CFM vs. Velocity

#21

One way to look at it would be find out what your engine wants. If you had a spreadsheet that would tell you the piston demand in CFM from TDC to BDC with a piston speed of around 4000 ft min. or whatever you want the peak to be. 4000 seems to work fairly well.

I think the peak speed limit is around 614' sec at the min CSA so if you keep south of that you could get some idea of what area/port vol will work in your application.

Energy goes up by the square of the speed e=mc2?. More port speed, more energy at intake closing or any point in between but too fast is worse than too slow and different heads have different limits.

Also remember heads are flowed at 28" h20 (2.07" hg) and a running engine sees much more than this, I think like 406" h20 or so (29.92" hg).

Maybe someone who know more about this could explain it better as I don't know nearly as much about this subject as I would like, its quite complex.

I think the peak speed limit is around 614' sec at the min CSA so if you keep south of that you could get some idea of what area/port vol will work in your application.

Energy goes up by the square of the speed e=mc2?. More port speed, more energy at intake closing or any point in between but too fast is worse than too slow and different heads have different limits.

Also remember heads are flowed at 28" h20 (2.07" hg) and a running engine sees much more than this, I think like 406" h20 or so (29.92" hg).

Maybe someone who know more about this could explain it better as I don't know nearly as much about this subject as I would like, its quite complex.

#22

FormerVendor

iTrader: (13)

At peak piston velocity an engine may pull 200" of H20 differential pressure, but you want cylinder filling to continue until the intake valve is closed, this is how you get over 100% volumetric effeciency. The intake valve on my street engine doesn't close until 76 degrees after bottom dead center, so the piston is more than 1/3 of the way back up the bore on the compression stroke before the intake valve closes. The intake valve theoretically closes to .050" at 54 degrees ABDC, but you have to factor in the rocker ratio which means it is actually .085". At that moment you are dealing with negative pressure, meaning there is more pressure in the cylinder than is in the port. This is why it is important to minimize low lift flow (.100" and below) otherwise the air goes back into the intake port and does not stay in the cylinder where you want it. So the whole thing is much more dynamic than simple formulas, and different ports with different valve events can yeild the same result.

BTW, I don't think an engine can pull 29.92" of Hg from the plenum to the cylinder (the way a flowbench measures), but can pull that much from the plenum to atmospheric upon deceleration. At WOT the plenum is usually .5"-1.5" of Hg (1.5" of Hg is where carbs are flowed at)

BTW, I don't think an engine can pull 29.92" of Hg from the plenum to the cylinder (the way a flowbench measures), but can pull that much from the plenum to atmospheric upon deceleration. At WOT the plenum is usually .5"-1.5" of Hg (1.5" of Hg is where carbs are flowed at)

Last edited by Brian Tooley Racing; 06-10-2008 at 04:06 PM.

#23

TECH Addict

iTrader: (22)

The velocity in the port is not nearly as important as the velocity around the circumference of the valve, and the velocity around the valve can be calculated.

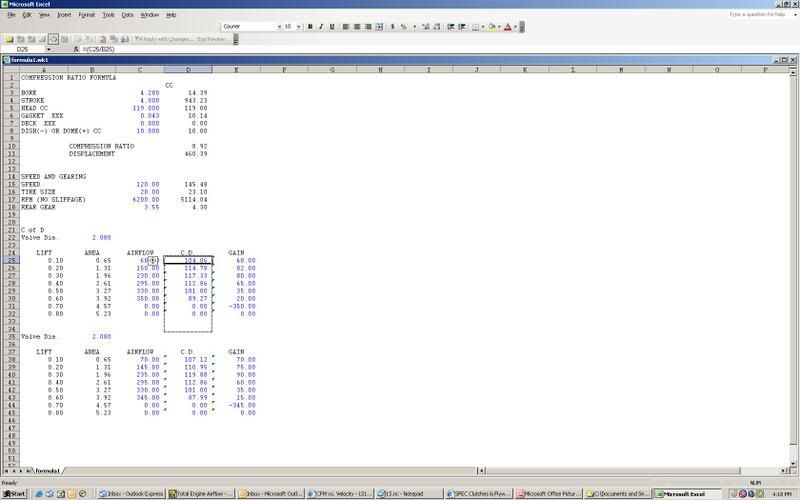

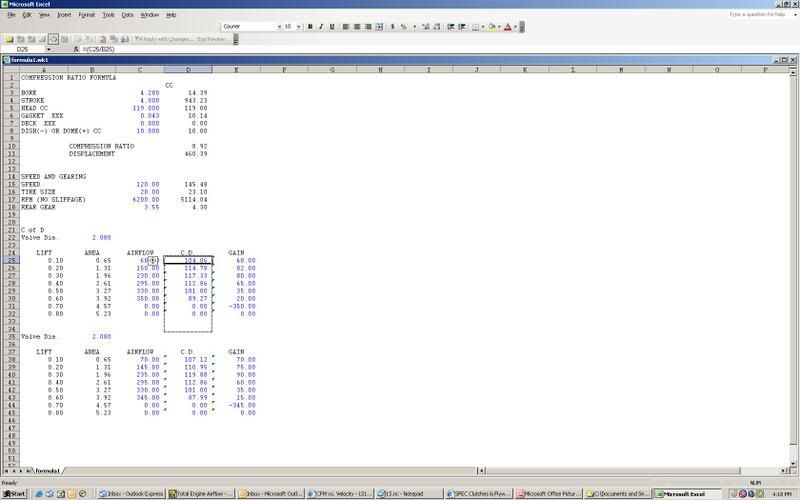

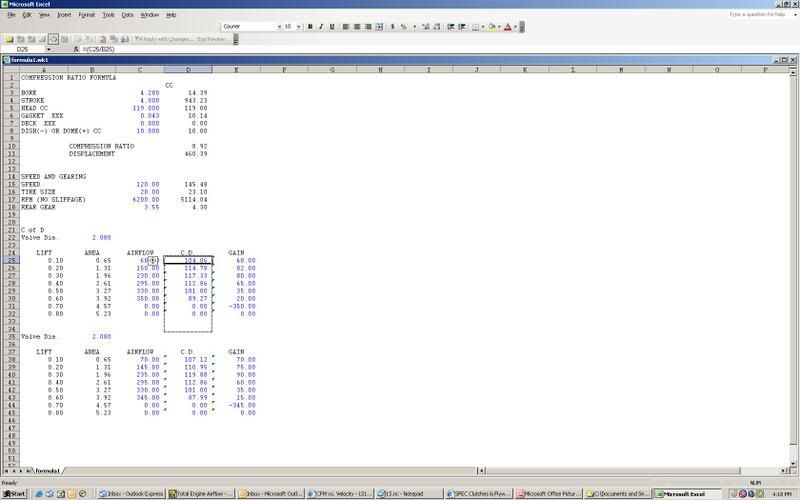

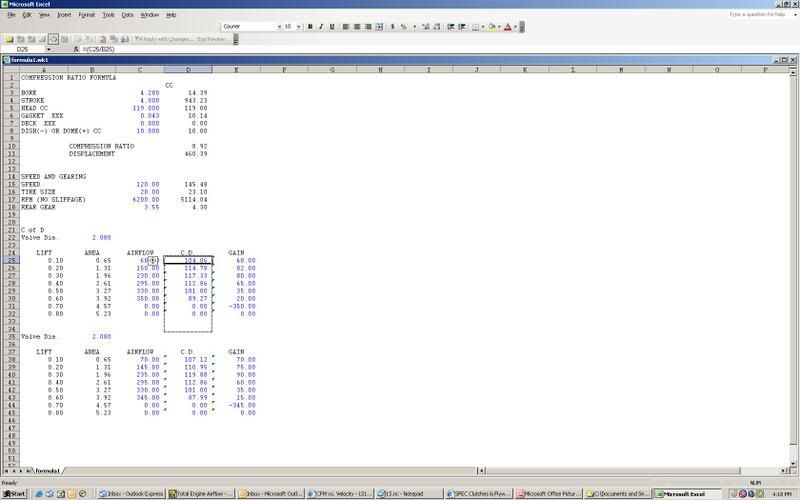

I use a "coefficient of discharge" formula. It is basically the airflow divided by the curtain area of the valve. Here is a screen shot of it, I can email it to anyone who wants to use it, just PM me your email address. The most important thing to remember for a street car is the discharge at .300"-.500" is THE KEY, and you DO NOT want a lot of discharge at .100".

You will discover heads with large intake valves have relatively poor discharge through the mid lift but a lot at .100". This is due to the larger a valve gets, the more air it flows at .100" unless you use a steeper seat angle (50-55 versus 45) and the larger it gets the more shrouded it is and the less midlift it has, but will usually show big airflow upstairs, which a street car never sees. Hope this helps.

I use a "coefficient of discharge" formula. It is basically the airflow divided by the curtain area of the valve. Here is a screen shot of it, I can email it to anyone who wants to use it, just PM me your email address. The most important thing to remember for a street car is the discharge at .300"-.500" is THE KEY, and you DO NOT want a lot of discharge at .100".

You will discover heads with large intake valves have relatively poor discharge through the mid lift but a lot at .100". This is due to the larger a valve gets, the more air it flows at .100" unless you use a steeper seat angle (50-55 versus 45) and the larger it gets the more shrouded it is and the less midlift it has, but will usually show big airflow upstairs, which a street car never sees. Hope this helps.

Let me ask you this Brian.

If you are running a cam with say .650-680 lift in a street car, why wouldn't you want big numbers at .650??

#24

TECH Addict

Thread Starter

iTrader: (24)

Join Date: Oct 2006

Location: Webb City, MO...out in the garage

Posts: 2,608

Likes: 0

Received 0 Likes

on

0 Posts

ok now we're getting some where....

and i second that: why wouldn't you want big numbers at .650"? i've been considering a cam in the mid-230's duration with ~.650" lift for my LSX build. i've seen/heard of a couple C6 Z's hitting 600rwhp with stock bottom ends and stock ported heads/intake.

so after all this info has been brought up, let's delete some variable with constants: we have a 434cid LSX, compstar crank/rods, wiesco pistons, desired SCR of ~11.8:1, hydraulic roller cam custom matched to heads....what heads would *YOU* run to try to hit 600rwhp?

i've looked at ported LS7's, TFS 245's, All Pro 'race prepped' LS2 style heads...to name a few...i really hate making "what do you think" threads, that's why i made this one. i want to be 100% independant when it comes to decission making. i want to become that way by understanding theory and principles of our engines, not by standing on others' shoulders

and i second that: why wouldn't you want big numbers at .650"? i've been considering a cam in the mid-230's duration with ~.650" lift for my LSX build. i've seen/heard of a couple C6 Z's hitting 600rwhp with stock bottom ends and stock ported heads/intake.

so after all this info has been brought up, let's delete some variable with constants: we have a 434cid LSX, compstar crank/rods, wiesco pistons, desired SCR of ~11.8:1, hydraulic roller cam custom matched to heads....what heads would *YOU* run to try to hit 600rwhp?

i've looked at ported LS7's, TFS 245's, All Pro 'race prepped' LS2 style heads...to name a few...i really hate making "what do you think" threads, that's why i made this one. i want to be 100% independant when it comes to decission making. i want to become that way by understanding theory and principles of our engines, not by standing on others' shoulders

#26

TECH Addict

iTrader: (5)

Talk to curtis boggs on yellowbullet.com He is the owner of Race flow developement and used to do a lot of design and testing for head companies and worked for sonnys racing.

He gave me some good info and is a really nice guy to talk to about heads. He explained that the biggest head with the most flow isn't going to give you the highest hp and that using the right size head for the motor tailored to the motor, port configuration, shape, valve size, port size made for your motor will make way more power than just just buying a big port head with high cfm numbers, BTW which most companies are full of **** and inflate cfm numbers for sales purposes.

He gave me some good info and is a really nice guy to talk to about heads. He explained that the biggest head with the most flow isn't going to give you the highest hp and that using the right size head for the motor tailored to the motor, port configuration, shape, valve size, port size made for your motor will make way more power than just just buying a big port head with high cfm numbers, BTW which most companies are full of **** and inflate cfm numbers for sales purposes.

#28

OWN3D BY MY PROF!

iTrader: (176)

I have been researching this argument for awhile to find out why my engine makes the power it does.

Basically, heads like Ls7's and L92's both have 2 issues that kill velocity.

1. is shrouding over the valve that hinders flow off the seat

2. large intake port kills velocity.

My solution was a smaller cam. Seemed to help a bit. Softer/Lazy lobe seems to allow the head to build velocity vs just opening fast off the seat.

Atleast this is what Rick at Synergy Motorsports or someone else explained to me.

Basically, heads like Ls7's and L92's both have 2 issues that kill velocity.

1. is shrouding over the valve that hinders flow off the seat

2. large intake port kills velocity.

My solution was a smaller cam. Seemed to help a bit. Softer/Lazy lobe seems to allow the head to build velocity vs just opening fast off the seat.

Atleast this is what Rick at Synergy Motorsports or someone else explained to me.

I realize that you will have different velocity in different areas of the port and runner for that matter. If you pick a standard location to measure cross sectional area and use the velocity given by that equation as an average velocity with full knowledge that it is going to have a higher velocity on the outside of turns, etc. you can use it to compare head velocities I would think.

The velocity in the port is not nearly as important as the velocity around the circumference of the valve, and the velocity around the valve can be calculated.

I use a "coefficient of discharge" formula. It is basically the airflow divided by the curtain area of the valve. Here is a screen shot of it, I can email it to anyone who wants to use it, just PM me your email address. The most important thing to remember for a street car is the discharge at .300"-.500" is THE KEY, and you DO NOT want a lot of discharge at .100".

You will discover heads with large intake valves have relatively poor discharge through the mid lift but a lot at .100". This is due to the larger a valve gets, the more air it flows at .100" unless you use a steeper seat angle (50-55 versus 45) and the larger it gets the more shrouded it is and the less midlift it has, but will usually show big airflow upstairs, which a street car never sees. Hope this helps.

I use a "coefficient of discharge" formula. It is basically the airflow divided by the curtain area of the valve. Here is a screen shot of it, I can email it to anyone who wants to use it, just PM me your email address. The most important thing to remember for a street car is the discharge at .300"-.500" is THE KEY, and you DO NOT want a lot of discharge at .100".

You will discover heads with large intake valves have relatively poor discharge through the mid lift but a lot at .100". This is due to the larger a valve gets, the more air it flows at .100" unless you use a steeper seat angle (50-55 versus 45) and the larger it gets the more shrouded it is and the less midlift it has, but will usually show big airflow upstairs, which a street car never sees. Hope this helps.

Blah blah blah, you always say stupid **** like this. How about you do something useful for a change and show us your *****.

#30

TECH Addict

Thread Starter

iTrader: (24)

Join Date: Oct 2006

Location: Webb City, MO...out in the garage

Posts: 2,608

Likes: 0

Received 0 Likes

on

0 Posts

NWS doesn't matter when you aren't at work.

NWS doesn't matter when you aren't at work.

#31

TECH Addict

Thread Starter

iTrader: (24)

Join Date: Oct 2006

Location: Webb City, MO...out in the garage

Posts: 2,608

Likes: 0

Received 0 Likes

on

0 Posts

so all of the USEFUL posts combined tell me i need to custom tailor heads to my bottom end and desired performance goals. where do i begin? valve size? port volume? port shape? combustion chamber size? spring pockets? rocker arms? ..... it seems i'm going to have as much thought/time/money in the heads as i will the rest of the motor...

#32

TECH Addict

iTrader: (22)

so all of the USEFUL posts combined tell me i need to custom tailor heads to my bottom end and desired performance goals. where do i begin? valve size? port volume? port shape? combustion chamber size? spring pockets? rocker arms? ..... it seems i'm going to have as much thought/time/money in the heads as i will the rest of the motor...

i applaud you for wanting to learn. Very admirable. However there comes a time that you have to decide to let a pro handle the specs or do it yourself.

There are very, very few of us that come out better when we do it.

#33

TECH Addict

Thread Starter

iTrader: (24)

Join Date: Oct 2006

Location: Webb City, MO...out in the garage

Posts: 2,608

Likes: 0

Received 0 Likes

on

0 Posts

basically i want the best bang for my bucks without leaving too much power on the table due to lack of topend performance. i'm fine with 600rwhp out of a motor that has the displacement for 750rwhp when built all-out....but i really want that 600....i just want a car that could pull the wheels, run 9's, and get 30mpg. is that so much to ask

#34

On The Tree

Join Date: Mar 2003

Location: Suffolk, VA

Posts: 115

Likes: 0

Received 0 Likes

on

0 Posts

[QUOTE=The main flaw in this is how would you determine the standard location? What about all the rest of the port?[/QUOTE]

Standard location is easy, the only place it really matters. Just before it enters the combustion chamber. I would think you would want to air to accelerate up to the point of entry (the valve) and not slow down before it gets there.

Standard location is easy, the only place it really matters. Just before it enters the combustion chamber. I would think you would want to air to accelerate up to the point of entry (the valve) and not slow down before it gets there.

#35

TECH Addict

Thread Starter

iTrader: (24)

Join Date: Oct 2006

Location: Webb City, MO...out in the garage

Posts: 2,608

Likes: 0

Received 0 Likes

on

0 Posts

that's a good point. i would think we want the air to be at peak acceleration/speed right as it enters the cylinder, but.....massive velocity, or potential for velocity, at the point on entry doesn't mean it will be a high flowing port. there needs to be some way to determine the overall efficiency of the given port. at least not necessarily. in most cases, that value at th point of entry would be more than likely a good representation of the heads flow capability, but in some cases it might not. i mean, how do you know the air is being accelerated up to the valve and not just at the last second?

#36

TECH Fanatic

ben, sorry to bust in on "YOUR" thread, but in my opinion, there is a lot of shaky info posted here.

The best advice I've read here is:

The best non-technical comment is:

You don't seem to want to heed Stang's advice about finding a pro to do your engine, which is unfortuante, but it's your money. I think you may be looking in all the wrong places for advice.

You may be your own worst enemy, 2000_SS.

FWIW, I think Jess significantly understated it. The folks who really know how to answer your questions either won't or don't post here. I talk with some of them occasionally and they hang out in other bars.

Jon

The best advice I've read here is:

i applaud you for wanting to learn. Very admirable. However there comes a time that you have to decide to let a pro handle the specs or do it yourself.

There are a lot of confused guys in this thread......

You may be your own worst enemy, 2000_SS.

FWIW, I think Jess significantly understated it. The folks who really know how to answer your questions either won't or don't post here. I talk with some of them occasionally and they hang out in other bars.

Jon

#37

On The Tree

Join Date: Jan 2008

Location: Where you least expect me

Posts: 100

Likes: 0

Received 0 Likes

on

0 Posts

To the OP, port velocity is difficult to measure but very easy to compare. Divide flow by port volume. The result is a "dimensionless velocity" in ports / second. If two heads flow the same, but one has a 200 cc port and the other has a 220 cc port, the 200 cc port has higher velocity. Pick the flow for the power you want (1 CFM at 1 port ~ 2 HP) and then select the smallest port that will get you there.

Camming for such is another question entirely.

#38

If two heads flow the same, but one has a 200 cc port and the other has a 220 cc port, the 200 cc port has higher velocity. Pick the flow for the power you want (1 CFM at 1 port ~ 2 HP) and then select the smallest port that will get you there.

#39

TECH Addict

Thread Starter

iTrader: (24)

Join Date: Oct 2006

Location: Webb City, MO...out in the garage

Posts: 2,608

Likes: 0

Received 0 Likes

on

0 Posts

ok genius, you wanna shed some light on why this is stupid? it makes sense to me. if 2 ports flow the same volume of air in the same amount of time, and one port is smaller, it MUST have more velocity....?