Mini Tubbing

#165

TECH Addict

iTrader: (5)

Have to make my panhard bracket braces and two new tabs for my relocated PHB.

Any new photos?

I got the frame boxed in and welded around the panhard bracket. Welded in the plates I made for the new shock holes up top, will grind those and smooth them out so it looks like factory

I really need to get a tig, I'd rather spend 5x the time and have it come out nicer.

Only worked on the car for about 30 minutes today.

I need to cut my panhard rod, shorten it and weld it back together so I can have something to center the rear until I make my new one.

#167

Launching!

iTrader: (1)

Join Date: Jul 2002

Location: Katy, TX

Posts: 205

Likes: 0

Received 0 Likes

on

0 Posts

I have not had allot of time this weekend to work on it. I have been helping my dad get into his new shop. Helping him move all his tools and stuff.

I am ready to get back to working on the car

I am ready to get back to working on the car

#168

7 Second Club

iTrader: (11)

Phil

#169

TECH Addict

iTrader: (5)

I already welded around the frame. I have to weld in some washers for the new LCA mount and then make my panhard bracket tabs to hold the panhard rod.

Couple other little things. I'm in no hurry though, don't have a rear end or the new rims and tires yet anyways.

Will have to see what santa brings for x-mas.

Couple other little things. I'm in no hurry though, don't have a rear end or the new rims and tires yet anyways.

Will have to see what santa brings for x-mas.

#172

the factory coating is a pain to get off, and doesnt weld worth a damn, when you think its clean grind some more lol, then its best to clean it with acetone or MEK to get all the residue from grinding off, that should help, also it is worse with the tig if it isnt super duper clean it will pop and spit, and wind up looking like a stick weld when you are done. so for the rest of it clean it alot, that coating is hard to get off

#173

TECH Addict

iTrader: (5)

the factory coating is a pain to get off, and doesnt weld worth a damn, when you think its clean grind some more lol, then its best to clean it with acetone or MEK to get all the residue from grinding off, that should help, also it is worse with the tig if it isnt super duper clean it will pop and spit, and wind up looking like a stick weld when you are done. so for the rest of it clean it alot, that coating is hard to get off

I have to get a new set of tubs now.

I'll wire brush the hell out of it before I start tacking those in.

I know both ways require clean metal, I just like the look of tig welded stuff it is so much cleaner, I am just kind of picky when it comes to my car.

I sure am not going to be driving some **** box no matter how fast it is.

#174

7 Second Club

iTrader: (11)

I already finished the welding.

I have to get a new set of tubs now.

I'll wire brush the hell out of it before I start tacking those in.

I know both ways require clean metal, I just like the look of tig welded stuff it is so much cleaner, I am just kind of picky when it comes to my car.

I sure am not going to be driving some **** box no matter how fast it is.

I have to get a new set of tubs now.

I'll wire brush the hell out of it before I start tacking those in.

I know both ways require clean metal, I just like the look of tig welded stuff it is so much cleaner, I am just kind of picky when it comes to my car.

I sure am not going to be driving some **** box no matter how fast it is.

#176

TECH Addict

iTrader: (5)

That looks good, doesn't look like you have much room to lower it though, does the sidewall stick out past the fender?How far is your offset LCA from the fender? I think mine was around 14.25-14.5.

Are you going to mount the LCA all the way to the inside? I know some guys take off the inner spacer and run it all the way against the metal, I think it gives you and extra 3/8-1/2" clearance.

#177

Launching!

iTrader: (1)

Join Date: Jul 2002

Location: Katy, TX

Posts: 205

Likes: 0

Received 0 Likes

on

0 Posts

That looks good, doesn't look like you have much room to lower it though, does the sidewall stick out past the fender?How far is your offset LCA from the fender? I think mine was around 14.25-14.5.

Are you going to mount the LCA all the way to the inside? I know some guys take off the inner spacer and run it all the way against the metal, I think it gives you and extra 3/8-1/2" clearance.

Are you going to mount the LCA all the way to the inside? I know some guys take off the inner spacer and run it all the way against the metal, I think it gives you and extra 3/8-1/2" clearance.

#178

TECH Addict

iTrader: (5)

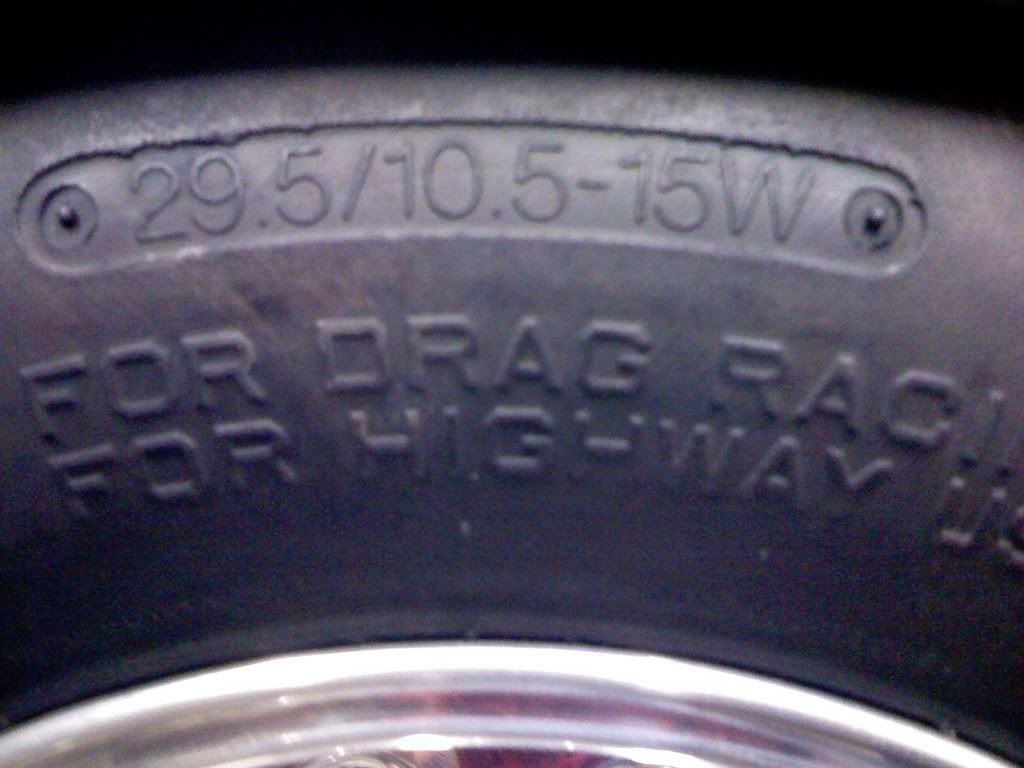

Plus you never know you might want to do a 31x10.5w and race one of those classes.

I have everything welded up and just have to order the tubs.

I was trying to figure out why it wasn't welding as smooth as it should and ran out of wire, then I opened up the case and saw the polarity was reversed, got new wire and finished welding everything up and it was welding awesome.

Then I ran out of gas just as I finished LOL.

I boxed in the panhard bracket on the frame then took my panhard rod and I lowered the car about 1.5" and set up the panhard rod and I don't even have to make tabs because to move the bar level with the ground it sits up way higher than stock.

The panhard rod will end up being "very" close to 3" shorter, so I gained about 2" of more clearance.

There is also about 2.5" of clearance from the stock gas tank.

The bracket looks like this I just have to drill the hole.

Last edited by RAGENZ28; 12-05-2007 at 07:38 PM.

#179

that damn polarity thing...one of the guys i work with tubbed his 2nd gen and put a cage in a box in it, and when i saw it i was like what the hell did you weld it with a stick welder? he said no a mig. I said you have like no penatration there, that cage needs to be cut out and scrapped, it isnt safe at all. couple weeks later we were talking about mig welders and i mentioned changeing the polarity for flux wire, he goes you cant change the polarity, so i showed him on the welders at the shop, he came in the next day and said you wont belive this, my welder was set for the wrong polarity all along. I asked did you ah read the manual before welding? , he said no i have been welding for years, probably before you were born. anyway moral of the story check the settings before welding lol. I lust hope he never needs his cage, i guess the good thing is he builds engines about like he welded his car, so far hes gone through 1 engine per race.

#180

TECH Addict

iTrader: (5)

that damn polarity thing...one of the guys i work with tubbed his 2nd gen and put a cage in a box in it, and when i saw it i was like what the hell did you weld it with a stick welder? he said no a mig. I said you have like no penatration there, that cage needs to be cut out and scrapped, it isnt safe at all. couple weeks later we were talking about mig welders and i mentioned changeing the polarity for flux wire, he goes you cant change the polarity, so i showed him on the welders at the shop, he came in the next day and said you wont belive this, my welder was set for the wrong polarity all along. I asked did you ah read the manual before welding? , he said no i have been welding for years, probably before you were born. anyway moral of the story check the settings before welding lol. I lust hope he never needs his cage, i guess the good thing is he builds engines about like he welded his car, so far hes gone through 1 engine per race.