1970 GTO Version 3.0

#141

TECH Senior Member

Andrew- With the Volt brushless fans with included controller, what else is needed wiring-wise (or additional components) to use them in a swap or any stand-alone situation?

I hope I'm not showing TOO much ignorance here... lol

I hope I'm not showing TOO much ignorance here... lol

#142

TECH Senior Member

Thread Starter

iTrader: (7)

Andrew

The following users liked this post:

G Atsma (04-01-2021)

#143

TECH Senior Member

Gotcha. So it really is not feasible in a standalone sense. It still needs an outside programable PWM signal and temp signal source.

Thank you!

Thank you!

#144

TECH Junkie

iTrader: (1)

To Andrewís and Willís point - Iíve been using PWM controlled cooling fans since 2003 (albeit with a stand alone controller). Itís the only way to go. When relays crank big amp fans on/off, the resulting transient voltage spikes/drops are hard on the charging and electrical systems. I avoid them if I can. PWM starter anyone? 🤪

The following users liked this post:

G Atsma (04-01-2021)

The following 3 users liked this post by Pro Stock John:

#146

TECH Senior Member

Thread Starter

iTrader: (7)

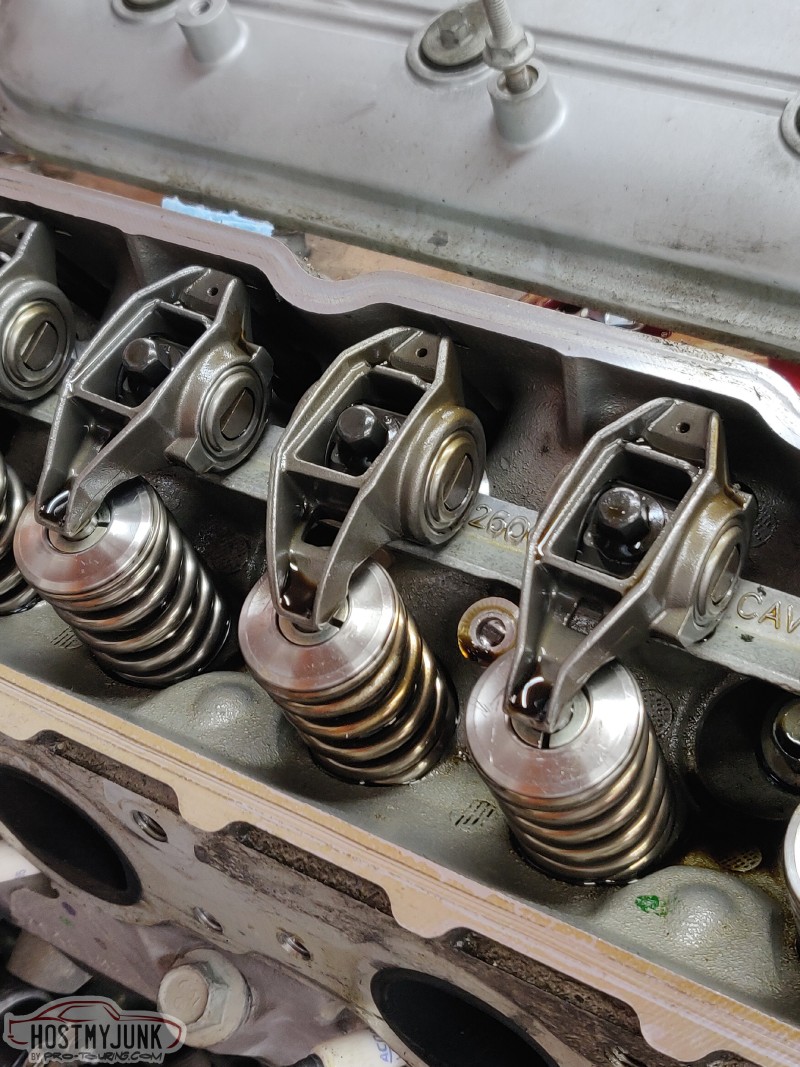

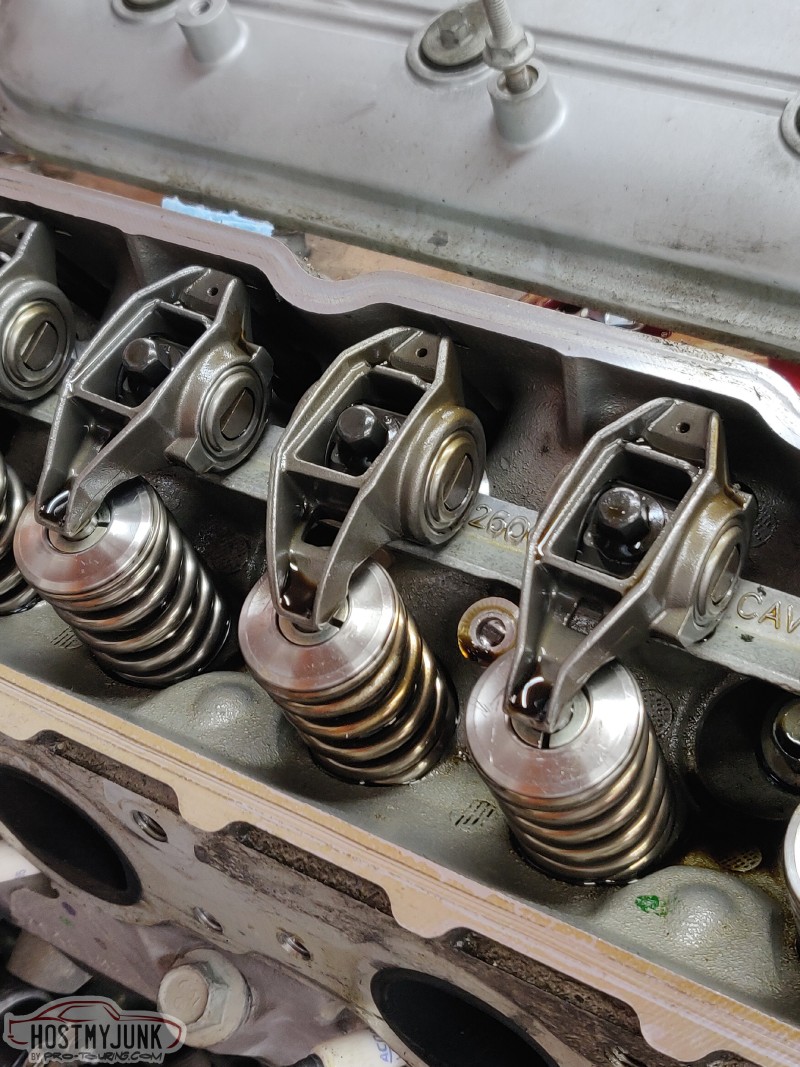

The weather was really nice this weekend, so I decided to mess around with the engine a little bit. Popped the valve covers off just to do a visual inspection. Everything looked really good.

Pulled the spark plugs and they all look like this. Also pretty good.

The counter sunk bolts that hold the engine mount adapter plates to the engine are going to be a problem. I got one loose, but the rest are stuck pretty good. I broke one 3/8" drive 6mm allen wrench in the process.

I am soaking them with some PB Blaster, so I hope that does the trick. If not, might have to add some heat.

Andrew

Pulled the spark plugs and they all look like this. Also pretty good.

The counter sunk bolts that hold the engine mount adapter plates to the engine are going to be a problem. I got one loose, but the rest are stuck pretty good. I broke one 3/8" drive 6mm allen wrench in the process.

I am soaking them with some PB Blaster, so I hope that does the trick. If not, might have to add some heat.

Andrew

#147

I wonder how many people forget to anti-seize them. I guess Iím lucky, I got a iron block. I never even thought about it before either.

Hopefully you can get them out

Hopefully you can get them out

The following users liked this post:

130fe (04-05-2021)

#149

Now that I think of it, I did have the exact same problem with my iron block. I remember having to grind a slot in the head to chisel it loose. I am hoping I had the common sense to lightly anti seize it.

Andrew,

what springs and retainers are those?

thanks,

Jim

Andrew,

what springs and retainers are those?

thanks,

Jim

#150

TECH Addict

ive had luck using a small flat ended punch to strike the head around the face perimeter. sometimes that is just enough to be able to break it loose with a hex key. propane also helps.

#151

TECH Senior Member

Thread Starter

iTrader: (7)

I actually always use anti-seize when using steel bolts in aluminum. I think the cone of the flat head bolt has a little rust where it touches the adapter plate. Using a punch is a great idea. I will try that next.

Does anyone have any suggestions for a product to clean the bare aluminum block?

Andrew

The following users liked this post:

Project GatTagO (04-05-2021)

#153

Andrew,

EAGLE MAG CLEANER 1. Something like that. Clint(Bandit) I believed talked about this in his thread. Back when I used it, There was two versions of this mag cleaner. One was safe and one was caustic. You have to read the labels to see which one youíre looking at.

It works great cleaning old aluminum parts to look new. Itís basically what Will is saying

EAGLE MAG CLEANER 1. Something like that. Clint(Bandit) I believed talked about this in his thread. Back when I used it, There was two versions of this mag cleaner. One was safe and one was caustic. You have to read the labels to see which one youíre looking at.

It works great cleaning old aluminum parts to look new. Itís basically what Will is saying

The following users liked this post:

Project GatTagO (04-05-2021)

The following users liked this post:

Project GatTagO (04-05-2021)

#158

On The Tree

If you haven't gotten those bolts out yet, take a small cutting wheel and cut a slot in the head. They will either come out with a flatblade, or a chisel hit or two.

The following 2 users liked this post by HILROD:

Jimbo1367 (04-07-2021), Project GatTagO (04-10-2021)

#159

TECH Senior Member

Thread Starter

iTrader: (7)

Still haven't gotten the bolts out, but haven't really tried. Today was super busy with having to juggle four tuning customers, but I did did get a few more parts.

I have mentioned it before, but part of the goal is to get the AC system fully functioning. It is an older VA Super Gen II system, but I see no reason why it can't work as it should. Another thing that I want to do is fully integrate the AC system with the Holley ECU. Today I received some of the parts to do that.

This is a new drier that I got from BP Automotive. What makes it unique is that it has both a binary switch for the compressor and it has a GM pressure sensor.

The binary switch will work as a safety for the compressor. The AC pressure switch will be an input to the Terminator X and will allow me to integrate AC as part of the cooling fan control.

I also picked up these pressure sensor connectors from EFI Connection. These connectors are pretty standard for GM and aftermarket 5v pressure transducers. What makes these a little unique is the little lip that is molded at the end of the connector. I plan to modify a lot of the Holley EFI harness and part of the modification will be sealing off the sections of harness for the pressure sensors. These sections of harness will be encapsulated in Raychem Dr25 heat shrink tubing and the connectors will have heat shrink boots on them.

Andrew

I have mentioned it before, but part of the goal is to get the AC system fully functioning. It is an older VA Super Gen II system, but I see no reason why it can't work as it should. Another thing that I want to do is fully integrate the AC system with the Holley ECU. Today I received some of the parts to do that.

This is a new drier that I got from BP Automotive. What makes it unique is that it has both a binary switch for the compressor and it has a GM pressure sensor.

The binary switch will work as a safety for the compressor. The AC pressure switch will be an input to the Terminator X and will allow me to integrate AC as part of the cooling fan control.

I also picked up these pressure sensor connectors from EFI Connection. These connectors are pretty standard for GM and aftermarket 5v pressure transducers. What makes these a little unique is the little lip that is molded at the end of the connector. I plan to modify a lot of the Holley EFI harness and part of the modification will be sealing off the sections of harness for the pressure sensors. These sections of harness will be encapsulated in Raychem Dr25 heat shrink tubing and the connectors will have heat shrink boots on them.

Andrew

The following users liked this post:

G Atsma (04-10-2021)