LQ4 into a 3rd Gen/1972 Nova

#961

11 Second Club

Join Date: Mar 2008

Location: New Westminster, B.C., Canada

Posts: 445

Likes: 0

Received 1 Like

on

1 Post

He's getting the block professionally prepped and machined. He has a new barbell, the crank is brand new and I've stressed to him the importance of having a 'clean room' to do his assembly and measurements.

#963

TECH Addict

iTrader: (1)

Dude I got mine into my Cobalt and I bet either of us could fit a second. Why didn't manly mantanium help you heave it into the trunk? Didn't want to break a nail? Too busy washing his car?

Machine shop should be done polishing my turd tomorrow. I better get the beverages chilling!

Machine shop should be done polishing my turd tomorrow. I better get the beverages chilling!

#966

11 Second Club

Join Date: Mar 2008

Location: New Westminster, B.C., Canada

Posts: 445

Likes: 0

Received 1 Like

on

1 Post

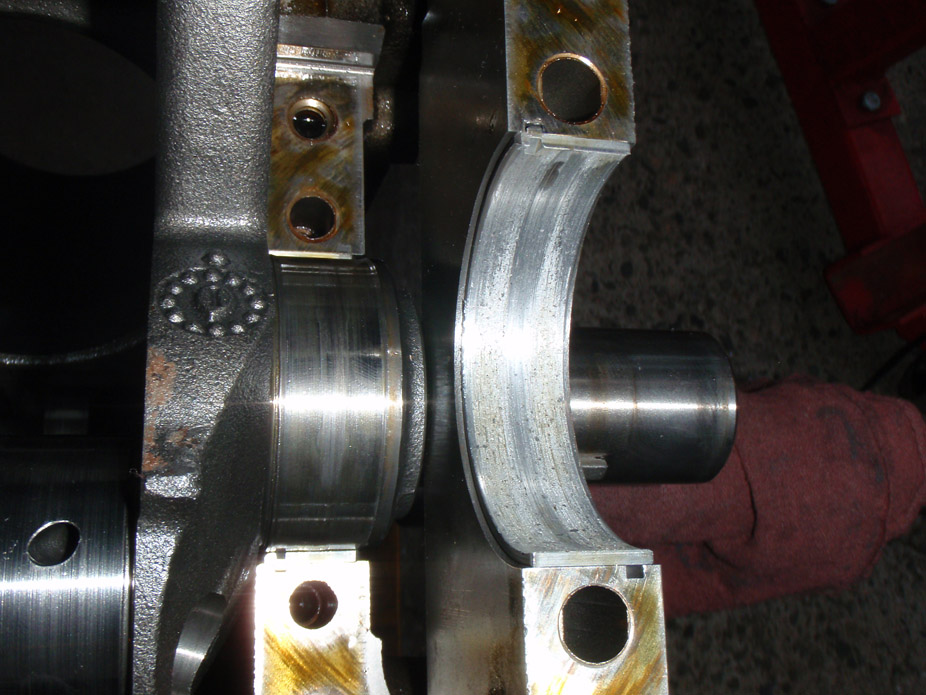

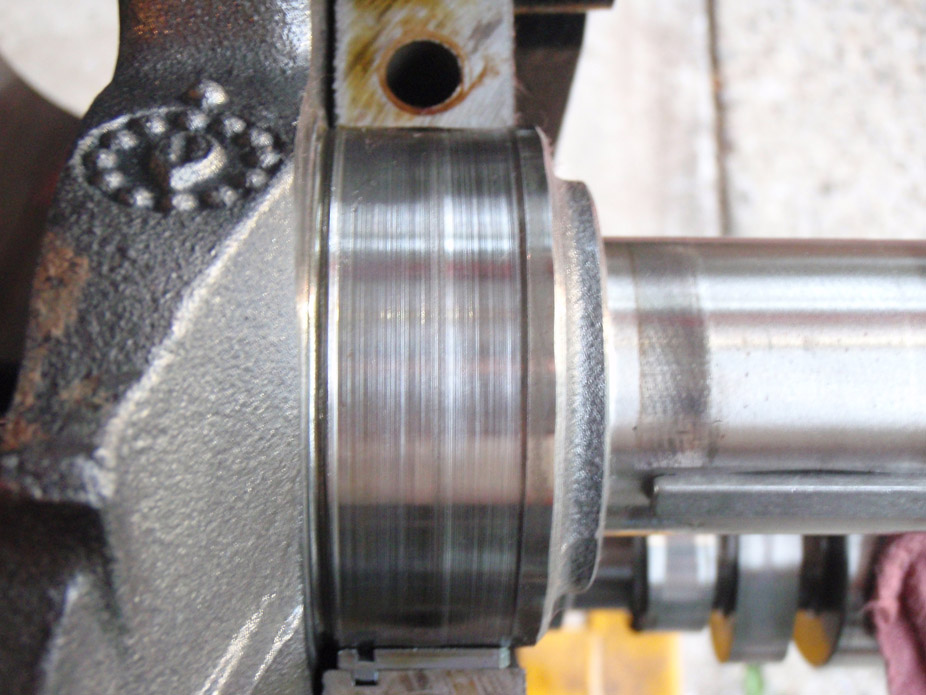

I imagine that before the turbo, you were on the verge of bearing failure. Once you were bleeding of oil pressure for the turbo that must have put it over the edge. That is the worst crank clearance I have ever seen. I'm not sure about the new nickname ????

#968

In my defense, the crank was really REALLY heavy.. could've used Man-hands McGee Marktainium to help lift it, oh well.

Dropped the block off at the machine shop this morning. Place is called Hi-Performance Engines, in Burnaby (for anyone reading local to Vancouver area). Owner of it Dave was super awesome to talk to, extremely knowledgeable, gave me a tour of the shop and explained how every single machine is used for different applications.. I have 100% confidence in these guys and they have a quick estimated turn-around too. If they're good enough for MarkyMantainium's standards then they'll be fine for me too.

Dropped the block off at the machine shop this morning. Place is called Hi-Performance Engines, in Burnaby (for anyone reading local to Vancouver area). Owner of it Dave was super awesome to talk to, extremely knowledgeable, gave me a tour of the shop and explained how every single machine is used for different applications.. I have 100% confidence in these guys and they have a quick estimated turn-around too. If they're good enough for MarkyMantainium's standards then they'll be fine for me too.

#969

TECH Addict

iTrader: (1)

What work is planned? I know hone at a minimum (with a deck plate?), but are you also decking, line honing, putting in cam bearings, etc? Are you having the shop gap the rings or are you doing it yourself? Whether they line hone or not, have them check the mains after putting in the studs or check them yourself with a bore gauge to make sure they're round. I decided to have my line honed as part of squaring the block.

I hope you didn't sustain damage to the turbo with debris in the oil from those bearings/journals. It seems unlikely, but you may want to take the turbo apart to check the bearings. If you do so, make sure you get the compressor clocked in the same orientation before & after to maintain balance. Did you ever split open your oil filter to check for debris?

I hope you didn't sustain damage to the turbo with debris in the oil from those bearings/journals. It seems unlikely, but you may want to take the turbo apart to check the bearings. If you do so, make sure you get the compressor clocked in the same orientation before & after to maintain balance. Did you ever split open your oil filter to check for debris?

#970

They're going to check the bores first, then hot tank it, bore, hone, check the mains with ARP studs torqued for need of line hone, and also check the decks, although I doubt I'd get any deck work done. They do all their boring with a torque plate on the deck. Also have new cam bearings that I'll get them to install. I'll be doing the ring gaps myself. I probably will take the turbo apart while I'm waiting, just to be safe.

#971

TECH Addict

iTrader: (1)

On the turbo, do a match mark on the compressor to make sure you put it back on in the same orientation. That will ensure the balance is maintained. You can mark/scribe the end of the shaft or mark (not scribe!) a line on both the turbine and compressor wheel. They aren't very hard to take apart & put back together, but be careful to keep things clean and use only engine oil for lube on the bearings.

#972

Your TC76 should have a filter on it...it is on the inlet side of the turbo from T-netics.

If the filter has not particulate on it, leave the turbo together.

Also, take the turbo and spray it out with carb cleaner into an old white cotton t-shirt.

If you see shinny things come out and cling to the shirt, you might want to sent the turbo out to be rebuilt....and throw the shirt away once complete as well...

If the filter has not particulate on it, leave the turbo together.

Also, take the turbo and spray it out with carb cleaner into an old white cotton t-shirt.

If you see shinny things come out and cling to the shirt, you might want to sent the turbo out to be rebuilt....and throw the shirt away once complete as well...

#974

Next size of displacement for stroker option would be 402 or 6.6L, so 10% more airflow, which would most definitely max out my single turbo, and there isn't much room for a bigger turbo relative to the hood, wastegate pipe, passenger-side hot pipe, etc. Plus it would certainly require bigger wastegate, needing modification to the pre-WG piping to allow the higher flow. And would definitely require freer-flowing exhaust after the downpipe which I'm not too enthusiastic about making just yet. Also would likely need bigger injectors altho could probably get away with just cranking the fuel pressure on the current 52 lb/hr injectors. Plus keeping it stock 6L will let me get "better fuel economy".. haha.

#977

TECH Regular

iTrader: (5)

Join Date: Mar 2010

Location: Vancouver area, West coast Canada

Posts: 403

Likes: 0

Received 30 Likes

on

20 Posts

In my defense, the crank was really REALLY heavy.. could've used Man-hands McGee Marktainium to help lift it, oh well.

Dropped the block off at the machine shop this morning. Place is called Hi-Performance Engines, in Burnaby (for anyone reading local to Vancouver area). Owner of it Dave was super awesome to talk to, extremely knowledgeable, gave me a tour of the shop and explained how every single machine is used for different applications.. I have 100% confidence in these guys and they have a quick estimated turn-around too. If they're good enough for MarkyMantainium's standards then they'll be fine for me too.

Dropped the block off at the machine shop this morning. Place is called Hi-Performance Engines, in Burnaby (for anyone reading local to Vancouver area). Owner of it Dave was super awesome to talk to, extremely knowledgeable, gave me a tour of the shop and explained how every single machine is used for different applications.. I have 100% confidence in these guys and they have a quick estimated turn-around too. If they're good enough for MarkyMantainium's standards then they'll be fine for me too.

#978

11 Second Club

Join Date: Mar 2008

Location: New Westminster, B.C., Canada

Posts: 445

Likes: 0

Received 1 Like

on

1 Post

I would think that it is unlikely that there is any debris in the turbo. The last stop on the oil's journey through the motor is the main bearings/rod bearings. After that the oil goes into the pan, and through the filter. Being that your turbo supply line is tapped into your oil filter "adapter" it is freshly filtered oil. I suppose if you had been running for ages to a point that the oil filter was bypassing, then yes, you could have debris in the turbo. Is your turbo a ball bearing turbo? Another thing to note is that looking at your bearings you can see the "debris" galled up and impregnated into the actual surface of the bearing. Plus the bearing material itself is soft metal. Just sayin'

#979

12 Second Club

iTrader: (12)

The last stop on the oil's journey through the motor is the main bearings/rod bearings.

Edit: I was wrong. Only the LSx block is a true priority-main system. Quite interesting.

Last edited by hookemdevils22; 08-23-2012 at 10:17 AM.

#980

That's true, depending on what the oil filter looks like, I may inspect anyways, but I'm not anticipating.. the turbo gets freshly cooled oil from right after the filter then cooler.

Dropped the pistons off at the machine shop today, they say the bores should be no problem to go only 0.005" over to 4.005", and should be done early next week.

Dropped the pistons off at the machine shop today, they say the bores should be no problem to go only 0.005" over to 4.005", and should be done early next week.