Sonnax HD 2-3 Shift valve install question

#21

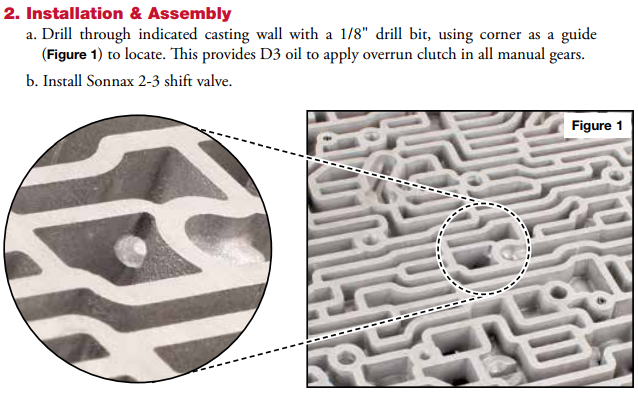

I notched the gasket like it is exactly in your diagram and felt that it wasn't effective. Didn't feel the positive downshifting like it was supposed

to do with overrun clutch applied. I took it

apart again then drilled it with the specified drill bit . Now I felt the difference on the downshifts like it was supposed to ! Do yourself a favor do it right

the first time with drill bit. Just blow

out shavings with brake clean and a air blow gun.

to do with overrun clutch applied. I took it

apart again then drilled it with the specified drill bit . Now I felt the difference on the downshifts like it was supposed to ! Do yourself a favor do it right

the first time with drill bit. Just blow

out shavings with brake clean and a air blow gun.

#22

Making the modifications to the steel spring retainer as TransGo does in their regular Shift kit, will help on the downshift clunks

#23

The grinding of the 4 slots is to help on the downshifts (lessen the clunks) when the shifter is in manual 3 ("D") when using the Sonnax HD 2-3 shift valve. Follow the TransGo instructions you see here for grinding the slots. I supply instructions for grinding these slots anytime a customer is going to install this valve from Sonnax.

#26

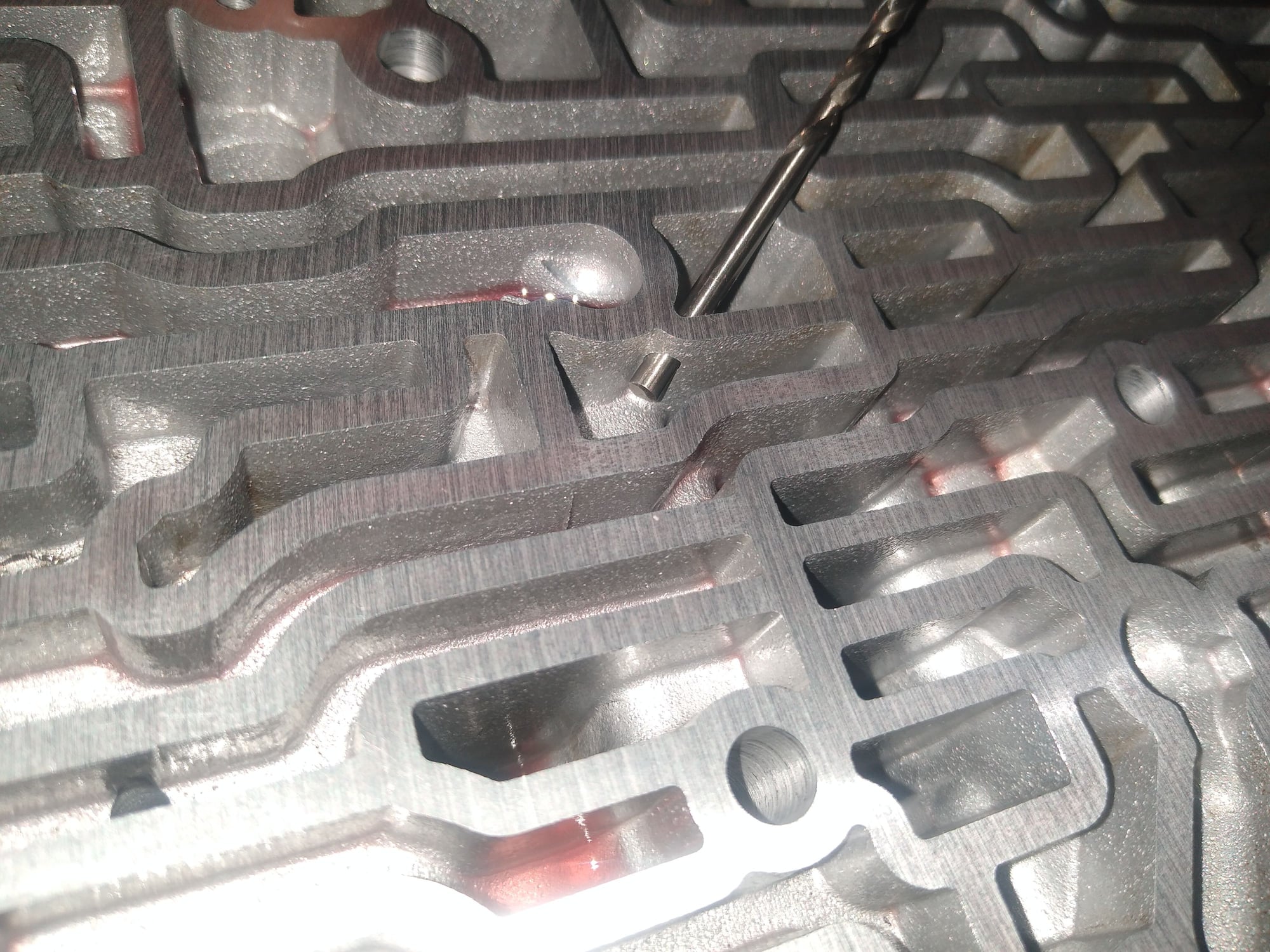

I know this is an old thread but wondering my drill bit kept sliding down the corner wall on my vb. I got the hole put in but there's some trailing from bit falling downwards a bit under it dug a little into the passage wall not very deep also slightly nicked the worm track behind it hardly at all but is this gonna hurt anything? Showed guy from sonnax the picture of Nick on worm track he got with me next day and said it wasn't anything to worry about. I forgot to show him the trailing under the hole but was wanting to just ask you guys on this forum what you thought I wish I would have used a sharper bit but the hole is there. Also have .500 transgo boost valve and Corvette servo should I do the notches on servo? Used checkballs to block isolator valve spring ,used scarf cut rings on pump with wide band any advice would be appreciated I know it's a lot of questions just throwing out everything thank you. I'll post pics tonight.

Last edited by RobPH; 01-19-2023 at 03:40 PM.

#27

TECH Addict

As long as the top of the worm track where it meets the case is not damage very deep and the hole is the correct size it will be okay. Make sure there isn't any loose burs.

You can do the notches on the servo or not it doesn't really matter.

You can do the notches on the servo or not it doesn't really matter.

#28

1/8 in hole worm track damage behind hole

#30

TECH Enthusiast

I know this is an old thread but wondering my drill bit kept sliding down the corner wall on my vb. I got the hole put in but there's some trailing from bit falling downwards a bit under it dug a little into the passage wall not very deep also slightly nicked the worm track behind it hardly at all but is this gonna hurt anything? Showed guy from sonnax the picture of Nick on worm track he got with me next day and said it wasn't anything to worry about. I forgot to show him the trailing under the hole but was wanting to just ask you guys on this forum what you thought I wish I would have used a sharper bit but the hole is there. Also have .500 transgo boost valve and Corvette servo should I do the notches on servo? Used checkballs to block isolator valve spring ,used scarf cut rings on pump with wide band any advice would be appreciated I know it's a lot of questions just throwing out everything thank you. I'll post pics tonight.

For the record, I use an automatic center punch to start. I then drill through the wall of the two passages (not the crook like Sonnax shows) with a 1/16" bit for a starter hole, then follow up with the 1/8" bit. The small bit gets guided by the punch and doesn't walk as bad as the larger one does.

You may also be better off to start a new thread.

#33

TECH Addict

Worm track will be fine, just file down any high spots. The gasket will take care of the rest.

Instructions for old TansGo kits would have you grind those notches but instructions that come with the kits now have left the notching out. The servo in my trans has the notches and the shifts are good. I have built other transmissions without the notches, and they shift fine. If it already has them, I wouldn't worry about it.

Instructions for old TansGo kits would have you grind those notches but instructions that come with the kits now have left the notching out. The servo in my trans has the notches and the shifts are good. I have built other transmissions without the notches, and they shift fine. If it already has them, I wouldn't worry about it.

The following users liked this post:

RobPH (01-20-2023)

#35

TECH Enthusiast

Worm track will be fine, just file down any high spots. The gasket will take care of the rest.

Instructions for old TansGo kits would have you grind those notches but instructions that come with the kits now have left the notching out. The servo in my trans has the notches and the shifts are good. I have built other transmissions without the notches, and they shift fine. If it already has them, I wouldn't worry about it.

Instructions for old TansGo kits would have you grind those notches but instructions that come with the kits now have left the notching out. The servo in my trans has the notches and the shifts are good. I have built other transmissions without the notches, and they shift fine. If it already has them, I wouldn't worry about it.

The 4L60E-HD2 want's a different shift feel so they use different ways for both the 1-2 & 2-3 shift over the small box kit. The PRO kit uses the same servo mods as the HD2 kit.

The only real thing I disagree on is the use of the gold shim's. I prefer to use a longer pin when required. What I have noticed is when using a B/W, Alto or GPX brand bands I don't usually need a longer pin. If using a Raybestos brand band of any kind I need the longest GM pin. So I have been leaning away from Raybestos bands for that reason. I have spoken with the Raybestos tech guy (Ivan Gers) about it. He sent production a note to check production spec's. That was several years ago and they still haven't changed. They did fix the case lug issue on the Super Pro wide band though, that was why I really called. I actually prefer the Raybestos Kevlar band but, the Borg/Warner band is $3 dollars more and It doesn't need the $17 longer pin...

I took the liberty to upload both set of instructions for the kits. FYI TransGo now has their SK instructions on their website for all to look at and download.

#37

TECH Enthusiast

I have had a friend drill the wrong passage and it slipped in all ranges. He drilled through channel 29 (3-4) into 35 (OR)

Sonnax has you connect D3 oil to OR oil by drilling the partition between channel 34/35

This was added to my "self Inflicted wounds" file...

The following users liked this post:

2BFAST (02-01-2023)

#38

Do you think it's ok to use the transgo divider abuse bore plugs with the reverse abuse and fwd abuse sonnax kits? (Rev and fwd same kit) I think they do the same thing as the transgo abuse kit I just bought those first so I want to use the sonnax ones I bought some transgo things later on and I think they would work well together they are a bit longer than the OE bore dividers but look like they would seal great you can also use a long bolt to push them into place like the transgo iso- valve I used one of those too. I also used some other things out of the transgo SK kit like the different valve springs the yellow medium weight accumulator valve spring and servo notches and 2nd piston springs then the sonnax 2-3 hd shift valve as you know.

Last edited by RobPH; 02-02-2023 at 02:02 PM.

#39

most here just use the sonnax abuse plugs, not.thw valve kit. i don't see why you couldn't use the 2 items together,but have no experience doing so. I find it interesting sonnax doesn't include the abuse plug with the abuse valve kit...

https://www.sonnax.com/parts/2460-fo...buse-bore-plug

https://www.sonnax.com/parts/2460-fo...buse-bore-plug

The following users liked this post:

bbond105 (02-02-2023)

#40

TECH Enthusiast

Do you think it's ok to use the transgo divider abuse bore plugs with the reverse abuse and fwd abuse sonnax kits? (Rev and fwd same kit) I think they do the same thing as the transgo abuse kit I just bought those first so I want to use the sonnax ones I bought some transgo things later on and I think they would work well together they are a bit longer than the OE bore dividers but look like they would seal great you can also use a long bolt to push them into place like the transgo iso- valve I used one of those too. I also used some other things out of the transgo SK kit like the different valve springs the yellow medium weight accumulator valve spring and servo notches and 2nd piston springs then the sonnax 2-3 hd shift valve as you know.

My GM tech guide gives this explanation of the forward abuse valve.

Forward Abuse Valve (357)

The forward abuse valve provides a faster apply of the forward

clutch when throttle position is greater than idle. During these

conditions, D4 fluid pressure increases and moves the valve

against spring force. D4 fluid can then quickly fill the forward

clutch feed fluid circuit. This bypasses the control of the forward

clutch accumulator orifice (#22) for a faster clutch apply.

Personally I started using the TransGo ones right after they came out. I got a few that didn't vacuum test well. I spoke with TransGo about them. They replaced them and those tested well. After that my warehouse ran out and I just used the Sonnax brand after that. I'm not bashing TransGo products they have been a very good company to work with & they helped me make a very nice living since 1977.

The following users liked this post:

RobPH (02-03-2023)