pin travel

#1

On The Tree

Thread Starter

iTrader: (2)

Join Date: Apr 2007

Location: SC

Posts: 178

Likes: 0

Received 0 Likes

on

0 Posts

im in the process of building my first 4l60e and ive gotten everything back in and im wanting to know how far down should the input drum sit below where the pump sits and also my kit from probuiltautomatic came with a new pin for the 2nd accum. And its alot longer than the oem one i ordered the jet billet servos from summit and im seeing where when u put a new pin in it must have the right travel. How do i check it

#2

Moderator

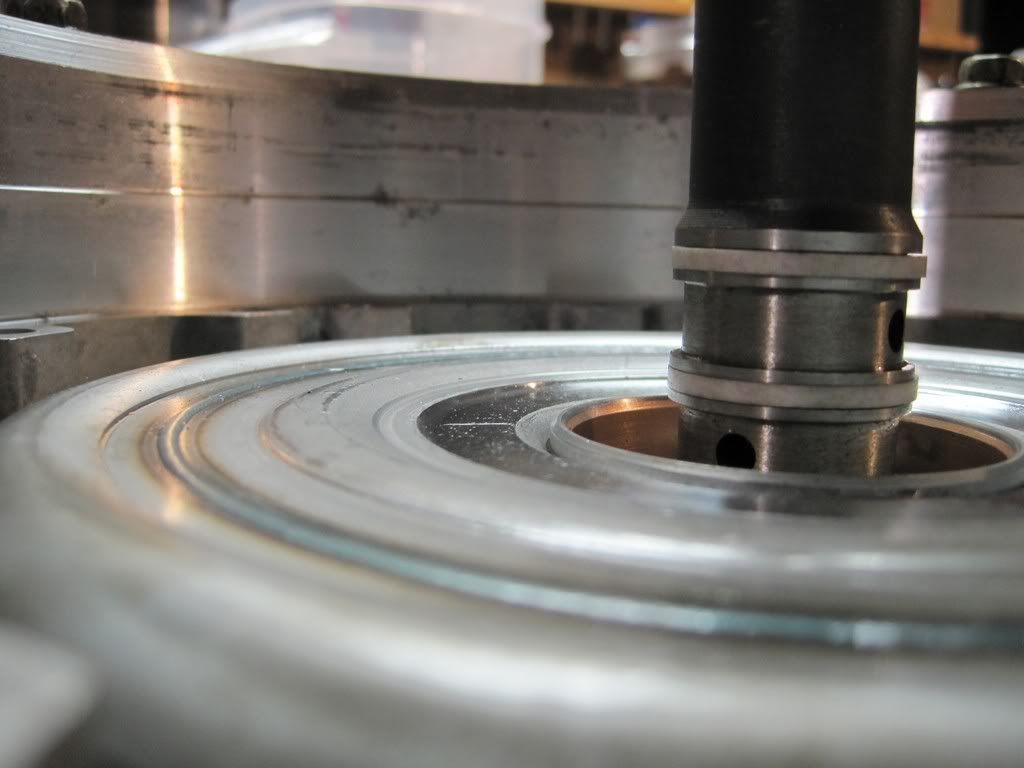

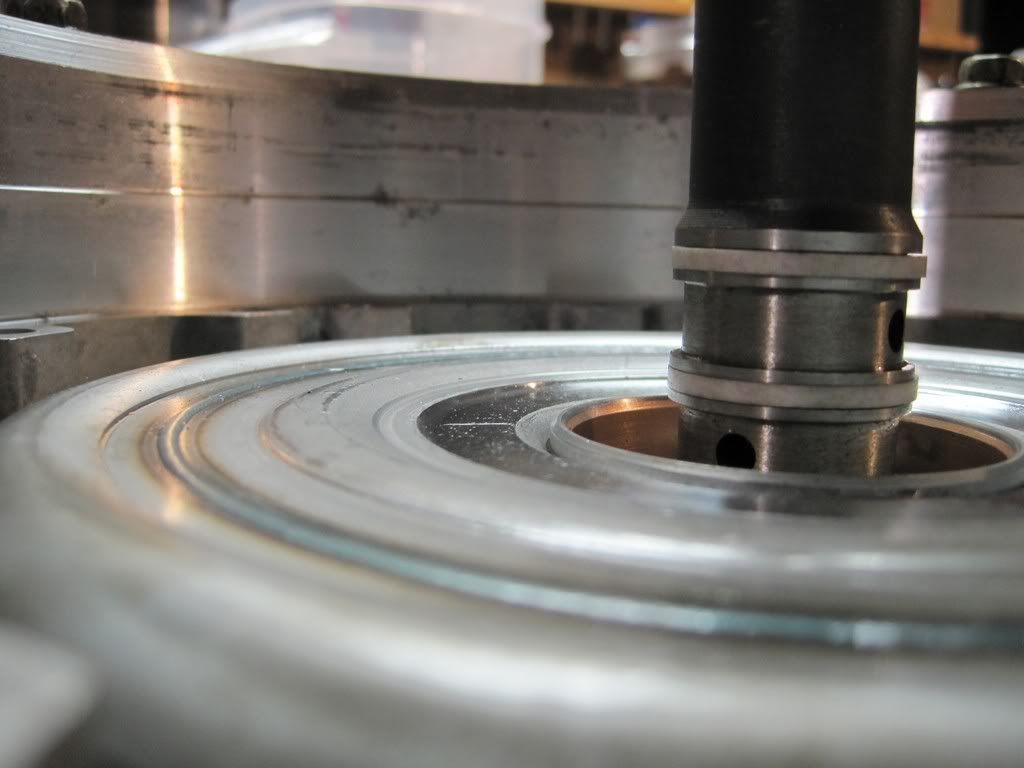

Is this what you are looking for:

I'm not sure what else you are asking, but let me try:

As long as the pin fits in the 1/2 accumulator case, it should be fine.

After final assembly, with the pump in, you can adjust the servo so that the drum barely has enough slack to let the drum turn by hand. (I adjust it before putting the pump in, but that is harder to explain.)

In case you are interested, I have hundreds of my 4L60E photos here:

http://s1015.photobucket.com/albums/...L60E%20Rebuild

I'm not sure what else you are asking, but let me try:

As long as the pin fits in the 1/2 accumulator case, it should be fine.

After final assembly, with the pump in, you can adjust the servo so that the drum barely has enough slack to let the drum turn by hand. (I adjust it before putting the pump in, but that is harder to explain.)

In case you are interested, I have hundreds of my 4L60E photos here:

http://s1015.photobucket.com/albums/...L60E%20Rebuild

#4

Moderator

The ATSG manual says at least 0.015 end play; my local builder says he aims for 0.012 as it will increase a bit with new parts.

So, if it is 0 now, you need to correct that. There is a "selective" washer underneath the input shaft bearing. You need an assortment of them. I would start with a thin .080, measure endplay and then get a thicker washer to drop the endplay to very close to 0.015. If even a .080 has 0 endplay, likely something is not assembled correctly.

HOWEVER, a rebuild generally shouldn't change it by all that much. Therefore, I would first be sure that the area around the front planetary and sun shell is assembled correctly.

Please tell me exactly what reaction carrier, sun shell and bearings you used in this area. (I have experimented with every combination, which you can probably find in my pictures.)

I was just helping another LS1TECH member this week, and he had an improperly rebuilt pump - the new stator shaft was not pressed in all the way and he therefore had no endplay. Check that too.

So, if it is 0 now, you need to correct that. There is a "selective" washer underneath the input shaft bearing. You need an assortment of them. I would start with a thin .080, measure endplay and then get a thicker washer to drop the endplay to very close to 0.015. If even a .080 has 0 endplay, likely something is not assembled correctly.

HOWEVER, a rebuild generally shouldn't change it by all that much. Therefore, I would first be sure that the area around the front planetary and sun shell is assembled correctly.

Please tell me exactly what reaction carrier, sun shell and bearings you used in this area. (I have experimented with every combination, which you can probably find in my pictures.)

I was just helping another LS1TECH member this week, and he had an improperly rebuilt pump - the new stator shaft was not pressed in all the way and he therefore had no endplay. Check that too.

#5

Registered User

Join Date: May 2012

Location: Kankakee, IL

Posts: 12

Likes: 0

Received 0 Likes

on

0 Posts

As far as the servo pin length, as a ruff check you should be able to wiggle the band side to side approx 1/8 inch through the case with the pump installed, or turn the output shaft both directions by use of one or two hands

#6

On The Tree

Thread Starter

iTrader: (2)

Join Date: Apr 2007

Location: SC

Posts: 178

Likes: 0

Received 0 Likes

on

0 Posts

The one under there now is a 70 and only thing I changed with the rebuild is the raybesto upgraded clutches with .030 clearance and the beast sunshell with brass bearing it had Torrington bearing but was told to use the brass one not sure if that's correct

#7

Moderator

Notice that the reaction carrier on the left has additional machining to hold a torrington bearing.

Trending Topics

#9

Moderator

IIRC, the #70 selective washer is one of the thinner ones, perhaps around .085. (They go up to around .115)

So something appears to be wrong.

Here are some questions:

1. Is your reverse drum sitting in the same position as in my picture?

2. Did you remember the gasket between the case and the pump?

3. Did you replace the stator shaft on the pump or just reuse it?

4. Can you measure the selective washer thickness and post it?

Hopefully I or a more experienced person can help you from those answers.

#10

On The Tree

Thread Starter

iTrader: (2)

Join Date: Apr 2007

Location: SC

Posts: 178

Likes: 0

Received 0 Likes

on

0 Posts

I kinda figured that replacing the torrington bearing with the (incorrect) brass washer wouldn't affect the endplay much, but it still is critical to have the correct bearing in there.

IIRC, the #70 selective washer is one of the thinner ones, perhaps around .085. (They go up to around .115)

So something appears to be wrong.

Here are some questions:

1. Is your reverse drum sitting in the same position as in my picture? Yes check and double checked

2. Did you remember the gasket between the case and the pump? Yes have a new one

3. Did you replace the stator shaft on the pump or just reuse it? Reused

Going to measure tomorrow and post pics I must have been mistaken on the 70 mine doesn't have anything stamped on the selective washer and I cant pull it off my other trans has a 69 clearly stamped on it but not this one

4. Can you measure the selective washer thickness and post it?

Hopefully I or a more experienced person can help you from those answers.

IIRC, the #70 selective washer is one of the thinner ones, perhaps around .085. (They go up to around .115)

So something appears to be wrong.

Here are some questions:

1. Is your reverse drum sitting in the same position as in my picture? Yes check and double checked

2. Did you remember the gasket between the case and the pump? Yes have a new one

3. Did you replace the stator shaft on the pump or just reuse it? Reused

Going to measure tomorrow and post pics I must have been mistaken on the 70 mine doesn't have anything stamped on the selective washer and I cant pull it off my other trans has a 69 clearly stamped on it but not this one

4. Can you measure the selective washer thickness and post it?

Hopefully I or a more experienced person can help you from those answers.

#11

Moderator

#13

Moderator

#14

Moderator

OK. Lets wait to see what the measurement of your selective washer is.

The reason I asked about the stator shaft is that I just helped someone else here who had a rebuilt pump with new stator shaft; unfortunately it was not pressed in all the way and this resulted in no endplay. Replacing the stator shaft in the pump is not a do-it-home project; take it to a trans shop and double-check even their work.

While you have your trans open, have you checked the inside of your reverse drum to be sure there is no wear where the teflon seals run. The $100 for a new reverse drum is often a good idea; it also lets you run a wider band.

The reason I asked about the stator shaft is that I just helped someone else here who had a rebuilt pump with new stator shaft; unfortunately it was not pressed in all the way and this resulted in no endplay. Replacing the stator shaft in the pump is not a do-it-home project; take it to a trans shop and double-check even their work.

While you have your trans open, have you checked the inside of your reverse drum to be sure there is no wear where the teflon seals run. The $100 for a new reverse drum is often a good idea; it also lets you run a wider band.

#16

Moderator

#18

Moderator

Well, you gotta get it out. Since it is spinning, its not stuck or anything. Perhaps the bearing failed and make the washer spin and cut a groove into the input shaft. (Replace the bearing!)

Try cussing or something.

Try cussing or something.

The following users liked this post:

james28909 (03-07-2022)

my other trans had 69 stamped in it this one is blank what am I doing wrong

my other trans had 69 stamped in it this one is blank what am I doing wrong