4l80E, HD-2, dual feed question

#1

I picked up another 80E core to build, when I tore it down it appears it was going to be dual feed, the rev. hole next to the center support bolt was tapped, and had a plug, but the 2nd seal on the ctr. sup. was still there, and the inner seal was still on the direct clutch piston. I planned on using the HD-2 kit, but not sure if I should do the dual feed, or not, and if I didn't should the plug be removed. The direct clutch steels were pretty burned.

#2

TECH Fanatic

If you going to use the HD-2.....Remove the plug & follow the directions, Though I would leave off the pressure blow off assembly.

By plugging the direct reverse feed but leaving the sealing ring & center drum lip seal in place.....Only the smaller of the 2 direct apply areas were being used in reverse which would not provide enough clamping force especially if it was in a 2500/3500 truck backing trailers & such.

If it were me....I wouldn't bother with the HD-2 kit because you can dual feed internally!! And it sounds like your already familiar with the procedure.

-Sonnax Boost Valve part# 4L80E-LB1

-Sonnax TCC Regulator Valve part# 34994-01K

-3rd & 4th accumulator delete, http://www.ckperformance.com/View/4L...TOR-DELETE-KIT

-HD Intermediate snap ring, http://www.ckperformance.com/View/TH...UTCH-SNAP-RING

-Check the AFL Valve bore for wear by moving the valve 3/16" off its stop & check for wobble.

-TH400 direct piston machined for 6 frictions, High rate return springs, TH400 spring retainer, http://www.ckperformance.com/View/4L...PRING-ASSEMBLY

-Source a TH400 Intermediate return spring retainer, Carefully pry all 12 springs off the 4L80E retainer & reuse them with the TH400 retainer.

I have more recommendations.....But I don't know how far you want to go?

By plugging the direct reverse feed but leaving the sealing ring & center drum lip seal in place.....Only the smaller of the 2 direct apply areas were being used in reverse which would not provide enough clamping force especially if it was in a 2500/3500 truck backing trailers & such.

If it were me....I wouldn't bother with the HD-2 kit because you can dual feed internally!! And it sounds like your already familiar with the procedure.

-Sonnax Boost Valve part# 4L80E-LB1

-Sonnax TCC Regulator Valve part# 34994-01K

-3rd & 4th accumulator delete, http://www.ckperformance.com/View/4L...TOR-DELETE-KIT

-HD Intermediate snap ring, http://www.ckperformance.com/View/TH...UTCH-SNAP-RING

-Check the AFL Valve bore for wear by moving the valve 3/16" off its stop & check for wobble.

-TH400 direct piston machined for 6 frictions, High rate return springs, TH400 spring retainer, http://www.ckperformance.com/View/4L...PRING-ASSEMBLY

-Source a TH400 Intermediate return spring retainer, Carefully pry all 12 springs off the 4L80E retainer & reuse them with the TH400 retainer.

I have more recommendations.....But I don't know how far you want to go?

The following users liked this post:

JoshuaGrooms83 (08-03-2022)

#3

Thanks, was hoping you would respond-I have used the HD-2 before, but never the dual feed, but I had read what is done. When I opened this trans up (Jasper rebuild) I couldn't get the gear train out, on closer insp. I found the rev plug, it was screwed in and touching the center support, stopping it from coming out. Its going in my turbo Nova, prob around 650 RWHP max.

I am no trans builder, but try, lol, its like every other part on the car, look at what needs to be done and do it, ck and measure everything.

I am no trans builder, but try, lol, its like every other part on the car, look at what needs to be done and do it, ck and measure everything.

#4

TECH Fanatic

Yeah....Just skip the HD-2, They are great when you don't want to open the trans up, But are a waste of money when building one. BTW....The HD-2 DOES dual feed the directs through the triple layer separator plate which can cause cross leaks.

Remove/omit the second from the top Sealing Ring on the Center Support.

Omit the "Center Drum" lip seal in the direct drum.

Plug the "Direct" Reverse Feed in the Case.....I do not like the thought of ramming a set screw into the Center Support, Loctite the set screw in place in a position where it does not interfere with the Support.

The industry standard is to use a parking pawl cup plug, But your case is tapped.

I also like to plug the reverse feed in the center support, Keeps 3rd/Reverse oil from leaking between the Support & Case. A TV Exhaust checkball from a 700R4 works great.

Most times.....The cast iron around the hole will raise up a bit after knocking the checkball in, File it down as it will keep the Support from sealing to the case!!

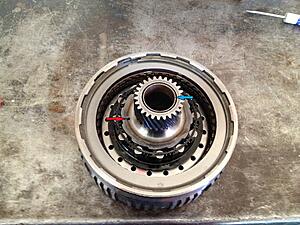

**This picture shows the 3rd feed blocked....For a Trans Brake TH400 with revised hydraulics, It's the only picture I have. Of course you will want to block the Reverse feed on the right **

Remove/omit the second from the top Sealing Ring on the Center Support.

Omit the "Center Drum" lip seal in the direct drum.

Plug the "Direct" Reverse Feed in the Case.....I do not like the thought of ramming a set screw into the Center Support, Loctite the set screw in place in a position where it does not interfere with the Support.

The industry standard is to use a parking pawl cup plug, But your case is tapped.

I also like to plug the reverse feed in the center support, Keeps 3rd/Reverse oil from leaking between the Support & Case. A TV Exhaust checkball from a 700R4 works great.

Most times.....The cast iron around the hole will raise up a bit after knocking the checkball in, File it down as it will keep the Support from sealing to the case!!

**This picture shows the 3rd feed blocked....For a Trans Brake TH400 with revised hydraulics, It's the only picture I have. Of course you will want to block the Reverse feed on the right **

#5

TECH Fanatic

#6

TECH Fanatic

Rollerize the Output!

Omit the Thrust Washer & 3 Tang Selectable.

Parts needed....

TH350 Pump Bearing, GM part# 9436851

TH350 Unit End-play Shims (assortment)

Case Bushing choices....

TH400 Case Bushing. Fluted

4L80E Pump Bushing. Non-Fluted

Sonnax 34006-SP. Fluted **MUST be installed BACKWARDS!!**

If you don't want to mess with setting the bushing height to index the bearing....Use the 34006-SP, Knock it all the way down from the BACK of the case using Loctite. Roughing up the OD of the bushing with some emery or scotchbrite will aid the loctite in holding the bushing from walking.

Bearing installs Black side facing the case, Silver side UP.

Set rear unit end-play to .003"-.008" using a dial indicator with the unit stacked to the center support snap ring.....You can leave out the Reaction Carrier & L/R Band while fiddling with the rear end-play.

Omit the Thrust Washer & 3 Tang Selectable.

Parts needed....

TH350 Pump Bearing, GM part# 9436851

TH350 Unit End-play Shims (assortment)

Case Bushing choices....

TH400 Case Bushing. Fluted

4L80E Pump Bushing. Non-Fluted

Sonnax 34006-SP. Fluted **MUST be installed BACKWARDS!!**

If you don't want to mess with setting the bushing height to index the bearing....Use the 34006-SP, Knock it all the way down from the BACK of the case using Loctite. Roughing up the OD of the bushing with some emery or scotchbrite will aid the loctite in holding the bushing from walking.

Bearing installs Black side facing the case, Silver side UP.

Set rear unit end-play to .003"-.008" using a dial indicator with the unit stacked to the center support snap ring.....You can leave out the Reaction Carrier & L/R Band while fiddling with the rear end-play.

#7

TECH Fanatic

Take the brass thrust that you removed from the output & use it to replace the plastic thrust between the reaction & output carriers.

Check Reaction Carrier to Center Support end-play by stacking the unit up to the center support on the bench.

Place your palms on the center support & lift up the reaction carrier....This is the end-play.

Adjust to roughly .010" using Sonnax part# 34006-05 shims under the thrust washer

Check Reaction Carrier to Center Support end-play by stacking the unit up to the center support on the bench.

Place your palms on the center support & lift up the reaction carrier....This is the end-play.

Adjust to roughly .010" using Sonnax part# 34006-05 shims under the thrust washer

Trending Topics

#8

TECH Fanatic

Rollerize the Forward Hub!

The best fitting OE bearing to use is a final drive sun gear bearing out of a Ford AXOD Part# E6DZ-7F404-A

Ford has discontinued this part, But Green Sales has them in stock Phone# 1-800-543-4959

Machining the Forward Hub rear thrust pad is necessary, Be very careful on your measurements because you will need to set Forward Hub to Direct Drum end play with the machining.

Start with +.035"......Lets say the bearing is .150", The original thrust is .064"

.150"-.064"=.086", .086"-.035"=.051", .051" is what you need to remove from the Thrust Pad to start with. If you have no end-play....Machine off .003" at a time 'til your in spec. These are hypothetical numbers!! Measure your new Bearing & old thrust BEFORE machining!!

Set Forward Hub to Direct Drum end-play to .003"-.008"

Checking Forward Hub to Direct Drum end play..... Stack the gear train up to the Direct drum, Place the Forward Hub over the Main Shaft, Hold the forward hub down with your palms & lift the direct drum with your fingers.....The play you feel is the end play.....Picture......

The best fitting OE bearing to use is a final drive sun gear bearing out of a Ford AXOD Part# E6DZ-7F404-A

Ford has discontinued this part, But Green Sales has them in stock Phone# 1-800-543-4959

Machining the Forward Hub rear thrust pad is necessary, Be very careful on your measurements because you will need to set Forward Hub to Direct Drum end play with the machining.

Start with +.035"......Lets say the bearing is .150", The original thrust is .064"

.150"-.064"=.086", .086"-.035"=.051", .051" is what you need to remove from the Thrust Pad to start with. If you have no end-play....Machine off .003" at a time 'til your in spec. These are hypothetical numbers!! Measure your new Bearing & old thrust BEFORE machining!!

Set Forward Hub to Direct Drum end-play to .003"-.008"

Checking Forward Hub to Direct Drum end play..... Stack the gear train up to the Direct drum, Place the Forward Hub over the Main Shaft, Hold the forward hub down with your palms & lift the direct drum with your fingers.....The play you feel is the end play.....Picture......

#10

TECH Enthusiast

Join Date: Sep 2016

Location: North Jersey

Posts: 518

Likes: 0

Received 0 Likes

on

0 Posts

#12

TECH Fanatic

#13

TECH Fanatic

#14

TECH Fanatic

#15

Good stuff

I did the Rollerize the Output on my 400, my concern was the shims didn't really register on anything, since the bearing took up all the room on the bushing, kind of leaving the shims to flop around. I guess if the bearing were

wide enough you could drive it in further, as long as it didn't get into the fillet of the output shaft.

Thanks

I did the Rollerize the Output on my 400, my concern was the shims didn't really register on anything, since the bearing took up all the room on the bushing, kind of leaving the shims to flop around. I guess if the bearing were

wide enough you could drive it in further, as long as it didn't get into the fillet of the output shaft.

Thanks

#16

TECH Fanatic

Good stuff

I did the Rollerize the Output on my 400, my concern was the shims didn't really register on anything, since the bearing took up all the room on the bushing, kind of leaving the shims to flop around. I guess if the bearing were

wide enough you could drive it in further, as long as it didn't get into the fillet of the output shaft.

Thanks

I did the Rollerize the Output on my 400, my concern was the shims didn't really register on anything, since the bearing took up all the room on the bushing, kind of leaving the shims to flop around. I guess if the bearing were

wide enough you could drive it in further, as long as it didn't get into the fillet of the output shaft.

Thanks

I have seen folks rollerize the output incorrectly & the aftermath of it.....Not pretty!

OK.....You want to place the shims in the case FIRST! Then the bearing with the "silver" side facing the Output Shaft thrust surface. This way only the silver race & the rollers inside will turn.

You DO NOT want the Black Race or the Shims to turn because they ride against the OD of the bushing.

If you pace the Shims against the Output &/or the Black Race against the Output....They will eat into the bushing.

The bushing needs to protrude about .075"-.080", At this height....It cannot run into the radius.

Some pictures to help. I was a work when I read your post so I was able get some better detail.

Last edited by clinebarger; 11-13-2017 at 09:19 PM.

#17

TECH Addict

Rollerize the Forward Hub!

The best fitting OE bearing to use is a final drive sun gear bearing out of a Ford AXOD Part# E6DZ-7F404-A

Ford has discontinued this part, But Green Sales has them in stock Phone# 1-800-543-4959

Machining the Forward Hub rear thrust pad is necessary, Be very careful on your measurements because you will need to set Forward Hub to Direct Drum end play with the machining.

Start with +.035"......Lets say the bearing is .150", The original thrust is .064"

.150"-.064"=.086", .086"-.035"=.051", .051" is what you need to remove from the Thrust Pad to start with. If you have no end-play....Machine off .003" at a time 'til your in spec. These are hypothetical numbers!! Measure your new Bearing & old thrust BEFORE machining!!

Set Forward Hub to Direct Drum end-play to .003"-.008"

Checking Forward Hub to Direct Drum end play..... Stack the gear train up to the Direct drum, Place the Forward Hub over the Main Shaft, Hold the forward hub down with your palms & lift the direct drum with your fingers.....The play you feel is the end play.....Picture......

The best fitting OE bearing to use is a final drive sun gear bearing out of a Ford AXOD Part# E6DZ-7F404-A

Ford has discontinued this part, But Green Sales has them in stock Phone# 1-800-543-4959

Machining the Forward Hub rear thrust pad is necessary, Be very careful on your measurements because you will need to set Forward Hub to Direct Drum end play with the machining.

Start with +.035"......Lets say the bearing is .150", The original thrust is .064"

.150"-.064"=.086", .086"-.035"=.051", .051" is what you need to remove from the Thrust Pad to start with. If you have no end-play....Machine off .003" at a time 'til your in spec. These are hypothetical numbers!! Measure your new Bearing & old thrust BEFORE machining!!

Set Forward Hub to Direct Drum end-play to .003"-.008"

Checking Forward Hub to Direct Drum end play..... Stack the gear train up to the Direct drum, Place the Forward Hub over the Main Shaft, Hold the forward hub down with your palms & lift the direct drum with your fingers.....The play you feel is the end play.....Picture......

what should the forward hub end play be in a stock trans? i am about to rollerize mine but put it all together with the plastic washer and im getting like 035 which has me very concerned that im missing a shim somewhere but i cant find anything missing.

thanks