Tuning MAF to give SD Throttle Response

#1

Hey guys,

I just finished up my H/C/I daily driver (02 WS6) and dialed in the VE tables along with the MAF calibration using HP tuners. While doing so, i noticed night and day differences between SD throttle response and the MAF throttle response despite the MAF tune being close to perfect. It just seems like the MAF isnt as responsive as the car being in SD mode for part throttle conditions and this is on a 11.1 setup with a very torquey 228r 112lsa cam and ported fast 92 with ported ls6 heads, full exhaust, SLP 85mm Maf, which has great throttle response to begin with. I began doing alot of research and the only thing i could come up with is that the MAF filtering tends to be slower due to more sensor input and variables to derive proper fueling than just having MAP,IAT, and VE for SD. It seems that charge temperature coefficents and tampering with this table by increasing the values has some better throttle response for some other people with MAF cars. Has anyone explored the MAF tables more in depth specifically relating to getting better throttle response by making it react quicker to sorting through information (i.e temperature, ve tables,airflow etc). There doesnt seem to be too much info out there on this.

I just finished up my H/C/I daily driver (02 WS6) and dialed in the VE tables along with the MAF calibration using HP tuners. While doing so, i noticed night and day differences between SD throttle response and the MAF throttle response despite the MAF tune being close to perfect. It just seems like the MAF isnt as responsive as the car being in SD mode for part throttle conditions and this is on a 11.1 setup with a very torquey 228r 112lsa cam and ported fast 92 with ported ls6 heads, full exhaust, SLP 85mm Maf, which has great throttle response to begin with. I began doing alot of research and the only thing i could come up with is that the MAF filtering tends to be slower due to more sensor input and variables to derive proper fueling than just having MAP,IAT, and VE for SD. It seems that charge temperature coefficents and tampering with this table by increasing the values has some better throttle response for some other people with MAF cars. Has anyone explored the MAF tables more in depth specifically relating to getting better throttle response by making it react quicker to sorting through information (i.e temperature, ve tables,airflow etc). There doesnt seem to be too much info out there on this.

Last edited by Formula934; 08-04-2016 at 06:48 AM.

#2

Moderator

iTrader: (11)

Join Date: Mar 2002

Location: East Central Florida

Posts: 12,605

Likes: 0

Received 6 Likes

on

6 Posts

This may be other than what you think, because when

MAP jumps (like tip-in) you are temporarily put into SD

mode (the "unsteady MAP" criterion) anyhow. Because

the MAF is indeed slow and will report yesterday's news.

I'd look for other things, like SD being so different from

MAF airflow that you're getting tip-in KR or something -

or that difference, with everything trimmed in to what

steady state MAF is doing, is putting you at a bad mixture

position when you pop to SD (presuming you're still in the

same trim cell).

MAP jumps (like tip-in) you are temporarily put into SD

mode (the "unsteady MAP" criterion) anyhow. Because

the MAF is indeed slow and will report yesterday's news.

I'd look for other things, like SD being so different from

MAF airflow that you're getting tip-in KR or something -

or that difference, with everything trimmed in to what

steady state MAF is doing, is putting you at a bad mixture

position when you pop to SD (presuming you're still in the

same trim cell).

#3

I sort of see what your saying. I used the stft to dial in the ve tables, which is no substitute for a wideband but you manage with what you have. I havnt seen any KR either while.tuning the maf or sd. Just think there must be a way to tweak the MAF to reduce some of the filtering of the data to prompt quicker fueling.

#4

TECH Fanatic

iTrader: (6)

There are a few settings in hptuners that have to do with how maf vs ve table is used in the airflow calculation. These are under engine->airflow->dynamic. There are the settings under "VE Correction Factor", and there's also "Dynamic Air Filt". Good luck finding good documentation for these, I've not found anything satisfactory (mostly just guesses), and I've played with the values a little but no clear or obvious results.

#6

Is MAF data also used ( or usable ) in a 2 BAR tune ?

.

Asked another way, is 2 Bar SD base VE mapping compatible with conventional MAF steady state operation ?

If so, how would one initially set up the transition parameters between MAF and SD ?

.

Asked another way, is 2 Bar SD base VE mapping compatible with conventional MAF steady state operation ?

If so, how would one initially set up the transition parameters between MAF and SD ?

Trending Topics

#8

Launching!

iTrader: (2)

I went through this same battle on my Thirdgen swap when I was still using the stock PCM. I loved the instant response of SD, the difference really was night and day.

After reading up, experimenting with the burst knock and other tables, I decided to install my MAF on the shelf at the shop and never look back. For me, personally, it's SD tune all the way. I even went OLSD since I could easily monitor the AFR all the time on the wideband. I was suprised how little it changed with the weather, although it was just a summer vehicle.

After reading up, experimenting with the burst knock and other tables, I decided to install my MAF on the shelf at the shop and never look back. For me, personally, it's SD tune all the way. I even went OLSD since I could easily monitor the AFR all the time on the wideband. I was suprised how little it changed with the weather, although it was just a summer vehicle.

#9

Banned

iTrader: (1)

Tips for getting response from a maf sensor

#1 use the smallest maf sensor possible

#2 use the correct plumbing diameter and length (there needs to be a significant length of straight pipe, especially after, the maf sensor.)

#3 use a re circulation fitting is using a turbocharger

#4 PRESSURE TEST the maf plumbing (this is really #1) any leaks will cause a significant delay!

#5 use a HIGH quality air filter!

And last, you need to watch the wideband log to figure out where the maf dead spot is. In other words, you stab the gas pedal and then review the log. If you see a leak spike the engine needs more accelerator pump enrichment (pump shot value) for the rate of change of tps (dTPS). All ECU have this function. Simply enlarge that value until the wideband log comes out clean like the SD log used to.

I've tuned 50+ maf setups and 50+ map setups and all of them achieve a similar if not identical drivability once these things are set right, you cant even tell. It might be the maf itself (I have had issues with people bringing me cars with too large of maf sensors. that is like having too large of a throttle body or too large of a carb, it will cause response issues as the airflow tends to move too slowly for the resolution of the sensor at low speeds (low mass air / time)).

Also many MAF setups are using a maf PRE compressor (so there is, oh I dont know, 10 feet between the maf and engine) and still work great. In fact many OEM setups achieve OEM drivability using turbochargers and maf sensors (every nissan sr20det from 1989 to 2002 ever produced does it this way). If they can get that response having the maf a mile away from the engine then I am sure you can do it with just a couple feet.

#1 use the smallest maf sensor possible

#2 use the correct plumbing diameter and length (there needs to be a significant length of straight pipe, especially after, the maf sensor.)

#3 use a re circulation fitting is using a turbocharger

#4 PRESSURE TEST the maf plumbing (this is really #1) any leaks will cause a significant delay!

#5 use a HIGH quality air filter!

And last, you need to watch the wideband log to figure out where the maf dead spot is. In other words, you stab the gas pedal and then review the log. If you see a leak spike the engine needs more accelerator pump enrichment (pump shot value) for the rate of change of tps (dTPS). All ECU have this function. Simply enlarge that value until the wideband log comes out clean like the SD log used to.

I've tuned 50+ maf setups and 50+ map setups and all of them achieve a similar if not identical drivability once these things are set right, you cant even tell. It might be the maf itself (I have had issues with people bringing me cars with too large of maf sensors. that is like having too large of a throttle body or too large of a carb, it will cause response issues as the airflow tends to move too slowly for the resolution of the sensor at low speeds (low mass air / time)).

Also many MAF setups are using a maf PRE compressor (so there is, oh I dont know, 10 feet between the maf and engine) and still work great. In fact many OEM setups achieve OEM drivability using turbochargers and maf sensors (every nissan sr20det from 1989 to 2002 ever produced does it this way). If they can get that response having the maf a mile away from the engine then I am sure you can do it with just a couple feet.

Last edited by kingtal0n; 08-14-2016 at 10:37 AM.

#10

Tips for getting response from a maf sensor

#1 use the smallest maf sensor possible

#2 use the correct plumbing diameter and length (there needs to be a significant length of straight pipe, especially after, the maf sensor.)

#3 use a re circulation fitting is using a turbocharger

#4 PRESSURE TEST the maf plumbing (this is really #1) any leaks will cause a significant delay!

#5 use a HIGH quality air filter!

And last, you need to watch the wideband log to figure out where the maf dead spot is. In other words, you stab the gas pedal and then review the log. If you see a leak spike the engine needs more accelerator pump enrichment (pump shot value) for the rate of change of tps (dTPS). All ECU have this function. Simply enlarge that value until the wideband log comes out clean like the SD log used to.

I've tuned 50+ maf setups and 50+ map setups and all of them achieve a similar if not identical drivability once these things are set right, you cant even tell. It might be the maf itself (I have had issues with people bringing me cars with too large of maf sensors. that is like having too large of a throttle body or too large of a carb, it will cause response issues as the airflow tends to move too slowly for the resolution of the sensor at low speeds (low mass air / time)).

Also many MAF setups are using a maf PRE compressor (so there is, oh I dont know, 10 feet between the maf and engine) and still work great. In fact many OEM setups achieve OEM drivability using turbochargers and maf sensors (every nissan sr20det from 1989 to 2002 ever produced does it this way). If they can get that response having the maf a mile away from the engine then I am sure you can do it with just a couple feet.

#1 use the smallest maf sensor possible

#2 use the correct plumbing diameter and length (there needs to be a significant length of straight pipe, especially after, the maf sensor.)

#3 use a re circulation fitting is using a turbocharger

#4 PRESSURE TEST the maf plumbing (this is really #1) any leaks will cause a significant delay!

#5 use a HIGH quality air filter!

And last, you need to watch the wideband log to figure out where the maf dead spot is. In other words, you stab the gas pedal and then review the log. If you see a leak spike the engine needs more accelerator pump enrichment (pump shot value) for the rate of change of tps (dTPS). All ECU have this function. Simply enlarge that value until the wideband log comes out clean like the SD log used to.

I've tuned 50+ maf setups and 50+ map setups and all of them achieve a similar if not identical drivability once these things are set right, you cant even tell. It might be the maf itself (I have had issues with people bringing me cars with too large of maf sensors. that is like having too large of a throttle body or too large of a carb, it will cause response issues as the airflow tends to move too slowly for the resolution of the sensor at low speeds (low mass air / time)).

Also many MAF setups are using a maf PRE compressor (so there is, oh I dont know, 10 feet between the maf and engine) and still work great. In fact many OEM setups achieve OEM drivability using turbochargers and maf sensors (every nissan sr20det from 1989 to 2002 ever produced does it this way). If they can get that response having the maf a mile away from the engine then I am sure you can do it with just a couple feet.

#11

Banned

iTrader: (1)

thank you

thank youA length of straight pipe after the maf, is to help keep air perturbations from influencing the maf sensor. For example, if you get out of the throttle, a tiny "shockwave" of pressure travels through the plumbing and interferes with the maf reading, the closer it is to the maf hot-wire. A surging compressor wheel does the same exact thing; you can even see the maf voltage spike up and down as the compressor is surging. It is therefore very important that we keep the maf as far from those sort of airflow variations as possible, the OEM have various methods; some of them use convoluted tube for example, that leads from the compressor to the air filter. You remove the convuluted tube for a straight piece and suddenly you get part throttle hesitation/lean stumbes, if the tube isn't long enough or the turbo is very small (easier to surge at low speeds because it is moving much faster)

a maf is very linear, sensitive device, you need to physically LOOK at the plumbing and TEST the plumbing for leaks by filling with pressure; you are l@@king for anything that might swirl / whip up the air, or cause it to flow backwards or "stall", so tight bends and throttle bodies and compressor wheels should be kept away from it. The air filter is also SUPER IMPORTANT. I can't stress this enough, to use a quality filter.

Last edited by kingtal0n; 08-15-2016 at 11:26 AM.

#12

8 Second Club

iTrader: (3)

I see nothing in my tune file that hints at an accelerator pump shot.

My C5 corvette is tuned MAF only and throttle response is excellent with the 85mm MAF.

It is a 2000 model with the stupid abbreviated VE table that is defaulted to when the MAF fails.

The low res table sucks when trying to run SD.

Tried 1 bar enhanced Speed Density, I did not like how it tuned.

My C5 corvette is tuned MAF only and throttle response is excellent with the 85mm MAF.

It is a 2000 model with the stupid abbreviated VE table that is defaulted to when the MAF fails.

The low res table sucks when trying to run SD.

Tried 1 bar enhanced Speed Density, I did not like how it tuned.

#13

Moderator

iTrader: (4)

Join Date: Jul 2014

Location: My own internal universe

Posts: 10,446

Received 1,836 Likes

on

1,145 Posts

Find power enrichment. Get rid of all the delays. Max out the ramp in rate.

#14

That'll make PE come in faster. His problem is when you don't tune the ve take you "short circuit" the PCMs ability to effectively calculate throttle transients. You can usually see it when you look at what airflow calc mode your in.

#15

Moderator

iTrader: (4)

Join Date: Jul 2014

Location: My own internal universe

Posts: 10,446

Received 1,836 Likes

on

1,145 Posts

Ten four. That comment was more directed at the "pump shot" than anything else.

#16

TECH Addict

iTrader: (3)

[QUOTE=kingtal0n;19359024]oh i love questions  thank you

thank you

A length of straight pipe after the maf, is to help keep air perturbations from influencing the maf sensor. For example, if you get out of the throttle, a tiny "shockwave" of pressure travels through the plumbing and interferes with the maf reading,

Here we go, so you have a meter that measures so called air peturbations, and shock wave, you know this for a fact or just theory, and if its fact, I would like to know how you measured for these anomalies.

thank you

thank youA length of straight pipe after the maf, is to help keep air perturbations from influencing the maf sensor. For example, if you get out of the throttle, a tiny "shockwave" of pressure travels through the plumbing and interferes with the maf reading,

Here we go, so you have a meter that measures so called air peturbations, and shock wave, you know this for a fact or just theory, and if its fact, I would like to know how you measured for these anomalies.

#17

oh i love questions  thank you

thank you

A length of straight pipe after the maf, is to help keep air perturbations from influencing the maf sensor. For example, if you get out of the throttle, a tiny "shockwave" of pressure travels through the plumbing and interferes with the maf reading, the closer it is to the maf hot-wire. A surging compressor wheel does the same exact thing; you can even see the maf voltage spike up and down as the compressor is surging. It is therefore very important that we keep the maf as far from those sort of airflow variations as possible, the OEM have various methods; some of them use convoluted tube for example, that leads from the compressor to the air filter. You remove the convuluted tube for a straight piece and suddenly you get part throttle hesitation/lean stumbes, if the tube isn't long enough or the turbo is very small (easier to surge at low speeds because it is moving much faster)

a maf is very linear, sensitive device, you need to physically LOOK at the plumbing and TEST the plumbing for leaks by filling with pressure; you are l@@king for anything that might swirl / whip up the air, or cause it to flow backwards or "stall", so tight bends and throttle bodies and compressor wheels should be kept away from it. The air filter is also SUPER IMPORTANT. I can't stress this enough, to use a quality filter.

thank you

thank youA length of straight pipe after the maf, is to help keep air perturbations from influencing the maf sensor. For example, if you get out of the throttle, a tiny "shockwave" of pressure travels through the plumbing and interferes with the maf reading, the closer it is to the maf hot-wire. A surging compressor wheel does the same exact thing; you can even see the maf voltage spike up and down as the compressor is surging. It is therefore very important that we keep the maf as far from those sort of airflow variations as possible, the OEM have various methods; some of them use convoluted tube for example, that leads from the compressor to the air filter. You remove the convuluted tube for a straight piece and suddenly you get part throttle hesitation/lean stumbes, if the tube isn't long enough or the turbo is very small (easier to surge at low speeds because it is moving much faster)

a maf is very linear, sensitive device, you need to physically LOOK at the plumbing and TEST the plumbing for leaks by filling with pressure; you are l@@king for anything that might swirl / whip up the air, or cause it to flow backwards or "stall", so tight bends and throttle bodies and compressor wheels should be kept away from it. The air filter is also SUPER IMPORTANT. I can't stress this enough, to use a quality filter.

#18

Banned

iTrader: (1)

[QUOTE=moehorsepower;19360071] the maf is the sensor/meter (mass air meter?) that measures these things. It show in the voltage graph. You simply log the maf output and look at it with ur eyes and judge for yourself if it looks all fucked up or if it looks nice and smooth.

And when I say quality filter, I was really thinking of an OEM paper element. The cone styles are fine for smoothing the air for the maf sensor; but they do not seem to filter as well as the OEM paper (not sure anything does). I should have been more specific, my bad, so to clarify: the maf needs a "well sealed up inlet with an air filter that can dampen/smooth the air completely. Any tight bends or weird shapes should be avoided." Think of what happens if you do NOT run a filter at all: the air can buffet the hotwire, the radiator fan can kick on and buffet the maf hotwire, heck you can blow on it and it will stall the engine. That is why the filter is so important there. With the engine at idle you should be able to blow on the filter/maf harshly (use an air compressor if you want gently) and it should not change the maf voltage/ or affect the idle of the engine. If it does, you need a "better filter" or a longer tube.

oh i love questions  thank you

thank you

A length of straight pipe after the maf, is to help keep air perturbations from influencing the maf sensor. For example, if you get out of the throttle, a tiny "shockwave" of pressure travels through the plumbing and interferes with the maf reading,

Here we go, so you have a meter that measures so called air peturbations, and shock wave, you know this for a fact or just theory, and if its fact, I would like to know how you measured for these anomalies.

thank you

thank youA length of straight pipe after the maf, is to help keep air perturbations from influencing the maf sensor. For example, if you get out of the throttle, a tiny "shockwave" of pressure travels through the plumbing and interferes with the maf reading,

Here we go, so you have a meter that measures so called air peturbations, and shock wave, you know this for a fact or just theory, and if its fact, I would like to know how you measured for these anomalies.

And when I say quality filter, I was really thinking of an OEM paper element. The cone styles are fine for smoothing the air for the maf sensor; but they do not seem to filter as well as the OEM paper (not sure anything does). I should have been more specific, my bad, so to clarify: the maf needs a "well sealed up inlet with an air filter that can dampen/smooth the air completely. Any tight bends or weird shapes should be avoided." Think of what happens if you do NOT run a filter at all: the air can buffet the hotwire, the radiator fan can kick on and buffet the maf hotwire, heck you can blow on it and it will stall the engine. That is why the filter is so important there. With the engine at idle you should be able to blow on the filter/maf harshly (use an air compressor if you want gently) and it should not change the maf voltage/ or affect the idle of the engine. If it does, you need a "better filter" or a longer tube.

Last edited by kingtal0n; 08-16-2016 at 08:42 PM.

#19

Banned

iTrader: (1)

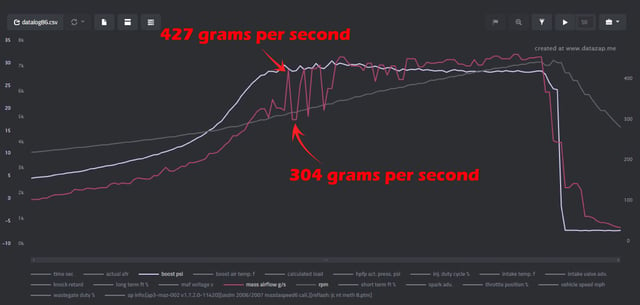

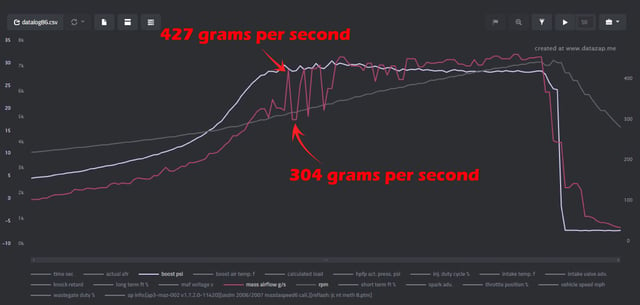

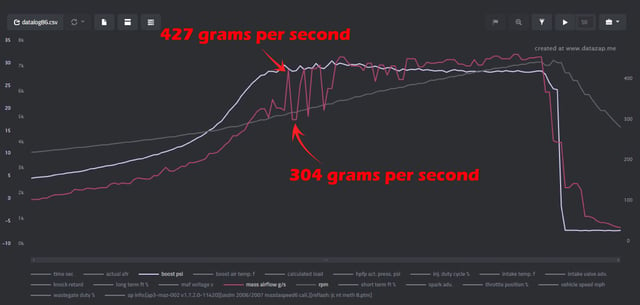

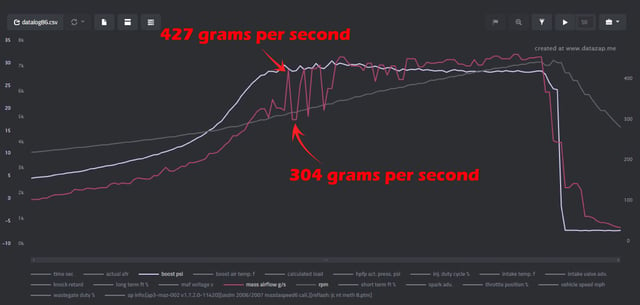

heres a random example from image search on the internet

See the @#*(@'d up graph with all the spikes? that is obvious compressor surge, or what it would/should look like. I dont know the history behind the graph but I can tell that the line is not nice and smooth.

found the site behind it :

http://blog.edgeautosport.com/when-is-a-turbo-too-big

The maf can read air flowing backwards through it just like it can read air flowing forwards. The two situations are NOT linear i.e. one does not compensate for the other perfectly. Its just a reminder for us that the MAF needs to have a continuous, gradual, smooth flow, and anything that interferes with that will screw the voltage curve up and make the engine run terrible. Note that the picture is showing a WOT surge, and this behavior can also be seen at idle if the bypass valve is tightly shut when it should be open, as well as part throttle or during throttle lift events (the most common point to surge is a lift event) and the result is the same: F#)(@#'d up maf voltage curve and terrible engine response, with a tapering recovery condition as the maf tries to straighten out and the engine tries to clear all the excess fuel that was probably just injected for no reason.

See the @#*(@'d up graph with all the spikes? that is obvious compressor surge, or what it would/should look like. I dont know the history behind the graph but I can tell that the line is not nice and smooth.

found the site behind it :

http://blog.edgeautosport.com/when-is-a-turbo-too-big

"This tells us that the turbo is back flowing into the intake through the surge ports on the turbo. The pressure builds up but isn’t ingested by the engine, instead, it goes back out the intake."

Last edited by kingtal0n; 08-16-2016 at 08:57 PM.

#20

TECH Veteran

iTrader: (1)

heres a random example from image search on the internet

See the @#*(@'d up graph with all the spikes? that is obvious compressor surge, or what it would/should look like. I dont know the history behind the graph but I can tell that the line is not nice and smooth.

found the site behind it :

http://blog.edgeautosport.com/when-is-a-turbo-too-big

The maf can read air flowing backwards through it just like it can read air flowing forwards. The two situations are NOT linear i.e. one does not compensate for the other perfectly. Its just a reminder for us that the MAF needs to have a continuous, gradual, smooth flow, and anything that interferes with that will screw the voltage curve up and make the engine run terrible. Note that the picture is showing a WOT surge, and this behavior can also be seen at idle if the bypass valve is tightly shut when it should be open, as well as part throttle or during throttle lift events (the most common point to surge is a lift event) and the result is the same: F#)(@#'d up maf voltage curve and terrible engine response, with a tapering recovery condition as the maf tries to straighten out and the engine tries to clear all the excess fuel that was probably just injected for no reason.

See the @#*(@'d up graph with all the spikes? that is obvious compressor surge, or what it would/should look like. I dont know the history behind the graph but I can tell that the line is not nice and smooth.

found the site behind it :

http://blog.edgeautosport.com/when-is-a-turbo-too-big

The maf can read air flowing backwards through it just like it can read air flowing forwards. The two situations are NOT linear i.e. one does not compensate for the other perfectly. Its just a reminder for us that the MAF needs to have a continuous, gradual, smooth flow, and anything that interferes with that will screw the voltage curve up and make the engine run terrible. Note that the picture is showing a WOT surge, and this behavior can also be seen at idle if the bypass valve is tightly shut when it should be open, as well as part throttle or during throttle lift events (the most common point to surge is a lift event) and the result is the same: F#)(@#'d up maf voltage curve and terrible engine response, with a tapering recovery condition as the maf tries to straighten out and the engine tries to clear all the excess fuel that was probably just injected for no reason.