4l80e problems again and again

#1

I am going to apologize in advance for the long post, but want to include as much info as possible.

The car:

1979 Z28 with a stock 6.0/4l80e and a stock truck converter

Engine was from my personal truck, 2wd trans was bought from a trans shop that was supposedly completely rebuilt.

swap finished spring 2015

2015:

Swap gets completed and transmission does not act right. When in gear it pulls the engine down so hard it will stall it. Seems to be okay while driving, but have to put it in neutral while at a stop light. I take it to the drag track and is not shifting right. It would not shift out of 1st under WOT. Let off the gas and it would shift into 2nd, get back on gas and it would shift 2-3, and 3-4 pretty quick, and it would be in OD before 1000 ft.

mrvedit came and helped me do some trans tuning as we thought it was all in the tuning. It got significantly better.

I went to go back to the track and test it, and the car dumped all the fluid driving down the highway on the way to the track. Got it towed home and pulled the inspection cover, and I could see the front seal was pushed out.

June 2016:

Decided to completely pull the trans down to see why the seal pushed out, and see what was going on as it still didn't seem right. The first thing we discovered was that when the cooler lines got switched to AN lines, the correct fitting was not installed. So that explained the pressure where it shouldn't be and pushed out the front seal, and why the shifting wasn't correct. We also found a few small missing pieces.

Did a full rebuild with red clutches, HD2 shift kit, and checked everything else out. Car shifts amazing, and I think everything is great.

August 2016:

Drive the car on the highway for about a 3 hour round trip to attend Camaro Fifty Fest in Lansing. The next day I drive about an hour to drop the car off at the tuner to finally get a tune done. The tuner drives it for less than a mile when it starts dumping fluid again. Get it towed home and see that the rear tailshaft bushing got pushed out, and pushed the rear seal out.

September 2016:

Install a new rear bushing and seal. Check and adjust pinion angle, and also realize that the yoke might be to long, as the u-joint is about 3-1/4" behind the back of the trans.

I make the bad choice to drive it to LSFest from Michigan. After about 4 hours on the highway, I can tell the driveshaft is wobbling around really bad, and I probably won't be able to make it the rest of the way. I trailer the rest of the the way to Kentucky, and have a new driveshaft made. (Overall length was correct. Cut the yoke down 2-1/4" and make the new tube 2-1/4" longer so the u-joint is 3/4" to 1" past the back of the trans.) Also installed a new bushing and had the driveshaft balanced.

2017:

Everything finally seems great. Put about 2000 miles on it this summer. Last week, I am driving down the road (cruising about 55) and it starts squealing really bad. I assume it is a belt squeak, as I have had some belt alignment issues in the past, and that is exactly what it sounded like, although quite a bit louder. Determined it was not a belt issue. I had several people look at it, and everyone thought it was a spun engine bearing. If you started the car cold, it would not make any noise. After about 45 seconds, it would start to squeal. It would change with RPM's, not speed. It would make the noise in any gear including park and neutral.

So I pulled the engine out and completely apart and everything looks great.

I look at the transmission and notice that the front bushing is worn on the bottom, but not the top. You can also feel a ridge on the snout of the converter. Not bad, but it is there. I also noticed the driveshaft is pretty sloppy in the back of the trans, and that bushing doesn't look good either. You can't really see any flake in the fluid, but if you shine a flashlight in it, you can see a metallic shine.

So my question is why do I keep losing the front and rear bushings??? Is my driveshaft causing the bushings to go out, or is something inside the trans causing them to go out and cause the slop in the bushings??? Any suggestions???? Help!!!

The car:

1979 Z28 with a stock 6.0/4l80e and a stock truck converter

Engine was from my personal truck, 2wd trans was bought from a trans shop that was supposedly completely rebuilt.

swap finished spring 2015

2015:

Swap gets completed and transmission does not act right. When in gear it pulls the engine down so hard it will stall it. Seems to be okay while driving, but have to put it in neutral while at a stop light. I take it to the drag track and is not shifting right. It would not shift out of 1st under WOT. Let off the gas and it would shift into 2nd, get back on gas and it would shift 2-3, and 3-4 pretty quick, and it would be in OD before 1000 ft.

mrvedit came and helped me do some trans tuning as we thought it was all in the tuning. It got significantly better.

I went to go back to the track and test it, and the car dumped all the fluid driving down the highway on the way to the track. Got it towed home and pulled the inspection cover, and I could see the front seal was pushed out.

June 2016:

Decided to completely pull the trans down to see why the seal pushed out, and see what was going on as it still didn't seem right. The first thing we discovered was that when the cooler lines got switched to AN lines, the correct fitting was not installed. So that explained the pressure where it shouldn't be and pushed out the front seal, and why the shifting wasn't correct. We also found a few small missing pieces.

Did a full rebuild with red clutches, HD2 shift kit, and checked everything else out. Car shifts amazing, and I think everything is great.

August 2016:

Drive the car on the highway for about a 3 hour round trip to attend Camaro Fifty Fest in Lansing. The next day I drive about an hour to drop the car off at the tuner to finally get a tune done. The tuner drives it for less than a mile when it starts dumping fluid again. Get it towed home and see that the rear tailshaft bushing got pushed out, and pushed the rear seal out.

September 2016:

Install a new rear bushing and seal. Check and adjust pinion angle, and also realize that the yoke might be to long, as the u-joint is about 3-1/4" behind the back of the trans.

I make the bad choice to drive it to LSFest from Michigan. After about 4 hours on the highway, I can tell the driveshaft is wobbling around really bad, and I probably won't be able to make it the rest of the way. I trailer the rest of the the way to Kentucky, and have a new driveshaft made. (Overall length was correct. Cut the yoke down 2-1/4" and make the new tube 2-1/4" longer so the u-joint is 3/4" to 1" past the back of the trans.) Also installed a new bushing and had the driveshaft balanced.

2017:

Everything finally seems great. Put about 2000 miles on it this summer. Last week, I am driving down the road (cruising about 55) and it starts squealing really bad. I assume it is a belt squeak, as I have had some belt alignment issues in the past, and that is exactly what it sounded like, although quite a bit louder. Determined it was not a belt issue. I had several people look at it, and everyone thought it was a spun engine bearing. If you started the car cold, it would not make any noise. After about 45 seconds, it would start to squeal. It would change with RPM's, not speed. It would make the noise in any gear including park and neutral.

So I pulled the engine out and completely apart and everything looks great.

I look at the transmission and notice that the front bushing is worn on the bottom, but not the top. You can also feel a ridge on the snout of the converter. Not bad, but it is there. I also noticed the driveshaft is pretty sloppy in the back of the trans, and that bushing doesn't look good either. You can't really see any flake in the fluid, but if you shine a flashlight in it, you can see a metallic shine.

So my question is why do I keep losing the front and rear bushings??? Is my driveshaft causing the bushings to go out, or is something inside the trans causing them to go out and cause the slop in the bushings??? Any suggestions???? Help!!!

#2

TECH Resident

iTrader: (14)

The front bushing issue sounds like a possible dowel pin issue.

The engine and transmission have to be in alignment and the dowels insure this.

Sounds like maybe you figured out the rear bushing issue.

Another issue to watch for that is often overlooked and critical is grounding.

Bushing issues and pump gear issues can be caused by arcing due to bad grounds.

The engine and transmission have to be in alignment and the dowels insure this.

Sounds like maybe you figured out the rear bushing issue.

Another issue to watch for that is often overlooked and critical is grounding.

Bushing issues and pump gear issues can be caused by arcing due to bad grounds.

#3

TECH Veteran

iTrader: (7)

What year trans-I found at one time the 04 (maybe 04-up?) took a diff rear bushing, an early one didn't fit as tight as it should, book even listed a diff one. Was the trans a converted 4WD unit. Is the converter registered into the crank, sounds like an alignment problem also

#4

The front bushing issue sounds like a possible dowel pin issue.

The engine and transmission have to be in alignment and the dowels insure this.

Sounds like maybe you figured out the rear bushing issue.

Another issue to watch for that is often overlooked and critical is grounding.

Bushing issues and pump gear issues can be caused by arcing due to bad grounds.

The engine and transmission have to be in alignment and the dowels insure this.

Sounds like maybe you figured out the rear bushing issue.

Another issue to watch for that is often overlooked and critical is grounding.

Bushing issues and pump gear issues can be caused by arcing due to bad grounds.

The dowel pins are the both in, and the same ones that have been in that engine since new.

I am still having the issue with the rear bushing too. I have had two different tail shafts, and I think 8 bushings total it has chewed through.

I would have never thought about the grounds causing an issue like that, but it makes sense. I believe I am grounded good I have three engine to body ground straps.

#5

What year trans-I found at one time the 04 (maybe 04-up?) took a diff rear bushing, an early one didn't fit as tight as it should, book even listed a diff one. Was the trans a converted 4WD unit. Is the converter registered into the crank, sounds like an alignment problem also

I believe it is an 04 up trans. The shop I bought it from didn't tell me what year it was. When I ordered parts, I matched up the sizes with transtar, and ordered the correct ones. I don't remember the difference but it was easy to get the right one. From what I was told it was always a 2wd trans. I was originally going to

Convert my 4x4 trans to 2wd, but found this one from a trans shop, so I figured I would keep my 4x4 trans as a backup for my plow trucks (which I ended up using)

I'm not sure what registered into the crank means, but the convertor was fully seated and hooked to the flex plate correctly.

#6

TECH Fanatic

Stock 4L80E converters can suffer from crank pilot wear, And the Adaptor it fit's into also wears.....This can cause pump bushing wear.

I prefer to run a aftermarket converter with a extended pilot along with a 4L60E dished flexplate to get rid of the wear prone 75 pound converter & Spacer.

Pull the driveshaft....And seal if you have to. Start the engine in park......There should be a steady stream of ATF coming out of the tailhousing bushing.

Driveline vibrations will walk a bushing out!

I prefer to run a aftermarket converter with a extended pilot along with a 4L60E dished flexplate to get rid of the wear prone 75 pound converter & Spacer.

Pull the driveshaft....And seal if you have to. Start the engine in park......There should be a steady stream of ATF coming out of the tailhousing bushing.

Driveline vibrations will walk a bushing out!

Trending Topics

#8

Stock 4L80E converters can suffer from crank pilot wear, And the Adaptor it fit's into also wears.....This can cause pump bushing wear.

I prefer to run a aftermarket converter with a extended pilot along with a 4L60E dished flexplate to get rid of the wear prone 75 pound converter & Spacer.

Pull the driveshaft....And seal if you have to. Start the engine in park......There should be a steady stream of ATF coming out of the tailhousing bushing.

Driveline vibrations will walk a bushing out!

I prefer to run a aftermarket converter with a extended pilot along with a 4L60E dished flexplate to get rid of the wear prone 75 pound converter & Spacer.

Pull the driveshaft....And seal if you have to. Start the engine in park......There should be a steady stream of ATF coming out of the tailhousing bushing.

Driveline vibrations will walk a bushing out!

Now that I completely disassembled the engine, I can't just start it up to check the fluid flow, but will check that in the future. Now I need to build an engine and a transmission.

I do still have a slight driveline vibration, but is way better than it has ever been. It is less than any of my trucks. I almost think the vibration might be internal in the trans, as my driveshaft has been balanced 2 times, and my driveline angles have been checked by two different people as well, and have replaced the I-joints twice.

#10

I'm not sure what the yoke was originally for. The guy that got said it was for a school bus. It was brand new, and made by spicer. That is something that I should check into for sure. We did check all the oil passages, and especially the one at the back, after the first time I lost a bushing. Everything seems clean, with good flow.

#11

I could grab a picture, but is the same flywheel that came on my engine when GM put it together when new.

#12

TECH Fanatic

Can you elaborate on the crank pilot wear, as well as the adapter and spacer? I know the early 6.0's needed an adapter/spacer to run certain transmissions, but not the 4l80e. Mine is an 03, and doesn't have a spacer/adapter as it was always mated to a 4l80e. I just want to check everything this go around, even though I thought I have. I am looking for another complete transmission to start with, as this one has been an ongoing problem for years now.

All 2001 & up LSx engines have the short crankshaft, If the engine was originally mated to a 4L80E......It WILL have a spacer & a FLAT flexplate with 6 torque converter bolt holes on a 11.50" circle.

The spacer used is not as hard as the/a crankshaft, I used to use a "T-Micrometer" on them to prove out wear....I no longer bother as 90% are worn .005" or more.

I usually see higher mileage set-up's, If yours is low mileage....It may be OK.

On performance applications......Get rid of the Spacer, Run a Dished 4L60E/6L80E Flexplate & have your Converter builder install a corresponding Cover on the Converter.

The '98-2000 4L60E Flexplates are the strongest of OEM pieces.

#13

Thank you for clearing that up. I knew the early ones had a longer crankshaft, but didn't realize they put a spacer in the later ones to make up the difference. My truck had 99,xxx miles on it when it got wrecked, and I have put around 4000 miles on since it has been in the Camaro. I guess while I am building a new transmission with new convertor, and rebuilding the engine for somewhere in the 500hp range, I should probably upgrade the flexplate. Do you recommend an aftermarket one, or the stock one you mentioned. Also, just so I am understanding, the 80 and 60 have different boot patterns? So I would have to order my new convertor for an 80, but with a 60 bolt patterns?

#14

TECH Addict

iTrader: (47)

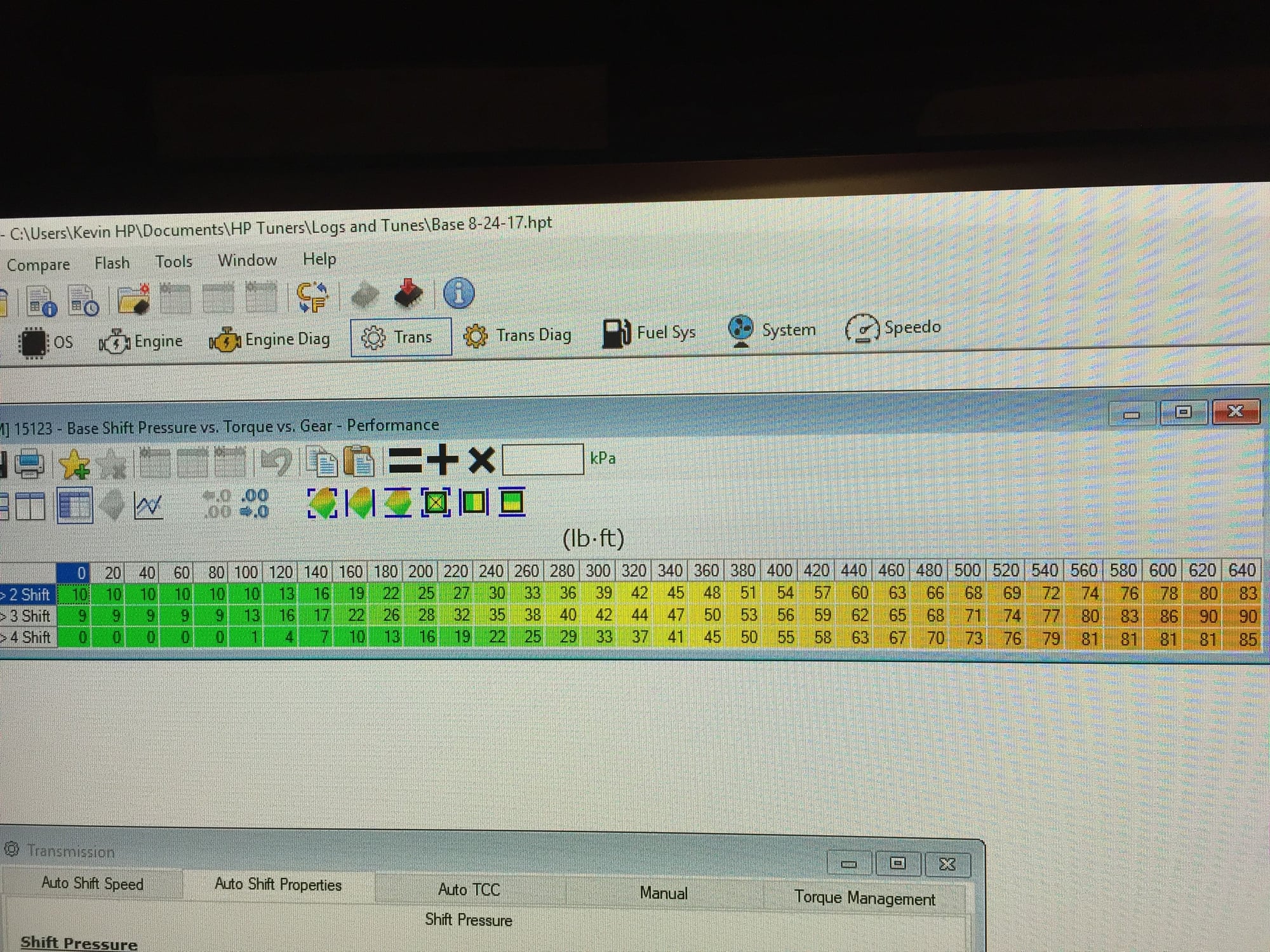

I am curious, did you ever change the transmission tune back to stock after you rebuilt the transmission? Or, at least close to a stock tune? I realize mrvedit has experience, but it sounds like the line pressure was turned up, and then, once it was rebuilt, it probably has a boost valve in it. Couple the 2 together, can cause really high pressure issues, which can really reek havoc on a transmission.

#15

TECH Fanatic

Thank you for clearing that up. I knew the early ones had a longer crankshaft, but didn't realize they put a spacer in the later ones to make up the difference. My truck had 99,xxx miles on it when it got wrecked, and I have put around 4000 miles on since it has been in the Camaro. I guess while I am building a new transmission with new convertor, and rebuilding the engine for somewhere in the 500hp range, I should probably upgrade the flexplate. Do you recommend an aftermarket one, or the stock one you mentioned. Also, just so I am understanding, the 80 and 60 have different boot patterns? So I would have to order my new convertor for an 80, but with a 60 bolt patterns?

4L60E/6L80E converters have a 11.062" bolt circle, Yes.....You will what this pattern on your new 4L80E converter to match the dished flexplate

#16

I am not a tuner by any means, so I don't know, but all the pressures seem low to other ones I have compared it too.

I am curious, did you ever change the transmission tune back to stock after you rebuilt the transmission? Or, at least close to a stock tune? I realize mrvedit has experience, but it sounds like the line pressure was turned up, and then, once it was rebuilt, it probably has a boost valve in it. Couple the 2 together, can cause really high pressure issues, which can really reek havoc on a transmission.

#17

I think I might have finally found the problem. Last time I went through the trans, I found 4 pieces missing. This time going through the schematics piece by piece, I realized that the rear seal and snap ring are missing from the case (not the tail shaft). From the way I see it, that would allow fluid to get to the rear bushing in the tail shaft, but not under pressure through the oil passage, and directly in the bushing. It appears that all the other pieces are there. I didn't have a good feeling about this trans from the day I bought it, but I never thought it would be this much trouble.

So now, I need recommedations on a converter manufacturer. The engine is at the machine shop now, and I am looking at making around 500hp at the flywheel. So I need to upgrade the converter. The guy helping me with the engine really likes the circle d converters, but I have heard good things about the boss Hoggs too. The car is primarily going to be used as a stret car, but will see it's fair share of track time in local drag racing, as well as I would like to do some auto cross and track events.

So now, I need recommedations on a converter manufacturer. The engine is at the machine shop now, and I am looking at making around 500hp at the flywheel. So I need to upgrade the converter. The guy helping me with the engine really likes the circle d converters, but I have heard good things about the boss Hoggs too. The car is primarily going to be used as a stret car, but will see it's fair share of track time in local drag racing, as well as I would like to do some auto cross and track events.

#19

TECH Fanatic

I think I might have finally found the problem. Last time I went through the trans, I found 4 pieces missing. This time going through the schematics piece by piece, I realized that the rear seal and snap ring are missing from the case (not the tail shaft). From the way I see it, that would allow fluid to get to the rear bushing in the tail shaft, but not under pressure through the oil passage, and directly in the bushing. It appears that all the other pieces are there. I didn't have a good feeling about this trans from the day I bought it, but I never thought it would be this much trouble.

So now, I need recommedations on a converter manufacturer. The engine is at the machine shop now, and I am looking at making around 500hp at the flywheel. So I need to upgrade the converter. The guy helping me with the engine really likes the circle d converters, but I have heard good things about the boss Hoggs too. The car is primarily going to be used as a stret car, but will see it's fair share of track time in local drag racing, as well as I would like to do some auto cross and track events.

So now, I need recommedations on a converter manufacturer. The engine is at the machine shop now, and I am looking at making around 500hp at the flywheel. So I need to upgrade the converter. The guy helping me with the engine really likes the circle d converters, but I have heard good things about the boss Hoggs too. The car is primarily going to be used as a stret car, but will see it's fair share of track time in local drag racing, as well as I would like to do some auto cross and track events.

I have a Circle D in my car & I really like it (Billet Single), Yank is also good as is Jakes Performance, North Texas Converter & Precision. Never ran or had a customer run a Boss Hogg so I can't comment.

The following users liked this post:

MoreDoorNoGo (10-15-2023)