My build - Lots of pics

#1

UPDATE! 4-18-2010 Car is turning into a drag only car! Lots of work to do!

This is my car - Sideways240sx - Chris

And my buddy Sean - Broke EF Has been there helping every part of the way.

Also, the car is about 1hr away at my parents. Updates only happen on saturdays when we can get out there. Progress isn't super fast, but i am trying to get the car going by the beginning of april, which shouldn't be a problem.

The car is a 1998 Trans AM WS6 clone, 6-speed, t-tops, leather, ect. When picked it up it had a VFN WS6 fiberglass hood, WS6 air box, WS6, wheels, WS6 badges, center force dual friction clutch, pro 5.0 shifter, bilstien shocks, eibach springs, and a moroso non adjustable panhard bar. Not a bad start, but far from what was wanted from the car. Over the next few months parts started to go on, SLP Smooth bellows, ported TB, ceramic coated long tube header, custom 3" dual exhaust with x-pipe and moroso spiral flow mufflers (dumped at axle), custom tune, 4:10 gear, UMI weld in box sub frame connectors, UMI adjustable rear lower control arms, and a UMI adjustable panhard bar. With that set up the car ran a best of 12.7 @ 111 MPH on a set of M/T 26x11.5 17" ET Streets. Now that summer was winding down, it was time to start making some winter plans. Lots of discussion went on about what to do, big cam and heads, nitrous, supercharger, stay bolt on and work on suspension more, and so on. After a LONG time we came to the conclusion that turbo would be the way to go. Once we decided on a turbo for the added power, the search started for what kit to get. When that was turning up nothing really impressive, we started to wonder..... How hard could it be??

This is where the real build starts, now the car had a direction with both short and long term goals laid out. So with no prior experience, and very little knowledge we started.

Parts-

PTE Gt4276 With 1.12 ar - 1200

tial 44mm wastegate black - 350

tial 50mm bov black- 190

Lots of 2.5, 3, and 4 inch pipe - 480

6.0 truck manifolds - 120 Junkyard

Garret 32x12x3 900 hp intercooler - 380

----------------------------------------

Total just under 2800 for what would normally come in a kit.

With fuel/More suspension/new Radiator/tune/ all new fluids/ belts hoses/lines/welder/band saw/ and a couple needed tools, this entire build should come in just under 6k.

Day 1

Backing it in for the last time

Engine bay before...

Pulling off the headers

Day 2

Bumper off (that was a pain in the ***)

Here is the old exhaust, headers, and the new truck manifolds.

Day 3

Getting all the un-needed crap out of the way

Most of what came off, never to go back on

What we have to work with more or less

Here is the first order of pipe (2.5" and 3") The turbo, waste gate, BOV, and intercooler.

Here is the second order or pipe (more 2.5" and 4")

The welder (Hobart handler 140)

Stuff to make new power steering lines (still missing 3 fittings in this pic)

thats a block of aluminum and a mason chisel for those who are wondering. Supposedly it the best way to cut AN line, well let you know cause we need to cut alot.

Day 4

Intercooler finally mounted, and bumper mostly done.

Placing the turbo (we did this alot)

Day 5

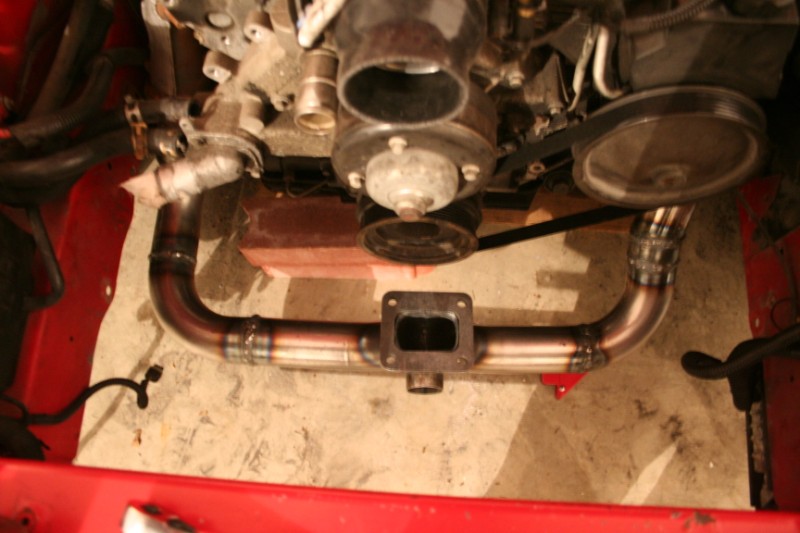

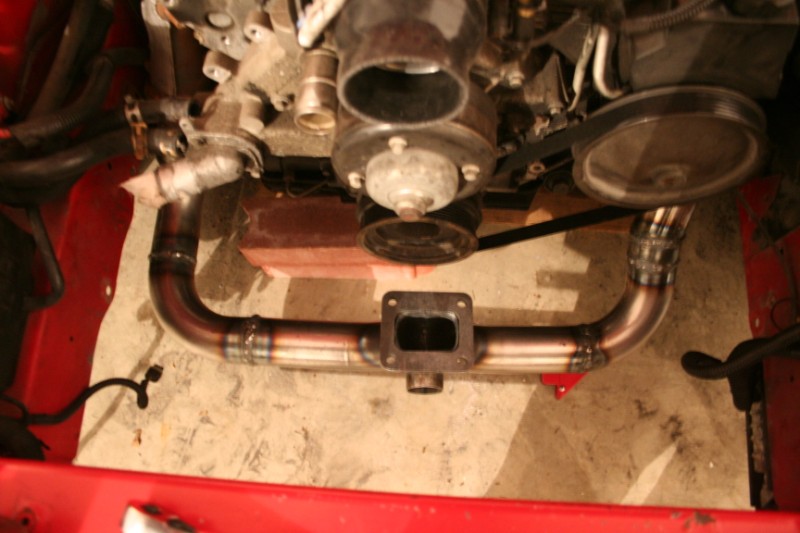

Sean welding the crossover pipe

The crossover pipe after Sean just finished it

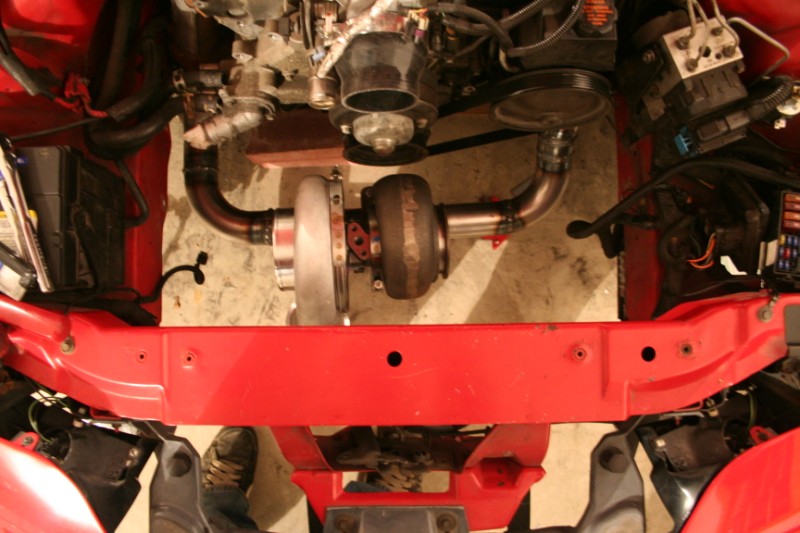

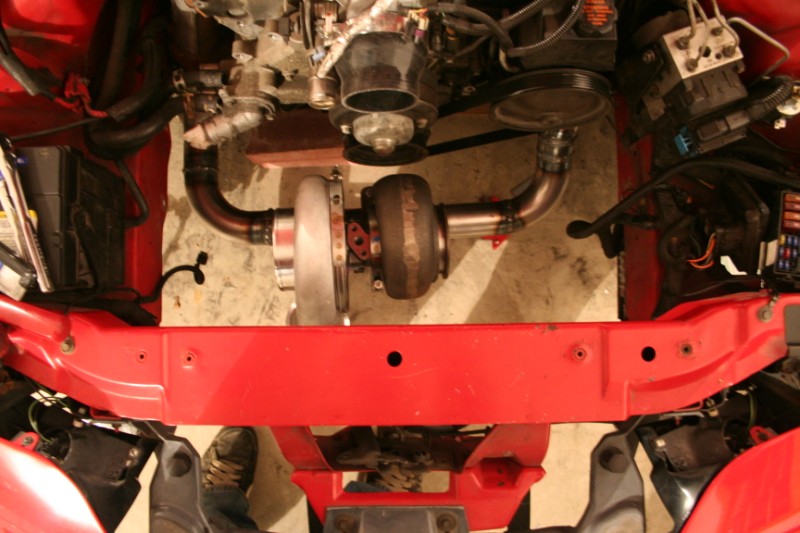

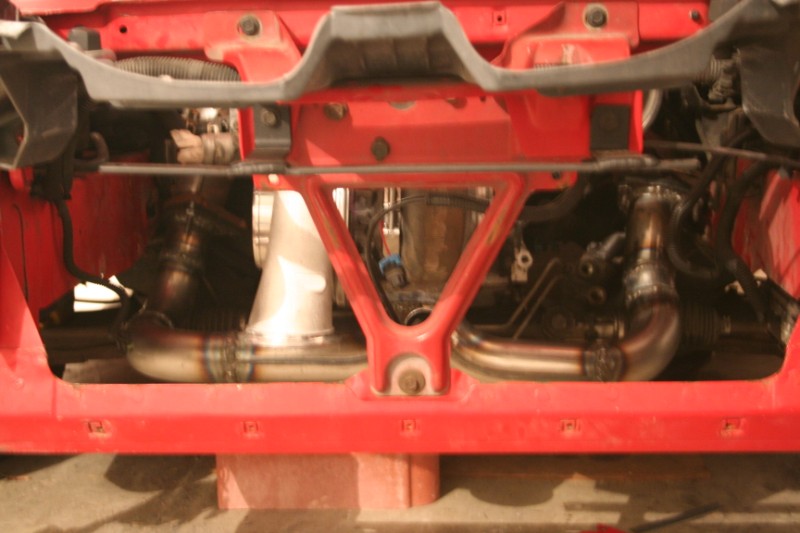

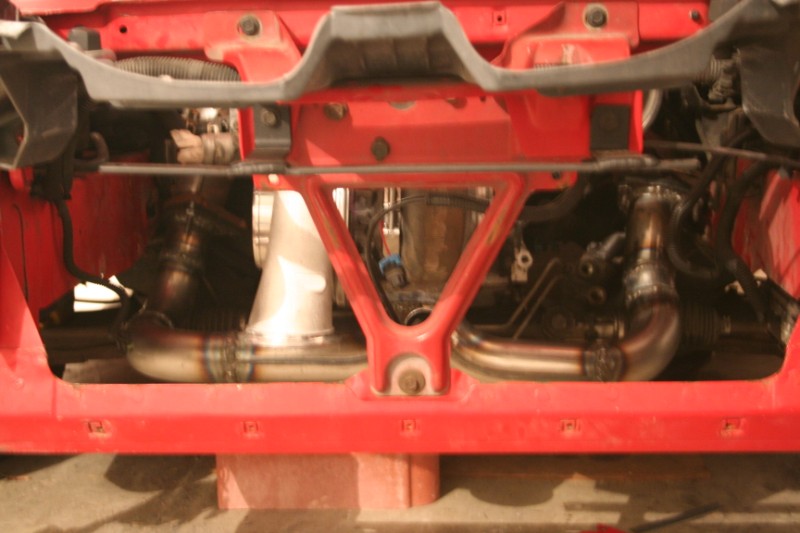

Crossover pipe in the car and bolted on for the first time

Turbo bolted on for the first time

Bottom shot, to see where the wastegate is goin.

Intercooler and turbo on the car

Thats about all for now, but this will stay updated.

Please post comments. I want to know what everyone thinks good or bad, so it can be fixed, or improved on if need be. We have done alot of research and tried to do everything in the best way we could think off.

Ic piping will not be a problem.

Dp is a 4 inch, and cant fit through stock k member, so for now i am using a 4 inch round to oval transistion under the kmember. Its not the best option in the world but i still have over 3.5 inches of ground clearance.

The car will get a k member sooner than later.

Also, i know the 4.10 gear is gonna suck. WHen turbo kit is done, im planning on throwing a 9 inch in, so im not to worried about that for now.

Any questions please ask. If anyone would like to see specific pictures of how anything was done, we have just over 400 pictures of the entire build up to this point and there will be alot more taken in the near future.

Chris

This is my car - Sideways240sx - Chris

And my buddy Sean - Broke EF Has been there helping every part of the way.

Also, the car is about 1hr away at my parents. Updates only happen on saturdays when we can get out there. Progress isn't super fast, but i am trying to get the car going by the beginning of april, which shouldn't be a problem.

The car is a 1998 Trans AM WS6 clone, 6-speed, t-tops, leather, ect. When picked it up it had a VFN WS6 fiberglass hood, WS6 air box, WS6, wheels, WS6 badges, center force dual friction clutch, pro 5.0 shifter, bilstien shocks, eibach springs, and a moroso non adjustable panhard bar. Not a bad start, but far from what was wanted from the car. Over the next few months parts started to go on, SLP Smooth bellows, ported TB, ceramic coated long tube header, custom 3" dual exhaust with x-pipe and moroso spiral flow mufflers (dumped at axle), custom tune, 4:10 gear, UMI weld in box sub frame connectors, UMI adjustable rear lower control arms, and a UMI adjustable panhard bar. With that set up the car ran a best of 12.7 @ 111 MPH on a set of M/T 26x11.5 17" ET Streets. Now that summer was winding down, it was time to start making some winter plans. Lots of discussion went on about what to do, big cam and heads, nitrous, supercharger, stay bolt on and work on suspension more, and so on. After a LONG time we came to the conclusion that turbo would be the way to go. Once we decided on a turbo for the added power, the search started for what kit to get. When that was turning up nothing really impressive, we started to wonder..... How hard could it be??

This is where the real build starts, now the car had a direction with both short and long term goals laid out. So with no prior experience, and very little knowledge we started.

Parts-

PTE Gt4276 With 1.12 ar - 1200

tial 44mm wastegate black - 350

tial 50mm bov black- 190

Lots of 2.5, 3, and 4 inch pipe - 480

6.0 truck manifolds - 120 Junkyard

Garret 32x12x3 900 hp intercooler - 380

----------------------------------------

Total just under 2800 for what would normally come in a kit.

With fuel/More suspension/new Radiator/tune/ all new fluids/ belts hoses/lines/welder/band saw/ and a couple needed tools, this entire build should come in just under 6k.

Day 1

Backing it in for the last time

Engine bay before...

Pulling off the headers

Day 2

Bumper off (that was a pain in the ***)

Here is the old exhaust, headers, and the new truck manifolds.

Day 3

Getting all the un-needed crap out of the way

Most of what came off, never to go back on

What we have to work with more or less

Here is the first order of pipe (2.5" and 3") The turbo, waste gate, BOV, and intercooler.

Here is the second order or pipe (more 2.5" and 4")

The welder (Hobart handler 140)

Stuff to make new power steering lines (still missing 3 fittings in this pic)

thats a block of aluminum and a mason chisel for those who are wondering. Supposedly it the best way to cut AN line, well let you know cause we need to cut alot.

Day 4

Intercooler finally mounted, and bumper mostly done.

Placing the turbo (we did this alot)

Day 5

Sean welding the crossover pipe

The crossover pipe after Sean just finished it

Crossover pipe in the car and bolted on for the first time

Turbo bolted on for the first time

Bottom shot, to see where the wastegate is goin.

Intercooler and turbo on the car

Thats about all for now, but this will stay updated.

Please post comments. I want to know what everyone thinks good or bad, so it can be fixed, or improved on if need be. We have done alot of research and tried to do everything in the best way we could think off.

Ic piping will not be a problem.

Dp is a 4 inch, and cant fit through stock k member, so for now i am using a 4 inch round to oval transistion under the kmember. Its not the best option in the world but i still have over 3.5 inches of ground clearance.

The car will get a k member sooner than later.

Also, i know the 4.10 gear is gonna suck. WHen turbo kit is done, im planning on throwing a 9 inch in, so im not to worried about that for now.

Any questions please ask. If anyone would like to see specific pictures of how anything was done, we have just over 400 pictures of the entire build up to this point and there will be alot more taken in the near future.

Chris

Last edited by Sideways240sx; 04-18-2010 at 05:22 PM.

#4

Chris

#5

Sean

P.S. I just want to point out that I have NEVER welded before we started on this.

#7

TECH Senior Member

iTrader: (16)

Broke EF, we all gotta start welding somewhere Major props to you guys taking on a project like this. My DP is routed the same way, but that was due to a quickly going from one kit to another and trying to keep as many things in the same place as possible to save on $$ and time welding...plus it was like 30 degrees outside when I did my truck manifold set up...so it needed to be done quickly too

Major props to you guys taking on a project like this. My DP is routed the same way, but that was due to a quickly going from one kit to another and trying to keep as many things in the same place as possible to save on $$ and time welding...plus it was like 30 degrees outside when I did my truck manifold set up...so it needed to be done quickly too I WILL be getting a BMR turbo k member this year to tuck the DP up over the K tho...mine doesn't really hit anything but I'd like to step up to a 4 inch DP and not the 3 I have on it now.

I WILL be getting a BMR turbo k member this year to tuck the DP up over the K tho...mine doesn't really hit anything but I'd like to step up to a 4 inch DP and not the 3 I have on it now.

Looks good

Major props to you guys taking on a project like this. My DP is routed the same way, but that was due to a quickly going from one kit to another and trying to keep as many things in the same place as possible to save on $$ and time welding...plus it was like 30 degrees outside when I did my truck manifold set up...so it needed to be done quickly too

Major props to you guys taking on a project like this. My DP is routed the same way, but that was due to a quickly going from one kit to another and trying to keep as many things in the same place as possible to save on $$ and time welding...plus it was like 30 degrees outside when I did my truck manifold set up...so it needed to be done quickly too I WILL be getting a BMR turbo k member this year to tuck the DP up over the K tho...mine doesn't really hit anything but I'd like to step up to a 4 inch DP and not the 3 I have on it now.

I WILL be getting a BMR turbo k member this year to tuck the DP up over the K tho...mine doesn't really hit anything but I'd like to step up to a 4 inch DP and not the 3 I have on it now.Looks good

Trending Topics

#10

i got a request for how we mounted the intercooler so i will try to show it best i can with the pics i have on my laptop.

Looking at this pic you can see there is a little black bar that runs across the ic. Its 1/4 thick 1.5 inch wide mild steel flat stock. The bar is bolted to the ic, and then has 2 pieces welded to it, that bolts to the car.

This is a little better pic without ic on, and you can see just the bracket here.

Chris

Looking at this pic you can see there is a little black bar that runs across the ic. Its 1/4 thick 1.5 inch wide mild steel flat stock. The bar is bolted to the ic, and then has 2 pieces welded to it, that bolts to the car.

This is a little better pic without ic on, and you can see just the bracket here.

Chris

#12

Looks good. The BMR Turbo k member is the hot ticket to DP routing. With some solid motor mounts you can make the 4" fit but its no fun. Super tight.

Keep up the good work.

Keep up the good work.

owell good luck

owell good luck