m/t 28x10.50x15s pressure

#1

i have a full weight M6 408 car.. and i was wondering what pressures to start at with the slicks.. had then at 20 and they sucked... thought it needed more spin so went to 22.... but it really really seems to much pressure????????????

#2

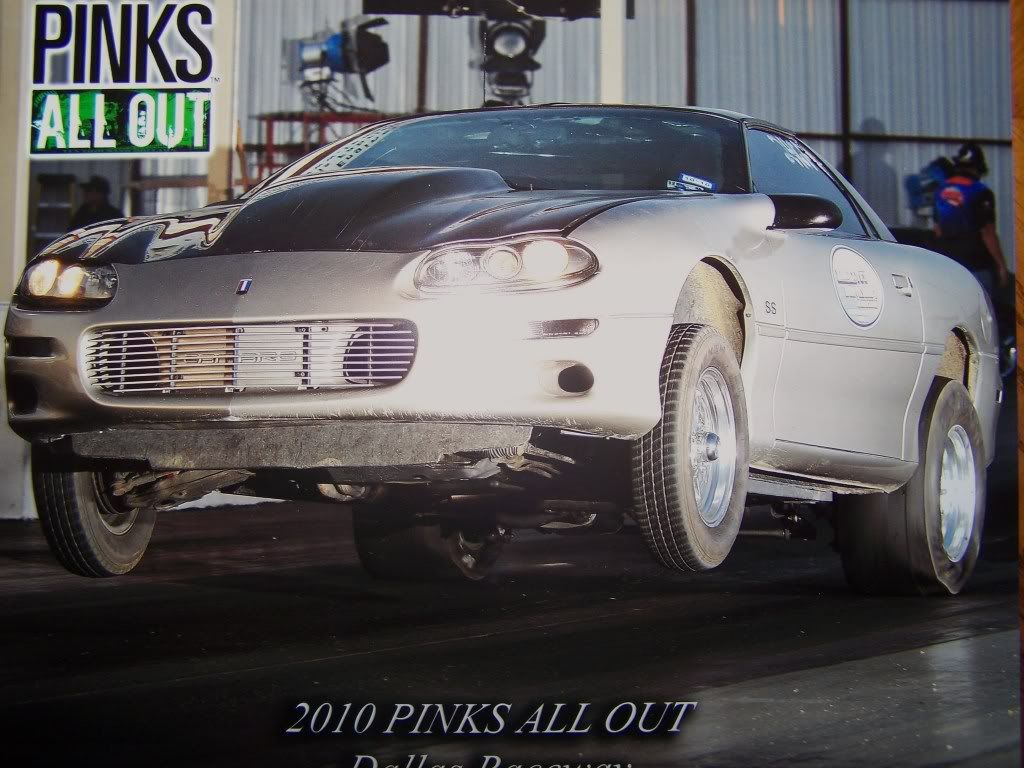

Car looks pretty nasty, but you can see how the back tires react to 15psi and 3500lbs.

#4

well i was running 20 and it was bogging HARD... so i went to 22 and dropped it at 5500 and it was "better" but broke the trutrack so i swapped tires and went home... so i need to be running them lower?

#5

#6

car weighs near 4000 raceweight...

makes 480 on motor

6 speed with 3.90's

28 inch mt slicks id guess

think hes got a bunch of suspension just not enough power/gear to 60 on motor...hes got dope

makes 480 on motor

6 speed with 3.90's

28 inch mt slicks id guess

think hes got a bunch of suspension just not enough power/gear to 60 on motor...hes got dope

#7

Trending Topics

#9

Or you can loosen the current nut off and drill a small hole in the bolt and put a cotter pin through it so it doesn't back off.

That will help significantly also.

Or just get some heim joint LCA's so they work freely.

Last edited by StreetSilverado; 05-16-2010 at 02:33 AM.

#10

Do you have the LCA's tightened really tight? You should use a lock nut on them and just have the snug, your LCA's aren't working if you have them tightened down too much.

Or you can loosen the current nut off and drill a small hole in the bolt and put a cotter pin through it so it doesn't back off.

That will help significantly also.

Or just get some heim joint LCA's so they work freely.

Or you can loosen the current nut off and drill a small hole in the bolt and put a cotter pin through it so it doesn't back off.

That will help significantly also.

Or just get some heim joint LCA's so they work freely.

what?

#11

he is probably just saying there is resistance or the possiablilty of bind with the poly bushings and the rod end has none...so there is more force needed to move the suspension and its taking away from the power transfer or something like that.. i remember my grandfather said they used to pull control arms out and grind down the sleves that had the groves on them lube the **** out of then and put them back on because the had less resistance when u moved them there for quicker and took lest power or someshit.... i was like sure thats what yall did but now i see the point

#12

he is probably just saying there is resistance or the possiablilty of bind with the poly bushings and the rod end has none...so there is more force needed to move the suspension and its taking away from the power transfer or something like that.. i remember my grandfather said they used to pull control arms out and grind down the sleves that had the groves on them lube the **** out of then and put them back on because the had less resistance when u moved them there for quicker and took lest power or someshit.... i was like sure thats what yall did but now i see the point

It has also helped one of my buddies with the (BMR or Spohn?) Non-Adjustable LCA's with the poly ends by loosening them off.

Just trying to help with the small stuff, because sometimes it will make a big difference.