nissan 240sx (S14) with Modded GTO pan (tons of pics)

#42

TECH Senior Member

iTrader: (8)

Join Date: Jan 2007

Location: Here and sometimes there too.

Posts: 13,845

Likes: 0

Received 0 Likes

on

0 Posts

What does NVH stand for? I know it's about vibration due to the motor plate but...?

Learned alot from this thread. Just bought a 95 240 and plan on doing the same stuff that your doing. Will start a thread when I start the project so.... Subscribing to this one!

Learned alot from this thread. Just bought a 95 240 and plan on doing the same stuff that your doing. Will start a thread when I start the project so.... Subscribing to this one!

#43

Well here is the cam that I cam up with and the engine specs all nice and neat thanks to the "Quick and Dirty Cam/SCR/DCR Calculator Spreadsheet

Modified and Simplified by PianoProdigy" that I found somewhere here on LS1tech.com

0.006 0.050 0.200

Intake Duration - ID (first number) 293 244 165

Exhaust Duration - ED (second number) 300 252 169

Lobe Center Angle - LCA (also known as LSA) 109 109 109

Intake Centerline - ICL (LSA - degrees of advance e.g. 114+2 = 112) 110 110 110

Intake Valve opens - IVO 36.5 12 -27.5 BTDC (- indicates ATDC)

Intake Valve closes - IVC 76.5 52 12.5 ABDC

Exhaust Valve Opens - EVO 78 54 12.5 BBDC

Exhaust Valve Closes - EVC 42 18 -23.5 ATDC (- indicates BTDC)

Exhaust Centerline - ECL 108 108 108

Overlap 78.5 30 -51 degrees

Bore 4.125

ST = Stroke 3.622

RL = Rod Length 6.2

Number of cylinders 8

Deck Height (how much pistons come out of the hole) -0.018

Piston Dome or Dish (- for a dome + for a dish) 2

Compressed Head gasket thickness 0.051 cometeic (stock is 0.054)

Cylinder Head Chamber Volume 62.5 (hopefully with the .045 mill)

Static Compression Ratio 12.06 :1

Dynamic Compresion Ratio 8.60 :1

Rod to Stroke Ratio 1.71 :1

Bore to Stroke Ratio 1.14 :1

The plan was to build a cam and motor that would make a ton of horsepower, but have less of a tire shredding tendency to help with traction out of the corners. Redline will most likely be 7500 rpm. I fear giong any higher because of the massive (read heavy) 2.200 stainless intake valves, that I have to use due to budget constraints, in the LS7 heads. I'm also using a milder lobe then most: the older comp "Xtreme RPM for LS1 Hi lift" Which will produce 0.630" lift on both intake and exhaust with the stock LS7 1.8 rockers.

I'm guessing that this engine will peak just under 6800 rpm without much fall off to redline. I'm using a stock but port-matched LS7 intake, and custom headers. The oversquare engine comes out to 392 ci. I think that the 30 degrees of overlap should be just streetable enough. It's the late IVC that I'm hoping will curb the dynamic compression ratio enough for the hi compression pump gas combo, and simultaneously help push the peak power rpm up above the 6300 wall that so many other LS1 engines seem to sit at.

This cam is all still theoretical; the heads and intake are not. So if anyone has any knowledgeable input/ideas to provide, I'm all ears.

Modified and Simplified by PianoProdigy" that I found somewhere here on LS1tech.com

0.006 0.050 0.200

Intake Duration - ID (first number) 293 244 165

Exhaust Duration - ED (second number) 300 252 169

Lobe Center Angle - LCA (also known as LSA) 109 109 109

Intake Centerline - ICL (LSA - degrees of advance e.g. 114+2 = 112) 110 110 110

Intake Valve opens - IVO 36.5 12 -27.5 BTDC (- indicates ATDC)

Intake Valve closes - IVC 76.5 52 12.5 ABDC

Exhaust Valve Opens - EVO 78 54 12.5 BBDC

Exhaust Valve Closes - EVC 42 18 -23.5 ATDC (- indicates BTDC)

Exhaust Centerline - ECL 108 108 108

Overlap 78.5 30 -51 degrees

Bore 4.125

ST = Stroke 3.622

RL = Rod Length 6.2

Number of cylinders 8

Deck Height (how much pistons come out of the hole) -0.018

Piston Dome or Dish (- for a dome + for a dish) 2

Compressed Head gasket thickness 0.051 cometeic (stock is 0.054)

Cylinder Head Chamber Volume 62.5 (hopefully with the .045 mill)

Static Compression Ratio 12.06 :1

Dynamic Compresion Ratio 8.60 :1

Rod to Stroke Ratio 1.71 :1

Bore to Stroke Ratio 1.14 :1

The plan was to build a cam and motor that would make a ton of horsepower, but have less of a tire shredding tendency to help with traction out of the corners. Redline will most likely be 7500 rpm. I fear giong any higher because of the massive (read heavy) 2.200 stainless intake valves, that I have to use due to budget constraints, in the LS7 heads. I'm also using a milder lobe then most: the older comp "Xtreme RPM for LS1 Hi lift" Which will produce 0.630" lift on both intake and exhaust with the stock LS7 1.8 rockers.

I'm guessing that this engine will peak just under 6800 rpm without much fall off to redline. I'm using a stock but port-matched LS7 intake, and custom headers. The oversquare engine comes out to 392 ci. I think that the 30 degrees of overlap should be just streetable enough. It's the late IVC that I'm hoping will curb the dynamic compression ratio enough for the hi compression pump gas combo, and simultaneously help push the peak power rpm up above the 6300 wall that so many other LS1 engines seem to sit at.

This cam is all still theoretical; the heads and intake are not. So if anyone has any knowledgeable input/ideas to provide, I'm all ears.

#44

Vibration

Harshness

There are teams of engineers at the big auto manufacturers for whom this is their entire world. Liquid filled suspension bushings and engine mounts, quieter accessory belt tensioners, etc. With no rubber between you and 8 angry (though well balanced) cylinders there's gunna be a little jiggle in yo jelly.

#45

I've heard two different, very reputable LSX engine builders mention these lobes in passing, and finally looked them up:

Comp Cams : XTREME MARINE™ HYDRAULIC ROLLERS - HIGH LIFT

These have the same ramp designs as the lower lift Xtreme Marine

™ designs but have higher lift to enhance power

output with cylinder head and engine modifications.

LOBE RATED DURATION IN LOBE TAPPET LIFT @ THEORETICAL VALVE LIFT

NUMBER DURATION DEGREES LIFT TDC @ “0” LASH ROCKER ARM RATIO

CAMSHAFT TYPE

.050 .200 106° 110° 1.5 1.6 1.7

3473 290 234 152 .360 .081 .068 .540 .576 .612

3474 292 236 154 .360 .085 .071 .540 .576 .612

3410 294 238 154 .350 .088 .075 .525 .560 .595

3475 294 238 156 .360 .088 .075 .540 .576 .612

3376 296 240 157 .360 .092 .078 .540 .576 .612

3411 300 244 159 .350 .099 .085 .525 .560 .595

3370 304 248 167 .380 .107 .092 .570 .608 .646

3377 306 250 166 .360 .111 .096 .540 .576 .612

3371 308 254 171 .380 .119 .103 .570 .608 .646

3372 314 258 175 .380 .126 .111 .570 .608 .646

3373 318 262 179 .380 .134 .118 .570 .608 .646

3374 322 266 182 .380 .142 .126 .570 .608 .646

3375 326 270 186 .380 .149 .134 .570 .608 .646

3447 330 274 190 .380 .157 .141 .570 .608 .646

also from the 2007 comp cams catalogue it says:

"These profiles use the same design techniques of the baseline Xtreme Energy

™ Hydraulic Rollers but have been optimized

to increase power and durability when run at steady rpm for extended periods of time. Specifically designed

for big blocks with heavier valve train components."

I'm only interested in the intake at 244 @ .05", but its advertised duration (or duration at .006" lift) is 300, vs the 293 of the origianl lobes I was going to use. These lobes sound great, they are designed for big *** heavy big block valves, which is exactly what I'm running with my 2.200" stainless intake valves. I don't need these lasier lobes on the exhaust because they are a more standard (and lighter) 1.600". The larger advertised duration (at the same .500" lift) will also allow me to run a little more advance and still have a lower DCR. At 8.6 I was pushing it a bit before.

I'll call comps help line before making any final decisions, but here's some food for thought.

Who would have thought, Marine Lobes in a road racer?!

Comp Cams : XTREME MARINE™ HYDRAULIC ROLLERS - HIGH LIFT

These have the same ramp designs as the lower lift Xtreme Marine

™ designs but have higher lift to enhance power

output with cylinder head and engine modifications.

LOBE RATED DURATION IN LOBE TAPPET LIFT @ THEORETICAL VALVE LIFT

NUMBER DURATION DEGREES LIFT TDC @ “0” LASH ROCKER ARM RATIO

CAMSHAFT TYPE

.050 .200 106° 110° 1.5 1.6 1.7

3473 290 234 152 .360 .081 .068 .540 .576 .612

3474 292 236 154 .360 .085 .071 .540 .576 .612

3410 294 238 154 .350 .088 .075 .525 .560 .595

3475 294 238 156 .360 .088 .075 .540 .576 .612

3376 296 240 157 .360 .092 .078 .540 .576 .612

3411 300 244 159 .350 .099 .085 .525 .560 .595

3370 304 248 167 .380 .107 .092 .570 .608 .646

3377 306 250 166 .360 .111 .096 .540 .576 .612

3371 308 254 171 .380 .119 .103 .570 .608 .646

3372 314 258 175 .380 .126 .111 .570 .608 .646

3373 318 262 179 .380 .134 .118 .570 .608 .646

3374 322 266 182 .380 .142 .126 .570 .608 .646

3375 326 270 186 .380 .149 .134 .570 .608 .646

3447 330 274 190 .380 .157 .141 .570 .608 .646

also from the 2007 comp cams catalogue it says:

"These profiles use the same design techniques of the baseline Xtreme Energy

™ Hydraulic Rollers but have been optimized

to increase power and durability when run at steady rpm for extended periods of time. Specifically designed

for big blocks with heavier valve train components."

I'm only interested in the intake at 244 @ .05", but its advertised duration (or duration at .006" lift) is 300, vs the 293 of the origianl lobes I was going to use. These lobes sound great, they are designed for big *** heavy big block valves, which is exactly what I'm running with my 2.200" stainless intake valves. I don't need these lasier lobes on the exhaust because they are a more standard (and lighter) 1.600". The larger advertised duration (at the same .500" lift) will also allow me to run a little more advance and still have a lower DCR. At 8.6 I was pushing it a bit before.

I'll call comps help line before making any final decisions, but here's some food for thought.

Who would have thought, Marine Lobes in a road racer?!

#46

TECH Resident

iTrader: (1)

Join Date: Nov 2004

Location: Spring / Sealy, TX

Posts: 909

Likes: 0

Received 0 Likes

on

0 Posts

extremely ignorant question here, but am i reading this right?

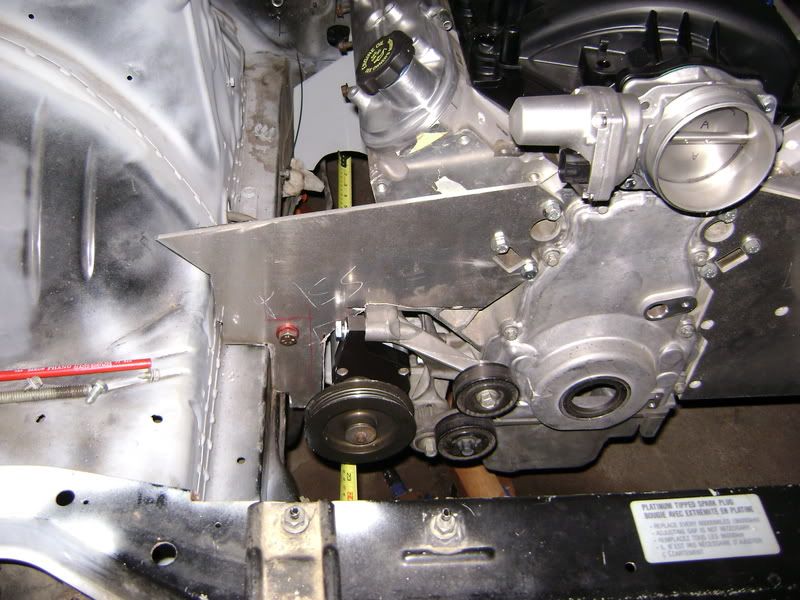

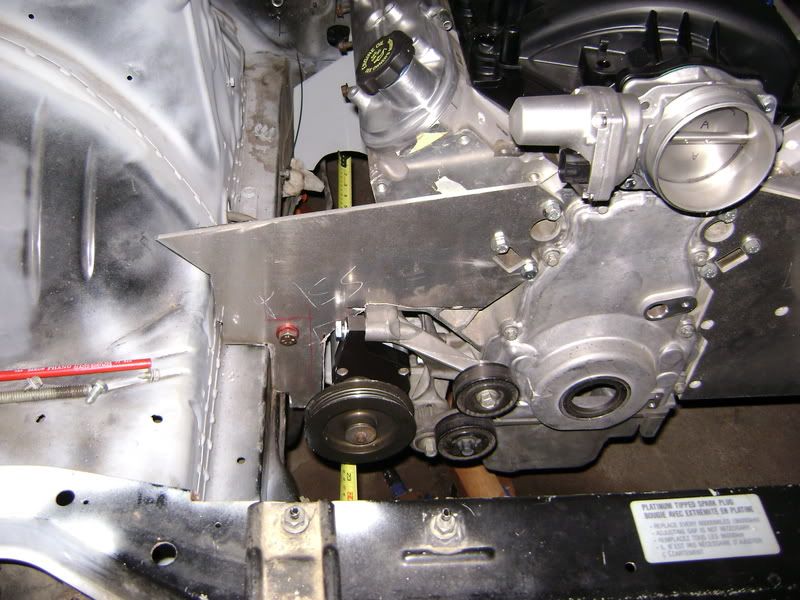

those two alum plates, and that tranny mount hold your motor in?

does that work okay?

you've only got what looks to be 3 8x1.25 bolts holding the front of hte mtoro on attatched to the front cover, has that been done before?

this is pure ignorance speaking.

those two alum plates, and that tranny mount hold your motor in?

does that work okay?

you've only got what looks to be 3 8x1.25 bolts holding the front of hte mtoro on attatched to the front cover, has that been done before?

this is pure ignorance speaking.

#47

In addition to the trans mount and front Al motorplates, there is also a steel mid plate that you may have trouble seeing sandwiched between the bellhousing and block, that will have at least two bolts per side. Also, those old pictures show only one or two bolts per side on the motor plates as I was just positioning, not finishing. Before completion there will be three or four bolts per side.

I'm not doing anything new by any stretch of the imagination. This is pure old skool drag tech from the 1950's. My motor plate came from madman racing at thunder racing, which normally only uses two bolts per side in the camaro kits. There have been multiple 1200+hp door slammer camaros running these with no issues and only two bolts per side. Some people even consider the midplates optional!

I'm not doing anything new by any stretch of the imagination. This is pure old skool drag tech from the 1950's. My motor plate came from madman racing at thunder racing, which normally only uses two bolts per side in the camaro kits. There have been multiple 1200+hp door slammer camaros running these with no issues and only two bolts per side. Some people even consider the midplates optional!

#48

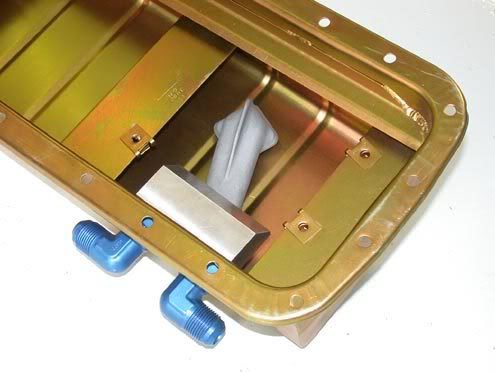

So I was reading my own 1st post and re-realized that the LS2 pan is a full 1.25 inches shallower than my GTO pan. Why can't a GTO pan be more shallow? I already have a 3L accusump sitting around. What if I take just enough off of the GTO pan to make my crossmember the lowest part in the engine bay again (would probably be around 0.75"). Modify the stock GTO oil pick up accordingly, keep the GTO baffles, and plumb in the accusump for insurance. Sure would be a lot more simple and inexpensive compared to a dry sump.

Mike (and other accusump users), how often do you hear your accusump discharging? Do you think it has ever discharged its full volume? How comfortable would you feel with a modified/shallow sump+accusump?

Mike (and other accusump users), how often do you hear your accusump discharging? Do you think it has ever discharged its full volume? How comfortable would you feel with a modified/shallow sump+accusump?

#49

TECH Resident

iTrader: (1)

Join Date: Nov 2004

Location: Spring / Sealy, TX

Posts: 909

Likes: 0

Received 0 Likes

on

0 Posts

those motor plates are kinda cool, i've honestly never seen that before, thats pretty cool.

honestly i haven't ran my car yet with accusump. i just know i've lost two motors due to oiling issues and i'm not losing a 3rd.

ls2 gto pan is different than the ls1 gto pan?

i've skimmed very lightly thru this thread a couple times but now that im actually looooking at it, i really like what you've done so far.

that crossmember modification is very very very nice. might have to steal your idea for next year on that one

honestly i haven't ran my car yet with accusump. i just know i've lost two motors due to oiling issues and i'm not losing a 3rd.

ls2 gto pan is different than the ls1 gto pan?

i've skimmed very lightly thru this thread a couple times but now that im actually looooking at it, i really like what you've done so far.

that crossmember modification is very very very nice. might have to steal your idea for next year on that one

Last edited by mikespeed95; 12-08-2007 at 04:35 PM.

#51

The mopar guys use these mounted directly to the lateral wall of their sumps. The idea being: swing to the back on a drag launch, and to the front at the end of the 1320 when serious breaking is needed to slow back down.

http://i69.photobucket.com/albums/i7...a69e0759-1.jpg

http://i69.photobucket.com/albums/i7...69e0759872.jpg

But drag racing is a secondary goal of this project. Road racing is what I really dream about.

So here's my big brilliant idea...

What if I mounted this pick up to the front wall, in the center of my sump?!?!?!

Last edited by GIGAPUNK; 12-08-2007 at 05:32 PM.

#52

TECH Resident

iTrader: (1)

Join Date: Nov 2004

Location: Spring / Sealy, TX

Posts: 909

Likes: 0

Received 0 Likes

on

0 Posts

hey dude, check out this thread, https://ls1tech.com/forums/road-racing/823691-dry-sump-accusump.html, and post the exact post you just posted there. theres already a discussino of swining pickups, dry sumps, accusumps etc in there that has some people that seem to know what they're talking about already.

#54

a bit.. but it's about to come to a screaming halt for the next three months.

I have to move to Trenton NJ for a surgical clerkship, and I'm going to have to take call, overnight every fourth night. Then I'll have to move again.

Went over to my old stomping grounds TTP in Passaic NJ and media blasted my valve covers. Worked out great. Then I used a dremel with a 80 grit roll to remove the casting marks. I think I'm going to try and polish 'em.

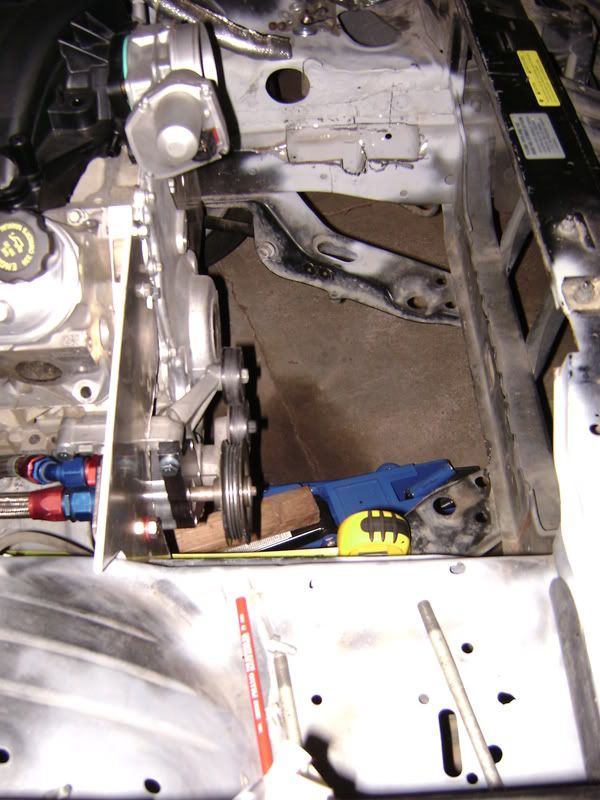

Took these pics for another thread to show how this bad boy is mid engine:

If you look close you can see the make-shift pendulum line that goes to the center of my front wheel. The car is level. And I think it's safe to say that this is a mid-engine car!

[IMG]http://i69.photobucket.com/albums/i70/SicBastard/0112081325.jpg[/IMG

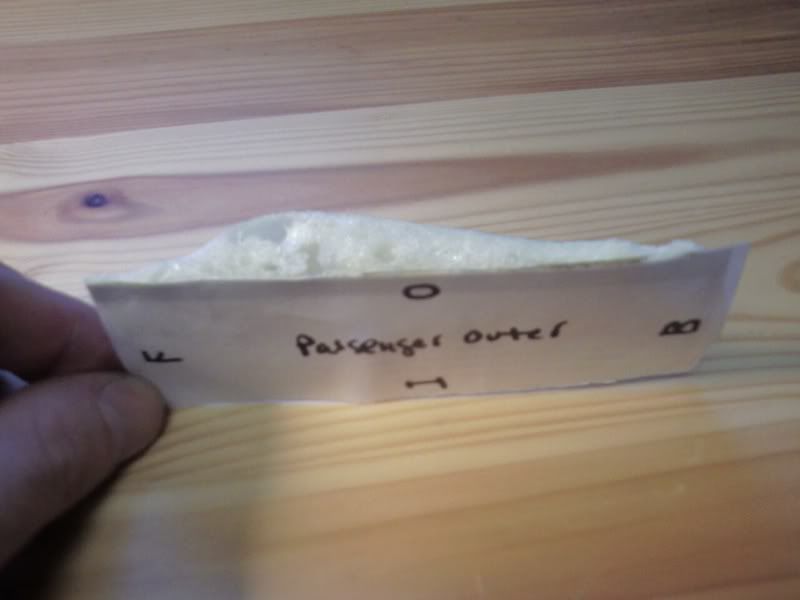

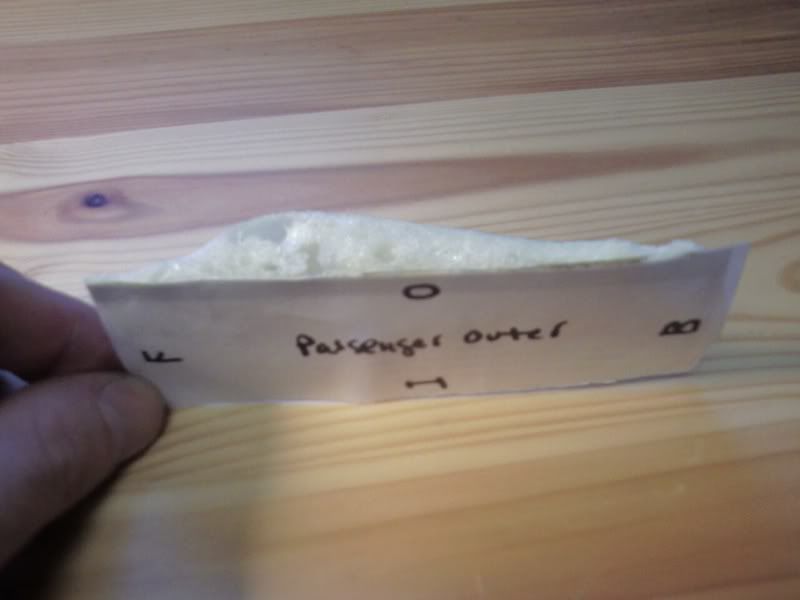

I've also been working hard on the seat mounts, because A: I want them low, and B: I want the seats in their final position before I weld in the harness bar.

First I removed the mini pilar that holds up the outer/rear stock seat mounting point, and then masked off everything. In order to make a template for the odd shaped floor, I bolted down my OMP seat mounts and injected some insulating foam. Cardboard templates may have been easier, but it was a fun experiment, and it worked out perfectly.

Notice the heater sitting in the car to get the foam to cure here in frozen NJ!

I have to move to Trenton NJ for a surgical clerkship, and I'm going to have to take call, overnight every fourth night. Then I'll have to move again.

Went over to my old stomping grounds TTP in Passaic NJ and media blasted my valve covers. Worked out great. Then I used a dremel with a 80 grit roll to remove the casting marks. I think I'm going to try and polish 'em.

Took these pics for another thread to show how this bad boy is mid engine:

If you look close you can see the make-shift pendulum line that goes to the center of my front wheel. The car is level. And I think it's safe to say that this is a mid-engine car!

[IMG]http://i69.photobucket.com/albums/i70/SicBastard/0112081325.jpg[/IMG

I've also been working hard on the seat mounts, because A: I want them low, and B: I want the seats in their final position before I weld in the harness bar.

First I removed the mini pilar that holds up the outer/rear stock seat mounting point, and then masked off everything. In order to make a template for the odd shaped floor, I bolted down my OMP seat mounts and injected some insulating foam. Cardboard templates may have been easier, but it was a fun experiment, and it worked out perfectly.

Notice the heater sitting in the car to get the foam to cure here in frozen NJ!

Last edited by GIGAPUNK; 01-12-2008 at 05:19 PM.

#55

The LS7 heads have forced me to go big bore. I knew this when I bought them, but I naively believed the GMPP catalog that said that they will work with a 4.065 bore which ment I had the option of using a $1400 brand new L92 block. According to my head builder, who I believe over the catalog, 4.100" is closer to the truth. Incase you didn't already know the stock bores are:

LS2 4.000"

LS3/L92 4.065"

LS7 4.125"

Road race engines have been succesfully built utilizing LS7 heads on .035" over L92 blocks (yields a 4.100". But of course you're not left with much cylinder wall left, and if anything goes wrong, you can't overbore, you have to sleeve. Also, this is all presuming that you're starting with a block with almost no core-shift, good luck finding that as the L92s are notorious for having odd sleeve placement/core-shift.

So I've been looking into the other big bore options out there. Since a C5R or Warhawk block is out of my price range, that leaves me with the

1)stock LS7 $2400 new (maybe $1800 used)

2)Katech sleeved "budget LS2" something like $4000 (doesn't seem very budget to me).

3)darton MID sleeve (actually strongest on a LS1 block) but you're looking at $1000 for the machine work, another $1500 for the sleeves themselves, and then of course you need a block. So lets say you get a good deal on a used LS1 for $500, once you're done with shipping, we're talking at lest $3100

4)Iron LSX: can be had for $1800, but it will still require stress relieving and boring (it comes stock at something like 3.900" bore). Oh and did I mention that it's like 120lbs heavier than anything mentioned so far.

5) LS2 block with Darton Dry liners. What I'm leaning towards right now.

Require less machine work than the MID sleeves, and cost a bunch less for the liners themselves. Unlike the MID sleeves they do not require evans coolant and pump (a hidden $600 of the MIDs). You can get the machine work and the liners together for $1500. I can probably get a used LS2 block for south of $750, and you're looking at a total of $2250. Compared to the stock LS7: the darton dry are made of a much more ductile/stronger steel, can be bored out to 4.190 vs 4.155, and can safely support the pistons with longer stroke cranks, because the sleeve is deeper than even the LS7 (which has the deepest sleeves of the stock blocks).

LS2 4.000"

LS3/L92 4.065"

LS7 4.125"

Road race engines have been succesfully built utilizing LS7 heads on .035" over L92 blocks (yields a 4.100". But of course you're not left with much cylinder wall left, and if anything goes wrong, you can't overbore, you have to sleeve. Also, this is all presuming that you're starting with a block with almost no core-shift, good luck finding that as the L92s are notorious for having odd sleeve placement/core-shift.

So I've been looking into the other big bore options out there. Since a C5R or Warhawk block is out of my price range, that leaves me with the

1)stock LS7 $2400 new (maybe $1800 used)

2)Katech sleeved "budget LS2" something like $4000 (doesn't seem very budget to me).

3)darton MID sleeve (actually strongest on a LS1 block) but you're looking at $1000 for the machine work, another $1500 for the sleeves themselves, and then of course you need a block. So lets say you get a good deal on a used LS1 for $500, once you're done with shipping, we're talking at lest $3100

4)Iron LSX: can be had for $1800, but it will still require stress relieving and boring (it comes stock at something like 3.900" bore). Oh and did I mention that it's like 120lbs heavier than anything mentioned so far.

5) LS2 block with Darton Dry liners. What I'm leaning towards right now.

Require less machine work than the MID sleeves, and cost a bunch less for the liners themselves. Unlike the MID sleeves they do not require evans coolant and pump (a hidden $600 of the MIDs). You can get the machine work and the liners together for $1500. I can probably get a used LS2 block for south of $750, and you're looking at a total of $2250. Compared to the stock LS7: the darton dry are made of a much more ductile/stronger steel, can be bored out to 4.190 vs 4.155, and can safely support the pistons with longer stroke cranks, because the sleeve is deeper than even the LS7 (which has the deepest sleeves of the stock blocks).

#57

I got asked which skyline crossmember I thought was best for the swap. Here's my reply:

Just use the stock x-member.

Compared to the 240sx the skyline x-members have the pedestals for the engine mounts positioned a little bit more forward. I don't think that it is worth the time, money, or trouble to procure one. And you have to modify them the same in the middle to clear the sump.

Just use the stock x-member.

If you want to have pedestals that are further forward (helps to match up to the stock mounting points on the LS1 block), cut off the stock pedestals (like I did, refer to pic on first page and you'll notice no pedestals) and weld up some new ones exactly where you want them.

I can't comment on the s13, but on the s14 crossmember, the engine mount pedestals are just a cheezy piece of sheet metal that it tacked ontop of the structural x-member. Hack that **** off, and grind smoothe!

Just use the stock x-member.

Compared to the 240sx the skyline x-members have the pedestals for the engine mounts positioned a little bit more forward. I don't think that it is worth the time, money, or trouble to procure one. And you have to modify them the same in the middle to clear the sump.

Just use the stock x-member.

If you want to have pedestals that are further forward (helps to match up to the stock mounting points on the LS1 block), cut off the stock pedestals (like I did, refer to pic on first page and you'll notice no pedestals) and weld up some new ones exactly where you want them.

I can't comment on the s13, but on the s14 crossmember, the engine mount pedestals are just a cheezy piece of sheet metal that it tacked ontop of the structural x-member. Hack that **** off, and grind smoothe!

Last edited by GIGAPUNK; 02-11-2008 at 07:54 AM.

#58

So I finally scored one of these on ebay the other week. (just the dry sump set up)

They were originally spec'd out by lingenfelter when they built the spec LS1 motors for the ASA race series.

I think that it's the third one that I've bid on over the last three years. But this one I won! It is a single stage scavenge only pump that was built by razor. Razor is a little unique because their pumps internal gears have fewer teath and therefore (supposedly) flow more oil for a given section length. But another neat feature is that they make crazy deep section lengths. This single stage is a whopping 1.825". Trust me that's big in the world of dry sump pumps. I wrote to razor about a rebuild on the pump and about the possiblilty of adding a few stages to it to increase the crankcase vacuum.

This was their reply:

Dru,

The price to convert your single stage pump to a two stage scavenge pump is $350. The price for a three stage is $479.

This is figuring new shafts, studs, fittings, pumps bodies, and gears for the new sections.

Razor

At first I thought that I would just go nuts and add two more monster 1.825" scavenge stages. At that point I would probably be pulling close to a full 15 psi of vacuum. With that much sucking going on bad things can start to happen to wrist pins (because there isn't any oil suspended in the crankcase air), so then you have to add piston oil squirters. It just kind of snow *****. Luckily I don't have to worry about engine mounts being in the way. But I do have to worry about the lines hitting the starter If I add too many stages.

I'm going to convert my gto oil pan to be more shallow and add a pick up or two or three. Then I'm probably going to mount a big fat oil tank in the trunk. So the beautiful, all steel, moroso LS1 dry sump pan that came with my kit is for sale here on ebay. If you're going to modify an LS1 oil pan, this is the one to have. Trust me, you don't want to be welding on cast Aluminum!

http://cgi.ebay.com/ebaymotors/ws/eB...m=130217297961

In other news I'm getting ready to move for the 4th time in 3 months come June, and I've been futzing with installing such mundane things as working locks and windows, just in case the car has to sit in storage for any length of time this summer.

That's all...

Peace and Tire Smoke.

They were originally spec'd out by lingenfelter when they built the spec LS1 motors for the ASA race series.

I think that it's the third one that I've bid on over the last three years. But this one I won! It is a single stage scavenge only pump that was built by razor. Razor is a little unique because their pumps internal gears have fewer teath and therefore (supposedly) flow more oil for a given section length. But another neat feature is that they make crazy deep section lengths. This single stage is a whopping 1.825". Trust me that's big in the world of dry sump pumps. I wrote to razor about a rebuild on the pump and about the possiblilty of adding a few stages to it to increase the crankcase vacuum.

This was their reply:

Dru,

The price to convert your single stage pump to a two stage scavenge pump is $350. The price for a three stage is $479.

This is figuring new shafts, studs, fittings, pumps bodies, and gears for the new sections.

Razor

At first I thought that I would just go nuts and add two more monster 1.825" scavenge stages. At that point I would probably be pulling close to a full 15 psi of vacuum. With that much sucking going on bad things can start to happen to wrist pins (because there isn't any oil suspended in the crankcase air), so then you have to add piston oil squirters. It just kind of snow *****. Luckily I don't have to worry about engine mounts being in the way. But I do have to worry about the lines hitting the starter If I add too many stages.

I'm going to convert my gto oil pan to be more shallow and add a pick up or two or three. Then I'm probably going to mount a big fat oil tank in the trunk. So the beautiful, all steel, moroso LS1 dry sump pan that came with my kit is for sale here on ebay. If you're going to modify an LS1 oil pan, this is the one to have. Trust me, you don't want to be welding on cast Aluminum!

http://cgi.ebay.com/ebaymotors/ws/eB...m=130217297961

In other news I'm getting ready to move for the 4th time in 3 months come June, and I've been futzing with installing such mundane things as working locks and windows, just in case the car has to sit in storage for any length of time this summer.

That's all...

Peace and Tire Smoke.

#59

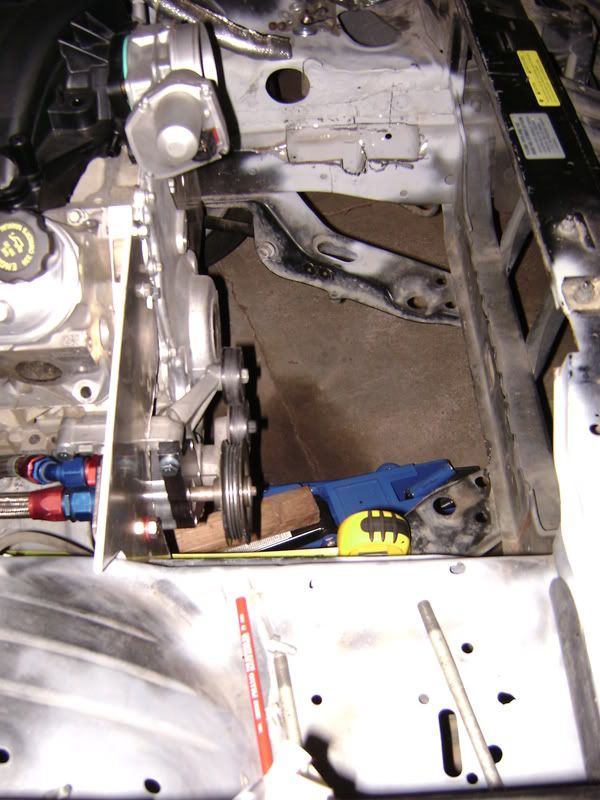

So I got the Razor pump mounted, just so I could check the clearance that I'd be left with if I converted it to a 3 stage. I'll clean up the motor plate/mount later on a mill. There should be zero issue with the starter clearance as I mistakenly feared before.

you can see the passenger side mid-plate (sandwiched between the block and bellhousing) pretty well in these next two:

I finally got around to trying to space out the 05 GTO driver side ex manifold to see if it would clear the steering knuckle/universal joint. Almost... There is a lot of grinding that could be done on the inside of the manifold though, so it still may be possible for anyone looking for a stock alternative. The passenger side will not work from the GTO because it sticks out too far laterally and hits the "frame".

Just for fun before I give them back to TTP (thanx for the loan)!

Twin Turbo anyone?

you can see the passenger side mid-plate (sandwiched between the block and bellhousing) pretty well in these next two:

I finally got around to trying to space out the 05 GTO driver side ex manifold to see if it would clear the steering knuckle/universal joint. Almost... There is a lot of grinding that could be done on the inside of the manifold though, so it still may be possible for anyone looking for a stock alternative. The passenger side will not work from the GTO because it sticks out too far laterally and hits the "frame".

Just for fun before I give them back to TTP (thanx for the loan)!

Twin Turbo anyone?

Last edited by GIGAPUNK; 04-28-2008 at 07:48 AM.

#60

I found these pics comparing the stock KA 5-speed to the t56 6-speed that's bolted up to the LS1 over on nico forum, as posted by "574-240sx"

You can also see from the pics why you end up having to bash the hell out of your trans tunnel to slide the t56 back up in there.

The stock one is LONGER!!! I never thought it about, but this is why the Hinson kit comes with a steeda long reach shifter, because with their kit the shifter ends up sitting FORWARD of the stock position.

Not to toot my own horn, but now I feel even more special

You can also see from the pics why you end up having to bash the hell out of your trans tunnel to slide the t56 back up in there.

The stock one is LONGER!!! I never thought it about, but this is why the Hinson kit comes with a steeda long reach shifter, because with their kit the shifter ends up sitting FORWARD of the stock position.

Not to toot my own horn, but now I feel even more special