1966 Corvette LS7/ 6L80E / Project

#1

New to site, but have been lurking for a while.

Saw the 66 GTO L92 / 6L80E Street Project thread and problem they had with the 6L80E 6 speed transmission an thought sharing my project problems as project moves along may be of benefit to at least those that might want to use the 6L80E in their mid year Vette. Where the 66 GTO project using the 6 speed auto was abandoned due to time constraints, I have to keep going, but some of you might not want to order one just yet....LOL

Haven't even got the chassis and all ready fighting first problem with one.

[IMG] [/IMG]

[/IMG]

[IMG] [/IMG]

[/IMG]

[IMG] [/IMG]

[/IMG]

[IMG] [/IMG]

[/IMG]

[IMG] [/IMG]

[/IMG]

When I ordered my Resto-Mod frame, engine and trans from Street Shop Inc for my 66 Corvette back last October, I had two goals in mind, one was not to have side pipes but 3.0" exhaust out the back and GM's new six speed auto.

Knew going in there were only a few cars/trucks that had been converted from 3 or 4 speed automatics or manual transmissions to a 6 speed auto and all would have their on conversion problems that would be different form installing one in a Mid-Year Vette.

Got a call from Street Shop telling me I had a problem with the transmission and exhaust, reguardless if I use 2.0", 2.5" or my 3.0" and I might want to reconsider using Side Exhaust instead of out the back exhaust and for that matter, consider not using the 6 speed auto, but 4L60E automatic instead of it my 2nd frame package.

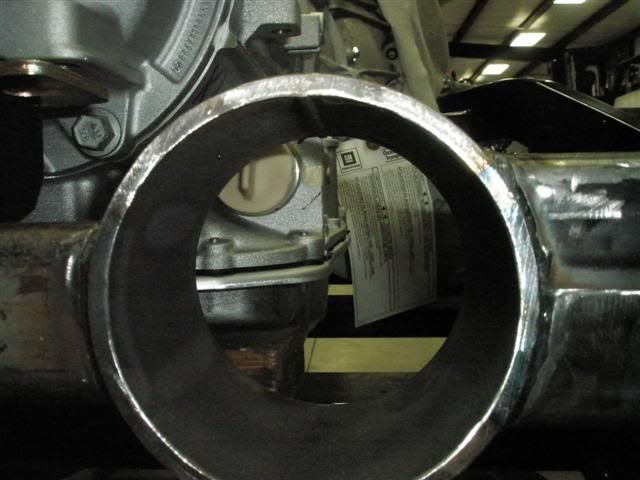

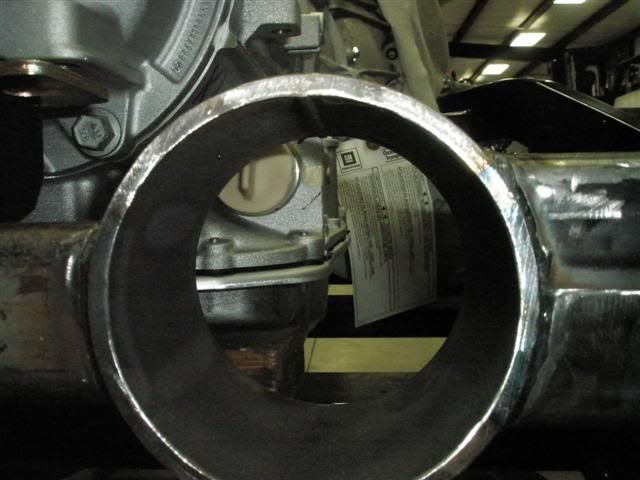

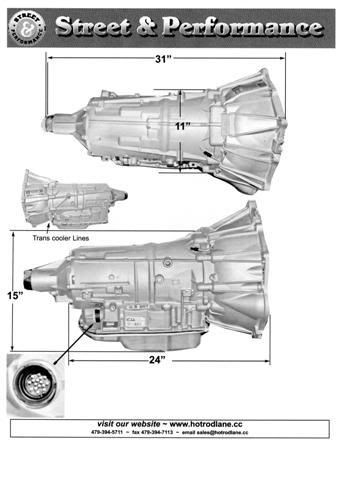

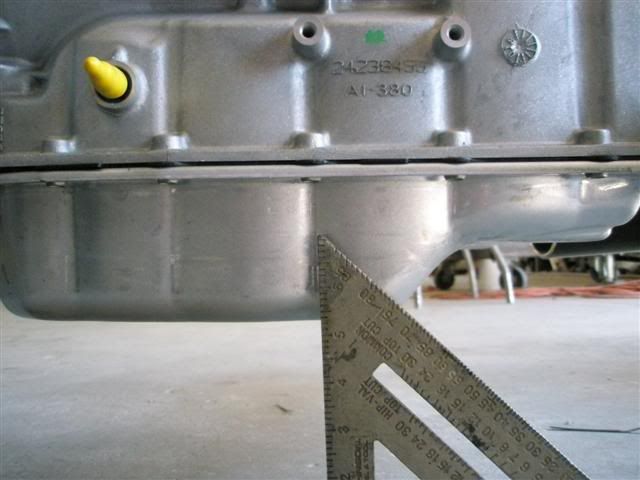

As you can see from the pictures the pan on this trans extends farther back than other GM autos so there is not enough room to get exhaust pipe thru even a 4.0" opening. While pan is 2 inches narrower than the 4L60E trans in the pan area and that helps fitment issue caused by wider pan, pan depth is about 1 3/4 inches deeper than the 60E's and extends back farther. Pan may hang below the frame making speed bumps, etc threats to take out the pan if one is not real careful.

What I'm also afraid of is due to the 6L80 not sloping down as much as the 4L60 right at the bellhousing, the trans will hit the tunnel at the fire wall using an LS engine as it does not have the 2.0" of space between back of engine and bellhousing like older style engines do. That probably would not be that much of a problem to deal with as if it hit tunnel where the mount is. Any modification to the firewall would not be seen. Moving the engine forward 1 1/2 inches using Street & Performance adapter plates is a possible option solution for that problem, if the adapter plates don't have a fitment issue with low mounted A/C compressor.

Because I refuse to use side exhaust due to noise level of them, friend an I drove over to Street Shop Inc and spent about 2 hours last week seeing what could be done to get exhaust out the back. Tried moving the engine forward 1 1/2 but still not enough room to get 3.0 inch exhaust pipe by trans and thur the opening in crossmember, but that still may need to be done if where the bellhousing and trans meet, it hits the tunnel at firewall with engine mounted in stock location (Believe this was part of the GTO's problem).

We decided that the only way and best way to deal with problem to maintain max exhaust to ground clearance, was to have Street Shop make a new crossmember and move the openings for the 3.0" exhaust outboard of their stock locations so exhaust will not have to be bent like standard Mid Year exhaust to fit through the openings.

In order to do this and not have interference problem with the floorpan, top of the pipe used for exhaust openings has to be dropped down and welded in flush with top of cross member so they clear the floorpan. This will put the bottom of the openings at about the same depth as the bottom of the transmission's pan, and with it's more mid car location make it more of a threat to hit/hang speed bumps than trans pan. Looks like I may need to start thinking about making and fitting a skid plate to protect the Transmission's pan too.

As soon as I get the chassis, I'll let y'all know if there is a fitment issue at firewall. At this time, I don't believe there will be and issue with the trans hittting the top or sides of the tunnel even at the back where the tunnel is the narrowest. Only time will tell if I guessed right on that.

Should have the chassis in hand 1st of April to sit the body on to see if there will be any trans to body interference problems that will require the thunnel to be modified to accept the trans.

Jere

Saw the 66 GTO L92 / 6L80E Street Project thread and problem they had with the 6L80E 6 speed transmission an thought sharing my project problems as project moves along may be of benefit to at least those that might want to use the 6L80E in their mid year Vette. Where the 66 GTO project using the 6 speed auto was abandoned due to time constraints, I have to keep going, but some of you might not want to order one just yet....LOL

Haven't even got the chassis and all ready fighting first problem with one.

[IMG]

[/IMG]

[/IMG][IMG]

[/IMG]

[/IMG][IMG]

[/IMG]

[/IMG][IMG]

[/IMG]

[/IMG][IMG]

[/IMG]

[/IMG]

When I ordered my Resto-Mod frame, engine and trans from Street Shop Inc for my 66 Corvette back last October, I had two goals in mind, one was not to have side pipes but 3.0" exhaust out the back and GM's new six speed auto.

Knew going in there were only a few cars/trucks that had been converted from 3 or 4 speed automatics or manual transmissions to a 6 speed auto and all would have their on conversion problems that would be different form installing one in a Mid-Year Vette.

Got a call from Street Shop telling me I had a problem with the transmission and exhaust, reguardless if I use 2.0", 2.5" or my 3.0" and I might want to reconsider using Side Exhaust instead of out the back exhaust and for that matter, consider not using the 6 speed auto, but 4L60E automatic instead of it my 2nd frame package.

As you can see from the pictures the pan on this trans extends farther back than other GM autos so there is not enough room to get exhaust pipe thru even a 4.0" opening. While pan is 2 inches narrower than the 4L60E trans in the pan area and that helps fitment issue caused by wider pan, pan depth is about 1 3/4 inches deeper than the 60E's and extends back farther. Pan may hang below the frame making speed bumps, etc threats to take out the pan if one is not real careful.

What I'm also afraid of is due to the 6L80 not sloping down as much as the 4L60 right at the bellhousing, the trans will hit the tunnel at the fire wall using an LS engine as it does not have the 2.0" of space between back of engine and bellhousing like older style engines do. That probably would not be that much of a problem to deal with as if it hit tunnel where the mount is. Any modification to the firewall would not be seen. Moving the engine forward 1 1/2 inches using Street & Performance adapter plates is a possible option solution for that problem, if the adapter plates don't have a fitment issue with low mounted A/C compressor.

Because I refuse to use side exhaust due to noise level of them, friend an I drove over to Street Shop Inc and spent about 2 hours last week seeing what could be done to get exhaust out the back. Tried moving the engine forward 1 1/2 but still not enough room to get 3.0 inch exhaust pipe by trans and thur the opening in crossmember, but that still may need to be done if where the bellhousing and trans meet, it hits the tunnel at firewall with engine mounted in stock location (Believe this was part of the GTO's problem).

We decided that the only way and best way to deal with problem to maintain max exhaust to ground clearance, was to have Street Shop make a new crossmember and move the openings for the 3.0" exhaust outboard of their stock locations so exhaust will not have to be bent like standard Mid Year exhaust to fit through the openings.

In order to do this and not have interference problem with the floorpan, top of the pipe used for exhaust openings has to be dropped down and welded in flush with top of cross member so they clear the floorpan. This will put the bottom of the openings at about the same depth as the bottom of the transmission's pan, and with it's more mid car location make it more of a threat to hit/hang speed bumps than trans pan. Looks like I may need to start thinking about making and fitting a skid plate to protect the Transmission's pan too.

As soon as I get the chassis, I'll let y'all know if there is a fitment issue at firewall. At this time, I don't believe there will be and issue with the trans hittting the top or sides of the tunnel even at the back where the tunnel is the narrowest. Only time will tell if I guessed right on that.

Should have the chassis in hand 1st of April to sit the body on to see if there will be any trans to body interference problems that will require the thunnel to be modified to accept the trans.

Jere

#2

I think I also saw that someone was trying to use the 6 sp Auto (6L80e) also.

I think they gave up due to the fact that the center line of the output shaft and the bottom of the trans would have been way to low, below the frame.. and dragging on the pavement !.. what is the distant from the shaft c/l to the bottom of the pan and will your Vette be able to clear and keep it above without having the engine and trans sticking way up above the current trans tunnel and hood ??

I think they gave up due to the fact that the center line of the output shaft and the bottom of the trans would have been way to low, below the frame.. and dragging on the pavement !.. what is the distant from the shaft c/l to the bottom of the pan and will your Vette be able to clear and keep it above without having the engine and trans sticking way up above the current trans tunnel and hood ??

#4

I think I also saw that someone was trying to use the 6 sp Auto (6L80e) also.

I think they gave up due to the fact that the center line of the output shaft and the bottom of the trans would have been way to low, below the frame.. and dragging on the pavement !.. what is the distant from the shaft c/l to the bottom of the pan and will your Vette be able to clear and keep it above without having the engine and trans sticking way up above the current trans tunnel and hood ??

I think they gave up due to the fact that the center line of the output shaft and the bottom of the trans would have been way to low, below the frame.. and dragging on the pavement !.. what is the distant from the shaft c/l to the bottom of the pan and will your Vette be able to clear and keep it above without having the engine and trans sticking way up above the current trans tunnel and hood ??

This much I can tell you and give you a couple of pictures to look at as reference.

The C/L of the tailshaft it'self is approximatly the same as that of a 4L60E from the mounting surface to it. The bottom of the pan is about 1.75" to 2.0" inches lower than the engines bellhousing, so it may be lower than bottom of the Vetted frame rails, how much if any, I don't know at this time.

What I do know is the bottom of the 4.5" pipe used to run the 3.0" exhaust thru will be approximatly 4.75" from bottom of floor pan to bottom of opening for exhaust pipe. Same openings that are in the stock crossmember are only 3.5" below the bottom of the floor pan and stock exhaust does not hang below frame rails.

Now those measurements were assuming the bottom of the floor pan has at least .250" clearance between it and transmission crossmember and that Street shops transmission crossmember is in stock location and not rasied or lowered. That pan is sitting somewhere from just inside frame rails or as much as 1 3/4 inches

lower than frame rails.

lower than frame rails. Had no way to measure actual pan to road clearance as there were no wheels to rest the chassic on and I forgot to get down and look to see how much below the frame rails pan might be.

That's why I mentioned I might have to make a skidplate to protect pan and will have to keep the car at stock ride height.

[IMG]

[/IMG]

[/IMG]

#5

http://www.streetshopinc.com/images/...r_large_16.jpg

Last edited by poorhousenext; 03-17-2008 at 04:06 PM.

#6

Hope it works out.. you might want to do some more reseach.. here is the thread that I had read and recalled about giving up on the 6L80E due to size, cost and time..

https://ls1tech.com/forums/showthrea...ighlight=6l80e

Good luck..

https://ls1tech.com/forums/showthrea...ighlight=6l80e

Good luck..

#7

Hope it works out.. you might want to do some more reseach.. here is the thread that I had read and recalled about giving up on the 6L80E due to size, cost and time..

https://ls1tech.com/forums/showthrea...ighlight=6l80e

Good luck..

https://ls1tech.com/forums/showthrea...ighlight=6l80e

Good luck..

I've alway known I might have to modify the vette's tunnel to get it to fit. Budgeted for that, but if it get's too complicated I will backtrack to a 4Lxx transmission.

I have a second frame that hasn't gone into work yet that I haven't ordered a trans for, but plan for it is LS3 480HP crate egine with the 6L80E trans too. Got the engine in for it last week. Want place trans order until I know just how much of a problem this one is going to be.

Jere

Trending Topics

#8

One thought on gaining more clearance for the exhaust under the floor-pan would be to use an oval shaped pipe in those close areas. There is a company called Dr. Gas, who makes most of the NASCAR exhaust pipes, who can ovalize up to a 4" pipe.

Best of luck with the project.

Rich

Best of luck with the project.

Rich

#9

I used one of Tray's frame set up in my 65 Vette. LS1w/4L60E. I had plenty of clearnce at the firewall. Every thing fit like a glove. I am running side pipes.

Having him move the openings in the crossmember farther out should take care of your problem. What I see of yous looks good so far.

Good luck

Phil

Having him move the openings in the crossmember farther out should take care of your problem. What I see of yous looks good so far.

Good luck

Phil

#10

I used one of Tray's frame set up in my 65 Vette. LS1w/4L60E. I had plenty of clearnce at the firewall. Every thing fit like a glove. I am running side pipes.

Having him move the openings in the crossmember farther out should take care of your problem. What I see of yous looks good so far.

Good luck

Phil

Having him move the openings in the crossmember farther out should take care of your problem. What I see of yous looks good so far.

Good luck

Phil

Have to say Tray has been very patient with me on this chassis combination. He has gone out of his way to help me an keep me from screwing up but to no avail.

I think he thinks I'm a little out of my mind for using the 6 speed this early in the game and my just having to have 3.0" exhaust out the back when side pipes would have been much easier, but I didn't want the noise are the fact 2.5" pipes stuff both LS7 and LS3 engines up. If I going to pay for the HP they can produce, I want all I can get out of them, even if I can't do anything with it but roast the tires...LOL

#11

9 Second Club/LS1TECH Sponsor

iTrader: (14)

Joined: Nov 2001

Posts: 1,707

Likes: 2

From: Anderson, Indiana

Great thread!

Glad to see someone sharing what it takes to swap the 6L80/6L90 into a car platform. I get questions every day on whether this trans will fit a particular car or not. All I can say is "I don't know". There are several projects underway but none are finished yet that I know of.

We did the swap into our 01 shop truck, but there was plenty of room in it. In fact, I was looking for an easy mechanical swap just so we could get going on the electronics/wiring/programming side of it.

https://ls1tech.com/forums/showthrea...313&highlight=

As long as you can get all of the issues worked out I think you will love the transmission! The gear spread is really good on these allowing you to plan your project for either banzai launches or super low highway RPM for great gas mileage, depending on which rear gears you choose.

Keep us posted on the good, the bad, and even the ugly of your project. MANY people want to know!

of your project. MANY people want to know!

Glad to see someone sharing what it takes to swap the 6L80/6L90 into a car platform. I get questions every day on whether this trans will fit a particular car or not. All I can say is "I don't know". There are several projects underway but none are finished yet that I know of.

We did the swap into our 01 shop truck, but there was plenty of room in it. In fact, I was looking for an easy mechanical swap just so we could get going on the electronics/wiring/programming side of it.

https://ls1tech.com/forums/showthrea...313&highlight=

As long as you can get all of the issues worked out I think you will love the transmission! The gear spread is really good on these allowing you to plan your project for either banzai launches or super low highway RPM for great gas mileage, depending on which rear gears you choose.

Keep us posted on the good, the bad, and even the ugly

of your project. MANY people want to know!

of your project. MANY people want to know!

__________________

91 Z28 LS2 408CI, LS9 Supercharger, LPE GT7 cam, Yank3000, 3450 raceweight.

Latest numbers: 9.71 ET, 141.42 MPH, 1.40 60' , 610 RWHP Mustang Dyno

www.speartech.com

91 Z28 LS2 408CI, LS9 Supercharger, LPE GT7 cam, Yank3000, 3450 raceweight.

Latest numbers: 9.71 ET, 141.42 MPH, 1.40 60' , 610 RWHP Mustang Dyno

www.speartech.com

#12

Great thread!

Glad to see someone sharing what it takes to swap the 6L80/6L90 into a car platform. I get questions every day on whether this trans will fit a particular car or not. All I can say is "I don't know". There are several projects underway but none are finished yet that I know of.

We did the swap into our 01 shop truck, but there was plenty of room in it. In fact, I was looking for an easy mechanical swap just so we could get going on the electronics/wiring/programming side of it.

https://ls1tech.com/forums/showthrea...313&highlight=

As long as you can get all of the issues worked out I think you will love the transmission! The gear spread is really good on these allowing you to plan your project for either banzai launches or super low highway RPM for great gas mileage, depending on which rear gears you choose.

Keep us posted on the good, the bad, and even the ugly of your project. MANY people want to know!

of your project. MANY people want to know!

Glad to see someone sharing what it takes to swap the 6L80/6L90 into a car platform. I get questions every day on whether this trans will fit a particular car or not. All I can say is "I don't know". There are several projects underway but none are finished yet that I know of.

We did the swap into our 01 shop truck, but there was plenty of room in it. In fact, I was looking for an easy mechanical swap just so we could get going on the electronics/wiring/programming side of it.

https://ls1tech.com/forums/showthrea...313&highlight=

As long as you can get all of the issues worked out I think you will love the transmission! The gear spread is really good on these allowing you to plan your project for either banzai launches or super low highway RPM for great gas mileage, depending on which rear gears you choose.

Keep us posted on the good, the bad, and even the ugly

of your project. MANY people want to know!

of your project. MANY people want to know!If it hadn't been for your 6L80E project, I would not have attempted mine. Looking forward to placing order for harness soon. Also looking forward to spring in IN so you can get work on programing cruise control to work.

The ugly should start around the frist of April when frame arrives.

#13

Tray does good work, I agree. When I ordered my frame he was unsure about the 4L60E. According to him everyone was running 5 or 6 speeds. Not what I wanted. I had to fabricate the rear mount, which was no problem.

If you are set on under the car exhaust, go for it. They may be a bit low to the ground, but what the heck. you are only going to drive on payments.

Will check on you from time to time to see how you are coming.

Phil

If you are set on under the car exhaust, go for it. They may be a bit low to the ground, but what the heck. you are only going to drive on payments.

Will check on you from time to time to see how you are coming.

Phil

#14

Frame arrive Friday so we got started this morning doing a body to transmission fit.

First thing I wanted to check was ground clearance as this is a deep transmission and pan depth along is 3.3" deep measured. Looks like with stock truck pan I have 5.25" of ground clearance. Haven't verified it but rumor is Pontiac G8 and Caddy use one that is 0.75" shorter than trucks. If so, I could get 6.0" of ground clearance by swapping over to one.

The 6L80 also is a fat transmission from front to back. It has the same fitment issues as a 6 speed manual in a 63-67 Mid Year vette and requires tunnel modification to accommodate it.

My transmission crossmember for 3.0" exhaust has to be redesigned also so that exhaust can go through it. This time the left and right foot wells are problem. We had to notch out the pipe for the exhaust to pass thru to get the body to sit on frame mounts. Looks like it down a another 1/2 inche and outboard around 2.0 inches.

First thing I wanted to check was ground clearance as this is a deep transmission and pan depth along is 3.3" deep measured. Looks like with stock truck pan I have 5.25" of ground clearance. Haven't verified it but rumor is Pontiac G8 and Caddy use one that is 0.75" shorter than trucks. If so, I could get 6.0" of ground clearance by swapping over to one.

The 6L80 also is a fat transmission from front to back. It has the same fitment issues as a 6 speed manual in a 63-67 Mid Year vette and requires tunnel modification to accommodate it.

My transmission crossmember for 3.0" exhaust has to be redesigned also so that exhaust can go through it. This time the left and right foot wells are problem. We had to notch out the pipe for the exhaust to pass thru to get the body to sit on frame mounts. Looks like it down a another 1/2 inche and outboard around 2.0 inches.

#15

For your exaust clearance issues there's always this option. This is an exaust a guy on another forum made so that it wouldn't stick down below the frame rails. With a little careful planning and creative fabrication you can maintain the same volume within the tubes and just change the shape, that way you create not only the clearance your looking for, but also do not create any unnecessary back pressure.

a little more information on this exaust can be found here

http://www.zilvia.net/f/showthread.php?t=171389&page=11

a little more information on this exaust can be found here

http://www.zilvia.net/f/showthread.php?t=171389&page=11

#16

Frame arrive Friday so we got started this morning doing a body to transmission fit.

First thing I wanted to check was ground clearance as this is a deep transmission and pan depth along is 3.3" deep measured. Looks like with stock truck pan I have 5.25" of ground clearance. Haven't verified it but rumor is Pontiac G8 and Caddy use one that is 0.75" shorter than trucks. If so, I could get 6.0" of ground clearance by swapping over to one.

The 6L80 also is a fat transmission from front to back. It has the same fitment issues as a 6 speed manual in a 63-67 Mid Year vette and requires tunnel modification to accommodate it.

First thing I wanted to check was ground clearance as this is a deep transmission and pan depth along is 3.3" deep measured. Looks like with stock truck pan I have 5.25" of ground clearance. Haven't verified it but rumor is Pontiac G8 and Caddy use one that is 0.75" shorter than trucks. If so, I could get 6.0" of ground clearance by swapping over to one.

The 6L80 also is a fat transmission from front to back. It has the same fitment issues as a 6 speed manual in a 63-67 Mid Year vette and requires tunnel modification to accommodate it.

Tunnel looks very accomodating. With your ground clearance @ 5.25", is that with a "loaded" chassis sitting at normal operating level? I know the G8 pan is shallower. Have been under and measured it. I have my fingers crossed the Cadi pan is even shallower, though I am guessing it will no better than the G8. 6" of ground clearance will be a great result!

Tunnel looks very accomodating. With your ground clearance @ 5.25", is that with a "loaded" chassis sitting at normal operating level? I know the G8 pan is shallower. Have been under and measured it. I have my fingers crossed the Cadi pan is even shallower, though I am guessing it will no better than the G8. 6" of ground clearance will be a great result!Gotta love that custom low profile exhaust on the 69 Camaro.

Cheers.

#17

For your exaust clearance issues there's always this option. This is an exaust a guy on another forum made so that it wouldn't stick down below the frame rails. With a little careful planning and creative fabrication you can maintain the same volume within the tubes and just change the shape, that way you create not only the clearance your looking for, but also do not create any unnecessary back pressure.

a little more information on this exaust can be found here

http://www.zilvia.net/f/showthread.php?t=171389&page=11

a little more information on this exaust can be found here

http://www.zilvia.net/f/showthread.php?t=171389&page=11

Have to say that Guy is creative... With redesign of transmission mount for exhaust opening, new location will make exhaust show below frame rail with bottom of exhaust pipe about the same as bottom of transmission pan. I'll probably stay with that for now and then if I think it hurts looks too much or go with shorter pan, I can make one with oval opening later. For now ugly exhaust will hide that ugly tranny pan from side...

#18

Thanks for the link as it does open up out of box thinking.

Have to say that Guy is creative... With redesign of transmission mount for exhaust opening, new location will make exhaust show below frame rail with bottom of exhaust pipe about the same as bottom of transmission pan. I'll probably stay with that for now and then if I think it hurts looks too much or go with shorter pan, I can make one with oval opening later. For now ugly exhaust will hide that ugly tranny pan from side...

Have to say that Guy is creative... With redesign of transmission mount for exhaust opening, new location will make exhaust show below frame rail with bottom of exhaust pipe about the same as bottom of transmission pan. I'll probably stay with that for now and then if I think it hurts looks too much or go with shorter pan, I can make one with oval opening later. For now ugly exhaust will hide that ugly tranny pan from side...

Yeah the guy that built that exhaust is quite the fabricator, he does it for a living from what I read in that thread, and is pretty good at in my opinion. I just wanted to show you another option because as with all projects where there's a will there's a way, especially if you can fabricate, can afford to fabricate, or know someone that will do it as a favor. The only catch is quality, I only wish I could weld at all, much less at the quality he is doing lol.

As for hiding the tranny pan, I'm one whom doesn't mind seeing that kind of stuff, not everything has to be built to riddler standards IMO and tranny pans are an unfortunate byproduct of the slush box lol.

As for the ground clearance issues and all, I'm a 240sx nut so ground clearance isn't a luxury I'm used to. My car had at most 4 inches of clearance to the frame rails for the last 4 years and that is stretching it a bit.

#19

Shop and myself have been working on shifter install and a way to hide that little monster without to much of a "My dog Fido's rear end look" to do it.

I chose to use one of the existing GM shifters that has Tap up & Tap down shifting built into floor mounted shifter that I know is a no brainer for company making the wire harness to make work at this time. This is area I can revisit again after I get entire retro Project completed and everything up and running to try and improves looks of.

Cheap looking Caddy shifter.

Nice looking Caddy shifter.

[IMG] [/IMG]

[/IMG]

Cheaper in looks and price, Pontiac G8 shifter.

[IMG] [/IMG]

[/IMG]

I decided on G8 shifter. It wasn't my first choice, but was the $600.00 dollar cheaper options. $523.00 dollars VS $1145.00+ dollar for what I considered to be the best looking of the Caddy shifters for my application. Due to Fords OZ supercar wins, I'll probably have to hide a Blue Oval in the car somewhere to make up for the Holden shifter.... Litte OZ humor my friends down under suggested...

Litte OZ humor my friends down under suggested...

I don't make the 134 mile round trip down to shop everyday, so things happen that I would have liked to have been different. Like forgetting to tell them when I gave them the shifter to install that they needed to elevate the front of base so top of shifter would sit level with top of console we would need to make. You can see they mounted it without thinking about that. Bolts in it are to short to install shims to level it.

Shifter also required tunnel to have to be cut and modified for actuator arm clearance also. I would have like to moved shifter back some to provide more clearance between shifter/console to house it and the Vette's dash, but couldn't do that due to drive shaft yoke, so shifter is mounted in original 4 speed shifter location.

Side view of shifter

Note: There may be 1 after market shifter from Retrotek Speed Inc that could have been wired in to do the manual shifts via acuator and then try to get it's paddled shifter option working to shift thru the 6 speeds.

http://www.retrotekspeed.com/product...th-f1-paddles/

I chose to use one of the existing GM shifters that has Tap up & Tap down shifting built into floor mounted shifter that I know is a no brainer for company making the wire harness to make work at this time. This is area I can revisit again after I get entire retro Project completed and everything up and running to try and improves looks of.

Cheap looking Caddy shifter.

Nice looking Caddy shifter.

[IMG]

[/IMG]

[/IMG]Cheaper in looks and price, Pontiac G8 shifter.

[IMG]

[/IMG]

[/IMG]I decided on G8 shifter. It wasn't my first choice, but was the $600.00 dollar cheaper options. $523.00 dollars VS $1145.00+ dollar for what I considered to be the best looking of the Caddy shifters for my application. Due to Fords OZ supercar wins, I'll probably have to hide a Blue Oval in the car somewhere to make up for the Holden shifter....

Litte OZ humor my friends down under suggested...

Litte OZ humor my friends down under suggested...

I don't make the 134 mile round trip down to shop everyday, so things happen that I would have liked to have been different. Like forgetting to tell them when I gave them the shifter to install that they needed to elevate the front of base so top of shifter would sit level with top of console we would need to make. You can see they mounted it without thinking about that. Bolts in it are to short to install shims to level it.

Shifter also required tunnel to have to be cut and modified for actuator arm clearance also. I would have like to moved shifter back some to provide more clearance between shifter/console to house it and the Vette's dash, but couldn't do that due to drive shaft yoke, so shifter is mounted in original 4 speed shifter location.

Side view of shifter

Note: There may be 1 after market shifter from Retrotek Speed Inc that could have been wired in to do the manual shifts via acuator and then try to get it's paddled shifter option working to shift thru the 6 speeds.

http://www.retrotekspeed.com/product...th-f1-paddles/

#20

Litte more on making Console to cover the G8 shifter.

Shop made progress on making a console to cover the shifter and tunnel. Also decide to delete the stock radio in order to try and improve looks of console to dash interface. I'll use a Marine Radio with wired remote to handle delivery of tunes.

Picture of start of mold for console to cover Shifter and mods to tunnel.

If you look right below the shifter at the stock tunnel right in front of seat, you can see where they had to cut stock tunnel for clearance to accommodate the shifter's shift actuator arm.

Picture of the mold shop built to lay up fiberglass console too.

Laying up fiberglass to mold.

Tunnel with mold and shifter removed.

Adding body filler to smooth it up.

First stage of console in place with radio delete dash to make mold and lay up console to dash transistion piece.

Knowing now what I know about what's required to install the 6L80E, I would have made a few visits to Salvage yards looking for a console that could be modified to fit. I believe a man could find one that would work and make an improvement to look of interior. We just kept it simple at this time.

Shop made progress on making a console to cover the shifter and tunnel. Also decide to delete the stock radio in order to try and improve looks of console to dash interface. I'll use a Marine Radio with wired remote to handle delivery of tunes.

Picture of start of mold for console to cover Shifter and mods to tunnel.

If you look right below the shifter at the stock tunnel right in front of seat, you can see where they had to cut stock tunnel for clearance to accommodate the shifter's shift actuator arm.

Picture of the mold shop built to lay up fiberglass console too.

Laying up fiberglass to mold.

Tunnel with mold and shifter removed.

Adding body filler to smooth it up.

First stage of console in place with radio delete dash to make mold and lay up console to dash transistion piece.

Knowing now what I know about what's required to install the 6L80E, I would have made a few visits to Salvage yards looking for a console that could be modified to fit. I believe a man could find one that would work and make an improvement to look of interior. We just kept it simple at this time.