Dissappointing AFR 205 Results

#103

Guys,

I made a little time to look over Rudy's heads this evening.

Here is a shot of one of the heads right out of the box....a few dings and dangs on the deck and some light scraping and general abrasion evident. I can only assume this stuff happened after the heads were removed (it didn't happen in shipping....they were packed well in an AFR box).

Note someone took the time to remove the carbon from the faces of the valves (at least get the heavy stuff off), but left the side that matters covered in gunk (the backside of the valves). These heads spent some time on an engine using oil....no doubt about it (likely the previous owner). These heavy oil deposits on the back face of the valve hurts low and midlift flow (essentially blocking some of the flow path at very low lifts) and changes the shape of the valve as far as the air is concerned going across it at the higher lifts (which also effects flow obviously).

Here is another shot of the exhaust port(s)....I actually used the flash here to try and show you guys how black the exhaust ports are....once again covered by a thick film of burnt oil and carbon.

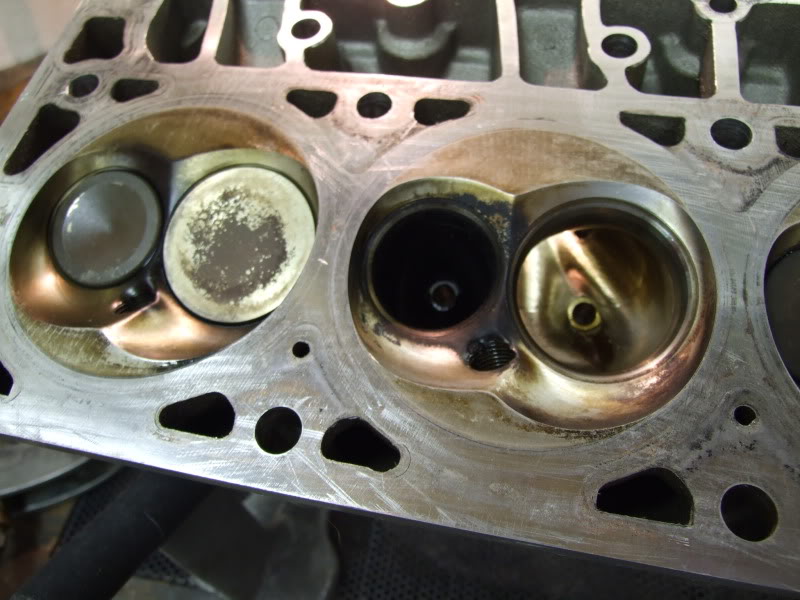

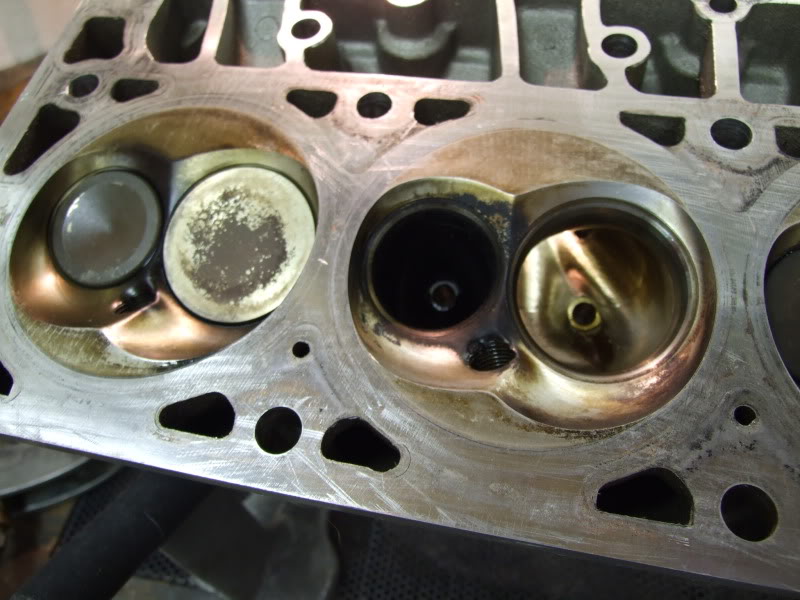

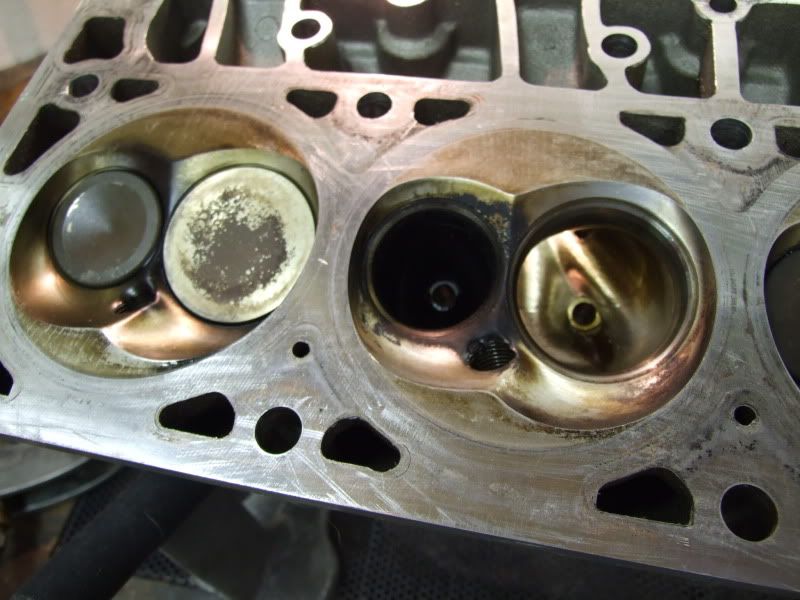

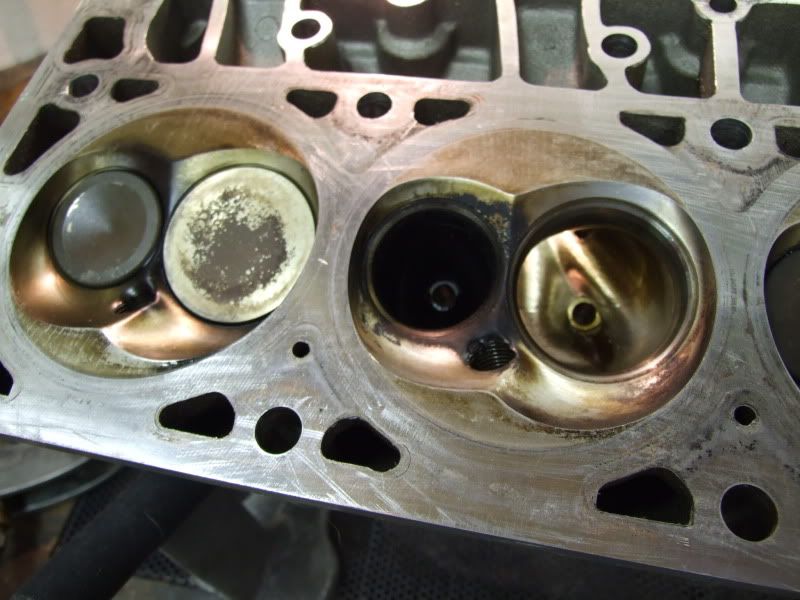

Besides what Ive already noted I really think the largest issue (or another contributing factor to what I think will show to be a low flowing head) is what I have photographed below. Looks like someone sunk a valvejob in the head fairly deep (both intake and exhaust) creating a "manhole cover" effect when the valves are sitting in the head (they sit too deep in the chamber now). Essentially part of the valve opening is blocked by the lip around the VJ and it once again will have a larger impact on the low and midlift flow but also effect peak flow as well as the air has to skip off that lip even when the valve is far away from the seat. Also, depending on the angles used for the new valvejobs, that may also have an adverse effect on overall flow.

Here are two pictures of what I'm discussing here....hard to get a good shot but I think you can pretty easily make out the lip around the perimeter of each valve. Ideally you would have ported the combustion chamber to better transition the VJ to the chamber profile....a critical area for finding (and losing) precious airflow.

Brian Tooley and I both speculated earlier in this thread the VJ may be a significant factor in the so-so showing of these unknown used heads and my guess is we were on the mark with that speculation. I haven't flowed the head yet but will bring them to AFR with me and run them across the flowbench sometime tomorrow.

My guess....the low lifts will be very soft with the .300 - .400 numbers (mids) also soft and lower than we advertise. I don't anticipate the peak numbers to look great either but they are more effected by the angles and its hard to tell looking by eye what VJ profile was utilized here.

The exhaust guides were also very worn (.003 over max allowable from AFR)....the intakes not as much (they were actually decent for a used head although I didnt check every hole of both heads....too time consuming).

Springs looked good checking in at 145-150 or so on the seat.

That's all for now....it's late and I still need to wrap up a few more things before hitting the sack.

Will update you guys when I get a chance....

Thanks,

Tony

I made a little time to look over Rudy's heads this evening.

Here is a shot of one of the heads right out of the box....a few dings and dangs on the deck and some light scraping and general abrasion evident. I can only assume this stuff happened after the heads were removed (it didn't happen in shipping....they were packed well in an AFR box).

Note someone took the time to remove the carbon from the faces of the valves (at least get the heavy stuff off), but left the side that matters covered in gunk (the backside of the valves). These heads spent some time on an engine using oil....no doubt about it (likely the previous owner). These heavy oil deposits on the back face of the valve hurts low and midlift flow (essentially blocking some of the flow path at very low lifts) and changes the shape of the valve as far as the air is concerned going across it at the higher lifts (which also effects flow obviously).

Here is another shot of the exhaust port(s)....I actually used the flash here to try and show you guys how black the exhaust ports are....once again covered by a thick film of burnt oil and carbon.

Besides what Ive already noted I really think the largest issue (or another contributing factor to what I think will show to be a low flowing head) is what I have photographed below. Looks like someone sunk a valvejob in the head fairly deep (both intake and exhaust) creating a "manhole cover" effect when the valves are sitting in the head (they sit too deep in the chamber now). Essentially part of the valve opening is blocked by the lip around the VJ and it once again will have a larger impact on the low and midlift flow but also effect peak flow as well as the air has to skip off that lip even when the valve is far away from the seat. Also, depending on the angles used for the new valvejobs, that may also have an adverse effect on overall flow.

Here are two pictures of what I'm discussing here....hard to get a good shot but I think you can pretty easily make out the lip around the perimeter of each valve. Ideally you would have ported the combustion chamber to better transition the VJ to the chamber profile....a critical area for finding (and losing) precious airflow.

Brian Tooley and I both speculated earlier in this thread the VJ may be a significant factor in the so-so showing of these unknown used heads and my guess is we were on the mark with that speculation. I haven't flowed the head yet but will bring them to AFR with me and run them across the flowbench sometime tomorrow.

My guess....the low lifts will be very soft with the .300 - .400 numbers (mids) also soft and lower than we advertise. I don't anticipate the peak numbers to look great either but they are more effected by the angles and its hard to tell looking by eye what VJ profile was utilized here.

The exhaust guides were also very worn (.003 over max allowable from AFR)....the intakes not as much (they were actually decent for a used head although I didnt check every hole of both heads....too time consuming).

Springs looked good checking in at 145-150 or so on the seat.

That's all for now....it's late and I still need to wrap up a few more things before hitting the sack.

Will update you guys when I get a chance....

Thanks,

Tony

Last edited by Tony Mamo @ AFR; 11-09-2010 at 09:59 AM.

#107

The drama continues....LOL

OK....flowed the head a couple of hours ago and honestly I was a little surprised. They definitely did better than I thought they would which is good and bad depending on your vantage point. It looks like the profile angles on the valvejob were good because the high lift flow numbers were pretty solid (certainly for an average 205 out of the box) and only the very lower lifts on the intake were a little soft.

The exhaust was soft across the board though....while our catalog/website only call for 230 @ .600 on a stock 205, I can tell you now that most heads flow 235 or so at .600 (this head was 220 @ .600)

Of course I really only tested one hole so there is a bit of an assumption being made here that the others would flow the same (in a brand new head that would certainly be the case).

Here are the numbers....

Intake

.200....139

.300....201

.400....250

.500....281

.550....290

.600....297

Exhaust

.200....119

.300....164

.400....194

.500....210

.600....220

I have to discuss with the OP some potential options but at the very least the heads need a skim cut on the deck before they get reinstalled....at the most he has me go thru them, clean them, port them, install lighter intake valves, new guides etc etc......LOL (It's a slippery slope for sure!!).

Catch you guys later....

-Tony

OK....flowed the head a couple of hours ago and honestly I was a little surprised. They definitely did better than I thought they would which is good and bad depending on your vantage point. It looks like the profile angles on the valvejob were good because the high lift flow numbers were pretty solid (certainly for an average 205 out of the box) and only the very lower lifts on the intake were a little soft.

The exhaust was soft across the board though....while our catalog/website only call for 230 @ .600 on a stock 205, I can tell you now that most heads flow 235 or so at .600 (this head was 220 @ .600)

Of course I really only tested one hole so there is a bit of an assumption being made here that the others would flow the same (in a brand new head that would certainly be the case).

Here are the numbers....

Intake

.200....139

.300....201

.400....250

.500....281

.550....290

.600....297

Exhaust

.200....119

.300....164

.400....194

.500....210

.600....220

I have to discuss with the OP some potential options but at the very least the heads need a skim cut on the deck before they get reinstalled....at the most he has me go thru them, clean them, port them, install lighter intake valves, new guides etc etc......LOL (It's a slippery slope for sure!!).

Catch you guys later....

-Tony

#108

I had a good talk with Tony today. I am going to think it over as far as what i am going to do with the heads.I will have something by end of this week. I am postitive i am going to go with the cam no matter what.

Thanks again Tony for taking the time to look over my heads free of charge and giving honest feedback of your findings.

Thanks again Tony for taking the time to look over my heads free of charge and giving honest feedback of your findings.

#109

TECH Addict

iTrader: (39)

Wow, those poor heads. They look like they could use a good bath in a hot tank for a little while. A little bit more build up on the backs of those valves, and they would probably just stop sealing all together. I hope you can get em straightened out, and making the power they should!

#110

Launching!

iTrader: (6)

Join Date: Nov 2010

Location: northern indiana

Posts: 272

Likes: 0

Received 0 Likes

on

0 Posts

Guys,

I made a little time to look over Rudy's heads this evening.

Here is a shot of one of the heads right out of the box....a few dings and dangs on the deck and some light scraping and general abrasion evident. I can only assume this stuff happened after the heads were removed (it didn't happen in shipping....they were packed well in an AFR box).

Note someone took the time to remove the carbon from the faces of the valves (at least get the heavy stuff off), but left the side that matters covered in gunk (the backside of the valves). These heads spent some time on an engine using oil....no doubt about it (likely the previous owner). These heavy oil deposits on the back face of the valve hurts low and midlift flow (essentially blocking some of the flow path at very low lifts) and changes the shape of the valve as far as the air is concerned going across it at the higher lifts (which also effects flow obviously).

Here is another shot of the exhaust port(s)....I actually used the flash here to try and show you guys how black the exhaust ports are....once again covered by a thick film of burnt oil and carbon.

Besides what Ive already noted I really think the largest issue (or another contributing factor to what I think will show to be a low flowing head) is what I have photographed below. Looks like someone sunk a valvejob in the head fairly deep (both intake and exhaust) creating a "manhole cover" effect when the valves are sitting in the head (they sit too deep in the chamber now). Essentially part of the valve opening is blocked by the lip around the VJ and it once again will have a larger impact on the low and midlift flow but also effect peak flow as well as the air has to skip off that lip even when the valve is far away from the seat. Also, depending on the angles used for the new valvejobs, that may also have an adverse effect on overall flow.

Here are two pictures of what I'm discussing here....hard to get a good shot but I think you can pretty easily make out the lip around the perimeter of each valve. Ideally you would have ported the combustion chamber to better transition the VJ to the chamber profile....a critical area for finding (and losing) precious airflow.

Brian Tooley and I both speculated earlier in this thread the VJ may be a significant factor in the so-so showing of these unknown used heads and my guess is we were on the mark with that speculation. I haven't flowed the head yet but will bring them to AFR with me and run them across the flowbench sometime tomorrow.

My guess....the low lifts will be very soft with the .300 - .400 numbers (mids) also soft and lower than we advertise. I don't anticipate the peak numbers to look great either but they are more effected by the angles and its hard to tell looking by eye what VJ profile was utilized here.

The exhaust guides were also very worn (.003 over max allowable from AFR)....the intakes not as much (they were actually decent for a used head although I didnt check every hole of both heads....too time consuming).

Springs looked good checking in at 145-150 or so on the seat.

That's all for now....it's late and I still need to wrap up a few more things before hitting the sack.

Will update you guys when I get a chance....

Thanks,

Tony

I made a little time to look over Rudy's heads this evening.

Here is a shot of one of the heads right out of the box....a few dings and dangs on the deck and some light scraping and general abrasion evident. I can only assume this stuff happened after the heads were removed (it didn't happen in shipping....they were packed well in an AFR box).

Note someone took the time to remove the carbon from the faces of the valves (at least get the heavy stuff off), but left the side that matters covered in gunk (the backside of the valves). These heads spent some time on an engine using oil....no doubt about it (likely the previous owner). These heavy oil deposits on the back face of the valve hurts low and midlift flow (essentially blocking some of the flow path at very low lifts) and changes the shape of the valve as far as the air is concerned going across it at the higher lifts (which also effects flow obviously).

Here is another shot of the exhaust port(s)....I actually used the flash here to try and show you guys how black the exhaust ports are....once again covered by a thick film of burnt oil and carbon.

Besides what Ive already noted I really think the largest issue (or another contributing factor to what I think will show to be a low flowing head) is what I have photographed below. Looks like someone sunk a valvejob in the head fairly deep (both intake and exhaust) creating a "manhole cover" effect when the valves are sitting in the head (they sit too deep in the chamber now). Essentially part of the valve opening is blocked by the lip around the VJ and it once again will have a larger impact on the low and midlift flow but also effect peak flow as well as the air has to skip off that lip even when the valve is far away from the seat. Also, depending on the angles used for the new valvejobs, that may also have an adverse effect on overall flow.

Here are two pictures of what I'm discussing here....hard to get a good shot but I think you can pretty easily make out the lip around the perimeter of each valve. Ideally you would have ported the combustion chamber to better transition the VJ to the chamber profile....a critical area for finding (and losing) precious airflow.

Brian Tooley and I both speculated earlier in this thread the VJ may be a significant factor in the so-so showing of these unknown used heads and my guess is we were on the mark with that speculation. I haven't flowed the head yet but will bring them to AFR with me and run them across the flowbench sometime tomorrow.

My guess....the low lifts will be very soft with the .300 - .400 numbers (mids) also soft and lower than we advertise. I don't anticipate the peak numbers to look great either but they are more effected by the angles and its hard to tell looking by eye what VJ profile was utilized here.

The exhaust guides were also very worn (.003 over max allowable from AFR)....the intakes not as much (they were actually decent for a used head although I didnt check every hole of both heads....too time consuming).

Springs looked good checking in at 145-150 or so on the seat.

That's all for now....it's late and I still need to wrap up a few more things before hitting the sack.

Will update you guys when I get a chance....

Thanks,

Tony

#112

**Update** Im going to let Tony completely rework the heads.From what i know he is going to port them, put new guides in the heads and also bigger valves in also. Maybe he can chime in and let everyone know what are all the small details.

#114

Rudy, thanks for the shout on yt. I bet you will see good numbers with Tony's work on his heads and a new cam! Car should be getting close to 10's! Hope you get it back together soon to take advantage of the cool air!

#115

Thought I would revive this thread quickly and give you guys an update....

I have been making some progress on these 205 heads and finally had a chance to bounce one of the finished ports across the flow bench late last night. They responded well to the work I have performed showing strong gains in the areas of the flow curve I typically see improve and I thought I would share some of the results with you.

It's important to keep in mind that the airflow gains being discussed here are accomplished with minimal aluminum removed from the port (only in key sensitive areas) so the high velocity approach which has been successful with the 205 head design is still in tact. The chambers have quite a bit of time invested in them and of course the proper valvejob and transitions into and out of very critical to flow. In fact this work increases the efficiency of an already efficient piece by fattening the flow curve significantly with only a minimal increase in volume and CSA of the actual port.

Here is some flow data from one of the ports I finished up last night.....still have more work to do on the heads and Im trying my best to ship them back to Rudy (the OP) prior to my departure to Orlando for the PRI show. I also included the original results from when I flowed them a couple of weeks ago....big gains across the lower and middle part of the flow curve that should really improve this engines ability to fill and evacuate the cylinder more effectively.

Intake

.200....139....161

.300....201....217

.400....250....263

.500....281....290

.550....290....303

.600....297....306

Exhaust

.200....119....133

.300....164....183

.400....194....215

.500....210....229

.600....220....240

I will post up a few pics when Im done with all the work....hopefully early next week time permitting. They are coming around nicely and look ALOT better than when I received them....LOL

Cheers,

Tony

I have been making some progress on these 205 heads and finally had a chance to bounce one of the finished ports across the flow bench late last night. They responded well to the work I have performed showing strong gains in the areas of the flow curve I typically see improve and I thought I would share some of the results with you.

It's important to keep in mind that the airflow gains being discussed here are accomplished with minimal aluminum removed from the port (only in key sensitive areas) so the high velocity approach which has been successful with the 205 head design is still in tact. The chambers have quite a bit of time invested in them and of course the proper valvejob and transitions into and out of very critical to flow. In fact this work increases the efficiency of an already efficient piece by fattening the flow curve significantly with only a minimal increase in volume and CSA of the actual port.

Here is some flow data from one of the ports I finished up last night.....still have more work to do on the heads and Im trying my best to ship them back to Rudy (the OP) prior to my departure to Orlando for the PRI show. I also included the original results from when I flowed them a couple of weeks ago....big gains across the lower and middle part of the flow curve that should really improve this engines ability to fill and evacuate the cylinder more effectively.

Intake

.200....139....161

.300....201....217

.400....250....263

.500....281....290

.550....290....303

.600....297....306

Exhaust

.200....119....133

.300....164....183

.400....194....215

.500....210....229

.600....220....240

I will post up a few pics when Im done with all the work....hopefully early next week time permitting. They are coming around nicely and look ALOT better than when I received them....LOL

Cheers,

Tony

Last edited by Tony Mamo @ AFR; 11-30-2010 at 02:18 PM.

#118

TECH Senior Member

iTrader: (4)

Your exhaust port flow is quite improved, what are you going to do with the cam since you have a long exhaust duration right now? Also, you may have to be careful on the intake duration if you don't want to flycut.

Last edited by vettenuts; 12-02-2010 at 11:30 AM.

#120