Post your best welds!

#261

8 Second Truck Club

iTrader: (32)

Question on atrocious welding: I've got a buddy who does great work on cars and he agreed to a great deal on welding in two cutouts for me. I sampled some of his work and it was god-awful. He spliced in a muffler for someone else with globs of welds and I'm considering going elsewhere. Great mechanic but awful welder. Would you guys say thanks but no thanks? Are there any issues that may arise from shoddy welding or is it simply a recognition of the beautification of workmanship?

#262

Question on atrocious welding: I've got a buddy who does great work on cars and he agreed to a great deal on welding in two cutouts for me. I sampled some of his work and it was god-awful. He spliced in a muffler for someone else with globs of welds and I'm considering going elsewhere. Great mechanic but awful welder. Would you guys say thanks but no thanks? Are there any issues that may arise from shoddy welding or is it simply a recognition of the beautification of workmanship?

#265

TECH Senior Member

iTrader: (25)

on beater cars that need exhaust work i go this place in the cuts

the guy doesnt even wear a hood, just peek-a-boos it lol

pretty terrible welds, just godawful bird poo lookin globs

but he's dirt cheap and I dont have to get under there.

now would i let that guy weld on my turbo truck? nope. would his welds fly in my workplace? nope.

but, horses for courses and all that

the guy doesnt even wear a hood, just peek-a-boos it lol

pretty terrible welds, just godawful bird poo lookin globs

but he's dirt cheap and I dont have to get under there.

now would i let that guy weld on my turbo truck? nope. would his welds fly in my workplace? nope.

but, horses for courses and all that

#267

Launching!

Join Date: Oct 2005

Location: Northern Chicago

Posts: 240

Likes: 0

Received 0 Likes

on

0 Posts

#268

#271

On a side note i love welding up that 11ga aluminum from RPS on downpipes. Slight bevel, start them at 170amps and usually turn down to 150 if it starts getting too hot. Can fill it out in one pass but boy are you running filler fast!

#272

TECH Senior Member

iTrader: (25)

yeah I do a lot of that stuff at work. thats kinda how I do everything. throttle up and get moving! sucks now that I'm trying to do some SS for my turbo adventure. BTW your SS looks great. Nice color. You purging or using solar flux?

@ 5spd-iroc, is that restricted 45* pipe the 6g test? you a pipefitter?

shearer. damn nice work pal. pulse? can I ask your settings? I'm newb to thin SS tube

@ 5spd-iroc, is that restricted 45* pipe the 6g test? you a pipefitter?

shearer. damn nice work pal. pulse? can I ask your settings? I'm newb to thin SS tube

#273

yeah I do a lot of that stuff at work. thats kinda how I do everything. throttle up and get moving! sucks now that I'm trying to do some SS for my turbo adventure. BTW your SS looks great. Nice color. You purging or using solar flux?

@ 5spd-iroc, is that restricted 45* pipe the 6g test? you a pipefitter?

shearer. damn nice work pal. pulse? can I ask your settings? I'm newb to thin SS tube

@ 5spd-iroc, is that restricted 45* pipe the 6g test? you a pipefitter?

shearer. damn nice work pal. pulse? can I ask your settings? I'm newb to thin SS tube

Also I know i could slow down and be a little more uniformed but on thin wall i typically run 50amps foot to the floor and stack filler through the keyhole as quickly as I can to keep the heat/puddle looking right. Vbands around 70amps and turbo flanges 100-120.

#275

Here is a tig tacking trick I learned a while back that works awesome if you do it right.

Lets say you're welding two pieces of material together and to weld you plan on dialing 90 amps (and using a foot control) to make the weld. Double the amperage you would typically use, so in this case crank the machine to 180 amp. Here is where it gets tricky. If your torch placement is correct, you can basically slightly roll into the throttle for maybe half a second to make sure the torch is where it needs to be, then go WOT for a split second and release. If you did it right, it makes a perfect tack. This tip works good on steel/4130/stainless for example, but not so much on aluminum as I like to add filler to aluminum tacks.

Sometimes if the torch angle isn't right or the fit up is not perfect, the blast of amperage can just burn the two pieces away from each other, leaving a bigger gap to fill. So use this tip wisely.

I run a 200 amp Miller Dynasty, so I just normally turn it up to 200 amps unless I'm doing some thin wall exhaust tubing. But I've had luck using this method on **** as small as 16 gauge steel set up around 150 amps.

Lets say you're welding two pieces of material together and to weld you plan on dialing 90 amps (and using a foot control) to make the weld. Double the amperage you would typically use, so in this case crank the machine to 180 amp. Here is where it gets tricky. If your torch placement is correct, you can basically slightly roll into the throttle for maybe half a second to make sure the torch is where it needs to be, then go WOT for a split second and release. If you did it right, it makes a perfect tack. This tip works good on steel/4130/stainless for example, but not so much on aluminum as I like to add filler to aluminum tacks.

Sometimes if the torch angle isn't right or the fit up is not perfect, the blast of amperage can just burn the two pieces away from each other, leaving a bigger gap to fill. So use this tip wisely.

I run a 200 amp Miller Dynasty, so I just normally turn it up to 200 amps unless I'm doing some thin wall exhaust tubing. But I've had luck using this method on **** as small as 16 gauge steel set up around 150 amps.

#276

TECH Regular

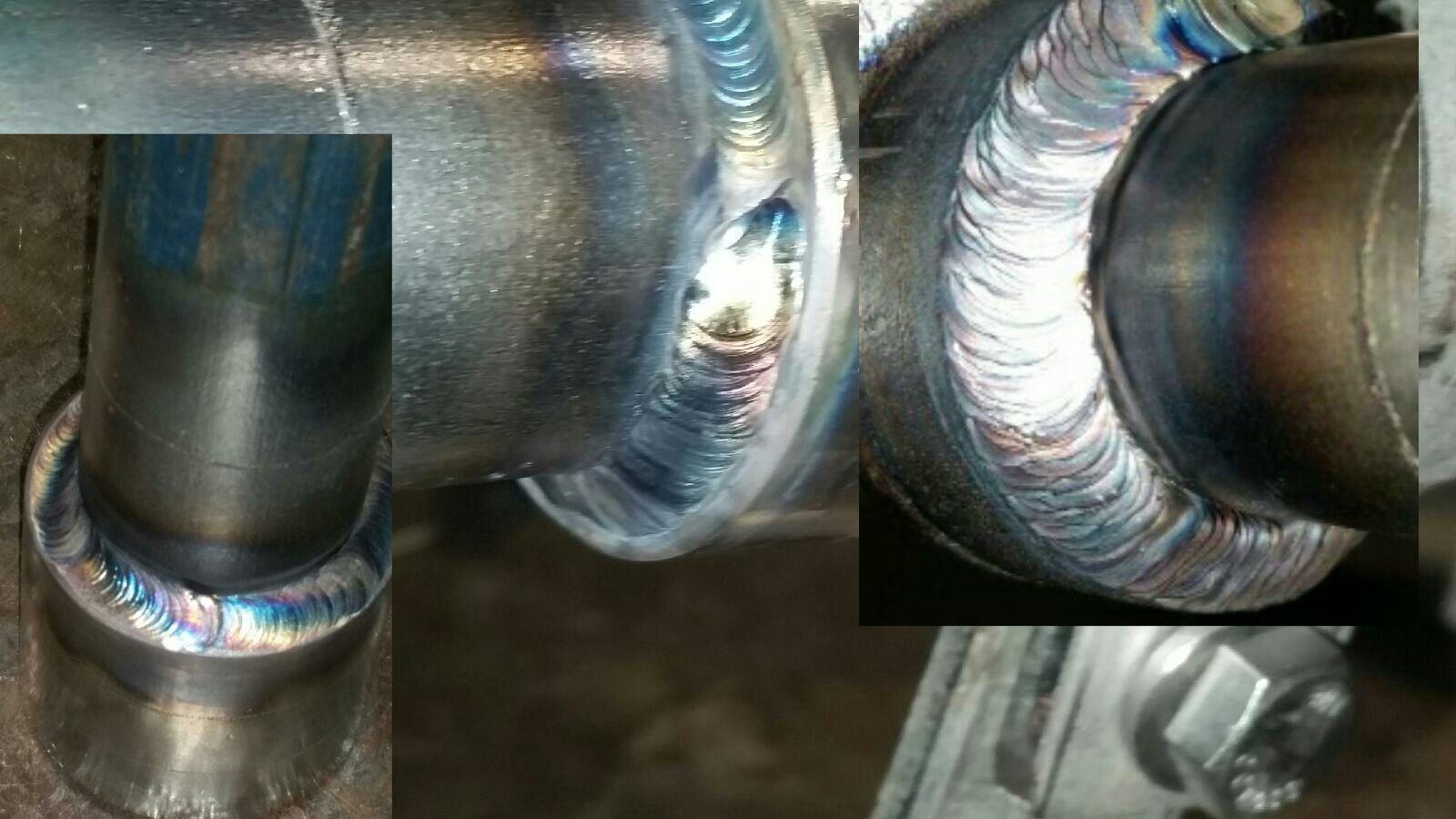

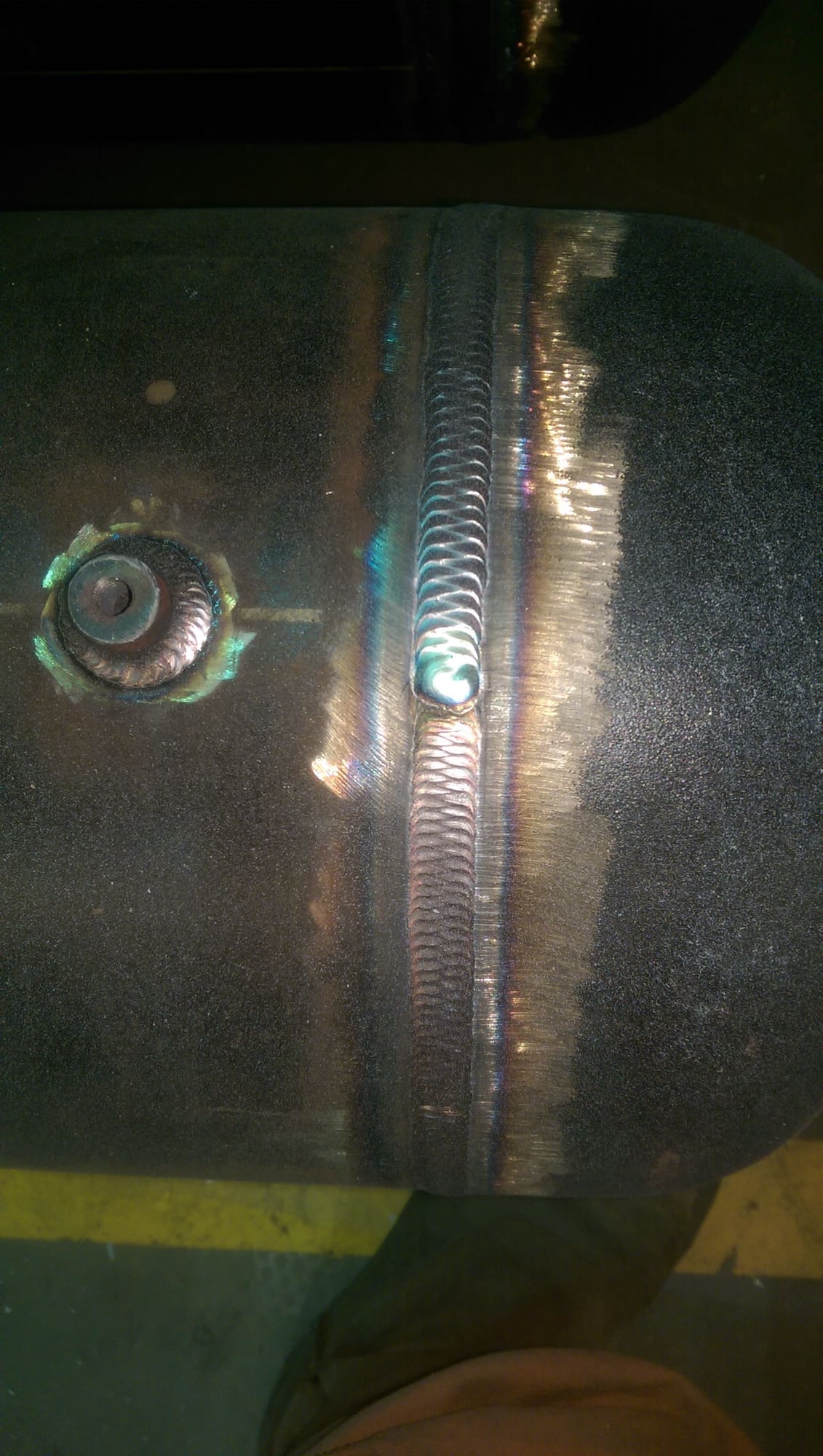

Not my best but it's all I had on my phone from when I sent them to a customer I build heat exchangers and high pressure vessels as well as reactors where I work

#279

yeah I do a lot of that stuff at work. thats kinda how I do everything. throttle up and get moving! sucks now that I'm trying to do some SS for my turbo adventure. BTW your SS looks great. Nice color. You purging or using solar flux?

@ 5spd-iroc, is that restricted 45* pipe the 6g test? you a pipefitter?

shearer. damn nice work pal. pulse? can I ask your settings? I'm newb to thin SS tube

@ 5spd-iroc, is that restricted 45* pipe the 6g test? you a pipefitter?

shearer. damn nice work pal. pulse? can I ask your settings? I'm newb to thin SS tube