nissan 240sx (S14) with Modded GTO pan (tons of pics)

#162

#163

Thanx Guys! A bit more Auto-Nerdery:

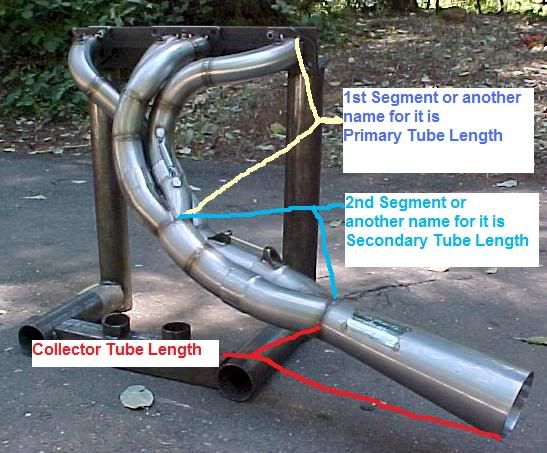

I purchased pipemax software last year to aid the header design, and have been very pleased with it. But I am having some trouble figuring out what lengths to use initially on a hybrid tri-y design, as it's not very common (probably because it makes the headers massive and requires a ton of fab) and not included in the software.

Normally a try-y header is tuned to have the first collector at the very short 3rd reflected value usually about 15" from the ex. valve. It would be very tough to get the collectors that close and I'd rather use the further 2nd reflected value about 29" from the ex valve, this set up is sometimes called a hybrid try-y because the try-y collectors start where a traditional 4-1 would.

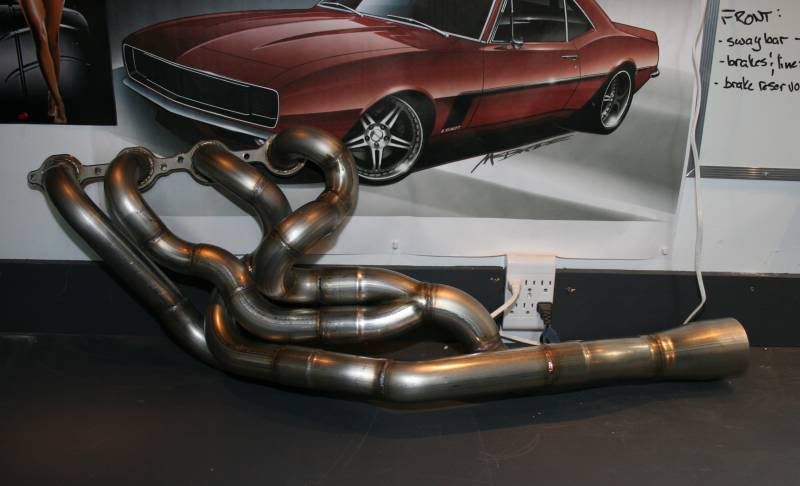

Except for the LS7 header with the pic of the 67 camaro in the background the other pics are of honda headers cuz they are easier to see, and also one of the only communities where hybrid tri-ys are common.

traditional tri-y

hybrid tri-y

same collector location as a traditional 4 into 1

The following is a letter I sent to Larry Meaux, the creator of the program pipeMax: I have been considering using a pair of used nascar tri-Y collectors in place of a traditional 4-1 collector on my LS7 427 V8. Problem is I don't have room to use RV3 (14")as is traditionally done as the location of the first 2-1 near the heads. I wanted to place the first set of collectors at RV2 (28"). My question is, "can I use the 4-1 (3.5") header collector LENGTH quote from pipeMax for the pair of collectors (2.5" each) from the first tri-y step to the second, or does the difference in diameter change the length required too much? Suggested collector lengths are 16" 26" or 64", would I be better off using one of these lengths or RV3 (14") length for a third time. And what about the final collector length?

I purchased pipemax software last year to aid the header design, and have been very pleased with it. But I am having some trouble figuring out what lengths to use initially on a hybrid tri-y design, as it's not very common (probably because it makes the headers massive and requires a ton of fab) and not included in the software.

Normally a try-y header is tuned to have the first collector at the very short 3rd reflected value usually about 15" from the ex. valve. It would be very tough to get the collectors that close and I'd rather use the further 2nd reflected value about 29" from the ex valve, this set up is sometimes called a hybrid try-y because the try-y collectors start where a traditional 4-1 would.

Except for the LS7 header with the pic of the 67 camaro in the background the other pics are of honda headers cuz they are easier to see, and also one of the only communities where hybrid tri-ys are common.

traditional tri-y

hybrid tri-y

same collector location as a traditional 4 into 1

The following is a letter I sent to Larry Meaux, the creator of the program pipeMax: I have been considering using a pair of used nascar tri-Y collectors in place of a traditional 4-1 collector on my LS7 427 V8. Problem is I don't have room to use RV3 (14")as is traditionally done as the location of the first 2-1 near the heads. I wanted to place the first set of collectors at RV2 (28"). My question is, "can I use the 4-1 (3.5") header collector LENGTH quote from pipeMax for the pair of collectors (2.5" each) from the first tri-y step to the second, or does the difference in diameter change the length required too much? Suggested collector lengths are 16" 26" or 64", would I be better off using one of these lengths or RV3 (14") length for a third time. And what about the final collector length?

#165

Yeah, I actually tried to change my name to Gigapunk over on zilvia.net but the mods never responded to my pms. I may start a very small company making rear wings some day. This thread alone has more than 20k hits, and I thought a little name recognition couldn't hurt. Then again, I doubt anyone wants "Gigapunk" on the side of their car.  So no loss, I suppose.

So no loss, I suppose.

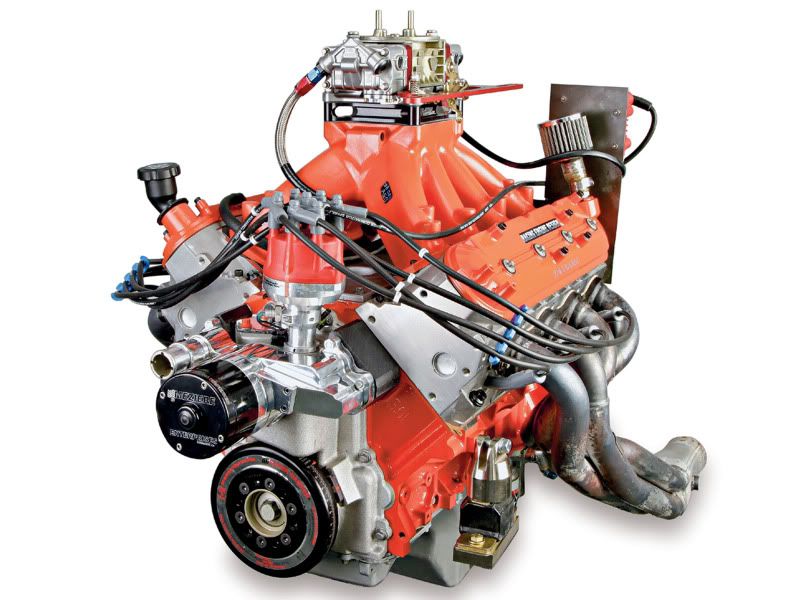

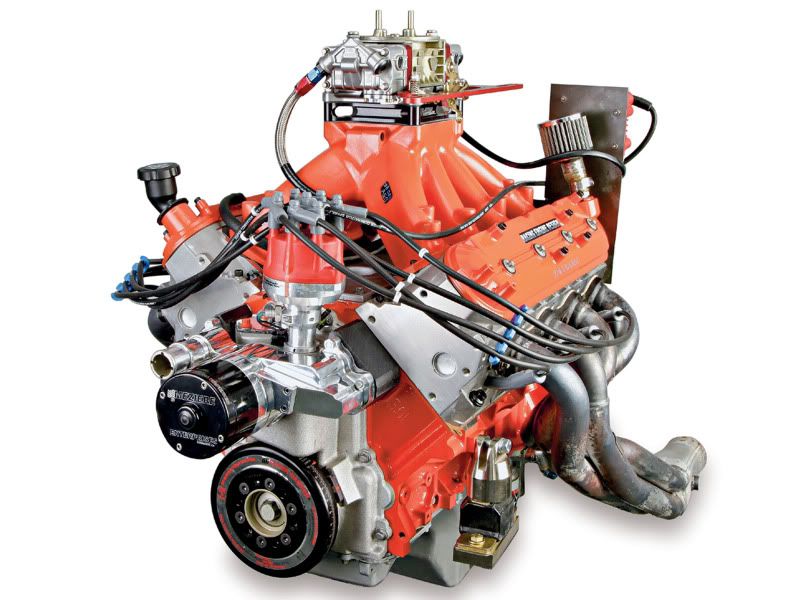

Just cuz I dig pictures: LS1 on L, LS7 on R

I was re-double checking that the LS7 and LS1 had the same location for the header bolts. They do.

I also got the a response from Larry Meaux, the creator of the PipeMax program. That was really cool of him, he didn't owe me nutt'n but sent me this great response.

"One thing-> when you switch over to TRI-Y design,the Primary 1st and 2nd Segment Lengths are very important

they must be within an inch or two from PipeMaxbut you can also "double" their lengths if necessaryto fit Headers inside bays or for a little more Torque.

TRI-Y example->suppose PipeMax predicts the total length of the 1st & 2nd Segments = 25 inchesthen you could use 50 inches if you needed to , but nothing in between

but if it was a 4-1 Header,then you could have very different Primary Pipe lengths (Unequal length Headers ),and not really see too much Loss if the Collector dia + its length were perfect to what PipeMax predicted

so in other words,

TRI-Y = Primary Lengths are almost as important as Collector Lengths 4-1 System= Primary Lengths are not that important, but Collector Lengths are critical !"

So no loss, I suppose.

So no loss, I suppose.Just cuz I dig pictures: LS1 on L, LS7 on R

I was re-double checking that the LS7 and LS1 had the same location for the header bolts. They do.

I also got the a response from Larry Meaux, the creator of the PipeMax program. That was really cool of him, he didn't owe me nutt'n but sent me this great response.

"One thing-> when you switch over to TRI-Y design,the Primary 1st and 2nd Segment Lengths are very important

they must be within an inch or two from PipeMaxbut you can also "double" their lengths if necessaryto fit Headers inside bays or for a little more Torque.

TRI-Y example->suppose PipeMax predicts the total length of the 1st & 2nd Segments = 25 inchesthen you could use 50 inches if you needed to , but nothing in between

but if it was a 4-1 Header,then you could have very different Primary Pipe lengths (Unequal length Headers ),and not really see too much Loss if the Collector dia + its length were perfect to what PipeMax predicted

so in other words,

TRI-Y = Primary Lengths are almost as important as Collector Lengths 4-1 System= Primary Lengths are not that important, but Collector Lengths are critical !"

#166

Larry Meaux from PipeMax is going to get back with me today with a picture of how I should build my headers! And last night I used some scrap steel and a dimple die to make the adapter for my throttle pedal. When I drove Courtney's LS2/S14 I saw that he had a simple 0.25" thick aluminum plate that bolted to the car's original bracket and shared one bolt with the GTO throttle pedal. Because I'm not as tall as he is, and my front seat is almost in the back seat I need the pedal ~2.6" spaced out. The brake and clutch peda will need to be spaced out about 3". Having the brake pedal sit about .50" closer to the driver than the throttle pedal will make heel-toe a bit easier I think? I ran out of argon/CO2 before I could finish. But here's where I'm at. It's very light and stiff already, and it's not even gusseted yet.

making it

test fit

progress, it was hard to get even these tacks done with no shielding gas on such thin gauge steel

making it

test fit

progress, it was hard to get even these tacks done with no shielding gas on such thin gauge steel

Last edited by GIGAPUNK; 03-06-2010 at 11:13 PM.

#169

I got a set of new LS7 cnc's heads for a crazy good deal a few years ago. And in sticking to my budget had to forgo the ti intake valves which run about $800 a set, and instead get stainless which are about 20% heavier.

For reference:

2.205 118.4g (the LS7 intake in SS from REV)

2.180 114.6g (a L92 valve in SS we use from REV)

2.160 106.5g (stock L92 replacement SS from REV)

1.600 92.3g (for reference an SS exhaust valve)

Stock LS7 Ti intake valves are probably in the 95g range as a guess.

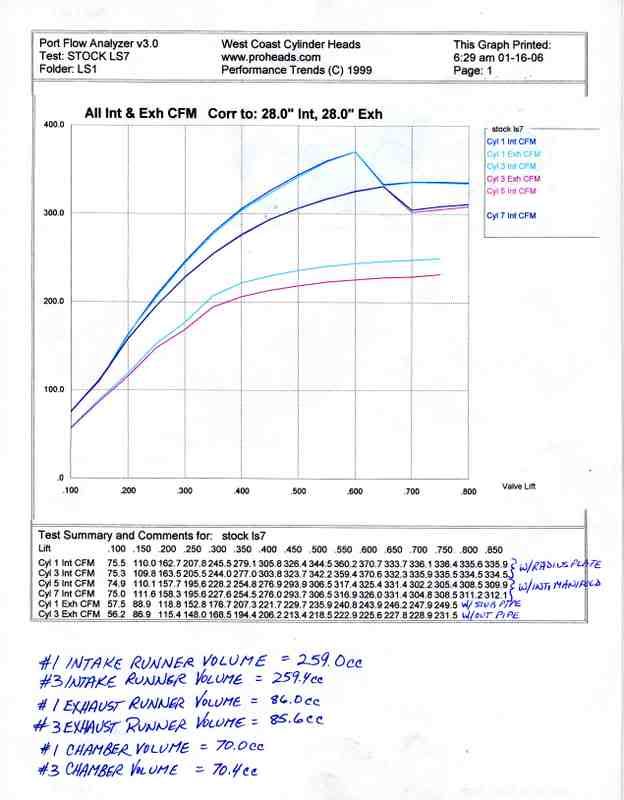

Richard at West Coast Cylinder Heads hooked me up with the most serious valve springs that can still be used with hydraulic rollers, as I plan on using the GMPP Cadillac lifters. These were developed for the speed GT racing series for the Cadillac STS-V team. Though hard to believe, these lifters are commonly used in 8000rpm road race motors! It's common knowlege that a lift much over 25% of the valves diameter usually yields very little gain in flow. The LS7 head is no exception.

As you can see from the flow data below. The flow at 25% of the 2.205" intake valve diameter (at a lift of ~.550"), to its max flow (which is at .650" lift), the flow only increases 4.4% with the manifold on. And with the manifold off the flow actually decreases at lifts much greater than the magical 25% diameter lift height!

Here's a chart I made regarding piston velocity: @ the LS7s stock 4.000” stroke which I plan on using.

RPM FPM

6000 4000 safe (street)

6300 4200

6500 4333 max (street)

6750 4500

7000 4666 LS7 sits here stock

7200 4800

7500 5000 GENERALLY CONSIDERED SAFE IF ALL FORGED COMPONENTS.

7650 5100 R07 nascar engine

8000 5333

8200 5466 Tosto Drag LSx

"During GM's reliability testing of this engine in its prototype phase, the LS7 was remarked to have been repeated tested to be 8000 rpm capable, although power was not made at that rpm level, due to the restraints of the camshaft's profile and the intake manifold ability to flow required air at that engine speed."

I see no reason a forged LS motor with a 4" stroke shouldn't have a 7500 rpm rev limit. 5000 fpm is considered a safe limit with many engine builders if the bottom end is built entirely of all forged components.

Unlike GM I can use whatever cam I want, so my limiting factor has become my valvetrain. I'm hoping to get around this with some seriously honkin valvesprings and stout push rods. Here are the springs I currently have.

My springs:The valves are REV stainless steel valves part numbers X1131 for the intakes and X1137 for the exhaust. And use 10 deg locks.

seat diameter: 1.450" (My LS7 heads were machined to take BBC size springs)

installed height: 1.855"

seat pressure: 163 lbs

.600" lift: 404 lbs

.650" lift: 426 lbs

.660" lift: 430 lbs (max rec lift)

I havn't measured coil bind yet.

Now the limiting factor is the 1.8:1 LS7 rockers give some lobes too damn much lift. And the other limiting factor is that I fear some of the more popular cam profiles might be too aggressive for such a heavy valve at 7500 rpm.

For example a comp cams LSK 240 duration at .050" lift lobe would have a lift of 0.687" lift with the 1.8:1 rockers! Too much for even my crazy BBC springs! If you want to figure out the lift that a lobe has that's quoted fot 1.7:1 rockers just multiply by 1.0588 to get the new lift with 1.8:1 rockers.

Common LS based comp lobes at 240 duration at .050" lift.

XFI (at 242) 0.648"

XER (at 240) 0.645"

LSK (at 240) 0.687"

Richard at WCCH suggested that I not go too much over 0.630" lift. Looking at the flow data of the heads with the manifold on I can see why. I'd like to keep using stock style lifters to help with the budget. So now the question is which lobe is going to help me get there?

I need something gentle, but of course don't want to sacrifice any ramp speed that I don't have to.

For reference:

2.205 118.4g (the LS7 intake in SS from REV)

2.180 114.6g (a L92 valve in SS we use from REV)

2.160 106.5g (stock L92 replacement SS from REV)

1.600 92.3g (for reference an SS exhaust valve)

Stock LS7 Ti intake valves are probably in the 95g range as a guess.

Richard at West Coast Cylinder Heads hooked me up with the most serious valve springs that can still be used with hydraulic rollers, as I plan on using the GMPP Cadillac lifters. These were developed for the speed GT racing series for the Cadillac STS-V team. Though hard to believe, these lifters are commonly used in 8000rpm road race motors! It's common knowlege that a lift much over 25% of the valves diameter usually yields very little gain in flow. The LS7 head is no exception.

As you can see from the flow data below. The flow at 25% of the 2.205" intake valve diameter (at a lift of ~.550"), to its max flow (which is at .650" lift), the flow only increases 4.4% with the manifold on. And with the manifold off the flow actually decreases at lifts much greater than the magical 25% diameter lift height!

Here's a chart I made regarding piston velocity: @ the LS7s stock 4.000” stroke which I plan on using.

RPM FPM

6000 4000 safe (street)

6300 4200

6500 4333 max (street)

6750 4500

7000 4666 LS7 sits here stock

7200 4800

7500 5000 GENERALLY CONSIDERED SAFE IF ALL FORGED COMPONENTS.

7650 5100 R07 nascar engine

8000 5333

8200 5466 Tosto Drag LSx

"During GM's reliability testing of this engine in its prototype phase, the LS7 was remarked to have been repeated tested to be 8000 rpm capable, although power was not made at that rpm level, due to the restraints of the camshaft's profile and the intake manifold ability to flow required air at that engine speed."

I see no reason a forged LS motor with a 4" stroke shouldn't have a 7500 rpm rev limit. 5000 fpm is considered a safe limit with many engine builders if the bottom end is built entirely of all forged components.

Unlike GM I can use whatever cam I want, so my limiting factor has become my valvetrain. I'm hoping to get around this with some seriously honkin valvesprings and stout push rods. Here are the springs I currently have.

My springs:The valves are REV stainless steel valves part numbers X1131 for the intakes and X1137 for the exhaust. And use 10 deg locks.

seat diameter: 1.450" (My LS7 heads were machined to take BBC size springs)

installed height: 1.855"

seat pressure: 163 lbs

.600" lift: 404 lbs

.650" lift: 426 lbs

.660" lift: 430 lbs (max rec lift)

I havn't measured coil bind yet.

Now the limiting factor is the 1.8:1 LS7 rockers give some lobes too damn much lift. And the other limiting factor is that I fear some of the more popular cam profiles might be too aggressive for such a heavy valve at 7500 rpm.

For example a comp cams LSK 240 duration at .050" lift lobe would have a lift of 0.687" lift with the 1.8:1 rockers! Too much for even my crazy BBC springs! If you want to figure out the lift that a lobe has that's quoted fot 1.7:1 rockers just multiply by 1.0588 to get the new lift with 1.8:1 rockers.

Common LS based comp lobes at 240 duration at .050" lift.

XFI (at 242) 0.648"

XER (at 240) 0.645"

LSK (at 240) 0.687"

Richard at WCCH suggested that I not go too much over 0.630" lift. Looking at the flow data of the heads with the manifold on I can see why. I'd like to keep using stock style lifters to help with the budget. So now the question is which lobe is going to help me get there?

I need something gentle, but of course don't want to sacrifice any ramp speed that I don't have to.

#170

I had been wondering whether or not the primaries ended at the start or end of the first collector.

Larry Meaux of the pipeMax software fame sent me the above photo. And the following info:

I also have a set of tri-y collectors from nascar suprlus that are for 2 OD primaries, and have 2.25 OD secondaries leading to a final merge collector that expands back out to 3.5. I also have a bunch of slip on extensions so that I can get what ever lengths I need, and to make dyno tuning a bit easier if I ever get to it. I'm hoping to use them if they aren't too far off. __________________________________________________ _______________ What you already have above sounds perfect !!!!

i calculate TRI-Y specs at :

anywhere from :

1st Primary Segment= 1 7/8ths to 2.000" diameter x 13.1" to 14.5" inches long2nd Segment= 2.000" to 2 1/16ths diameter x 13.1" to 14.5" long

Collector tapers or diverges from 2.811" to 3.816 over 16.0" inches long

so the 2.811 could round-off to 3.000 if need be

and the 3.816 could round-off to 4.000 if need be ? a merge collector ending at 3.5" diameter looks OK too , its in the ballpark.

___________________________________________

for TRI-Y's, the 1st and segment lengths are critic also they could either be->13.1 to 14.5" inches long for each of the 1st and 2nd segments which = 26.2 to 29 total length

or they could be 26.2 to 29 long for each of the segments which equals = 52.4 to 58 total lengths

the 13.1 to 14.5 will give you the most HP

the 26.2 to 29 will give you the most peak TQ and bottom end

the only bad thing about TRI-Y's is that to see any real benefitsover a 4-1 Header, the TRI-Y specs must be exact ! otherwise you are better off with 4-1 setup

Larry MeauxMeaux Racing Heads MaxRace Software

http://www.maxracesoftware.com/

maxracesoftware@inbox.com

#172

Yeah, I was in Clifton for a year or two. I'm out in Long Island now. I don't really do work, this all just for fun. I'd really suggest that you give my old shop TTP a call.

They are in GMHTP magazine again this month

http://www.gmhightechperformance.com.../photo_01.html

They get **** done!

http://www.ttperformance.net/

TT Performance Parts Inc.

5 Cardinal Drive

Little Falls, NJ 07424

Tel: (973) 256 - 1234

Fax: (973) 256 - 1772

sales@ttperformance.net

They are in GMHTP magazine again this month

http://www.gmhightechperformance.com.../photo_01.html

They get **** done!

http://www.ttperformance.net/

TT Performance Parts Inc.

5 Cardinal Drive

Little Falls, NJ 07424

Tel: (973) 256 - 1234

Fax: (973) 256 - 1772

sales@ttperformance.net

#174

There's a lot of competition in that area for work, and a lot of poor loosers. Plus people don't seem to have a good grasp of the amount of hours that good work really takes, nor any appreciation for the risky nature of modding your car. **** happens, it not the guy whos mowing your lawns fault. I worked there, it's a good shop full of good people.

#175

I'm toying with building my own wing. And started a little conversation on it over here:

http://www.f1technical.net/forum/vie...161858#p161858

http://www.f1technical.net/forum/vie...161858#p161858

#176

A recent Engine Masters Challenge redefined what blocks you could use the LS7 heads on. Just like the guys at RED I scored a bare set of LS7 heads for a screamin deal. But now don't want to pony up the cash for the big bore block that they really require. Before this article came out the smallest bore I've heard an LS7 head being on was a .035" over LS3 block at 4.100".

Here's the article in question,

http://www.popularhotrodding.com/tec...ine/index.html

Per the article RED made no changes to the combustion chamber. But did swap out the stock 1.61" exhaust valves for smaller 1.54" exhaust valves. This would free up 0.035" on the exhaust side and possibly allow for a 4.065" bore, but the RED 370 supposedly was on a 30 over LQ9 block at 4.030".

Where did they come up with that other 0.035" of clearance? Moving the valves with a fancy valve job, offset block to head dowels? Or maybe it just works!

RED 370 EMC

MY STOCK LS7 CHAMBERS

It doesn't look they moved the valve at all. And you can pick up an LQ9 block for $250.

Here's the article in question,

http://www.popularhotrodding.com/tec...ine/index.html

Per the article RED made no changes to the combustion chamber. But did swap out the stock 1.61" exhaust valves for smaller 1.54" exhaust valves. This would free up 0.035" on the exhaust side and possibly allow for a 4.065" bore, but the RED 370 supposedly was on a 30 over LQ9 block at 4.030".

Where did they come up with that other 0.035" of clearance? Moving the valves with a fancy valve job, offset block to head dowels? Or maybe it just works!

RED 370 EMC

MY STOCK LS7 CHAMBERS

It doesn't look they moved the valve at all. And you can pick up an LQ9 block for $250.

Last edited by GIGAPUNK; 06-18-2010 at 11:59 AM.

#179

On The Tree

iTrader: (3)

Join Date: Jun 2006

Location: Westminster, MD

Posts: 164

Likes: 0

Received 0 Likes

on

0 Posts

Isn't the LQ9 block cast iron? Doesn't that get you about 90 - 100 lb weight penalty? All this work to get the engine back to equalize weight, it would seem like a step backwards to go "iron".

#180

Other news:

Bad News... The power in my garage went out and it's going to be a while before it's back on

No welding or cutting for a while.

No welding or cutting for a while.Good News... I'm getting better and better at tuning the AEM EMS in my supercharged miata. I've got an appointment to dyno, tune, and corner weight it next thursday at TTP in New Jersey. I raced it in SCCA SSM last month at Nassau Colliseum, and have two more races there next month Aug 14 and 21st.

A good launch at Nasau Colliseum:

http://www.youtube.com/watch?v=8WrhWDq0G6s

I want to mess with the traction control and launch control in the AEM EMS, but I'm worried about braking drivetrain parts. The miat's fast enough. No I'm serious. 19 lbs of boost in 2200lbs of rear wheel drive on 14 inch tires. It's enough till the nissan's done.

I also went to Italy last month and got to drive a ferrari f430 in the hills of Maranello! I edited it down to my favorite 5 minutes. The vid and my **** eating grin speaks for it self

http://www.youtube.com/watch?v=GGAJPkbWEsA

keep truckin, I'll get a real Nissan update... eventually