Story of our LS1 swap into 67 Camaro

#81

TECH Resident

iTrader: (2)

Join Date: Jun 2006

Location: Roswell, GA

Posts: 802

Likes: 0

Received 0 Likes

on

0 Posts

Those look like the same "short & wide" Energy Suspension mounts that I'm running, #3.1114G? If so, did you throw away the spacer plates that the ES instructions say you must use? You don't need them with the adapters, and if you try to use them, it'll cause exactly the problem you are seeing (happened to me).

If that's not the problem, how well do the mounts fit over the frame stands? If the there's a 1/4" gap, it means you have '69 302/350 frame stands that require "tall & narrow" mounts, #3.1117G.

If that's not it, then either the stands are wrong or the subframe is tweaked (more likely the stands are wrong). David Pozzi has a bunch of info on the various frame stands on his website, http://www.pozziracing.com/camaro_engine.htm.

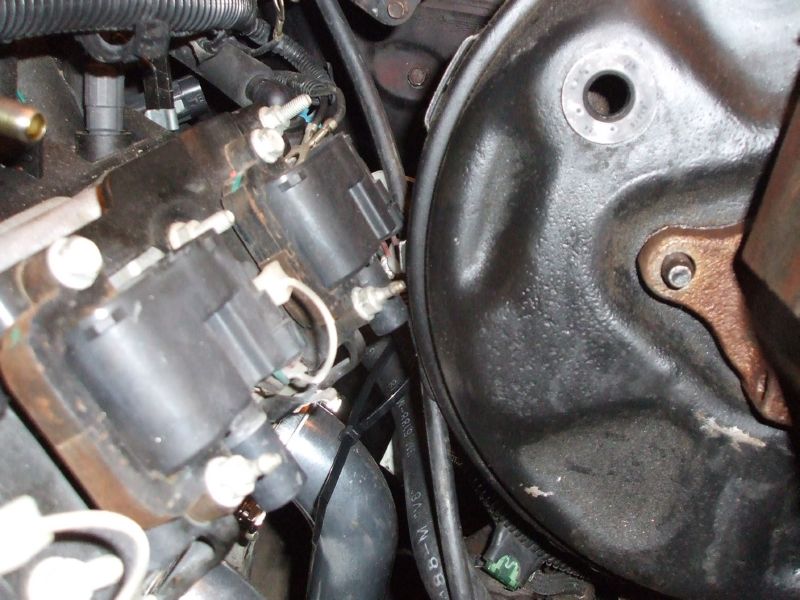

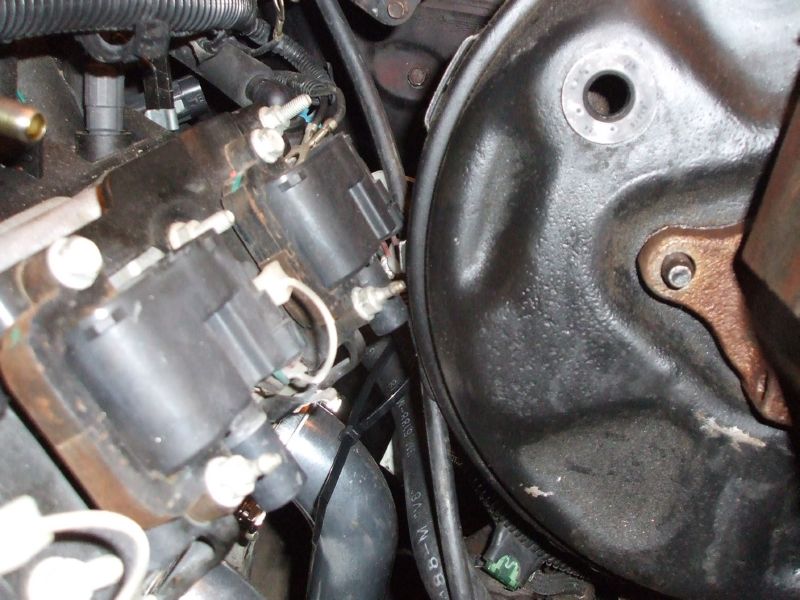

I've got about 2 3/4" from the back of the left valve cover to firewall:

And I've got about an inch of clearance to the wiper motor. My ATS-style mounts put the engine lower than your S&P mounts, so you may be close but I'm pretty sure it'll fit.

The only clearance issue I had was my brake booster. I could have switched to a smaller booster or relocated the coils, but I decided to go with a hydroboost unit.

If that's not the problem, how well do the mounts fit over the frame stands? If the there's a 1/4" gap, it means you have '69 302/350 frame stands that require "tall & narrow" mounts, #3.1117G.

If that's not it, then either the stands are wrong or the subframe is tweaked (more likely the stands are wrong). David Pozzi has a bunch of info on the various frame stands on his website, http://www.pozziracing.com/camaro_engine.htm.

I've got about 2 3/4" from the back of the left valve cover to firewall:

And I've got about an inch of clearance to the wiper motor. My ATS-style mounts put the engine lower than your S&P mounts, so you may be close but I'm pretty sure it'll fit.

The only clearance issue I had was my brake booster. I could have switched to a smaller booster or relocated the coils, but I decided to go with a hydroboost unit.

#82

On The Tree

iTrader: (1)

67rsss i had the same problem with the mounts. i have the s&p engine mounts like you the stock cheap rubber mounts work but not the energy or the prothane. s&p had no clue what to do, i had 4 sets of motor mounts and only the junk rubber one worked. i took off my frame mounts,welded the holes shut and redrilled them. now it sets in there great. money wasted sending stuff back to summit, mike

#83

TECH Fanatic

Thread Starter

iTrader: (4)

Join Date: Mar 2007

Location: Twin Cities, MN

Posts: 1,062

Likes: 0

Received 0 Likes

on

0 Posts

Thanks for the pics, and the link was very helpful. Just got off the phone with S&P, and found out the plates are meant to be used with 71 Chevelle 307 mounts. Not sure where it said that in their HUGE website, but it is a valuable piece of information to have. The 71 mounts are slotted, and interlocking, and more importantly, they are thinner. It looks like we won't have trouble with the wiper motor until we paint the car and add the coil covers. We will either have to notch the cover, or update the wiper motor to a more modern unit with 5 speed delay. Have seen a kit for that in the $280 to $300 range, so we will keep that in the back of the mind. The thinner mounts will drop the engine a little more, and a fit with the trans will give us the right heigth for the back of the motor. Preliminary measurements show the shifter being about 3/4 to 1 inch to far back even with the offset shifter. Doesn't matter to us, we can move the console, but if it is the case, we will let everyone know what offset to order.

#85

Staging Lane

iTrader: (4)

Join Date: Jan 2007

Location: 54669

Posts: 64

Likes: 0

Received 0 Likes

on

0 Posts

Just chiming in here. I am in roughly the same stage as you are. I used trans-dapt engine mounts and hooker headers. No clearance issues to speak of. I removed complete subrame from car for mock up then raised engine, trans(richmond rod 6 speed) into the car. Connected exhaust, driveshaft steering linkage(rear mount rack and pinion) and other components, then removed all from the car again. Working on frame notch for A/C. For clutch I went with centerforce steel flywheel and dual friction clutch. I had the same clutch setup in car with the sbc and it worked great.

Just my 2 cents

Just my 2 cents

#86

TECH Fanatic

Thread Starter

iTrader: (4)

Join Date: Mar 2007

Location: Twin Cities, MN

Posts: 1,062

Likes: 0

Received 0 Likes

on

0 Posts

Tonights update....

The 307 engine mounts fit much better. We still have to grind an 1/8" in each pedastal, but that is livable. The back of the 307 mounts needed to be ground smooth to work with the S&P brackets. We test fit the motor, and feel a lot better about clearance of the heater hoses and wiper. Wiper will interfere with the fuel rail covers, but we will deal with that during paint and body. Maybe we will do the modern wiper box. Started to try fitting with the trans, but the silly engine levelor with the angle brackets hits the firewall when we move it up to the head. We will either cut it down tomorow, or buy a different levelor. We really don't like this one anyway. We do think that 2.3 inches of forward offset on the shifter would not put it back in the factory location. Looks to be an inch short. Wonder if they meant 3.2 inches? It will work for us, we can place the console wherever we want to. The Rock Valley tank showed up a week early. Pretty stoked about that. Thing is heavy! PST showed up today, but the control arms haven't yet. Maybe next week. We have a lot of yard work to do this fine weekend, so our only goal is to get the motor and trans in, locate the crossmember, and measure for the driveshaft. Have to figure out a good place to go for that in the Twin Cities area.

Just a little off...

More clearance

Linkage is not an issue!

Temporary storage for the night

Stainless tank from Rock Valley

The 307 engine mounts fit much better. We still have to grind an 1/8" in each pedastal, but that is livable. The back of the 307 mounts needed to be ground smooth to work with the S&P brackets. We test fit the motor, and feel a lot better about clearance of the heater hoses and wiper. Wiper will interfere with the fuel rail covers, but we will deal with that during paint and body. Maybe we will do the modern wiper box. Started to try fitting with the trans, but the silly engine levelor with the angle brackets hits the firewall when we move it up to the head. We will either cut it down tomorow, or buy a different levelor. We really don't like this one anyway. We do think that 2.3 inches of forward offset on the shifter would not put it back in the factory location. Looks to be an inch short. Wonder if they meant 3.2 inches? It will work for us, we can place the console wherever we want to. The Rock Valley tank showed up a week early. Pretty stoked about that. Thing is heavy! PST showed up today, but the control arms haven't yet. Maybe next week. We have a lot of yard work to do this fine weekend, so our only goal is to get the motor and trans in, locate the crossmember, and measure for the driveshaft. Have to figure out a good place to go for that in the Twin Cities area.

Just a little off...

More clearance

Linkage is not an issue!

Temporary storage for the night

Stainless tank from Rock Valley

#87

TECH Fanatic

Thread Starter

iTrader: (4)

Join Date: Mar 2007

Location: Twin Cities, MN

Posts: 1,062

Likes: 0

Received 0 Likes

on

0 Posts

Saturday afternoon notes.

We got the motor and trans in and placed the trans cross member. We are not real happy with the McLeod slick shift location. To get our 4* down angle on the trans, we are almost hitting the tunnel with the rubber bumper on top of the trans. We also had to cut the tunnel to clear the whole shifter. It is not in the factory position. Wouldn't matter if it was anyway, as the shift relocater sits higher than the plast ic slider in the console. We are going to have to have a custom leather shift boot made to fit the console. Not happy about that one. Overall, everything went alright. We have a bit of grinding to do on the x-member to make it easier to get in and out for service. We are also going to add small slots to the braket to compensate for variations in replacement mounts. Almost have the motor mounts done, still need to grind a little bit more yet to get a comfortable fit. Overall we are happy with our days progress.

Driver side firewall with engine and trans mounted.

Passenger side (with damaged heater core, oops)

Trans crossmember....

Shifter

Again...

We got the motor and trans in and placed the trans cross member. We are not real happy with the McLeod slick shift location. To get our 4* down angle on the trans, we are almost hitting the tunnel with the rubber bumper on top of the trans. We also had to cut the tunnel to clear the whole shifter. It is not in the factory position. Wouldn't matter if it was anyway, as the shift relocater sits higher than the plast ic slider in the console. We are going to have to have a custom leather shift boot made to fit the console. Not happy about that one. Overall, everything went alright. We have a bit of grinding to do on the x-member to make it easier to get in and out for service. We are also going to add small slots to the braket to compensate for variations in replacement mounts. Almost have the motor mounts done, still need to grind a little bit more yet to get a comfortable fit. Overall we are happy with our days progress.

Driver side firewall with engine and trans mounted.

Passenger side (with damaged heater core, oops)

Trans crossmember....

Shifter

Again...

#89

TECH Fanatic

Thread Starter

iTrader: (4)

Join Date: Mar 2007

Location: Twin Cities, MN

Posts: 1,062

Likes: 0

Received 0 Likes

on

0 Posts

Indy,

Are you using a console? One bummer with the 67 is how SHORT it is. Unlike the 68 and 69 that bubble out around the shifter, the 67 gets shorter as it goes forward, and we are now trying to figure out what car is going to be a good donor for a leather shifter boot. If we mill the plate up to the chrome trim, we can use it as a boot ring, and if we can find something that started at almost the right size, we may still make it look nice. I can see how the slickshift relocator would work for a 68 and 69, but a 67 with a console is *** out of luck. We are happy to finally have the motor in though. It is a shame that when it comes out tomorow, it will be several weeks before it goes back in. A lot of plumbing, cleanup, suspension work to do! We also need to do the gauge conversion harness wiring for the console, cleanup the hack and slash under the dash from the last 40 years of people messing with it, get the clutch master in, run the new brake lines, master, booster and front disk's. Oh, and redo the rear suspension too! The gas tank promises to be fun. Just a million little things to do, and we still have no idea where we are goin gto mount the computer. You have pics of your project posted?

Are you using a console? One bummer with the 67 is how SHORT it is. Unlike the 68 and 69 that bubble out around the shifter, the 67 gets shorter as it goes forward, and we are now trying to figure out what car is going to be a good donor for a leather shifter boot. If we mill the plate up to the chrome trim, we can use it as a boot ring, and if we can find something that started at almost the right size, we may still make it look nice. I can see how the slickshift relocator would work for a 68 and 69, but a 67 with a console is *** out of luck. We are happy to finally have the motor in though. It is a shame that when it comes out tomorow, it will be several weeks before it goes back in. A lot of plumbing, cleanup, suspension work to do! We also need to do the gauge conversion harness wiring for the console, cleanup the hack and slash under the dash from the last 40 years of people messing with it, get the clutch master in, run the new brake lines, master, booster and front disk's. Oh, and redo the rear suspension too! The gas tank promises to be fun. Just a million little things to do, and we still have no idea where we are goin gto mount the computer. You have pics of your project posted?

#91

TECH Fanatic

Thread Starter

iTrader: (4)

Join Date: Mar 2007

Location: Twin Cities, MN

Posts: 1,062

Likes: 0

Received 0 Likes

on

0 Posts

Sorry guys, nothing to report today, drove all over hell and back looking for a pilot bearing puller, finaly found one at Harbor Freight 50 miles from here. Did pick up a few more neat tools along the way, and a couple of SAE and Meteric O-ring kits just because we had to. Yard work all afternoon. Word of advice, you can have a big yard OR a big house, don't ever do both. We spend way to much time looking after trees, grass and gardens, and still have to keep up on the house. Spend your money on garages and pole barns, not living space that you never use!!!!

#92

Launching!

Join Date: Aug 2002

Location: Los Angeles, CA

Posts: 242

Likes: 0

Received 0 Likes

on

0 Posts

We put our crossmember at 3 degrees down and still have room in the tunnel. Also that crossmember looks like it is in the way of where the exhaust is supposed to go, are you going to route the pipes over or under the crossmember?

Tyler

Tyler

#93

TECH Fanatic

Thread Starter

iTrader: (4)

Join Date: Mar 2007

Location: Twin Cities, MN

Posts: 1,062

Likes: 0

Received 0 Likes

on

0 Posts

Tyler,

We are hoping to tuck the pipes over the cross member, and tonight, we are going to cut a piece of 2.5 inch and see what kind of clearance we are looking at. We really want to avoid the problems we had with the old exhaust interfereing with the e-brake cable. We went with 4 degrees down angle as this was the point where the rubber bumper on top of the trans was .125 inch away from the tunnel. We will be reinforcing this location, as this tunnel has been cut up a few times in the last 40 years. Could you post a pic of how you ran your crossmember and exhaust, and how this works in relation to the e-brake cable? Thanks!

We are hoping to tuck the pipes over the cross member, and tonight, we are going to cut a piece of 2.5 inch and see what kind of clearance we are looking at. We really want to avoid the problems we had with the old exhaust interfereing with the e-brake cable. We went with 4 degrees down angle as this was the point where the rubber bumper on top of the trans was .125 inch away from the tunnel. We will be reinforcing this location, as this tunnel has been cut up a few times in the last 40 years. Could you post a pic of how you ran your crossmember and exhaust, and how this works in relation to the e-brake cable? Thanks!

#94

Launching!

Join Date: Aug 2002

Location: Los Angeles, CA

Posts: 242

Likes: 0

Received 0 Likes

on

0 Posts

Here is our crossmember tucked up into the floor. I don't have one I can find right this second with our Tri-Y headers going under it, but the colloectors are 3.5" and don't hang below the frame.

Tyler

Tyler

#95

TECH Fanatic

Thread Starter

iTrader: (4)

Join Date: Mar 2007

Location: Twin Cities, MN

Posts: 1,062

Likes: 0

Received 0 Likes

on

0 Posts

Made a few quick calls this afternoon:

For the more modern wiper motor with delay, DSE sells tham for $299 with matching ****. This unit only sticks out 2.75 inches from the firewall!!!!! You need a seperate pump motor for washy fluid.

Called Mark at S&P, there shouldn't be a rubber bumper on top of our trans, this would explain why no-one has ever mentioned it. We will keep the 4.5degrees however, since this will work just fine. Must have been added. As a by note, the crossmember from the donor was attached with a very work mount, thought that happened in shipping...

Looks like our motor mount pedastals may have been messed with in the last 40 years as well. We may just order new ones, they cost $35 at Ricks.

As for the console not fitting, no-one has done a 67 with console at S&P, so they didn't know it wouldn't fit. 2.3 is still what they recomend for the 68-69, and the height is fine for those HUGE consoles. Looks like we are going to be doing a custom boot arrangment for the 67, as we don't want to go to a 68 style console.

Took a real quick look, and a 2.25 or 2.5 inch exhaust will easily clear the floor, trans and tuck in over the crossmember. Custom bend only here though.

For the more modern wiper motor with delay, DSE sells tham for $299 with matching ****. This unit only sticks out 2.75 inches from the firewall!!!!! You need a seperate pump motor for washy fluid.

Called Mark at S&P, there shouldn't be a rubber bumper on top of our trans, this would explain why no-one has ever mentioned it. We will keep the 4.5degrees however, since this will work just fine. Must have been added. As a by note, the crossmember from the donor was attached with a very work mount, thought that happened in shipping...

Looks like our motor mount pedastals may have been messed with in the last 40 years as well. We may just order new ones, they cost $35 at Ricks.

As for the console not fitting, no-one has done a 67 with console at S&P, so they didn't know it wouldn't fit. 2.3 is still what they recomend for the 68-69, and the height is fine for those HUGE consoles. Looks like we are going to be doing a custom boot arrangment for the 67, as we don't want to go to a 68 style console.

Took a real quick look, and a 2.25 or 2.5 inch exhaust will easily clear the floor, trans and tuck in over the crossmember. Custom bend only here though.

#96

TECH Enthusiast

iTrader: (3)

Originally Posted by 67rsss

Yard work all afternoon. Word of advice, you can have a big yard OR a big house, don't ever do both. We spend way to much time looking after trees, grass and gardens, and still have to keep up on the house. Spend your money on garages and pole barns, not living space that you never use!!!!

I feel your pain. I only have .2 acres w/3600sq ft and i'll be damned if it doesn't eat a whole day during spring and fall, and i've lost a lot of days to working on the yard when i coulda been working on the truck.

it would almost be a shame to cover up the stainless, but ... i took my aluminum tank to a shop and had them squirt it with Line-X - cost me $60, and looks great. It's not like you need to worry about the elements, but just tossing an idea out there. really enjoying your build thread!

#97

TECH Fanatic

Thread Starter

iTrader: (4)

Join Date: Mar 2007

Location: Twin Cities, MN

Posts: 1,062

Likes: 0

Received 0 Likes

on

0 Posts

Thanks Shifty' it has been an experience so far! There are days I wish we only had .2 Acres!!!! We maintain a little over 2 with 5 gardens, and a lot of trees (apple trees are NOT your friend!). Really can eat up the weekend.

#98

TECH Fanatic

Thread Starter

iTrader: (4)

Join Date: Mar 2007

Location: Twin Cities, MN

Posts: 1,062

Likes: 0

Received 0 Likes

on

0 Posts

****! Discovered something horrible. We went to loosen the motor mount pedastals, and discovered that the bolts were on nuts inside the crossmember. Just barely. All the nuts are now IN the crossmember. What is the best way to get them out, and how the hell do we get them back on? Didn't expect that one!!!!

#99

TECH Resident

iTrader: (2)

Join Date: Jun 2006

Location: Roswell, GA

Posts: 802

Likes: 0

Received 0 Likes

on

0 Posts

Have fun fishing with a magnetic pickup tool... I don't know any other way than pulling the subframe and turning it on its side (might be an option for you since the sheetmetal is off already?). Mine was missing a couple of bolts, and the rest were loose. I managed to get nuts on them by taping the nut into a box end wrench and feeding it up through the lower control arm slots. I may have had to tape two wrenches together to get more length for some of them. It would have been a lot easier with the LCAs removed.

#100

TECH Fanatic

Thread Starter

iTrader: (4)

Join Date: Mar 2007

Location: Twin Cities, MN

Posts: 1,062

Likes: 0

Received 0 Likes

on

0 Posts

Rodder, as for fishing them out, it will suck, but we will do it when the A-arms are off. For the nuts, I found a great solution. I have a sample set of 6 Atlas SpinTite AELS-518-150 coming in tomorrow. Fix this problem forever. I wanted the AESS-518-150-875 studs, but there is 100k minimum order, 10 week lead. Nuts work fine for free!!!! Sometimes it is good to be an Engineer... Check this stuff out....

http://www.pemnet.com/fastening_products/pdf/aedata.pdf

Hard to get, but a hobbyist can get a lot of this stuff through McMaster, Grainger, etc.

http://www.pemnet.com/fastening_products/pdf/aedata.pdf

Hard to get, but a hobbyist can get a lot of this stuff through McMaster, Grainger, etc.