

iTrader: (10)

Join Date: Jun 2010

Location: Boston

Posts: 728

Likes: 0

Received 0 Likes

on

0 Posts

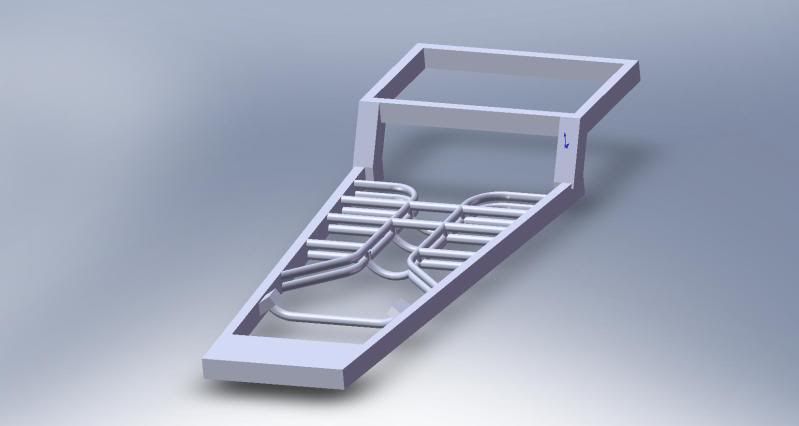

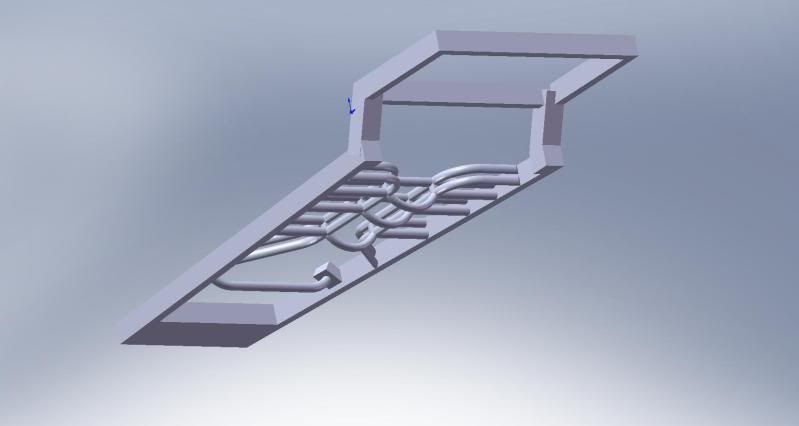

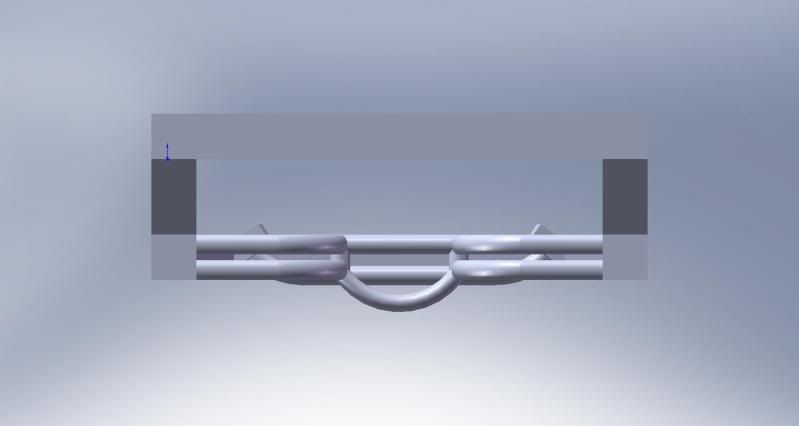

So i did redraw the frame to add a dip for the exhaust to fit through. I'm adding more too it like A arms and such for fun.

I also finally was able to get a reasonable quote for DOM tubing. Everywhere i called either didn't carry it or wanted between 7-8 a foot. Found a place that will deliver it to my work for me for 5.50ish a foot for 60ft. Im sure if i got alot more the price would drop further. Now i just need to get my *** in the cold carport and measure if i need mroe than 60ft or not. I rather have more than less, considering the leaning curve on tube bending.

I also finally was able to get a reasonable quote for DOM tubing. Everywhere i called either didn't carry it or wanted between 7-8 a foot. Found a place that will deliver it to my work for me for 5.50ish a foot for 60ft. Im sure if i got alot more the price would drop further. Now i just need to get my *** in the cold carport and measure if i need mroe than 60ft or not. I rather have more than less, considering the leaning curve on tube bending.

#18

TECH Enthusiast

Thread Starter

iTrader: (10)

Join Date: Jun 2010

Location: Boston

Posts: 728

Likes: 0

Received 0 Likes

on

0 Posts

Actually i ment roll bar. Since its a roadster i dont want the halo. But i want it to be a simple job if i decide to do it. May make a removable halo for personal safty not racing.