Intake Manifold for Centri blower?

#1

The plenum of the stock LT1/LT4 intakes measures right at 2.88 liters which equates to 175ci (50% of a 350ci motor) For measurement sake 1liter=61ci. My intake measures 6.45liters=393ci. The rule of thumb in building intake manifolds is start at 50-75% of the motors cubic inch and you can go up to 120-130% of the CI, going more than that makes lagged throttle response and can slow the car at the track. Using this information this intake would be 112% on a 350ci, 1.03% on a 383 and 99% on a 396, which is prefect within those requirements. From the information above we can also derive that the stock intake barley has enough plenum for a Stock 350ci motor right at 50%, on a 383 that number lowers to a 34% and a 396 is 27%. Something I picked up from Joe Overton (fastest N/A LT1) is that rpm isn’t the issue with an LT1 intake it’s the plenum volume and the turbulence it creates. It becomes turbulent b/c of the small plenum; it starves the cylinders for airflow in the upper rpm levels which indirectly effects the performance of the small 3inch runners. This intake IMO would be a great candidate for a N/A application.

The runners have had a lot of attention since I felt that they where one of the biggest problems with the factory intake (well again that’s all relevant to how much rpm you plan to run as well, but the plenum is still an issue). The stocker measured right at 3inches in length which between the lengths of the intake runner of the head+intake that runs off the 5th harmonic wave. I decided against modifing the length in a physical sense, but I received some very good info from Larry Meaux (who is on this site every now and again) , he said, “The sharp knife-edged Runner entries are effectively "lengthening" the runners by causing a sharper harder hit on runner wave tuning. If the runner is a little too short for RPM range, a sharper divider can act like its slightly longer returning a more powerful wave at Intake Valve closing point. Knife-edge is used sometimes to effectively fool the manifold runner length into thinking it’s longer, and too much radius effectively fools the runner into thinking its shorter than it measures.” So by making the knife-edge entry I am tricking the runners into thinking there longer making more average TQ and HP.

Taper is often used on intakes to increase the FPS of airflow, but adding taper into a manifold’s runner actually shortens the runner. Since the runners on the LT1 intakes are so small in length it is best IMO to keep any taper out of the intake, and this will make the runner think its longer as well.

These actions may possible throw this intake in with the 4th harmonic wave, which would be nice for some more power gain.

The roof on the stock intake and the entry into the runners seem to be a big problem. On the stock intake the roof of the runner was lowered around .250 to get the injectors to fit into the rails. Over the years I have seen people raise the roofs .100-.125 without welding and around .200 with welding. I have raised the roof to around .350-.400. Again this goes back to working the runners for greater volume and I have a bell mouth "style" entry into the runners.

I worked the runners for greater volume, but I did not touch the gasket area. When installing the intake I plan on removing the top to see how well the ports line up. Air should not know when the intake/head starts or ends, should be one continuous runner.

The intake weighs right at 13lbs, on the same scale the intake before modding (stock form) weighed 19.2lbs. Many people convert Holley steathrams over for LT1/4's and they have to be around 35lbs. For comparison sake LSX style plastic manifolds (LS1, L76, LS2, LS7 etc weigh in the 10-12lb range)

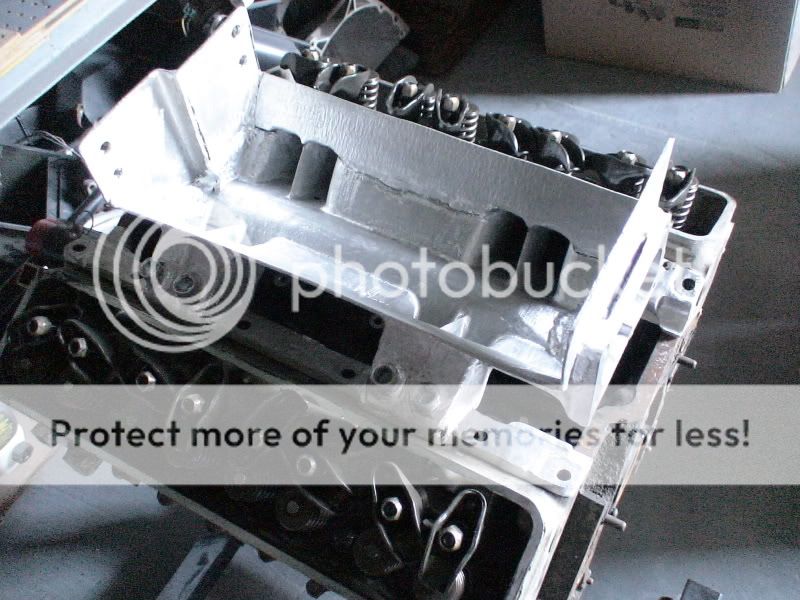

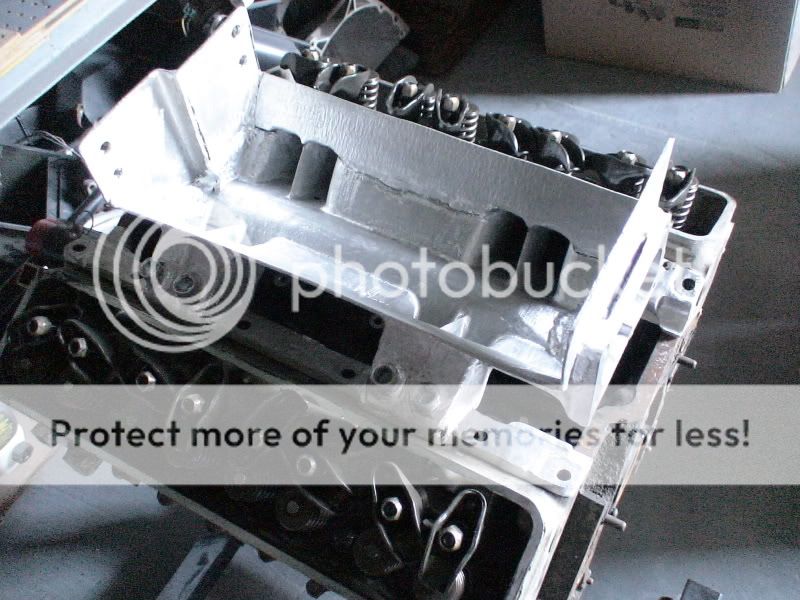

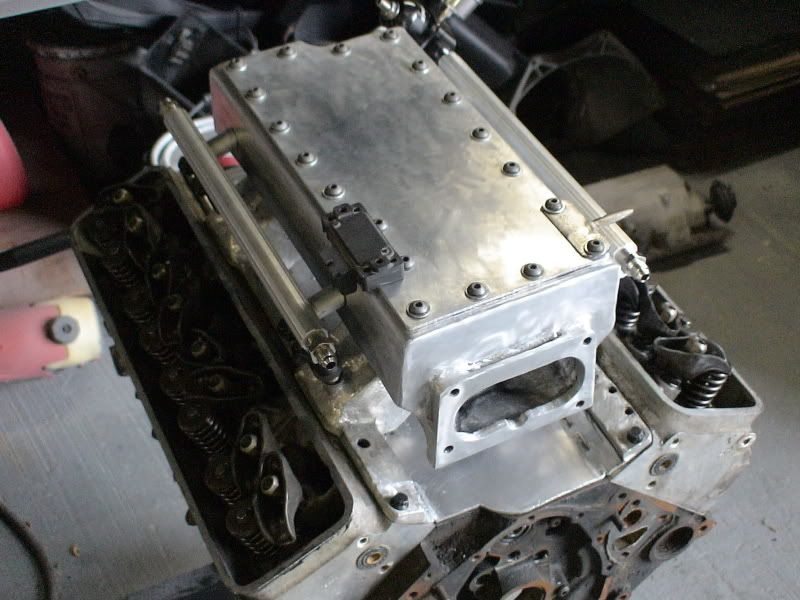

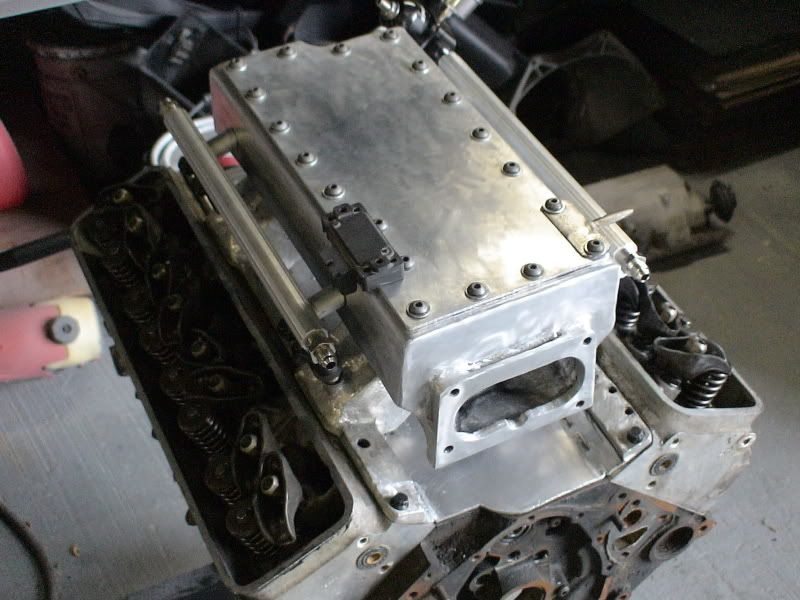

Here are a few pics of the intake (A little old, but you guys will get the idea, looks better now, just no updated pics).

Before welding up the top of the intake I worked the on the inside of the intake, notice the entry bell entry near the top of the runner (the intake is actually smoother now as opposed to the pic) and notice the knife edged runner entry.

Just for comparison sake here is a pic of my factoy LT4 intake worked over by a very reputable porter in the LTx community. Notice how only the TB opening has been worked over and the runners have been worked. The only way to work over the inside of the factory intake is to cut the top off. Other things I don't like the is the protrusions from the fuel rail crossover and fittings. Also the number 8 is right against the wall, that must be hurting flow into that cylinder. For that matter air likes radiused entries so air feeding from the top of the plenum would not flow as efficient as air from a bellmouth style entry.

The car has a D1SC at the moment (1400cfm) and in the near future I plan to uprade to a F1A Procharger (1650cfm). So I have a few questions regarding on what I could do to enhance the performance of the intake.

One of my main concerns is what about CSA are at the entry of the runner, since the car is boosted could I get away with a larger CSA as opposed to a N/A combo?

Does runner length matter on a blower application, I would think the intake harmonics would not matter since the intake manifold would be pressurized?

Would Taper, play a role in? IMO it would not since the airspeed is already probably twice as fast since the car has a blower. And again, if runner length is actually important on a build like this one, I can use all the runner length I can.

Plenum volume IMO is about perfect for a any N/A LT1 application (350-396 ci motors), but for a boosted application could a larger plenum be beneficial?

The runners have had a lot of attention since I felt that they where one of the biggest problems with the factory intake (well again that’s all relevant to how much rpm you plan to run as well, but the plenum is still an issue). The stocker measured right at 3inches in length which between the lengths of the intake runner of the head+intake that runs off the 5th harmonic wave. I decided against modifing the length in a physical sense, but I received some very good info from Larry Meaux (who is on this site every now and again) , he said, “The sharp knife-edged Runner entries are effectively "lengthening" the runners by causing a sharper harder hit on runner wave tuning. If the runner is a little too short for RPM range, a sharper divider can act like its slightly longer returning a more powerful wave at Intake Valve closing point. Knife-edge is used sometimes to effectively fool the manifold runner length into thinking it’s longer, and too much radius effectively fools the runner into thinking its shorter than it measures.” So by making the knife-edge entry I am tricking the runners into thinking there longer making more average TQ and HP.

Taper is often used on intakes to increase the FPS of airflow, but adding taper into a manifold’s runner actually shortens the runner. Since the runners on the LT1 intakes are so small in length it is best IMO to keep any taper out of the intake, and this will make the runner think its longer as well.

These actions may possible throw this intake in with the 4th harmonic wave, which would be nice for some more power gain.

The roof on the stock intake and the entry into the runners seem to be a big problem. On the stock intake the roof of the runner was lowered around .250 to get the injectors to fit into the rails. Over the years I have seen people raise the roofs .100-.125 without welding and around .200 with welding. I have raised the roof to around .350-.400. Again this goes back to working the runners for greater volume and I have a bell mouth "style" entry into the runners.

I worked the runners for greater volume, but I did not touch the gasket area. When installing the intake I plan on removing the top to see how well the ports line up. Air should not know when the intake/head starts or ends, should be one continuous runner.

The intake weighs right at 13lbs, on the same scale the intake before modding (stock form) weighed 19.2lbs. Many people convert Holley steathrams over for LT1/4's and they have to be around 35lbs. For comparison sake LSX style plastic manifolds (LS1, L76, LS2, LS7 etc weigh in the 10-12lb range)

Here are a few pics of the intake (A little old, but you guys will get the idea, looks better now, just no updated pics).

Before welding up the top of the intake I worked the on the inside of the intake, notice the entry bell entry near the top of the runner (the intake is actually smoother now as opposed to the pic) and notice the knife edged runner entry.

Just for comparison sake here is a pic of my factoy LT4 intake worked over by a very reputable porter in the LTx community. Notice how only the TB opening has been worked over and the runners have been worked. The only way to work over the inside of the factory intake is to cut the top off. Other things I don't like the is the protrusions from the fuel rail crossover and fittings. Also the number 8 is right against the wall, that must be hurting flow into that cylinder. For that matter air likes radiused entries so air feeding from the top of the plenum would not flow as efficient as air from a bellmouth style entry.

The car has a D1SC at the moment (1400cfm) and in the near future I plan to uprade to a F1A Procharger (1650cfm). So I have a few questions regarding on what I could do to enhance the performance of the intake.

One of my main concerns is what about CSA are at the entry of the runner, since the car is boosted could I get away with a larger CSA as opposed to a N/A combo?

Does runner length matter on a blower application, I would think the intake harmonics would not matter since the intake manifold would be pressurized?

Would Taper, play a role in? IMO it would not since the airspeed is already probably twice as fast since the car has a blower. And again, if runner length is actually important on a build like this one, I can use all the runner length I can.

Plenum volume IMO is about perfect for a any N/A LT1 application (350-396 ci motors), but for a boosted application could a larger plenum be beneficial?

Last edited by T/A KID; 08-07-2009 at 07:02 PM.

#4

Awesome craftsmanship, curious to see how it works out.

I have done a enormous amount of research on intake design and I have talked to several people in the LTX community that have had weld work on there LT1/4 intake over the years. I think I have a winner here, time will tell.

#7

Depending on performance, I actually thought about making these. They could be tailored for N/A or FI applications since both setups would like only a few things changed up.

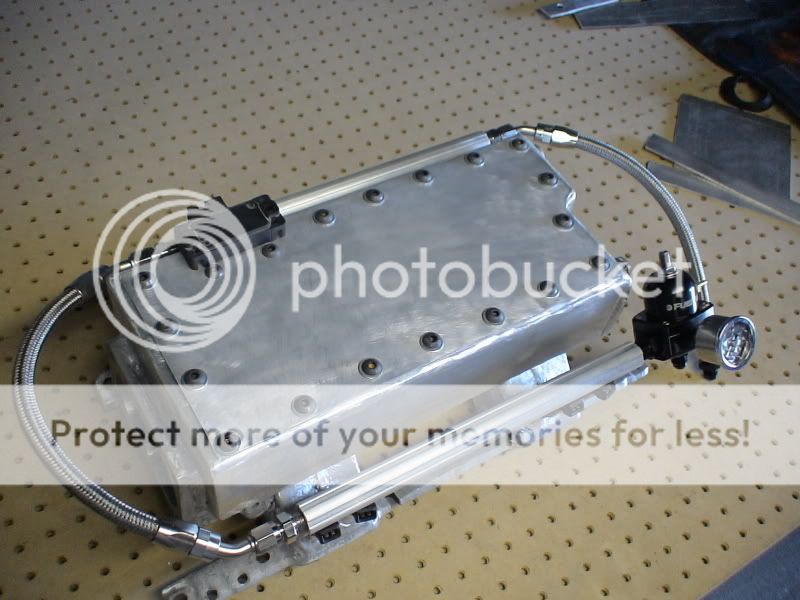

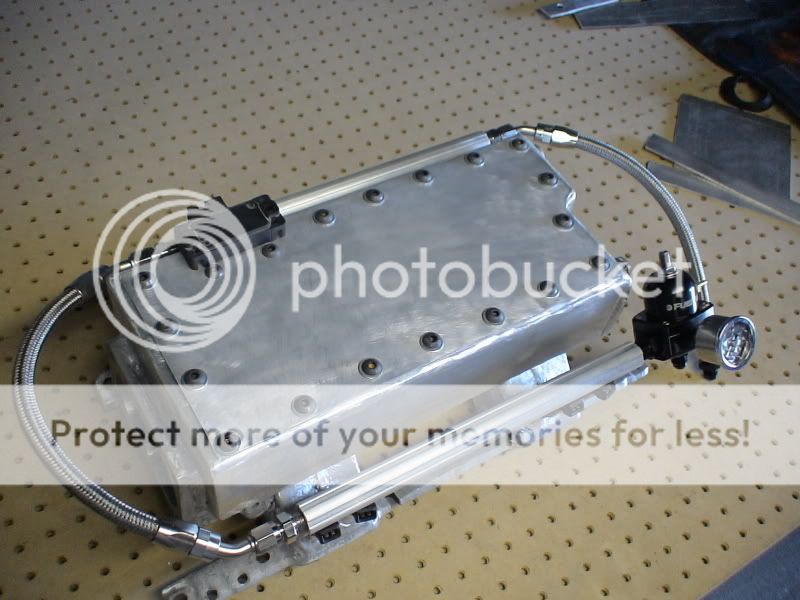

Here is good pic of it on my mock up motor, notice the Throttle cable setup, nice and simple (custom made from stock bracket)

The rear of the manifold accepts the factory fittings.

Here is good pic of it on my mock up motor, notice the Throttle cable setup, nice and simple (custom made from stock bracket)

The rear of the manifold accepts the factory fittings.

Last edited by T/A KID; 08-09-2009 at 11:38 PM.

Trending Topics

#10

Any mods to the cowl area needed for this to fit?

#14

TECH Enthusiast

iTrader: (1)

Join Date: Jun 2008

Location: Naperville, Ill

Posts: 510

Likes: 0

Received 0 Likes

on

0 Posts

Runner length, again, is less important with F.I.

Simply put, when the manifold is pressurized, it will be forced to gulp down as much air as it can, not having to pull it in.

Turbos/Superchargers also prevent the air starvation and inherent rich conditions that result in the cylinders most distal to the Throttle Body.

Really, simplicity and strength count.

As for the N/A applications Larger plenums help mitigate rich running conditions at very high rpm, however too large and air velocity suffers creating turbulence.

Just been rambling in my morning haze. I'll check back in a little while.

Project Looks awesome by the way, should make good Tq. on that LTx!

#15

Ice78Transam thanks for the info, I have been lerking on speedtalk.com for awhile. A lot of people on there that really know there stuff.

Thanks for the compliment, I am hoping we can add a good bit of hp/tq throughout the rpm range. I will tune the car with the LT4 Edelbrock I have at the moment and just do one change, which will be this intake. Will be on the same dyno and hopefully the same day (to make a valid test). Hopefully the car will loose some boost and we will have to add fuel.

Anyone else have any input?

P.S. I ordered some Devcon F epoxy this morning, the intake should be perfect (in my standards) when I get that applied

Project Looks awesome by the way, should make good Tq. on that LTx!

Anyone else have any input?

P.S. I ordered some Devcon F epoxy this morning, the intake should be perfect (in my standards) when I get that applied