LQ4 swap wont go into Closed Loop

#1

Teching In

Thread Starter

Join Date: Apr 2023

Location: South Jersey

Posts: 7

Likes: 0

Received 0 Likes

on

0 Posts

I'm not certain this post is in the right place because it kind of walks a line between PCM diagnostics/tuning and swaps...

I've got a basically stock LQ4 in an MK3 Supra that I'm trying to hammer the kinks out of.

Some back story on my bastard child is that it has an LS1 intake with stock LS1 (12564271) injectors, homemade 3 inch exhaust, MAF off of something (25168491), it's mated to the stock Toyota 5spd R154 transmission. The engine is from an 04 Silverado 2500HD, PCM from an 03 Tahoe 1500 5.3L (12576106) and I adapted to DBC because I didn't want to try mounting a pedal in the car..

There's plenty of issues to sort through but for now I'm focusing on trying to get the thing to go into closed loop so i can attain some form of drivability to confirm all the other wacky stuff I did works properly...

After dealing with an open loop fault, fuel system status is now reading "OL-Accel/Decel" and my current guess is that the O2 sensors aren't heating up completely because voltage isn't oscillating - I can't seem to find anything confirming that voltage should oscillate in OL as well as CL. I got new OE sensors for it to be sure the cheapo china specials I had before weren't the issue and now they're at least reading fairly consistently, just without any fluctuation. I copied all the 6 liter tables into the current PCM to get things running but I'm also second guessing if there's some setting that could be causing me my trouble considering everything is geared towards something this currently isn't.

My thoughts are kind of all over the place, I know, and I don't want to ramble too much more than I already have so I'll just attach my current tune file and a short log of it running in the driveway this afternoon and say thanks in advance for any help anyone can offer!

I've got a basically stock LQ4 in an MK3 Supra that I'm trying to hammer the kinks out of.

Some back story on my bastard child is that it has an LS1 intake with stock LS1 (12564271) injectors, homemade 3 inch exhaust, MAF off of something (25168491), it's mated to the stock Toyota 5spd R154 transmission. The engine is from an 04 Silverado 2500HD, PCM from an 03 Tahoe 1500 5.3L (12576106) and I adapted to DBC because I didn't want to try mounting a pedal in the car..

There's plenty of issues to sort through but for now I'm focusing on trying to get the thing to go into closed loop so i can attain some form of drivability to confirm all the other wacky stuff I did works properly...

After dealing with an open loop fault, fuel system status is now reading "OL-Accel/Decel" and my current guess is that the O2 sensors aren't heating up completely because voltage isn't oscillating - I can't seem to find anything confirming that voltage should oscillate in OL as well as CL. I got new OE sensors for it to be sure the cheapo china specials I had before weren't the issue and now they're at least reading fairly consistently, just without any fluctuation. I copied all the 6 liter tables into the current PCM to get things running but I'm also second guessing if there's some setting that could be causing me my trouble considering everything is geared towards something this currently isn't.

My thoughts are kind of all over the place, I know, and I don't want to ramble too much more than I already have so I'll just attach my current tune file and a short log of it running in the driveway this afternoon and say thanks in advance for any help anyone can offer!

#2

Teching In

Thread Starter

Join Date: Apr 2023

Location: South Jersey

Posts: 7

Likes: 0

Received 0 Likes

on

0 Posts

Bump for thoughts/opinions and additional information

Closed loop trigger temp is 131* I'm pretty certain - at that point, fuel system status goes from "OL-NotReady" to "OL-Accel/Decel" can anyone tell me specifically what that mode refers to/actually means?

I don't think it makes any difference but the VSS wire isn't hooked to anything, this only sends a signal to an electric speedo, right? or is that an input? I can't remember at this point..

The only sensor that I can tell is sending any odd signals is the oil pressure sensor, which shows like 130psi in VCM scanner all the time. I can't find any definitive information on what parameters the PCM takes into account so I can't figure if this would have any affect.

The only code that comes up is for an open tach circuit which I'm trying to figure out as well but nothing I try there gives me any results.

The PCM refusing to go into closed loop and it going like 17:1 and stumbling when I try driving around the block are my bigger issues currently

Thanks

Closed loop trigger temp is 131* I'm pretty certain - at that point, fuel system status goes from "OL-NotReady" to "OL-Accel/Decel" can anyone tell me specifically what that mode refers to/actually means?

I don't think it makes any difference but the VSS wire isn't hooked to anything, this only sends a signal to an electric speedo, right? or is that an input? I can't remember at this point..

The only sensor that I can tell is sending any odd signals is the oil pressure sensor, which shows like 130psi in VCM scanner all the time. I can't find any definitive information on what parameters the PCM takes into account so I can't figure if this would have any affect.

The only code that comes up is for an open tach circuit which I'm trying to figure out as well but nothing I try there gives me any results.

The PCM refusing to go into closed loop and it going like 17:1 and stumbling when I try driving around the block are my bigger issues currently

Thanks

#4

Teching In

Thread Starter

Join Date: Apr 2023

Location: South Jersey

Posts: 7

Likes: 0

Received 0 Likes

on

0 Posts

#6

Teching In

Thread Starter

Join Date: Apr 2023

Location: South Jersey

Posts: 7

Likes: 0

Received 0 Likes

on

0 Posts

Trending Topics

#9

Teching In

Thread Starter

Join Date: Apr 2023

Location: South Jersey

Posts: 7

Likes: 0

Received 0 Likes

on

0 Posts

Do you know or have a link to the parameters the PCM uses to gauge CL readiness?

I'm still going to work on the other things that were suggested, even if they may not be related to CL, but I'm just really curious how the computer judges when to start reading o2 signals and making fuel changes.

I'm just learning everything as I go and have much more ahead of me, but when I try answering that question, I only find dead end after dead end. maybe I'm searching with the wrong keywords..?

#10

Sorry, VSS won’t influence your going into CL, but not having it will give you other weird drivability symptoms.

Last edited by clay68c10; 05-07-2023 at 09:52 PM.

#11

11 Second Club

iTrader: (88)

So what wiring issues, other than something to do with the o2 sensors would cause closed loop to not enable?

Do you know or have a link to the parameters the PCM uses to gauge CL readiness?

I'm still going to work on the other things that were suggested, even if they may not be related to CL, but I'm just really curious how the computer judges when to start reading o2 signals and making fuel changes.

I'm just learning everything as I go and have much more ahead of me, but when I try answering that question, I only find dead end after dead end. maybe I'm searching with the wrong keywords..?

Do you know or have a link to the parameters the PCM uses to gauge CL readiness?

I'm still going to work on the other things that were suggested, even if they may not be related to CL, but I'm just really curious how the computer judges when to start reading o2 signals and making fuel changes.

I'm just learning everything as I go and have much more ahead of me, but when I try answering that question, I only find dead end after dead end. maybe I'm searching with the wrong keywords..?

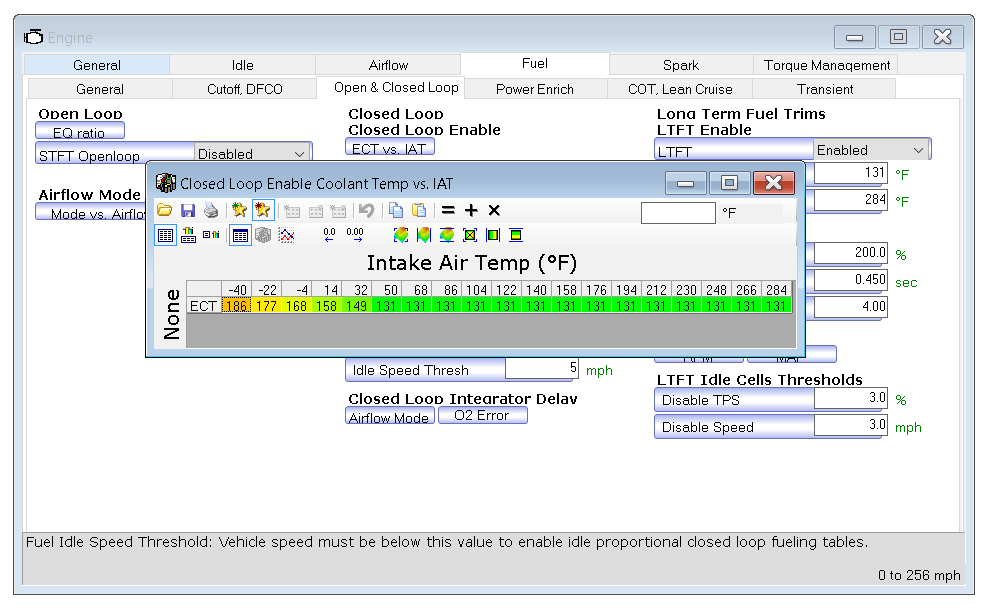

I stated the parameters, the Coolant Temp is what you can set to make it go into Closed Loop compared to Intake Air Temp. That's it.

From my HP Tuners..

#12

TECH Veteran

iTrader: (1)

Under engine-fuel-open loop, you have STFT open loop enabled. This keeps you from going into closed loop. The short term trims should work, but I think they max around 10% if I remember correctly. Also, since I did not see anyone answer your earlier question, o2 sensors only oscillate because the ECM "dithers" the fueling back and forth around stoichiometric. In open loop they will read a steady voltage.

#13

Teching In

Thread Starter

Join Date: Apr 2023

Location: South Jersey

Posts: 7

Likes: 0

Received 0 Likes

on

0 Posts

Under engine-fuel-open loop, you have STFT open loop enabled. This keeps you from going into closed loop. The short term trims should work, but I think they max around 10% if I remember correctly. Also, since I did not see anyone answer your earlier question, o2 sensors only oscillate because the ECM "dithers" the fueling back and forth around stoichiometric. In open loop they will read a steady voltage.

#15

Teching In

Thread Starter

Join Date: Apr 2023

Location: South Jersey

Posts: 7

Likes: 0

Received 0 Likes

on

0 Posts

So I think I got my vacuum leak sorted out, I had a cheap clamp on the throttle body and swapped to a T-bolt.

I was also brainstorming and it finally dawned on me that I copied the tables for the LQ4 but I've got injectors and the intake from an LS1. duh...

I changed some tables to match the LS1 data and finally the O2 sensors are oscillating, the idle AFR went from like 17:1 to 14:1 and the short term fuel trims are making small adjustments.

The fuel status still reads OL-Accel/Decel but it's starting to do the right things at least.. One setting I saw was a set-point for the max throttle percentage before jumping into closed loop, I think it's set at 5%.

So my question there is if the TPS is reading ~.83volts, and the range is supposed to be approximately between .5 and 4.5 so 1% throttle would be roughly equivalent to .04 volts if I'm .3 volts above normal, would the computer see that as ~12% throttle and not follow that setting? or am I misinterpreting this setting?

I'm at work right now so I can't post another log or the tune/screenshot of what I'm looking at - I'll post that when I get home, I just wanted to update the thread.

I was also brainstorming and it finally dawned on me that I copied the tables for the LQ4 but I've got injectors and the intake from an LS1. duh...

I changed some tables to match the LS1 data and finally the O2 sensors are oscillating, the idle AFR went from like 17:1 to 14:1 and the short term fuel trims are making small adjustments.

The fuel status still reads OL-Accel/Decel but it's starting to do the right things at least.. One setting I saw was a set-point for the max throttle percentage before jumping into closed loop, I think it's set at 5%.

So my question there is if the TPS is reading ~.83volts, and the range is supposed to be approximately between .5 and 4.5 so 1% throttle would be roughly equivalent to .04 volts if I'm .3 volts above normal, would the computer see that as ~12% throttle and not follow that setting? or am I misinterpreting this setting?

I'm at work right now so I can't post another log or the tune/screenshot of what I'm looking at - I'll post that when I get home, I just wanted to update the thread.