Lets discuss your oriface

#1

TECH Fanatic

Thread Starter

iTrader: (1)

Join Date: Mar 2004

Location: Southern NH

Posts: 1,644

Likes: 0

Received 0 Likes

on

0 Posts

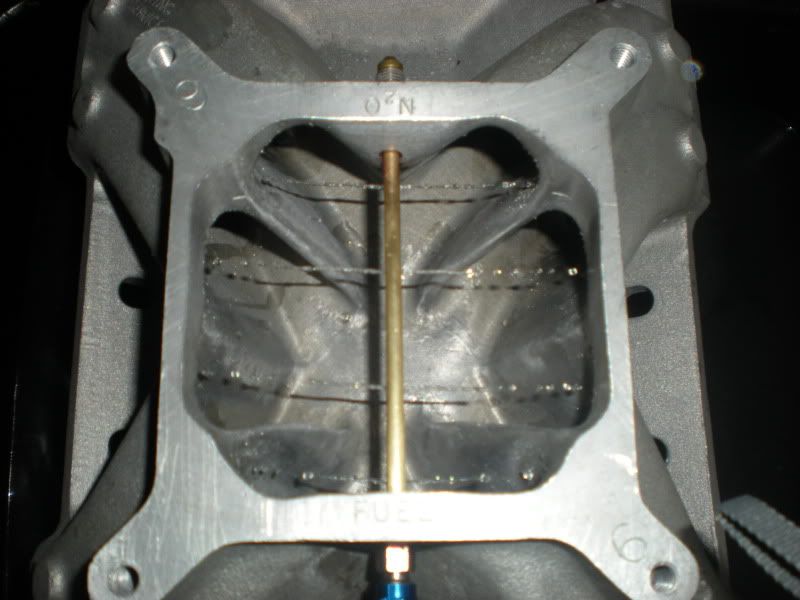

I've been messing around with a 4bbl spray bar set-up, and hole sizes in the spary bars have me going crazy.

I started by just bench flowing water throgh the fuel side, and was very surprised to find out how uneven the distribution is. Here are actual #'s of the 'stock' bar. Testing done with a 41fuel jet @12psi. This was done by flowing for exactly 2 minutes, and the measureing the water in a graduated cylinder.

Front 1&2- 160ml/min

cyl 3&4- 190ml/min

cyl 5&6- 210ml/min

Rear, cyl 7&8- 260ml/min

The holes in the 'stock' spray bar all pin-out between .051-.055" They are not in a partictular pattern, just crappy craftsmanship.

So, I decided to make a new spray bar with holes decreasing in dia as they get towards th rear. So I made a set that had a

.053

.047

.043

.043

This bar flowed very well. All cylinders were now within 15ml/min.

Front 1&2- 205ml/min

cyl 3&4- 200ml/min

cyl 5&6- 190ml/min

Rear, cyl 7&8- 205ml/min

So I thought I was done, and just just messing around giving it shot after shot for no apparent reason, until all of a sudden the flow got all messed up, and it started only flowing through the rear 2 holes with a airated pattern. I kept trying it and about 1 out of every 10 shots it only flows out the rear two holes, while the other 9 shots flow perfect. What happens is, sometimes the flowing water pulls a venturi across the front holes and actually pulls air into the tube, instead of pushing water out. This happens about once every 10 shots with a.041 jet, and happens about 50% of the time with a .031 jet, and never happens with a .052"+ jet. This would be disasterous if it happened during use for obvious reasons.

I hooked up the origional spray bar after seeing this, and it does the same thing.

So it seems like I still need to decrease the hole size in the bar, but I'm wondering anyone has experimented with this before? If so, what size holes did you end up with? and for what size shot?

I started by just bench flowing water throgh the fuel side, and was very surprised to find out how uneven the distribution is. Here are actual #'s of the 'stock' bar. Testing done with a 41fuel jet @12psi. This was done by flowing for exactly 2 minutes, and the measureing the water in a graduated cylinder.

Front 1&2- 160ml/min

cyl 3&4- 190ml/min

cyl 5&6- 210ml/min

Rear, cyl 7&8- 260ml/min

The holes in the 'stock' spray bar all pin-out between .051-.055" They are not in a partictular pattern, just crappy craftsmanship.

So, I decided to make a new spray bar with holes decreasing in dia as they get towards th rear. So I made a set that had a

.053

.047

.043

.043

This bar flowed very well. All cylinders were now within 15ml/min.

Front 1&2- 205ml/min

cyl 3&4- 200ml/min

cyl 5&6- 190ml/min

Rear, cyl 7&8- 205ml/min

So I thought I was done, and just just messing around giving it shot after shot for no apparent reason, until all of a sudden the flow got all messed up, and it started only flowing through the rear 2 holes with a airated pattern. I kept trying it and about 1 out of every 10 shots it only flows out the rear two holes, while the other 9 shots flow perfect. What happens is, sometimes the flowing water pulls a venturi across the front holes and actually pulls air into the tube, instead of pushing water out. This happens about once every 10 shots with a.041 jet, and happens about 50% of the time with a .031 jet, and never happens with a .052"+ jet. This would be disasterous if it happened during use for obvious reasons.

I hooked up the origional spray bar after seeing this, and it does the same thing.

So it seems like I still need to decrease the hole size in the bar, but I'm wondering anyone has experimented with this before? If so, what size holes did you end up with? and for what size shot?

#4

FormerVendor

iTrader: (4)

Join Date: Jul 2005

Location: Glenolden, PA

Posts: 1,954

Likes: 0

Received 0 Likes

on

0 Posts

I've been messing around with a 4bbl spray bar set-up, and hole sizes in the spary bars have me going crazy.

I started by just bench flowing water throgh the fuel side, and was very surprised to find out how uneven the distribution is. Here are actual #'s of the 'stock' bar. Testing done with a 41fuel jet @12psi. This was done by flowing for exactly 2 minutes, and the measureing the water in a graduated cylinder.

Front 1&2- 160ml/min

cyl 3&4- 190ml/min

cyl 5&6- 210ml/min

Rear, cyl 7&8- 260ml/min

The holes in the 'stock' spray bar all pin-out between .051-.055" They are not in a partictular pattern, just crappy craftsmanship.

So, I decided to make a new spray bar with holes decreasing in dia as they get towards th rear. So I made a set that had a

.053

.047

.043

.043

This bar flowed very well. All cylinders were now within 15ml/min.

Front 1&2- 205ml/min

cyl 3&4- 200ml/min

cyl 5&6- 190ml/min

Rear, cyl 7&8- 205ml/min

So I thought I was done, and just just messing around giving it shot after shot for no apparent reason, until all of a sudden the flow got all messed up, and it started only flowing through the rear 2 holes with a airated pattern. I kept trying it and about 1 out of every 10 shots it only flows out the rear two holes, while the other 9 shots flow perfect. What happens is, sometimes the flowing water pulls a venturi across the front holes and actually pulls air into the tube, instead of pushing water out. This happens about once every 10 shots with a.041 jet, and happens about 50% of the time with a .031 jet, and never happens with a .052"+ jet. This would be disasterous if it happened during use for obvious reasons.

I hooked up the origional spray bar after seeing this, and it does the same thing.

So it seems like I still need to decrease the hole size in the bar, but I'm wondering anyone has experimented with this before? If so, what size holes did you end up with? and for what size shot?

I started by just bench flowing water throgh the fuel side, and was very surprised to find out how uneven the distribution is. Here are actual #'s of the 'stock' bar. Testing done with a 41fuel jet @12psi. This was done by flowing for exactly 2 minutes, and the measureing the water in a graduated cylinder.

Front 1&2- 160ml/min

cyl 3&4- 190ml/min

cyl 5&6- 210ml/min

Rear, cyl 7&8- 260ml/min

The holes in the 'stock' spray bar all pin-out between .051-.055" They are not in a partictular pattern, just crappy craftsmanship.

So, I decided to make a new spray bar with holes decreasing in dia as they get towards th rear. So I made a set that had a

.053

.047

.043

.043

This bar flowed very well. All cylinders were now within 15ml/min.

Front 1&2- 205ml/min

cyl 3&4- 200ml/min

cyl 5&6- 190ml/min

Rear, cyl 7&8- 205ml/min

So I thought I was done, and just just messing around giving it shot after shot for no apparent reason, until all of a sudden the flow got all messed up, and it started only flowing through the rear 2 holes with a airated pattern. I kept trying it and about 1 out of every 10 shots it only flows out the rear two holes, while the other 9 shots flow perfect. What happens is, sometimes the flowing water pulls a venturi across the front holes and actually pulls air into the tube, instead of pushing water out. This happens about once every 10 shots with a.041 jet, and happens about 50% of the time with a .031 jet, and never happens with a .052"+ jet. This would be disasterous if it happened during use for obvious reasons.

I hooked up the origional spray bar after seeing this, and it does the same thing.

So it seems like I still need to decrease the hole size in the bar, but I'm wondering anyone has experimented with this before? If so, what size holes did you end up with? and for what size shot?

Easiest solution would be to just ditch the fuel and put it at the injector

but I don't think that's an option since she's missing some holes at the bottom of the runner.

but I don't think that's an option since she's missing some holes at the bottom of the runner.

So...

What size jet are you looking to run? Ballpark it.

What size ID tube is it?

What pump are you using at 14psi? You sure it didn't change pressures on you?

What are you using to regulate your flow on the bench? Deadhead or bypass?

Nick

#5

TECH Fanatic

Thread Starter

iTrader: (1)

Join Date: Mar 2004

Location: Southern NH

Posts: 1,644

Likes: 0

Received 0 Likes

on

0 Posts

Easiest solution would be to just ditch the fuel and put it at the injector  but I don't think that's an option since she's missing some holes at the bottom of the runner.

but I don't think that's an option since she's missing some holes at the bottom of the runner.

So...

What size jet are you looking to run? Ballpark it.

What size ID tube is it?

What pump are you using at 14psi? You sure it didn't change pressures on you?

What are you using to regulate your flow on the bench? Deadhead or bypass?

Nick

but I don't think that's an option since she's missing some holes at the bottom of the runner.

but I don't think that's an option since she's missing some holes at the bottom of the runner.

So...

What size jet are you looking to run? Ballpark it.

What size ID tube is it?

What pump are you using at 14psi? You sure it didn't change pressures on you?

What are you using to regulate your flow on the bench? Deadhead or bypass?

Nick

Agreed with most every you stated, reversion does suck for even distribution. Especially when these systems try to have a big range of shot sizes.

Here are the answers to your questions:

-Fuel jet is a .041,

-FFP in the car is 9.5-10 psi depending on weather conditions. its on a return system.

-FFP on my test set-up is 12psi. No regulator at all, just a holley blue pump, which seems to hold 12psi flowing or not.

Tube I.D.=.124"

Vinny

#7

FormerVendor

iTrader: (25)

Vinny,

One of the guys shot me a link to this. I can tell by looking at the job who did it and I know it was not us.

I am slammed at the shop right now but I will try to get back on the board and respond to this later tonight.

In my opinion there could be many reasons why your test showed the results they did and reasons for certain things you are seeing.

Dave

One of the guys shot me a link to this. I can tell by looking at the job who did it and I know it was not us.

I am slammed at the shop right now but I will try to get back on the board and respond to this later tonight.

In my opinion there could be many reasons why your test showed the results they did and reasons for certain things you are seeing.

Dave

Trending Topics

#8

TECH Fanatic

Thread Starter

iTrader: (1)

Join Date: Mar 2004

Location: Southern NH

Posts: 1,644

Likes: 0

Received 0 Likes

on

0 Posts

Vinny,

One of the guys shot me a link to this. I can tell by looking at the job who did it and I know it was not us.

I am slammed at the shop right now but I will try to get back on the board and respond to this later tonight.

In my opinion there could be many reasons why your test showed the results they did and reasons for certain things you are seeing.

Dave

One of the guys shot me a link to this. I can tell by looking at the job who did it and I know it was not us.

I am slammed at the shop right now but I will try to get back on the board and respond to this later tonight.

In my opinion there could be many reasons why your test showed the results they did and reasons for certain things you are seeing.

Dave

or give me a call if thats easier.

#10

TECH Fanatic

Thread Starter

iTrader: (1)

Join Date: Mar 2004

Location: Southern NH

Posts: 1,644

Likes: 0

Received 0 Likes

on

0 Posts

As far as distribution goes, thats the point of flowing it. Even distribution is the reason for custom set-ups like this, and both the fuel and N20 are right on target for the runners.

#11

TECH Fanatic

Thread Starter

iTrader: (1)

Join Date: Mar 2004

Location: Southern NH

Posts: 1,644

Likes: 0

Received 0 Likes

on

0 Posts

Update:

After revision 4, I have something that is working very well. It now has even distribution, and does not ever venturi/ cavitate.

I have made the holes smaller, and still stepping them down at each set of runners.

Also, I noticed the biggest thing that helped prevent the venturi across the first set of holes was to increase the distance from the jet to the first set of holes.

As a side note, we are very lucky to have some fantastic board sponsors here. I think its great when they go out of their way to help out even when its not their parts that are causing grief.

After revision 4, I have something that is working very well. It now has even distribution, and does not ever venturi/ cavitate.

I have made the holes smaller, and still stepping them down at each set of runners.

Also, I noticed the biggest thing that helped prevent the venturi across the first set of holes was to increase the distance from the jet to the first set of holes.

As a side note, we are very lucky to have some fantastic board sponsors here. I think its great when they go out of their way to help out even when its not their parts that are causing grief.

#12

FormerVendor

iTrader: (25)

Vinny,

There are a few things working against you in the testing which may have you chasing an issue that is not there. I am going to share some basics here online and then discuss the rest over when you and I talk for obvious reasons. (Don’t want to share our hard R&D)

1.st In the way you are testing your flow results can have several factors that can produce different results. Using a non certified flow gauge is not an accurate way to measure flow. Voltage spikes or drops to the fuel pump can alter flow numbers as well. Pump flow can alter as well due to how the pump works. Even in a perfect flow environment if you were to take a digital certified gauge on a flow bench and flow a one orifice jet discharge over and over and measure it the chances of the measurement being different from time to time are highly likely.

2nd. There is no way you can reproduce the same atmosphere as to when the motor is in use. In your testing for closer results you should have blown the spray bar out and dry each time it was flowed. Something as simple as a water droplet stuck to the hole can change direction. In an engine’s real atmosphere the spray bar is sucked dry shortly after firing. You have to keep in mind that the air velocity cutting across the spray bar tube creates vacuum pulling the fuel and drying it out. In your testing you are also missing the fact the nitrous cuts across the fuel discharge and colliding with the fuel creating suction as well.

There are so many factors that come into play. This is just the simple version. We do a lot of spray bar set ups and companies have produced plates for years with spray bars tube in. I run spray bars on my own cars and I would not due it if there was an issue with them. Of course being properly done is the key as well as knowing which intake’s flow properly with a spray bar feed discharge and which ones do no not.

As to the comment about reversion, reversion has nothing to do with this.

Dave

There are a few things working against you in the testing which may have you chasing an issue that is not there. I am going to share some basics here online and then discuss the rest over when you and I talk for obvious reasons. (Don’t want to share our hard R&D)

1.st In the way you are testing your flow results can have several factors that can produce different results. Using a non certified flow gauge is not an accurate way to measure flow. Voltage spikes or drops to the fuel pump can alter flow numbers as well. Pump flow can alter as well due to how the pump works. Even in a perfect flow environment if you were to take a digital certified gauge on a flow bench and flow a one orifice jet discharge over and over and measure it the chances of the measurement being different from time to time are highly likely.

2nd. There is no way you can reproduce the same atmosphere as to when the motor is in use. In your testing for closer results you should have blown the spray bar out and dry each time it was flowed. Something as simple as a water droplet stuck to the hole can change direction. In an engine’s real atmosphere the spray bar is sucked dry shortly after firing. You have to keep in mind that the air velocity cutting across the spray bar tube creates vacuum pulling the fuel and drying it out. In your testing you are also missing the fact the nitrous cuts across the fuel discharge and colliding with the fuel creating suction as well.

There are so many factors that come into play. This is just the simple version. We do a lot of spray bar set ups and companies have produced plates for years with spray bars tube in. I run spray bars on my own cars and I would not due it if there was an issue with them. Of course being properly done is the key as well as knowing which intake’s flow properly with a spray bar feed discharge and which ones do no not.

As to the comment about reversion, reversion has nothing to do with this.

Dave

#13

FormerVendor

iTrader: (25)

Update:

After revision 4, I have something that is working very well. It now has even distribution, and does not ever venturi/ cavitate.

I have made the holes smaller, and still stepping them down at each set of runners.

Also, I noticed the biggest thing that helped prevent the venturi across the first set of holes was to increase the distance from the jet to the first set of holes.

As a side note, we are very lucky to have some fantastic board sponsors here. I think its great when they go out of their way to help out even when its not their parts that are causing grief.

After revision 4, I have something that is working very well. It now has even distribution, and does not ever venturi/ cavitate.

I have made the holes smaller, and still stepping them down at each set of runners.

Also, I noticed the biggest thing that helped prevent the venturi across the first set of holes was to increase the distance from the jet to the first set of holes.

As a side note, we are very lucky to have some fantastic board sponsors here. I think its great when they go out of their way to help out even when its not their parts that are causing grief.

#14

TECH Fanatic

Thread Starter

iTrader: (1)

Join Date: Mar 2004

Location: Southern NH

Posts: 1,644

Likes: 0

Received 0 Likes

on

0 Posts

Vinny,

There are a few things working against you in the testing which may have you chasing an issue that is not there. I am going to share some basics here online and then discuss the rest over when you and I talk for obvious reasons. (Donít want to share our hard R&D)

1.st In the way you are testing your flow results can have several factors that can produce different results. Using a non certified flow gauge is not an accurate way to measure flow. Voltage spikes or drops to the fuel pump can alter flow numbers as well. Pump flow can alter as well due to how the pump works. Even in a perfect flow environment if you were to take a digital certified gauge on a flow bench and flow a one orifice jet discharge over and over and measure it the chances of the measurement being different from time to time are highly likely.

2nd. There is no way you can reproduce the same atmosphere as to when the motor is in use. In your testing for closer results you should have blown the spray bar out and dry each time it was flowed. Something as simple as a water droplet stuck to the hole can change direction. In an engineís real atmosphere the spray bar is sucked dry shortly after firing. You have to keep in mind that the air velocity cutting across the spray bar tube creates vacuum pulling the fuel and drying it out. In your testing you are also missing the fact the nitrous cuts across the fuel discharge and colliding with the fuel creating suction as well.

There are so many factors that come into play. This is just the simple version. We do a lot of spray bar set ups and companies have produced plates for years with spray bars tube in. I run spray bars on my own cars and I would not due it if there was an issue with them. Of course being properly done is the key as well as knowing which intakeís flow properly with a spray bar feed discharge and which ones do no not.

As to the comment about reversion, reversion has nothing to do with this.

Dave

There are a few things working against you in the testing which may have you chasing an issue that is not there. I am going to share some basics here online and then discuss the rest over when you and I talk for obvious reasons. (Donít want to share our hard R&D)

1.st In the way you are testing your flow results can have several factors that can produce different results. Using a non certified flow gauge is not an accurate way to measure flow. Voltage spikes or drops to the fuel pump can alter flow numbers as well. Pump flow can alter as well due to how the pump works. Even in a perfect flow environment if you were to take a digital certified gauge on a flow bench and flow a one orifice jet discharge over and over and measure it the chances of the measurement being different from time to time are highly likely.

2nd. There is no way you can reproduce the same atmosphere as to when the motor is in use. In your testing for closer results you should have blown the spray bar out and dry each time it was flowed. Something as simple as a water droplet stuck to the hole can change direction. In an engineís real atmosphere the spray bar is sucked dry shortly after firing. You have to keep in mind that the air velocity cutting across the spray bar tube creates vacuum pulling the fuel and drying it out. In your testing you are also missing the fact the nitrous cuts across the fuel discharge and colliding with the fuel creating suction as well.

There are so many factors that come into play. This is just the simple version. We do a lot of spray bar set ups and companies have produced plates for years with spray bars tube in. I run spray bars on my own cars and I would not due it if there was an issue with them. Of course being properly done is the key as well as knowing which intakeís flow properly with a spray bar feed discharge and which ones do no not.

As to the comment about reversion, reversion has nothing to do with this.

Dave

2.nd I know the atmosphere is way different at WOT. There is no way to reproduce that, but a simple bench flow test is important, to see if its even close. How many times have I seen flow paths totally miss runners, or have a clogged hole etc. so there is something to be learned from simple bench flow tests.

I feel if it looks reasonable, then run it, and checking plugs is the final say.