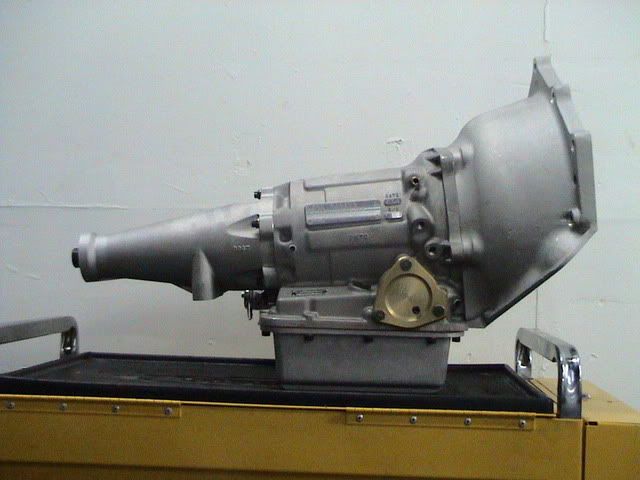

ACE Racing Transmissions 2,000 H/P Powerglide

#1

FormerVendor

Thread Starter

We are frequently asked for information regarding our High End Racing Units. Because of that I thought I would offer a write up of a unit we built for a customer who is building a 10.5 F-Body.

I was asked to not discuss build details regarding the car and engine platform, but I can discuss the Transmission. So it is my sincere desire to show you guys the inner workings and details of a very high end Powerglide Drag Racing Transmission. Grab your favorite beverage, sit back and enjoy!

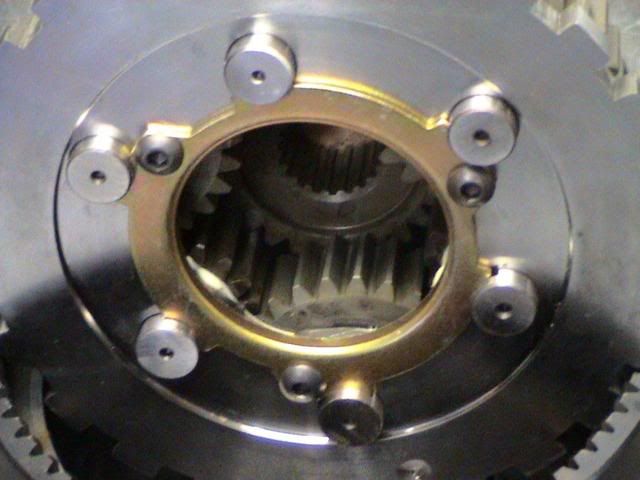

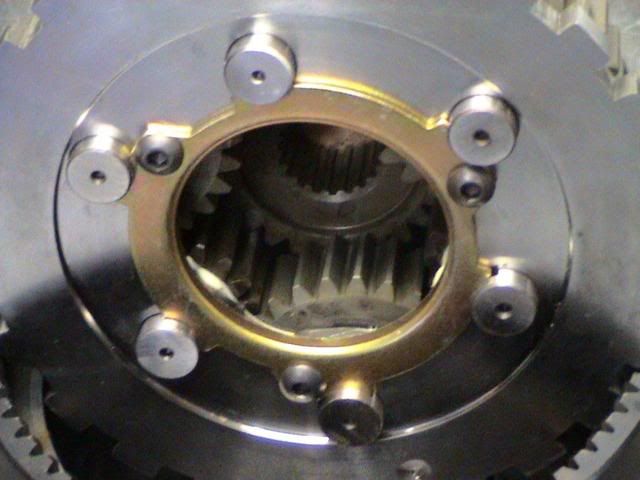

The backbone of this unit is the Output Assy. It consists of a 4340 Steel Carrier, 4340 Straight Cut Gears, Sun Gear and Ring Gear. The Output Shaft is made of 9310 steel. The only stronger assy. utilizes a Vasco Steel Output Shaft.

Notice the bolt on Planet Gear Pin Retainer. This piece allows for inexpensive gear swaps and inexpensive repairs should there be a failure.

Here is the Ring Gear that interacts with the Low/Reverse clutches and the Planet Gears.

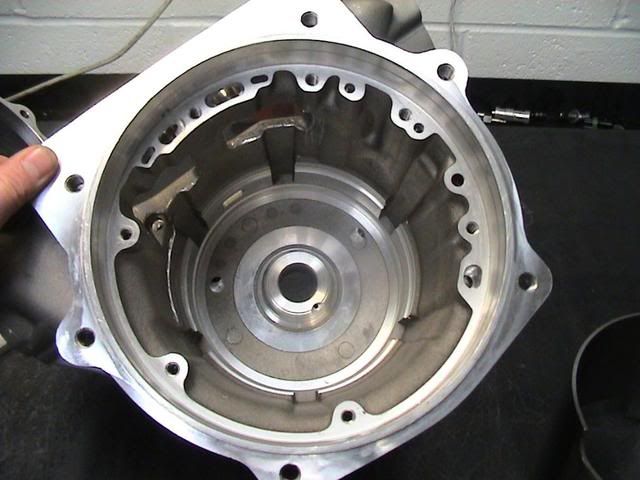

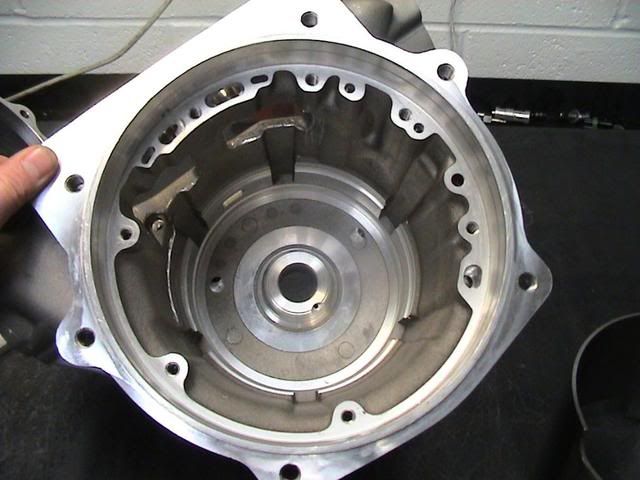

If that's the backbone so to speak, here is the exoskeleton! The 3 piece ATI Supercase is one of the premier cases on the market today.

Now, one very special safety feature of these units is the Steel Inner Liner. It's job is to catch any shrapnel or debris should the unit explode under stress. Between the Inner Liner and extra thick Supercase itself, very few Drivers or floopans are ever hurt when these are used!

The Bellhousing and Rollerized Tailhousing.

I was asked to not discuss build details regarding the car and engine platform, but I can discuss the Transmission. So it is my sincere desire to show you guys the inner workings and details of a very high end Powerglide Drag Racing Transmission. Grab your favorite beverage, sit back and enjoy!

The backbone of this unit is the Output Assy. It consists of a 4340 Steel Carrier, 4340 Straight Cut Gears, Sun Gear and Ring Gear. The Output Shaft is made of 9310 steel. The only stronger assy. utilizes a Vasco Steel Output Shaft.

Notice the bolt on Planet Gear Pin Retainer. This piece allows for inexpensive gear swaps and inexpensive repairs should there be a failure.

Here is the Ring Gear that interacts with the Low/Reverse clutches and the Planet Gears.

If that's the backbone so to speak, here is the exoskeleton! The 3 piece ATI Supercase is one of the premier cases on the market today.

Now, one very special safety feature of these units is the Steel Inner Liner. It's job is to catch any shrapnel or debris should the unit explode under stress. Between the Inner Liner and extra thick Supercase itself, very few Drivers or floopans are ever hurt when these are used!

The Bellhousing and Rollerized Tailhousing.

#2

FormerVendor

Thread Starter

Beware that the use of a rollerized tailhousing requires the use of a hardened driveshaft yoke! Mark Williams Enterprises is one supplier to consider.

Next are the remaining rotating assy components...

10 clutch billet steel high gear drum and related components.

Billet Steel Hub

Clutches and Billet Hub installed into Billet Drum.

Sun Gear installed into Drum assy.

Vasco Steel Input Shaft

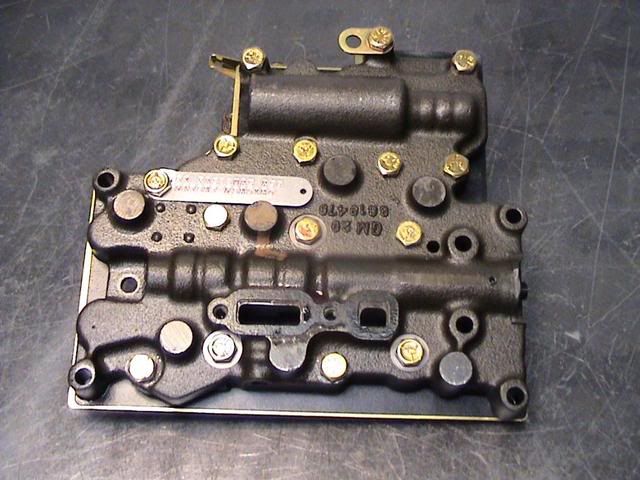

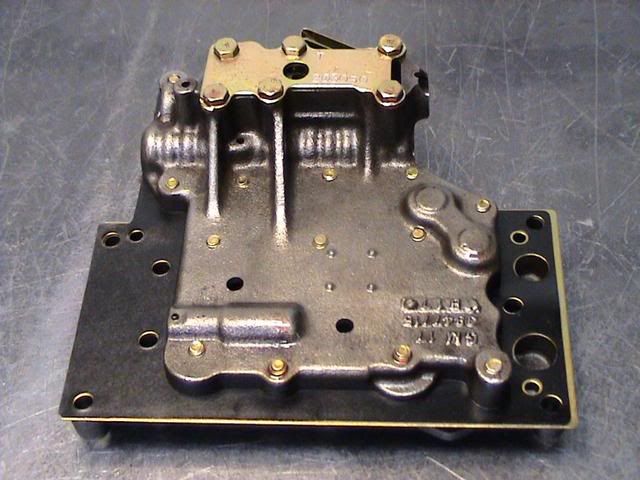

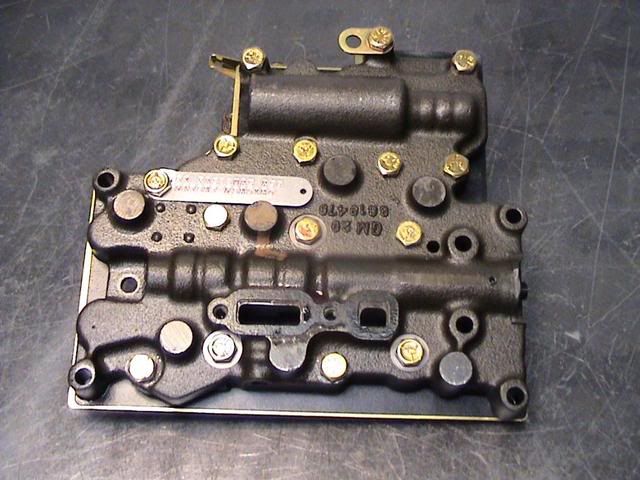

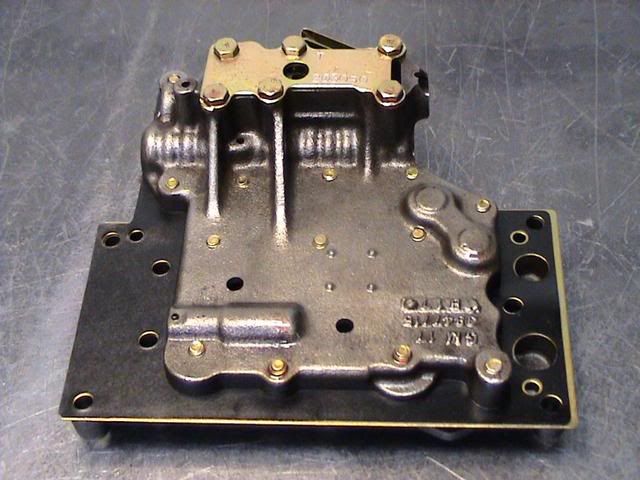

Next is the Valve Body. This is an ATI FMVB w/ Brake. The reason I spec'd this particular Valve Body is because the Line pressure is adjusted not by installing washers, but by adjusting a set screw. This is much more desireable IMHO.

Here is the cast aluminum pan and filter assy.

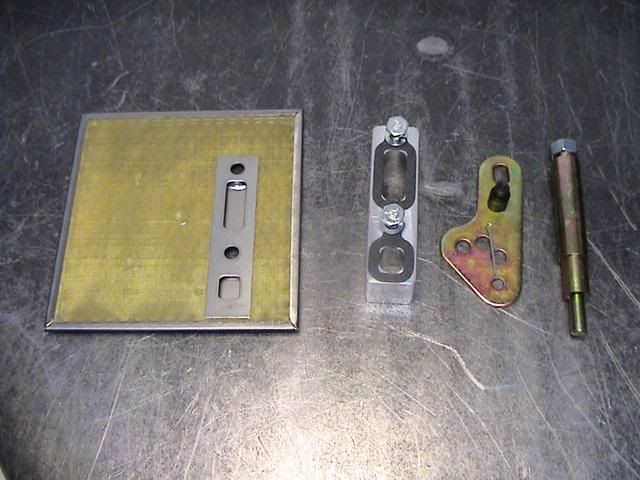

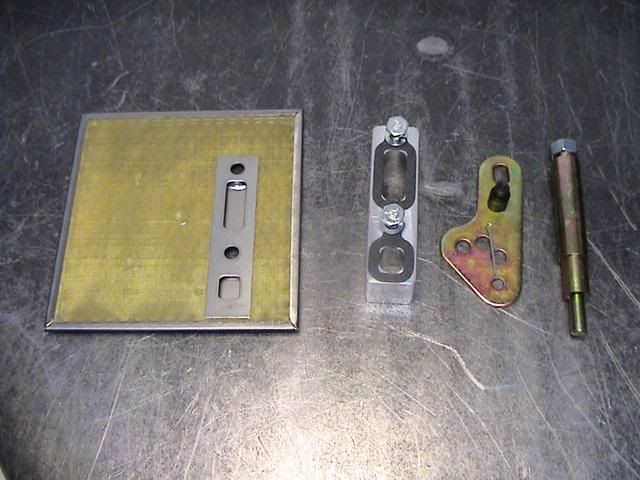

Very nice custom billet dual ring Servo and cover. The Servo is the component that applies the band.

And of course, the most vital of components! The Brake Solenoid!

For this application we used our Custom ACE Racing Transmissions original factory cast iron pump. This is a component that will be replaced when we step up the program! There are several Billet pump on he market, our budget alloted did not allow for the expense of an aftermarket billet pump.

Next are the remaining rotating assy components...

10 clutch billet steel high gear drum and related components.

Billet Steel Hub

Clutches and Billet Hub installed into Billet Drum.

Sun Gear installed into Drum assy.

Vasco Steel Input Shaft

Next is the Valve Body. This is an ATI FMVB w/ Brake. The reason I spec'd this particular Valve Body is because the Line pressure is adjusted not by installing washers, but by adjusting a set screw. This is much more desireable IMHO.

Here is the cast aluminum pan and filter assy.

Very nice custom billet dual ring Servo and cover. The Servo is the component that applies the band.

And of course, the most vital of components! The Brake Solenoid!

For this application we used our Custom ACE Racing Transmissions original factory cast iron pump. This is a component that will be replaced when we step up the program! There are several Billet pump on he market, our budget alloted did not allow for the expense of an aftermarket billet pump.

#5

TECH Senior Member

iTrader: (21)

Join Date: Nov 2001

Location: Cecil County Raceway!!!

Posts: 8,484

Likes: 0

Received 0 Likes

on

0 Posts

very similar to the tranny I just had built.

except I went with the ringless input shaft

superpump

vasco gearset

for reference, here is what the pumps look like compared to each other

except I went with the ringless input shaft

superpump

vasco gearset

for reference, here is what the pumps look like compared to each other

#6

Let me start by saying it looks top notch.

Now for the questions. Never been in a glide before. So theres just one clutch pack and a band? sheesh thats WAY simple next to a 60e. Whose clutch pack is that? Any pics of the band, how wide is it?

Also just something that came to mind, why exactly did they use such a long tail/output shaft? Any insight there? Seems like the longer output would be at a disadvantage when it came to bending and torsional load and make it more prone to shear.

What does something like that run if you get a billet pump? A breakdown would be nice if you dont care.

Now for the questions. Never been in a glide before. So theres just one clutch pack and a band? sheesh thats WAY simple next to a 60e. Whose clutch pack is that? Any pics of the band, how wide is it?

Also just something that came to mind, why exactly did they use such a long tail/output shaft? Any insight there? Seems like the longer output would be at a disadvantage when it came to bending and torsional load and make it more prone to shear.

What does something like that run if you get a billet pump? A breakdown would be nice if you dont care.

#7

FormerVendor

Thread Starter

very similar to the tranny I just had built.

except I went with the ringless input shaft

superpump

vasco gearset

except I went with the ringless input shaft

superpump

vasco gearset

I had originally spec'd this unit out to include those same components. But, because of budgetary constraints we decided to go the route we did. We agreed to consider this a "shakedown" build. The customer will be going to a much more potent combination after he get's some seat time and has all of the new car bugs behind him. Once he put's it under the knife we'll get that unit back for the upgrades. As strong as the Input Shaft and Output assy are, they can still be considered the weak spots in our build.

It's all about the compromises!

No doubt you have a very nice transmission!

g

Trending Topics

#8

FormerVendor

Thread Starter

Let me start by saying it looks top notch.

Now for the questions. Never been in a glide before. So theres just one clutch pack and a band? sheesh thats WAY simple next to a 60e. Whose clutch pack is that? Any pics of the band, how wide is it?

Also just something that came to mind, why exactly did they use such a long tail/output shaft? Any insight there? Seems like the longer output would be at a disadvantage when it came to bending and torsional load and make it more prone to shear.

What does something like that run if you get a billet pump? A breakdown would be nice if you dont care.

Now for the questions. Never been in a glide before. So theres just one clutch pack and a band? sheesh thats WAY simple next to a 60e. Whose clutch pack is that? Any pics of the band, how wide is it?

Also just something that came to mind, why exactly did they use such a long tail/output shaft? Any insight there? Seems like the longer output would be at a disadvantage when it came to bending and torsional load and make it more prone to shear.

What does something like that run if you get a billet pump? A breakdown would be nice if you dont care.

Good questions! The photos only depict one clutch pack, there are two. I did not include the Low/Reverse Clutches as I did not have them nor the Band when the pics were taken. When they did come in I simply did not remember to get pics... it's an old guy thing. LOL

The clutches shown are Raybestos, theses are commonly referred to as Blue Plate Specials, however these aren't Blue... it gave us concern so we checked with Raybestos on them, they are what we asked for.

The Low Reverse Piston was cut down on our Lathe in order to accomodate extra clutches. We used Alto Red clutches in the back.

We installed a Kevlar Band. I'll try to get a pic up of Powerglide Band soon, they are not similar in construction to a 60E. It is a very heavy steel design.

The "long" tailshaft is a standard 28" piece. The shorties, 18" long, are use primarily in rear engine Dragsters.

The Billet Pump weighs in at just under $600.00.

A Powerglide like what is depicted here would retail somewhere in the $4,500.00 range. And as you can see there are lot's of ways we can make it stronger. It is not uncommon to see a Max Effort Glide come in around $7,000.00. It all depends on the weight of the car and the amount of energy going into it.

g

#9

I cut my teeth on the 60e  .

.

At first I had thought you were running a z-pack thier color etc but the steel and dual sided clutch discs didnt jive with that.

I haven't ever heard any good with a kevlar band, but maybe with the different design it works. They always seem to burn in 60e's from what I hear so I have just always avoided them. Looking forward to the pictures.

Dont sweat it low reverse clutches aren't that exciting. Wouldnt mind seeing the mods you did to the piston though.

Out of curiosity what sort of line pressure does a pg run. Seems to me like alot of times the 60e runs a ton of max line compared to other stuff. Like my 60e's end up usually in 210-220psi. I know others like the 350 are happy with 165-175 or so for line.

Does the ati case have a bigger cylinder for the servo to get more apply out of it. Just kind of curious because of the billet servo cover.

Anybody got an exploded view of a pg?

.

.At first I had thought you were running a z-pack thier color etc but the steel and dual sided clutch discs didnt jive with that.

I haven't ever heard any good with a kevlar band, but maybe with the different design it works. They always seem to burn in 60e's from what I hear so I have just always avoided them. Looking forward to the pictures.

Dont sweat it low reverse clutches aren't that exciting. Wouldnt mind seeing the mods you did to the piston though.

Out of curiosity what sort of line pressure does a pg run. Seems to me like alot of times the 60e runs a ton of max line compared to other stuff. Like my 60e's end up usually in 210-220psi. I know others like the 350 are happy with 165-175 or so for line.

Does the ati case have a bigger cylinder for the servo to get more apply out of it. Just kind of curious because of the billet servo cover.

Anybody got an exploded view of a pg?

#10

FormerVendor

Thread Starter

Well the Kevlar Band was conceived to be able to withstand the rigors of high horsepower combinations... it is the "go to" component in these applications. Indeed in street / strip applications it can be abusive on the drum.

No pics of the customized piston. Maybe it'll be an excuse to dig this thread up next time we build a Glide. That operation is SOP here at ACE with any Glide.. and many other shops I might add.

Well there are builders out there that like to see line pressure up in the 280 - 300 psi ranges. We don't like to see our pressures up there. Reason being it is simply too hard on the aluminum pistons. In a unit like this we like to see the pressure in the 240 - 250 psi range. However, we would not run those pressures with a stock case as there is a tendency to blow out the back of the case (Low / Reverse area) when the Brake is applied and it is seeing max line pressure.

The Servo bore in an ATI case is a standard bore size. However, ATI has a very trick new Servo out that gives the ability to increase the bore size from 2.750" to 3.25"! They tell us that this allows for a clamping forces equal to 300 psi from a unit running less than 220 psi.

The reason for the billet servo cover is simple... I would not build one of these units and install an ugly looking stock cover! It's simply installed for aesthetics! LOL. I wouldn't want to spend that kind of money for a unit like that, un-crate it and see a stock cover and I know my clients wouldn't either!

g

No pics of the customized piston. Maybe it'll be an excuse to dig this thread up next time we build a Glide. That operation is SOP here at ACE with any Glide.. and many other shops I might add.

Well there are builders out there that like to see line pressure up in the 280 - 300 psi ranges. We don't like to see our pressures up there. Reason being it is simply too hard on the aluminum pistons. In a unit like this we like to see the pressure in the 240 - 250 psi range. However, we would not run those pressures with a stock case as there is a tendency to blow out the back of the case (Low / Reverse area) when the Brake is applied and it is seeing max line pressure.

The Servo bore in an ATI case is a standard bore size. However, ATI has a very trick new Servo out that gives the ability to increase the bore size from 2.750" to 3.25"! They tell us that this allows for a clamping forces equal to 300 psi from a unit running less than 220 psi.

The reason for the billet servo cover is simple... I would not build one of these units and install an ugly looking stock cover! It's simply installed for aesthetics! LOL. I wouldn't want to spend that kind of money for a unit like that, un-crate it and see a stock cover and I know my clients wouldn't either!

g

#12

TECH Fanatic

iTrader: (2)

Those clutches look identical to a set that I put in a 400 about a month ago. They weren't the blue plates, they were the Raybestos HD plates. They were brown and "waffle" style. All of the blue plates that I've seen aren't the "waffle" type, they just have straight ridges.

#14

FormerVendor

Thread Starter

did you go with the "wide" band?

are you worried about the ring lands on the input shaft? (stress riser)

The Vasco shaft is one of the toughest shafts on the market. But, it does have it's limitations... and yes the ring lands are definitely a stress point!

Those clutches look identical to a set that I put in a 400 about a month ago. They weren't the blue plates, they were the Raybestos HD plates. They were brown and "waffle" style. All of the blue plates that I've seen aren't the "waffle" type, they just have straight ridges.

It's the shafts that give me heartburn. There's no doubt that we have a solid foundation to work with here long term. I doubt seriously this unit will grenade and need to be replaced wholesale as we are not taking it much over 1,700 h/p.

For all of my high end Glide customers I offer a maintenance deal. If the unit fails or needs freshening up all that is required of that client is to get it back on my bench and pay $250.00 labor + parts and shipping. Regardless of what the unit needs.

g

#15

TECH Senior Member

iTrader: (21)

Join Date: Nov 2001

Location: Cecil County Raceway!!!

Posts: 8,484

Likes: 0

Received 0 Likes

on

0 Posts

Have you seen the catch can ATI makes for the glide? when do you think it becomes a good idea to have one? I bought one for mine just in case

My thought is anything you can do to keep fluids off the track is a good thing

My thought is anything you can do to keep fluids off the track is a good thing

#16

FormerVendor

Thread Starter

My opinion is if you are running a Glide in any trailer car it is absolutely a must! I think it is one of the best safety components to come along in quite some time.

The key is, anytime you are on the Brake you are generating gobs of heat. As much as 10* per second conservatively speaking. And of course it's right after that event that the unit is most likely to push fluid out of the vent. Anything a guy can do to keep liquids off of the back tires is just going to make his car that much safer.

g

#17

TECH Senior Member

iTrader: (21)

Join Date: Nov 2001

Location: Cecil County Raceway!!!

Posts: 8,484

Likes: 0

Received 0 Likes

on

0 Posts

I have seen them, I have installed them as well. Furthermore, I am in negotiations with a Chassis / Fab shop here locally to produce a similar product!

My opinion is if you are running a Glide in any trailer car it is absolutely a must! I think it is one of the best safety components to come along in quite some time.

The key is, anytime you are on the Brake you are generating gobs of heat. As much as 10* per second conservatively speaking. And of course it's right after that event that the unit is most likely to push fluid out of the vent. Anything a guy can do to keep liquids off of the back tires is just going to make his car that much safer.

g

My opinion is if you are running a Glide in any trailer car it is absolutely a must! I think it is one of the best safety components to come along in quite some time.

The key is, anytime you are on the Brake you are generating gobs of heat. As much as 10* per second conservatively speaking. And of course it's right after that event that the unit is most likely to push fluid out of the vent. Anything a guy can do to keep liquids off of the back tires is just going to make his car that much safer.

g

#18

TECH Fanatic

iTrader: (2)

Originally Posted by Ratchthed

They easily could be H/D clutches... after calling Raybestos and seeing the part number cross reference we were satisfied. Either way I'm not concerned about the Direct clutches living in this one as they are woven and will be able to dissipate heat well.

#19

FormerVendor

Thread Starter

They appear to be nice frictions. I haven't used enough of them to really know yet though. Do you put the bushing in the end of the stator tube, or leave it out? Here recently, I've been using the bushings. I had a bad experience with a glide, and I think the bushing not being use was the problem. It kept burning up bands, and my theory on it was that the input shaft was moving around, making the drum off center. The third time on the bench, I decided to put a bushing in for the hell of it, and it never came back. I think that also has a lot to do with the converter being used. I believe the theory is that the converter is supposed to center the end of the input shaft.

If the Pump Stator has no bushing then the shaft must be supported with a bushing in the converter turbine. This is only when a Turbo shaft is used.

Hope that helps.

g