How can I get my front wheels to stick in the fenderwell more?

#1

12 Second Club

Thread Starter

Join Date: Feb 2006

Location: Catlettsburg, Ky

Posts: 876

Likes: 0

Received 0 Likes

on

0 Posts

Currently I'm running a set of 15x3.5" draglites and a 5/16" spacer up front with stock brakes/spindles. Stupid me, I ordered PA Racing a arms in stock width. Is there any other way to get the wheels to stick in the fenderwell more? New spindles? New brakes/hubs? Are there Any wheels that could clear with more backspacing (instead of 1.75" like I have now)?

Last edited by Mighty Whitey; 12-09-2011 at 06:49 PM.

#2

TECH Senior Member

iTrader: (28)

I did my aliment myself, and tucked them in as much as I could. With normal parts, I have the front end 1/2 maybe 5/8 inward more then stock. I ran the gear weld 15x3.5 I htink the BS is 1.75 abut it looks better then beofre. I was in the lanes with jolster, and I could tell my front end was tucked more.

https://ls1tech.com/forums/drag-raci...h-diet-30.html

The camber at ride height is 90.0 I think squatted (or maybe it was jacked up?) is 89.8 I know checking it at a height it .2 outward at the top, But I dont want to redo the caster ( I have that pretty leaned back, the car straitens out nicely) I have a BMR Kmember with the slots. I got used 4130 racefraft lower arms. poly/rod end. Yes I wish I had rod/rod but these were just test fit and less the half new. I got them to work. I had to get upper arms. I got rod/rod BMRs new, the upper arms don't alot of weight, some are even heavier then stocks btw. I took the rod ends out, and had to run a 3/4 tap in farther (cut some threads out the outside of the bend tube) So I couls start the aliment with the rod ends in all the way. That acuttly worked out, I iddnt touch the upper BMR arms at all BTW. And I spent some time bending the tabs on the stock upper mounts, and added a washer on one side of the arms. So they were spaced right in the upper mount and moved free. Full tigthned, if you just put them together the spacing is off a little and the arms kinda lock up and bind. You want it free so the shocks can work.

The lowers arms, with one end poly its fixed. So if you have the rod end in all the way, Its spaced too closed to the poly bushing hole. And will not be able to get both bolts in the Kember. So I had to only tight the rod end 3/4 of the way. But started with the bolts inside the slots all the way. And worked out form there, setting the caster and camber. ( the racecraft arms come with bigger greade8 bolts so I had to grind the slots in the Kmember open a little with the die grinder. 3/8th oval burr) if you have to do that, look at the slots. One slot you have to grind a little on both sides, so suspention works better. The old location you can grind it all on one side, and they will help you for a tighter wheel base. And I just tightne ther **** out of the bolts and they havnt moved with some small wheelies. I know some guys that crash some down bad, Have had the bolts move in the slots. When that happens you tack weld the washers to the Kemeber after you have it aliened.

https://ls1tech.com/forums/drag-raci...h-diet-30.html

The camber at ride height is 90.0 I think squatted (or maybe it was jacked up?) is 89.8 I know checking it at a height it .2 outward at the top, But I dont want to redo the caster ( I have that pretty leaned back, the car straitens out nicely) I have a BMR Kmember with the slots. I got used 4130 racefraft lower arms. poly/rod end. Yes I wish I had rod/rod but these were just test fit and less the half new. I got them to work. I had to get upper arms. I got rod/rod BMRs new, the upper arms don't alot of weight, some are even heavier then stocks btw. I took the rod ends out, and had to run a 3/4 tap in farther (cut some threads out the outside of the bend tube) So I couls start the aliment with the rod ends in all the way. That acuttly worked out, I iddnt touch the upper BMR arms at all BTW. And I spent some time bending the tabs on the stock upper mounts, and added a washer on one side of the arms. So they were spaced right in the upper mount and moved free. Full tigthned, if you just put them together the spacing is off a little and the arms kinda lock up and bind. You want it free so the shocks can work.

The lowers arms, with one end poly its fixed. So if you have the rod end in all the way, Its spaced too closed to the poly bushing hole. And will not be able to get both bolts in the Kember. So I had to only tight the rod end 3/4 of the way. But started with the bolts inside the slots all the way. And worked out form there, setting the caster and camber. ( the racecraft arms come with bigger greade8 bolts so I had to grind the slots in the Kmember open a little with the die grinder. 3/8th oval burr) if you have to do that, look at the slots. One slot you have to grind a little on both sides, so suspention works better. The old location you can grind it all on one side, and they will help you for a tighter wheel base. And I just tightne ther **** out of the bolts and they havnt moved with some small wheelies. I know some guys that crash some down bad, Have had the bolts move in the slots. When that happens you tack weld the washers to the Kemeber after you have it aliened.

#4

12 Second Club

Thread Starter

Join Date: Feb 2006

Location: Catlettsburg, Ky

Posts: 876

Likes: 0

Received 0 Likes

on

0 Posts

I've followed along with your build quite a bit Here lately.

My a arms are just poly/Delrin with a steel sleeve, and the lowers are poly/Delrin in the front part, rodend in the rear (which I think they all are)

On both uppers and lowers, I did a little work, and shortened the steel sleeve, and machined a few spacers to put on the ends of each sleeve/bushing, and drilled/tapped each a arm for grease fittings:

Front end assembled with no spring, I can grab the spindle and move the frontend through it's entire range of motion, bind free, until the upper A arm hits the fenderwell or the balljoint binds, and the body of the lower a arm's rod end hits the k member mounting tabs (way beyond the travel limits of the shock) with strange SA shocks and 275lb/in springs, I should be able to get the front end unloaded and accelerating upward fairly easy, before The unsprung weight comes in to play.

I'm seriously thinking about buying a couple bogart front wheels, I know they're expensive as hell, but they will help with the front track width and still allow me to run stock wheels as well (compared to a racecraft or similar spindle)

My a arms are just poly/Delrin with a steel sleeve, and the lowers are poly/Delrin in the front part, rodend in the rear (which I think they all are)

On both uppers and lowers, I did a little work, and shortened the steel sleeve, and machined a few spacers to put on the ends of each sleeve/bushing, and drilled/tapped each a arm for grease fittings:

Front end assembled with no spring, I can grab the spindle and move the frontend through it's entire range of motion, bind free, until the upper A arm hits the fenderwell or the balljoint binds, and the body of the lower a arm's rod end hits the k member mounting tabs (way beyond the travel limits of the shock) with strange SA shocks and 275lb/in springs, I should be able to get the front end unloaded and accelerating upward fairly easy, before The unsprung weight comes in to play.

I'm seriously thinking about buying a couple bogart front wheels, I know they're expensive as hell, but they will help with the front track width and still allow me to run stock wheels as well (compared to a racecraft or similar spindle)

#5

12 Second Club

Thread Starter

Join Date: Feb 2006

Location: Catlettsburg, Ky

Posts: 876

Likes: 0

Received 0 Likes

on

0 Posts

Ditching the spacer is definately a viable option.

smaller brakes? Ehh.. This is somewhat of a double edged sword.

I'm not paying ~ $1k for drag brakes for 4th gen spindles and lose 15lbs. When I can buy racecraft spindles setup for a 3rd gen, and the matching 3rd gen drag brakes, and lose 40lbs for the same money.

That's fine and all, but I'd like to be able to bolt on a stock wheel at some point in time, and I'm not sure I'd even an s10/3rd gen wheel would work then.

smaller brakes? Ehh.. This is somewhat of a double edged sword.

I'm not paying ~ $1k for drag brakes for 4th gen spindles and lose 15lbs. When I can buy racecraft spindles setup for a 3rd gen, and the matching 3rd gen drag brakes, and lose 40lbs for the same money.

That's fine and all, but I'd like to be able to bolt on a stock wheel at some point in time, and I'm not sure I'd even an s10/3rd gen wheel would work then.

#7

12 Second Club

Thread Starter

Join Date: Feb 2006

Location: Catlettsburg, Ky

Posts: 876

Likes: 0

Received 0 Likes

on

0 Posts

I think I'm gonna unbolt the spindle/brake assembly and take it to work one evening and face mill the front face of the caliper, until it clears. That way I can check, mill, check, etc and KNOW before I drag it a back home if it's going to work.

Trending Topics

#8

TECH Senior Member

iTrader: (28)

you gain a ton of room in the brake pads. new pads and worn pads move the caliper out 1/4. You could cut the pads and just run them with a little of the meat on them,(well just the outside pad) And change them once a year.

Im not sure on the brakes, I hear one style moved the rotor out a little more then stock, and another in? if thats 4th and 3rd gen kits, or just strange/areoapce Im not sure. The strange pro2. are alittle thicker rotor hat then the fully steel normal rotors.

if you do get drag brakes chack the lower balljoiunt cup for hiting the rotor. Im not sure on thouse LCA. Nice work on the bushings.

Im not sure on the brakes, I hear one style moved the rotor out a little more then stock, and another in? if thats 4th and 3rd gen kits, or just strange/areoapce Im not sure. The strange pro2. are alittle thicker rotor hat then the fully steel normal rotors.

if you do get drag brakes chack the lower balljoiunt cup for hiting the rotor. Im not sure on thouse LCA. Nice work on the bushings.

#9

TECH Apprentice

iTrader: (9)

I recently switched to the Strange front drag brakes on stock spindles. I think it tucked the wheels just a bit more, but I wasn't running a spacer before so it's hard to tell for sure. FWIW I saved 30 lbs over stock, and I had to trim the lower control arm to clear the rotor. Stock arms though. Studderin's right about new pads vs old pads too. I had my rears ground to clear pro stars, and when I put new pads in I gouged the **** out of the wheels backing out of the garage. Took the pads out and knocked off about half and no problems.

#10

TECH Senior Member

iTrader: (28)

thats my car with the strange 3rd gen kit on racecraft 2 drop spindles. Stock lower arms, you can see if the rotors were 2inch down you will have to grind the Aarms.

This is with burhart arms at stock height......But I put racecraft lower arms, and ther smaller balljoint cup to clear, I know you can get BMR arms with a notched cup t clear too

And I just looked at some pics when I was going the alinment. Looks like I gained 5/8th per side.

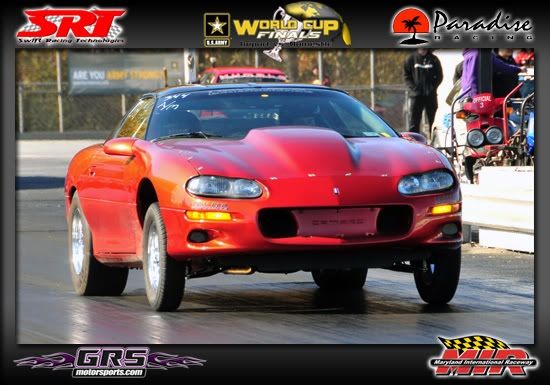

heres the only pic I can find with the aliment to bring it in, I think you can tell its tucked a little more. (this is the same normal 15x3.5 1.75 BS rims)

stock spec , its about flush ( and sig)

Last edited by studderin; 12-10-2011 at 06:48 PM.

#11

Race your car!

iTrader: (50)

If you go with the new spindles and use 3rd gen brakes it saves you about 400 bucks over using the 4th gen stuff, and that will get you the ability to ditch the spacer. that gets you 5/16 right there.

Once you ditch that, you can, get wheels with something other then the 1.75 backspace if you want... if you call a rim manufacturer that makes a 3 piece wheel they can make you a center portion for the wheel that will pull it in another 1/4 inch or so and that will should still clear without any issues. That got you a total of 9/16 in more then you are now.

If you want to go in any more then that shorter a arms are probably your only bet. I had mine built an inch shorter per side... and it pulled the tires in a good bit, looks like they're pulled in like a pro stock now

Once you ditch that, you can, get wheels with something other then the 1.75 backspace if you want... if you call a rim manufacturer that makes a 3 piece wheel they can make you a center portion for the wheel that will pull it in another 1/4 inch or so and that will should still clear without any issues. That got you a total of 9/16 in more then you are now.

If you want to go in any more then that shorter a arms are probably your only bet. I had mine built an inch shorter per side... and it pulled the tires in a good bit, looks like they're pulled in like a pro stock now