looseing oil pressure on launch

#82

8 Second Club

iTrader: (26)

I lost an engine due to oiling issues with the stock pan. I found an LS7 takeoff oil pan, pump and front cover for about $500, cured all of my troubles. Obvoisly it's not for everyone but it is a great budget option. My new engine is getting a real dry sump. Oil pan from Jeff Johnstons Billet fabrications and a Petersons R4 5 stage pump. Jeff uses a 3/8" billet rail, engine is getting a girdle so pan strenght is not an issue. I wish they made a baffle system like this a couple of years ago. I think anybody that runs 1.50 60' or better would be a fool not to buy this baffle system.

#83

8 Second Club

iTrader: (18)

Join Date: Oct 2002

Location: Waterloo, Ontario

Posts: 2,609

Likes: 0

Received 0 Likes

on

0 Posts

Here's what we recommend:

1. Add an extra quart to the sump, along with an oil catch can (because you will get more oil sucked into the intake via the PCV line).

2. If that doesn't solve the problem, add a bolt-in baffle like the one we sell. Or purchase a cast-aluminum aftermarket pan with trap door baffling (we recommend staying away from welded sheet-metal pans).

3. If that doesn't solve the problem, add an oil accumulator (Accusump).

4. If that doesn't solve the problem, you will have to convert to a dry sump system.

We don't recommend high-flow oil pumps. You will drain your oil pan much faster. These engines already have an issue with slow drain-back from the heads, and the drain-back rate can't keep up with a high-flow pump when there are high G-forces involved.

1. Add an extra quart to the sump, along with an oil catch can (because you will get more oil sucked into the intake via the PCV line).

2. If that doesn't solve the problem, add a bolt-in baffle like the one we sell. Or purchase a cast-aluminum aftermarket pan with trap door baffling (we recommend staying away from welded sheet-metal pans).

3. If that doesn't solve the problem, add an oil accumulator (Accusump).

4. If that doesn't solve the problem, you will have to convert to a dry sump system.

We don't recommend high-flow oil pumps. You will drain your oil pan much faster. These engines already have an issue with slow drain-back from the heads, and the drain-back rate can't keep up with a high-flow pump when there are high G-forces involved.

#84

LS1Tech Sponsor

The solutions I listed above apply as well, except that there are no trap-door baffles available for the Corvette pan. We are working on a cast-aluminum pan that may fit the Corvette, however.

The Z06 semi-dry sump system works pretty well, but some people still have oil pressure drops in long left-handers. Adding a baffle to the oil tank seems to solve that problem. Often times you can get a used Z06 setup for a very reasonable price.

Another trick a lot of people do that seems to help is to drill small holes in the lifter trays to help the oil drain back.

Crank scrapers are also supposed to help, however we have no direct experience with them. We may try one out on our shop car and see if it helps.

The Z06 semi-dry sump system works pretty well, but some people still have oil pressure drops in long left-handers. Adding a baffle to the oil tank seems to solve that problem. Often times you can get a used Z06 setup for a very reasonable price.

Another trick a lot of people do that seems to help is to drill small holes in the lifter trays to help the oil drain back.

Crank scrapers are also supposed to help, however we have no direct experience with them. We may try one out on our shop car and see if it helps.

#86

10 Second Club

iTrader: (47)

Join Date: Nov 2001

Location: Pace, FL

Posts: 1,453

Likes: 0

Received 0 Likes

on

0 Posts

The guys are trimming for strokers, where you trimming? Where the pickup runs the side of the pan on that front diverter? I run a 4.100 and have been eyeing this baffle. Also, you guys runnning a little extra oil in the system?

#87

LS1Tech Sponsor

The pickup tube and/or pickup tube bracket may contact the baffle in strokers. We did add a cut-out to provide more clearance for strokers, but you may still have a little bit of interference that requires some grinding/filing on the baffle. Shouldn't be much. We will try to add even more clearance on the next batch we make.

#88

This is all done, very nice part

https://ls1tech.com/forums/drag-raci...h-diet-36.html

install/baffle info from my build thread.

https://ls1tech.com/forums/drag-raci...h-diet-36.html

install/baffle info from my build thread.

Got the oil pan out,without having to take the headers off, the intake, or lower the Kemeber.

Saw in the rod bolt write up to jack you on the pan all the way, then hold to motor and remove the jack, then lower the Kmeber still. When you jack up on the pan it kinds tips the motor forward and the header collectors hit after only going up a little, with still a ton of room on the back of the heads and the intake. Trans is out, and Ypipe BTW.. and the Lid/maff.. disconnect the battery ect.. I tried a different way and it worked out really well, making a wood motor mount stand and jack that up. The pan came right off around it, you have room to work still with the little alum jack in the middle you could do rod bolts like this, working in front and behind it alot better then having **** to tip the cradle back, or the engine stand legs. The 2x4s were spaced 15", go between the open forks on the Kmeber, set them right under the mounts (stock with poly I have) I trimmed them down on the ends so whey not so wide to fit better, and a little 45* notch for the header tube on the driver side Still have 1.5x3 not sure if I would do a LSX block, but its super strong upright, look at the wood use some clean strait grain, no knots or cross grain on them.

Used 2 15" upright, anything form 12-17 would work I bet. If you can get the jack under it, I went long so the jack had less swing.

Stand the uprights on the 15" wide 2x4s (fits under the mounts), used some 3inch screw predrilled, thu the 1st plate one, up into them. was gona make a side brace, you would have to tip it bad to have them pull out, its gona fall off the jack then anyway.

Picking up on the mounts worked great keeps the engine more level for what you need to not hit, to jack it up. I kept the motor mount in the Kmember stand things. If you go up past them, THE ENGINE COULD FALL OUT!!! I did this alone, just watched things, when the intake was close, and the mounts were still on the stand a safe amount. Buzzed the bolts out and the pan came right out. I'm sure on the way up its not perfectly balanced and it tipping a little inside the Kemeber stands, just dont be a dumbass and pull in the headers, or the TB. Only had about 4 bolt in the pan and broke it loose already, I would do that before with in not jacked up or just a little for room. So is its ready to come out easy withing pulling in it hard.

Think this is jacked up?

This might be lowered back down?

Saw in the rod bolt write up to jack you on the pan all the way, then hold to motor and remove the jack, then lower the Kmeber still. When you jack up on the pan it kinds tips the motor forward and the header collectors hit after only going up a little, with still a ton of room on the back of the heads and the intake. Trans is out, and Ypipe BTW.. and the Lid/maff.. disconnect the battery ect.. I tried a different way and it worked out really well, making a wood motor mount stand and jack that up. The pan came right off around it, you have room to work still with the little alum jack in the middle you could do rod bolts like this, working in front and behind it alot better then having **** to tip the cradle back, or the engine stand legs. The 2x4s were spaced 15", go between the open forks on the Kmeber, set them right under the mounts (stock with poly I have) I trimmed them down on the ends so whey not so wide to fit better, and a little 45* notch for the header tube on the driver side Still have 1.5x3 not sure if I would do a LSX block, but its super strong upright, look at the wood use some clean strait grain, no knots or cross grain on them.

Used 2 15" upright, anything form 12-17 would work I bet. If you can get the jack under it, I went long so the jack had less swing.

Stand the uprights on the 15" wide 2x4s (fits under the mounts), used some 3inch screw predrilled, thu the 1st plate one, up into them. was gona make a side brace, you would have to tip it bad to have them pull out, its gona fall off the jack then anyway.

Picking up on the mounts worked great keeps the engine more level for what you need to not hit, to jack it up. I kept the motor mount in the Kmember stand things. If you go up past them, THE ENGINE COULD FALL OUT!!! I did this alone, just watched things, when the intake was close, and the mounts were still on the stand a safe amount. Buzzed the bolts out and the pan came right out. I'm sure on the way up its not perfectly balanced and it tipping a little inside the Kemeber stands, just dont be a dumbass and pull in the headers, or the TB. Only had about 4 bolt in the pan and broke it loose already, I would do that before with in not jacked up or just a little for room. So is its ready to come out easy withing pulling in it hard.

Think this is jacked up?

This might be lowered back down?

#89

Pan looked really dirty  Not sludge, I change the oil every 1-2K miles and cleaned it out a few years ago when I did rod bolts. The oil is clean, but the stock baffle had a nice coating of dust clinging to it, no flakes, or chucks. Found some valve seal springs, a few in the pickup screen. 1-2 little black RTV boogers off the timming cover.

Not sludge, I change the oil every 1-2K miles and cleaned it out a few years ago when I did rod bolts. The oil is clean, but the stock baffle had a nice coating of dust clinging to it, no flakes, or chucks. Found some valve seal springs, a few in the pickup screen. 1-2 little black RTV boogers off the timming cover.

A few red locktight half ring off I think a cam plate bolt in the pickup screen too

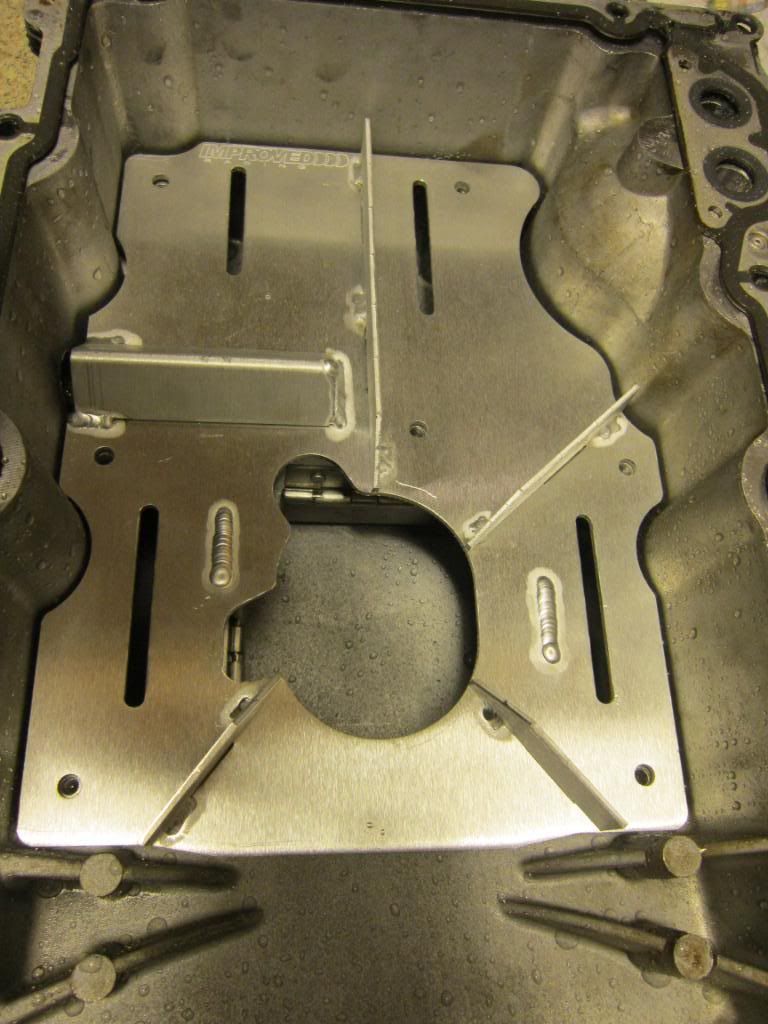

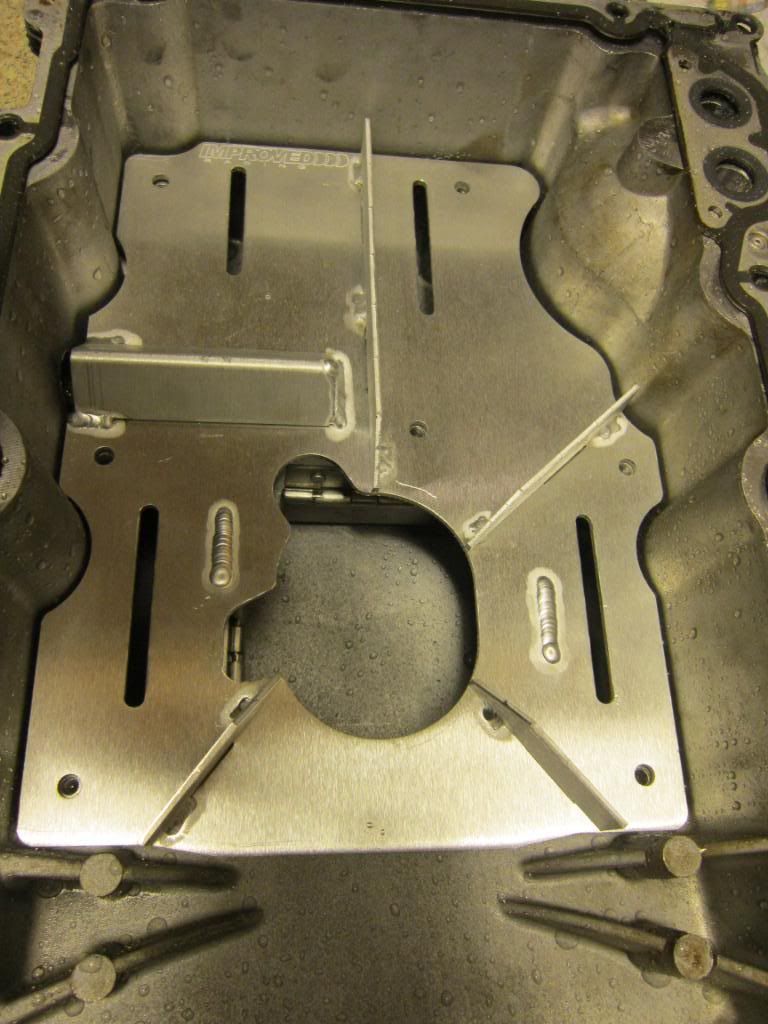

blasted the pan with hot wated dawm quick, but going to grind the back flush for the blocksaver plate while its out, so final clean after that. This imporved racing baffle fits good. I dont really need the side doors, kinds wish it was just strait across the the front, One bigger place to keep oil. Not sure If the smaller middle one with the side closed off can get sucked dry. If you carry a long wheelie?

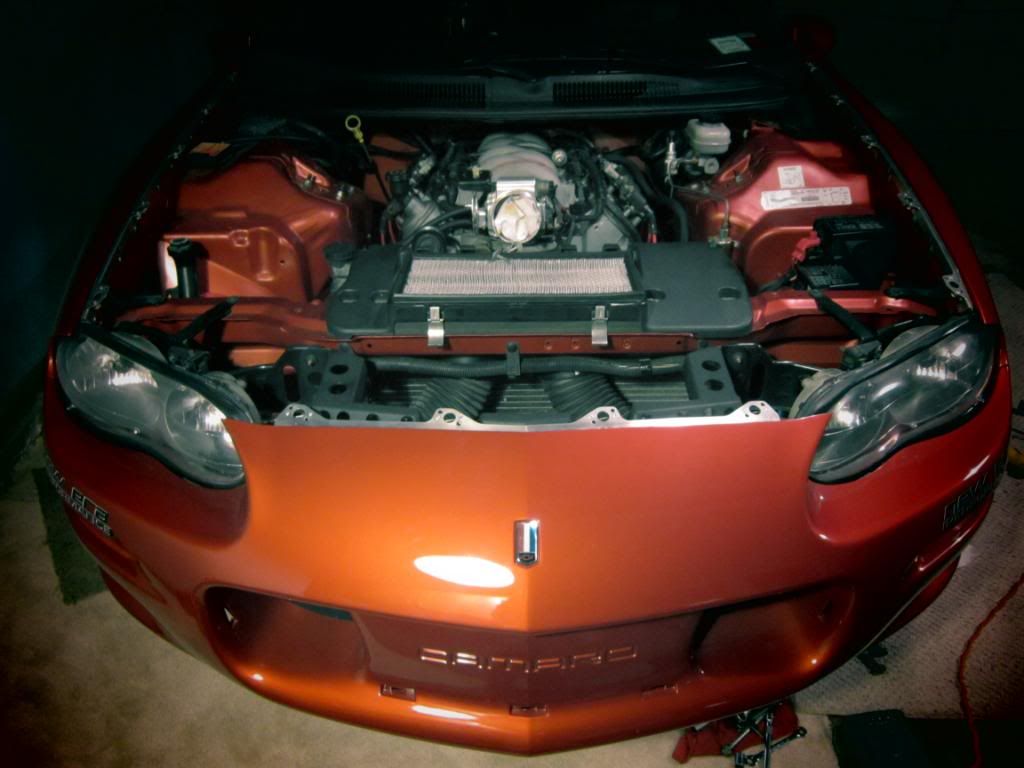

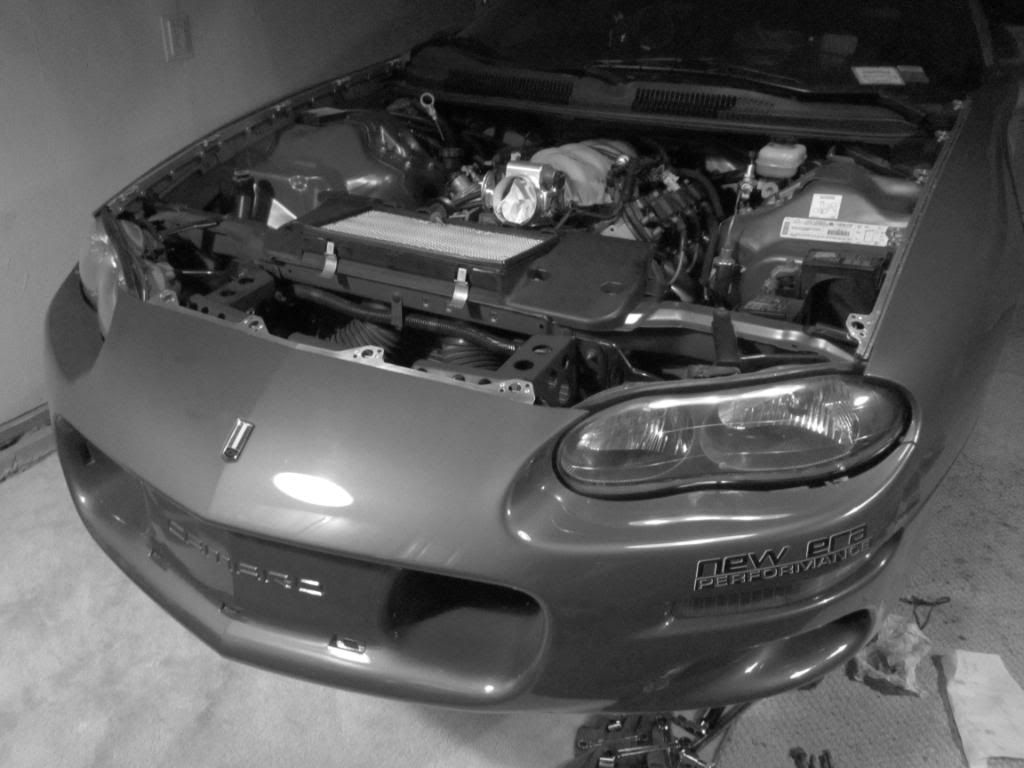

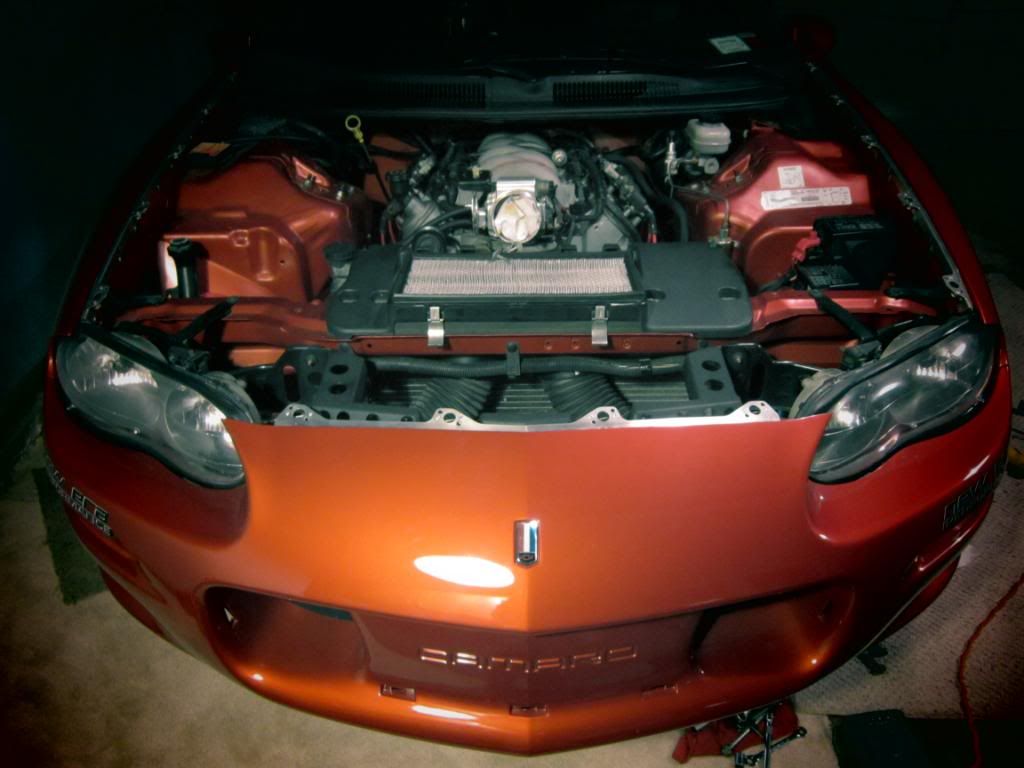

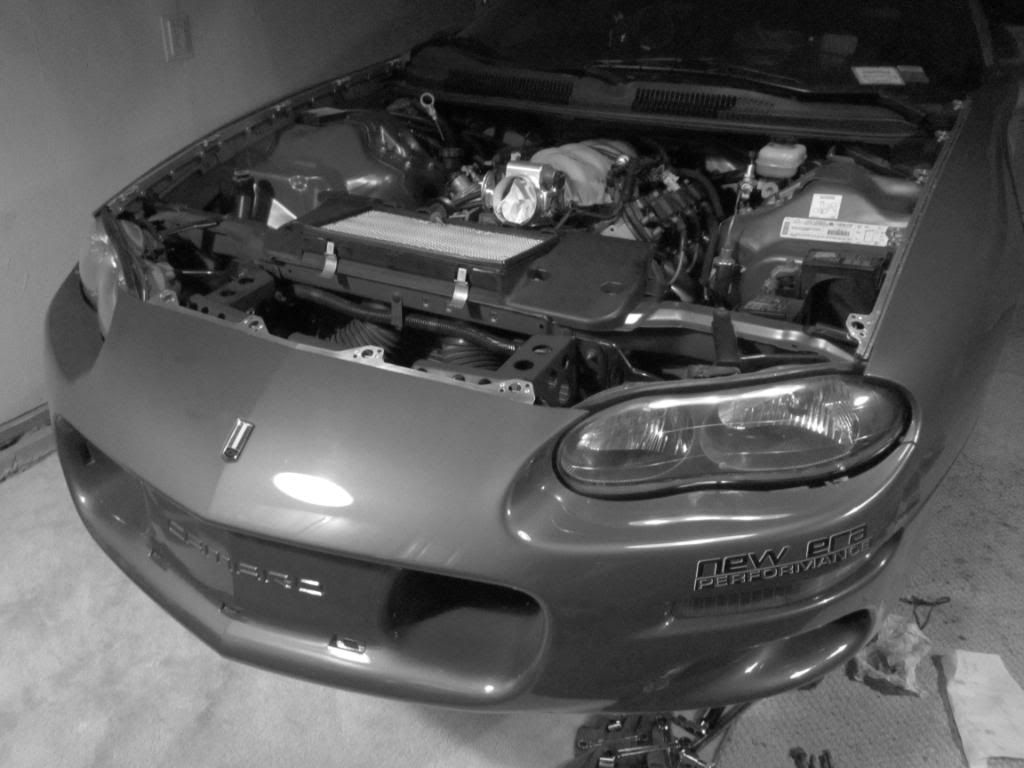

Some pics of the front end, trimmed up light. Still have the stock airdamn, and some other things.

still not leaking

Might get a new oil pan gasket, the back got a little ripped up trying to get the pan off 1st time. And somthing was leaking over the filter area, the oil passages are right there.

Took some affect pics.

Not sludge, I change the oil every 1-2K miles and cleaned it out a few years ago when I did rod bolts. The oil is clean, but the stock baffle had a nice coating of dust clinging to it, no flakes, or chucks. Found some valve seal springs, a few in the pickup screen. 1-2 little black RTV boogers off the timming cover.

Not sludge, I change the oil every 1-2K miles and cleaned it out a few years ago when I did rod bolts. The oil is clean, but the stock baffle had a nice coating of dust clinging to it, no flakes, or chucks. Found some valve seal springs, a few in the pickup screen. 1-2 little black RTV boogers off the timming cover.

A few red locktight half ring off I think a cam plate bolt in the pickup screen too

blasted the pan with hot wated dawm quick, but going to grind the back flush for the blocksaver plate while its out, so final clean after that. This imporved racing baffle fits good. I dont really need the side doors, kinds wish it was just strait across the the front, One bigger place to keep oil. Not sure If the smaller middle one with the side closed off can get sucked dry. If you carry a long wheelie?

Some pics of the front end, trimmed up light. Still have the stock airdamn, and some other things.

still not leaking

Might get a new oil pan gasket, the back got a little ripped up trying to get the pan off 1st time. And somthing was leaking over the filter area, the oil passages are right there.

Took some affect pics.

They all get that dirty/dusty look on them. Had a cam only ls1 that did it after 50 street miles and 25 passes or so. Nothing in the filter when cutting them open ever or on the magnetic drain plug.

What's your opinion on that baffle ? Think it'll stop all the oil starvation at the launch that people are having?

What's your opinion on that baffle ? Think it'll stop all the oil starvation at the launch that people are having?

I think that baffle is really good, I'm not a oil system expert or anything but dont think you can do anything better with the stock pan and pickup. The stock baffle looks like a piece of junk,It might stop oil for sloshing for .04 secs, and it will just go around it.

I think it would be better for drag racing if there was a baffle with a new pickup moved to the rear. And the baffle just strait across in the back, with the flap doors. Or even just a L shape on the passenger corner, the oil filter dosn't allow much room for the driver side corner in the pan anyway. But this is more for all around, and handling I think and it just happens to stop rear flow too. So we can use it for drag racing too.

Got the high spots on the back of the pan all flush. I did a little porting on the oil passages going to the filer. So just final wash everything good, and I can get it all back on today. Just gona use the stock oil pan gasket, little RTV in the back corners were it peeling.

I think it would be better for drag racing if there was a baffle with a new pickup moved to the rear. And the baffle just strait across in the back, with the flap doors. Or even just a L shape on the passenger corner, the oil filter dosn't allow much room for the driver side corner in the pan anyway. But this is more for all around, and handling I think and it just happens to stop rear flow too. So we can use it for drag racing too.

Got the high spots on the back of the pan all flush. I did a little porting on the oil passages going to the filer. So just final wash everything good, and I can get it all back on today. Just gona use the stock oil pan gasket, little RTV in the back corners were it peeling.

Ya, I looked into one. Has some things I like and some I didn't. Can't think of a better spot for the oil filter to move to, and like using the lower trans bolts. Most guys that run them have a th350/400 I would guess. I could use it again if I build a bigger motor or something, but for now dont have any really problem with the stock one. It would be about $900 -$950 to run the moroso pan with the oil filter setup and everything. Did you guys run one the the Smurf cam only stock motor?

The stock baffle dose really nothing for acceleration, and wheelies. It has a open V behind the pickup. But it doesn't hold enough oil back or slow it down, even for a 1.5 60' it was really dropping oil pressure for me.

Remember the rear of the pan would be on the right, not the way it is in the background

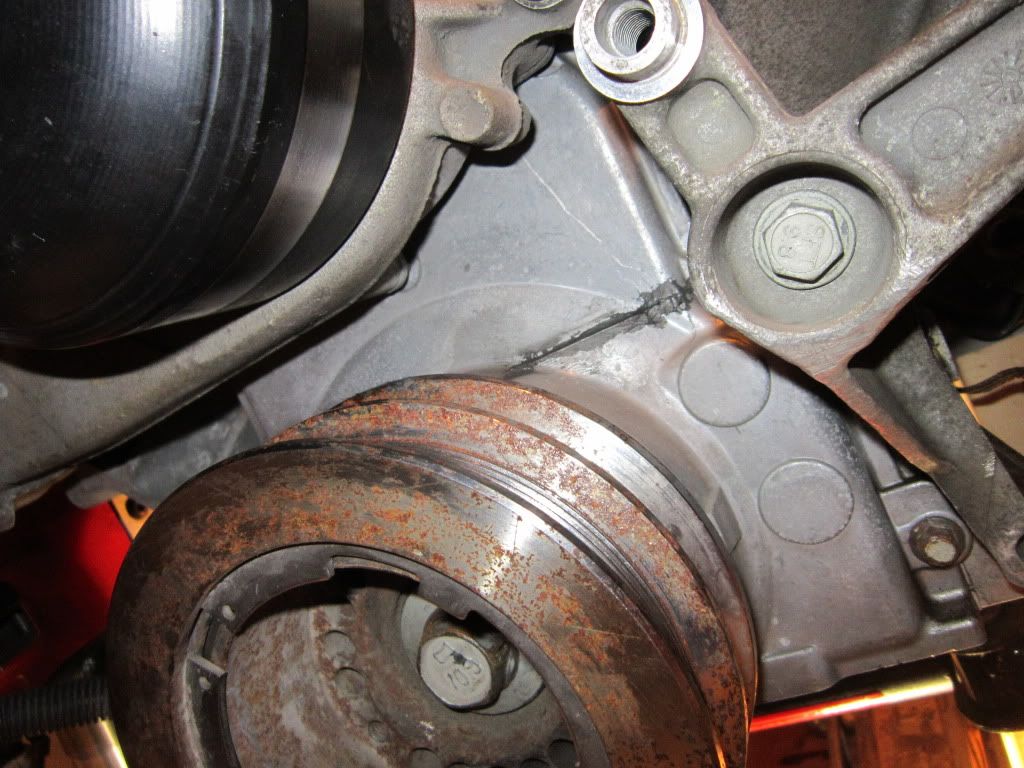

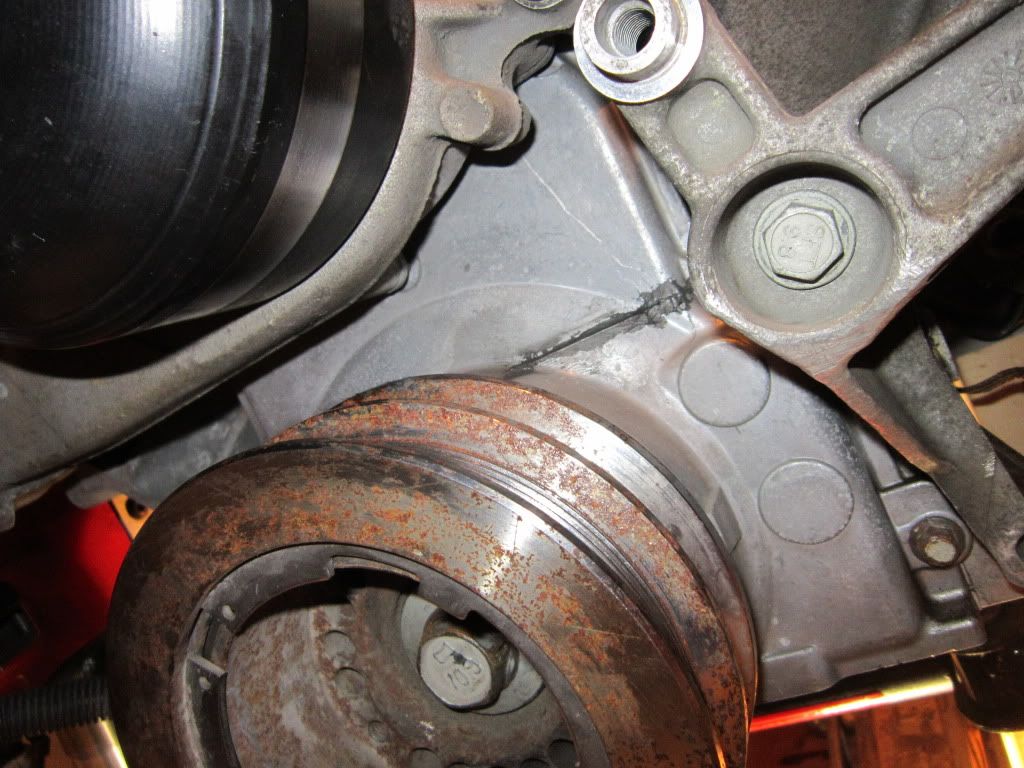

Cleaned up these passages going to the filter, they were square edge drilled intersecting holes.

Its all back on, waiting for the bell housing then the trans can get installed.

The stock baffle dose really nothing for acceleration, and wheelies. It has a open V behind the pickup. But it doesn't hold enough oil back or slow it down, even for a 1.5 60' it was really dropping oil pressure for me.

Remember the rear of the pan would be on the right, not the way it is in the background

Cleaned up these passages going to the filter, they were square edge drilled intersecting holes.

Its all back on, waiting for the bell housing then the trans can get installed.

#90

LS1Tech Sponsor

#91

TECH Resident

iTrader: (9)

Join Date: Oct 2005

Location: TEXAS

Posts: 989

Likes: 0

Received 0 Likes

on

0 Posts

Did you guys fix the stroker crank clearance issue with your new batch? I am gonna give you guys a call tomorrow, I wanna order one of these.

Last edited by mcamarols1; 04-10-2012 at 07:10 AM.

#93

LS1Tech Sponsor

The current batch doesn't have any changes, but we plan on adding a little more clearance on the next batch. However the guys who did report having to grind away any material have all said it was very minimal, and that's only if you have a 4" or bigger stroke.

#95

Michael, what do you think about the stock pickup? the stock setup being a restriction? I thought about cutting out the metal cap? ) leave it 1/8 form the pinch to keep that tight, or cut it open and weld the screen right on or something? I think you can get a replacement pickup that has a bigger opening screen too. But I'm not sure if I want to do that, I had some valve seal springs down there I would think they could get past that screen and get into the pump.

Last edited by studderin; 04-10-2012 at 04:54 PM.

#96

LS1Tech Sponsor

Michael, what do you think about the stock pickup? the stock setup being a restriction? I thought about cutting out the metal cap? ) leave it 1/8 form the pinch to keep that tight, or cut it open and weld the screen right on or something? I think you can get a replacement pickup that has a bigger opening screen too. But I'm not sure if I want to do that, I had some valve seal springs down there I would think they could get past that screen and get into the pump.