CFM vs. Velocity

#1

TECH Addict

Thread Starter

iTrader: (24)

Join Date: Oct 2006

Location: Webb City, MO...out in the garage

Posts: 2,610

Likes: 0

Received 0 Likes

on

0 Posts

obviously the higher the CFM the better in a cylinder head, but it seems to me that a higher velocity head with 'good' cfm will outperform a 'high' cfm head with less velocity. is this true? how can you measure/judge a heads velocity characteristics?

the reason i ask is i'm trying to decide what heads to use on my new engine once the shortblock is done. all i can say for sure at this point is it is a LSX block. bore, stroke, deck clearance, cam specs, etc...are still up in the air. i imagince it will be at least a 4.125 bore/4" stroke. i was planning on running CNC'd LS7 heads since they flow upwards of and sometime over 400cfm on the intake side and 250+cfm on the exhaust side. i've seen TFS 245's that stop flowing around 375/230 that made the same power on the same cubic inches with similar cam/intake setups.

i haven't seen a apples to apples comparison, but it seems a lower-flowing cathedral port head, still equals or outperforms a high-flowing L92/LS3/LS7 head, OE or aftermarket....

...and......DISCUSS!

thanks,

ben

the reason i ask is i'm trying to decide what heads to use on my new engine once the shortblock is done. all i can say for sure at this point is it is a LSX block. bore, stroke, deck clearance, cam specs, etc...are still up in the air. i imagince it will be at least a 4.125 bore/4" stroke. i was planning on running CNC'd LS7 heads since they flow upwards of and sometime over 400cfm on the intake side and 250+cfm on the exhaust side. i've seen TFS 245's that stop flowing around 375/230 that made the same power on the same cubic inches with similar cam/intake setups.

i haven't seen a apples to apples comparison, but it seems a lower-flowing cathedral port head, still equals or outperforms a high-flowing L92/LS3/LS7 head, OE or aftermarket....

...and......DISCUSS!

thanks,

ben

#2

6 & 8 Second Club

Join Date: Aug 2006

Location: Illinois, RT 66 dragway area

Posts: 2,284

Likes: 0

Received 0 Likes

on

0 Posts

.

Different animal from you. I have a set of heads that flowed 488 @ .750 lift. The shop had another set that also flowed 488 exactly. On the bench, mine were very quiet, when testing. The builder told me that meant better velocity, more power.

In the real world, my heads did make more power. So from the one case I saw, velocity did make more power. Good luck.

.

Different animal from you. I have a set of heads that flowed 488 @ .750 lift. The shop had another set that also flowed 488 exactly. On the bench, mine were very quiet, when testing. The builder told me that meant better velocity, more power.

In the real world, my heads did make more power. So from the one case I saw, velocity did make more power. Good luck.

.

#3

TECH Addict

Thread Starter

iTrader: (24)

Join Date: Oct 2006

Location: Webb City, MO...out in the garage

Posts: 2,610

Likes: 0

Received 0 Likes

on

0 Posts

different animal or not, it's still a port that air must flow through. the principle is the same.

so i guess what i'm getting at is cfm dependant on velocity or vice versa? or can you improve one without affecting the other? i.e. take a 400cfm LS7 head and, i dunno, put a mirror finish polish on the port walls? would that improve the velocity? or maybe a cermic coating?

OR is velocity totally dependant on the design of the port?

so i guess what i'm getting at is cfm dependant on velocity or vice versa? or can you improve one without affecting the other? i.e. take a 400cfm LS7 head and, i dunno, put a mirror finish polish on the port walls? would that improve the velocity? or maybe a cermic coating?

OR is velocity totally dependant on the design of the port?

#4

10 Second Club

iTrader: (5)

Join Date: Jul 2005

Location: by my computer

Posts: 2,958

Likes: 0

Received 0 Likes

on

0 Posts

I have been researching this argument for awhile to find out why my engine makes the power it does.

Basically, heads like Ls7's and L92's both have 2 issues that kill velocity.

1. is shrouding over the valve that hinders flow off the seat

2. large intake port kills velocity.

My solution was a smaller cam. Seemed to help a bit. Softer/Lazy lobe seems to allow the head to build velocity vs just opening fast off the seat.

Atleast this is what Rick at Synergy Motorsports or someone else explained to me.

Basically, heads like Ls7's and L92's both have 2 issues that kill velocity.

1. is shrouding over the valve that hinders flow off the seat

2. large intake port kills velocity.

My solution was a smaller cam. Seemed to help a bit. Softer/Lazy lobe seems to allow the head to build velocity vs just opening fast off the seat.

Atleast this is what Rick at Synergy Motorsports or someone else explained to me.

#5

TECH Addict

Thread Starter

iTrader: (24)

Join Date: Oct 2006

Location: Webb City, MO...out in the garage

Posts: 2,610

Likes: 0

Received 0 Likes

on

0 Posts

see that kinda makes sense to me. i've talked with a guy in florida who i was going to sent a set of LS7's to for him to port. he said he was getting 600rwhp out of new Z06's with a 230's@.050/.650" cam and his port work.

so does this mean that a larger bore (say, 4.185") engine couples with a cam with a late IVO will allow for more velocity if the chamber is opened up?

so does this mean that a larger bore (say, 4.185") engine couples with a cam with a late IVO will allow for more velocity if the chamber is opened up?

#6

10 Second Club

iTrader: (17)

Join Date: Oct 2005

Location: Tulsa, OK

Posts: 611

Likes: 0

Received 0 Likes

on

0 Posts

I've thought alot about how to measure velocity on an port. I talked to my physics proff about it and he said it would be very complicated to try to measure the velocity of a certain amount of air flowing through something shaped like a port on a head. Thats probaly why no body ever talks about it.

#7

I've thought alot about how to measure velocity on an port. I talked to my physics proff about it and he said it would be very complicated to try to measure the velocity of a certain amount of air flowing through something shaped like a port on a head. Thats probaly why no body ever talks about it.

Trending Topics

#8

Jordan S. I've thought alot about how to measure velocity on an port. I talked to my physics proff about it and he said it would be very complicated to try to measure the velocity of a certain amount of air flowing through something shaped like a port on a head. Thats probaly why no body ever talks about it.

#10

On The Tree

Join Date: Mar 2003

Location: Suffolk, VA

Posts: 115

Likes: 0

Received 0 Likes

on

0 Posts

(ft^3/minute)/(ft^2) = Ft/minute.

#11

10 Second Club

iTrader: (17)

Join Date: Oct 2005

Location: Tulsa, OK

Posts: 611

Likes: 0

Received 0 Likes

on

0 Posts

The velocity isn't constant across that plane (the area you picked on your cross sectional area). From what I understand thats why you can't use that simple formula you picked and be accurate.

#12

6 & 8 Second Club

Join Date: Aug 2006

Location: Illinois, RT 66 dragway area

Posts: 2,284

Likes: 0

Received 0 Likes

on

0 Posts

Don't know about the velocity, but the bigger bore will 100% help with total CFM.

We tested a head with a 4.250, 4.500 & 4.600 adapter. Damn what a shock, big time increase in CFM.

As said, that formula is hard to use in the real world. I just had a buddy that had a local porter (so called)

ruin a set of big money heads. He hogged the hell out of them. Actually so bad that they were un-useable.

The new engine shop said the velocity was so bad they couldn't even be saved. They flowed big numbers on the bench,

but when they tried to dyno the engine it ran like crap. I guess the fuel was puddling like crazy.

He sold them to a blower guy that was going to spend a bunch of money on epoxy.

(he told him the truth, the guy knew what was wrong with them)

.

#14

On The Tree

Join Date: Mar 2003

Location: Suffolk, VA

Posts: 115

Likes: 0

Received 0 Likes

on

0 Posts

I realize that you will have different velocity in different areas of the port and runner for that matter. If you pick a standard location to measure cross sectional area and use the velocity given by that equation as an average velocity with full knowledge that it is going to have a higher velocity on the outside of turns, etc. you can use it to compare head velocities I would think.

#15

TECH Addict

Thread Starter

iTrader: (24)

Join Date: Oct 2006

Location: Webb City, MO...out in the garage

Posts: 2,610

Likes: 0

Received 0 Likes

on

0 Posts

for the sake of argument, let's say (IN THEORY) that it's impossible to calculate the total or average velocity of a given port. THEN how do you know which head will outperfrom the other? in other words, should i use the 400cfm @.650" LS7 heads, or the 353cfm @.600" cathedral ports on my engine...say a 4.160 bore/4" stroke. if i'm looking to make 600rwhp, NOT 599rwhp, with a hydraulic roller cam and some prehistoric form of driveability, what do i do? do i hunt for the head with the best velocity, or just go with a big cfm head and ultra-light valvetrain and big, violent cam lobes?

#16

TECH Addict

Thread Starter

iTrader: (24)

Join Date: Oct 2006

Location: Webb City, MO...out in the garage

Posts: 2,610

Likes: 0

Received 0 Likes

on

0 Posts

I realize that you will have different velocity in different areas of the port and runner for that matter. If you pick a standard location to measure cross sectional area and use the velocity given by that equation as an average velocity with full knowledge that it is going to have a higher velocity on the outside of turns, etc. you can use it to compare head velocities I would think.

i see what your saying. BUT when comparing a cathedral port to a rectangular port, it isn't apples to apples and the comparison, although informative, wouldn't be truly accurate...at least i don't think so.

#17

10 Second Club

iTrader: (17)

Join Date: Oct 2005

Location: Tulsa, OK

Posts: 611

Likes: 0

Received 0 Likes

on

0 Posts

I realize that you will have different velocity in different areas of the port and runner for that matter. If you pick a standard location to measure cross sectional area and use the velocity given by that equation as an average velocity with full knowledge that it is going to have a higher velocity on the outside of turns, etc. you can use it to compare head velocities I would think.

#19

TECH Addict

iTrader: (22)

You have to consider the manifold in this also. In effect it is part of the head. Air downd't know any difference.

FWIW, both of the heads you listed will get you there. But one will do it with a smaller club.

The more the head flows, the less time you need to keep valve open, BUT you have to make sure you are opening and closing them at the right time. For that you need someone alot better than me.

FWIW, both of the heads you listed will get you there. But one will do it with a smaller club.

The more the head flows, the less time you need to keep valve open, BUT you have to make sure you are opening and closing them at the right time. For that you need someone alot better than me.

#20

FormerVendor

iTrader: (13)

The velocity in the port is not nearly as important as the velocity around the circumference of the valve, and the velocity around the valve can be calculated.

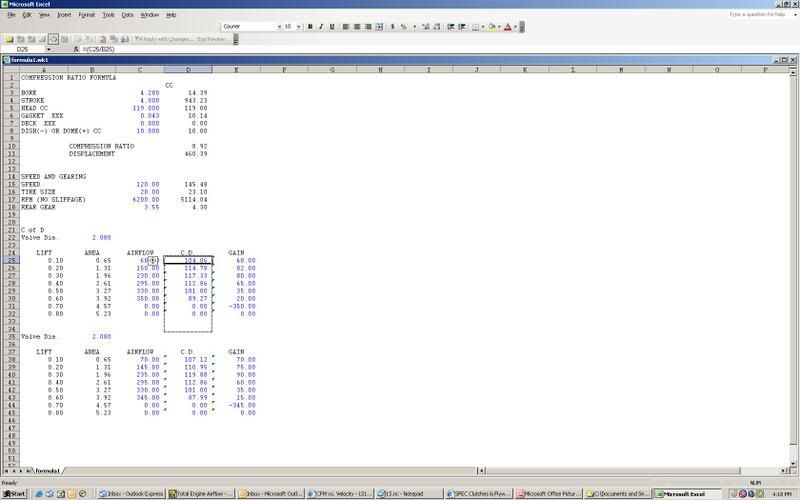

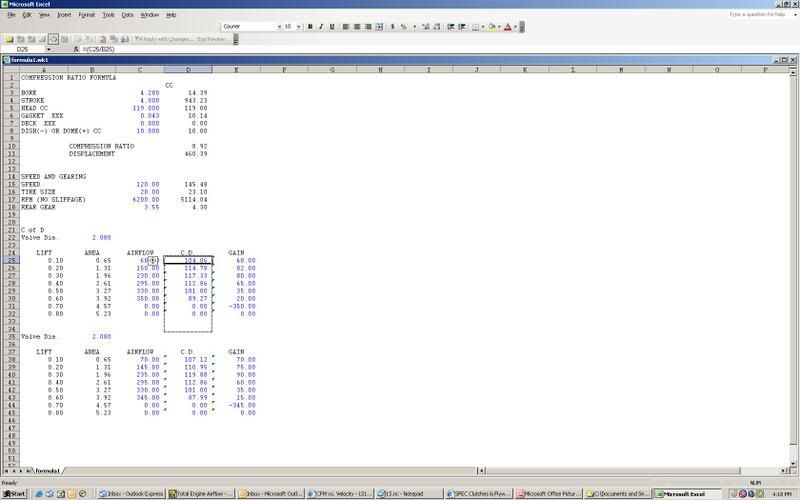

I use a "coefficient of discharge" formula. It is basically the airflow divided by the curtain area of the valve. Here is a screen shot of it, I can email it to anyone who wants to use it, just PM me your email address. The most important thing to remember for a street car is the discharge at .300"-.500" is THE KEY, and you DO NOT want a lot of discharge at .100".

You will discover heads with large intake valves have relatively poor discharge through the mid lift but a lot at .100". This is due to the larger a valve gets, the more air it flows at .100" unless you use a steeper seat angle (50-55 versus 45) and the larger it gets the more shrouded it is and the less midlift it has, but will usually show big airflow upstairs, which a street car never sees. Hope this helps.

I use a "coefficient of discharge" formula. It is basically the airflow divided by the curtain area of the valve. Here is a screen shot of it, I can email it to anyone who wants to use it, just PM me your email address. The most important thing to remember for a street car is the discharge at .300"-.500" is THE KEY, and you DO NOT want a lot of discharge at .100".

You will discover heads with large intake valves have relatively poor discharge through the mid lift but a lot at .100". This is due to the larger a valve gets, the more air it flows at .100" unless you use a steeper seat angle (50-55 versus 45) and the larger it gets the more shrouded it is and the less midlift it has, but will usually show big airflow upstairs, which a street car never sees. Hope this helps.