Poor man's method to better belt wrap on an fbody

#262

11 Second Club

iTrader: (19)

Ok, I got my 3.5" pulley from Autozone installed the other night and had a buddy of mine machine my standoffs. It was a tight fit. My original 37" belt was shot and I couldn't get it to fit. I got a 38" belt and a 38-3/4" belt but both were way to big. I tried to get a 37.5" belt local but nobody had one. I finally found a 37.1" belt. I had to increase the length of the tensioner pulley slot by about an 1/8" to get the belt on. I tried all sorts of ways to avoid machining the bracket but this was the only way to get it to work. Once the belt was on it was already pretty tight. I had to move the tensioner pulley down an 1/8" to get it off of the idler on the serpentine drive system. I have yet to drive it but it seems to be good. I think I added 1" on the supercharger pulley and 2" on the balancer pulley. I can still get one finger in between the new idler and the tensioner. I will post pics tonight.

Just so you guys know, a (1') increase in belt size is ALOT! Always try to increase in 1/2" increments or you'll be running back and fourth to the auto parts store like I did!

Just so you guys know, a (1') increase in belt size is ALOT! Always try to increase in 1/2" increments or you'll be running back and fourth to the auto parts store like I did!

#263

9 Second Club

iTrader: (27)

Ok, I made a thread on my setup, but it seems to have been deleted. I used a Mitsu pulley and a Gatorback belt 4080407. It has a ton of belt wrap, but I seem to still have some boost loss issues. I'm using the 3.4 pulley on the D1, and it's spiking to 14-15, then falling back to 12. I'm still on the black bypass valve, and the tuner thinks that may be the culprit. I could probably go a little shorter with the belt, but Goodyear jumps down from a 40.75 effective lenght to a 40, and I dont think I could stretch that one on there. I'm going to get some pics tonight of the finished setup. I had to shorten the standoff about .325, and use a little longer bolt, but that's it. Hopefull switching to the red bypass valve will solve my issues. Any other ideas on where my boost is going?

#264

11 Second Club

iTrader: (19)

I used the larger of the pulleys and I just had the car dyno tuned. I lost about 1# of boost. I think the blet is slipping but looking at it you could never tell. I just installed a full 3" true dual exhaust. Before that I had a 2.5" true dual. Do you guys think the larger exhaust could have done this?

#266

11 Second Club

iTrader: (19)

I should have stated this before but as we were dyno testing it my boost was going up and down a pound every run. It was very inconsistent. It would go to 7, drop down to 5 and then go back to 6. I have never had this problem with the old Procharger setup. I re-tightened the belt but we only did one more run after that. I did make more power though. I went from 486 rwhp to 495 rwhp.

#267

Thats weird.. Definitely sounds like belt slip. Is there any dust on the bracket? Did you try putting the other belt back on and not using the extra idler? Does the boost fluctuate during street driving? I cant imagine this mod causing more belt slip.

#268

11 Second Club

iTrader: (19)

Yes, there was dust on the belt itself. No, I didn't remove the extra idler and try it without. It has been raining here so no way to get her into boost to test it. I did put more tension on the belt. The belt is starting to look weird. You can see the ribs on the smooth side of the belt. I am thinking that it is too much rap for the belt and it is causing it to bind.

#270

TECH Enthusiast

iTrader: (8)

Join Date: Feb 2006

Location: Denver Colo.

Posts: 524

Likes: 0

Received 0 Likes

on

0 Posts

Have you checked if it's rubbing on one of the stand-offs? Have you confirmed the idler is rotating? My serp belt looked like that after installed it wrong. It cut into the stand-off about an 1/16" and turned silver like that.

#272

Technically, I don't see how it could be applying anymore stress? It is a fixed idler. Is it possible the belt is rubbing itself between the stock tensioner and the idler?

#273

Take the extra idler off and see if that helps.. Thats about the simplest problem solving effort you can do that will give you a definitive answer if this mod is helping or hurting you. Thats about all I can say. I know it worked great for me. I have no idea how too much belt wrap could possibly hurt your system.

#274

11 Second Club

iTrader: (19)

Take the extra idler off and see if that helps.. Thats about the simplest problem solving effort you can do that will give you a definitive answer if this mod is helping or hurting you. Thats about all I can say. I know it worked great for me. I have no idea how too much belt wrap could possibly hurt your system.

I tightened the belt even further and my boost still fluctuates a pound of two. This sucks! I can't figure out what would cause this.

#275

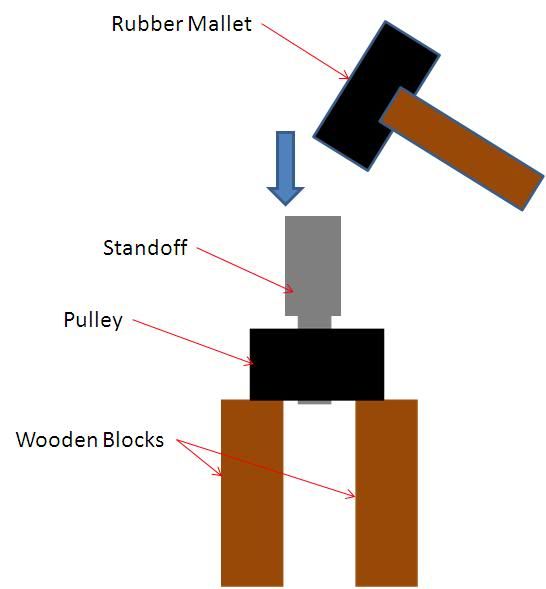

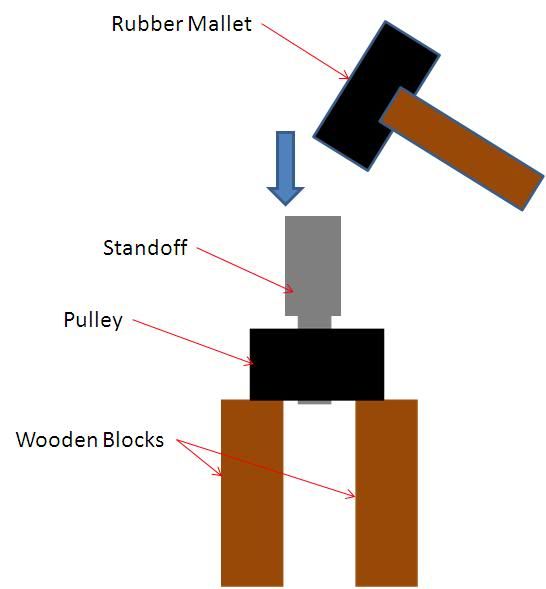

I cant believe I am having to post this, but I've got inquiries on how to install (and remove) the pulley from the standoff. After spelling it out, I figured it would be more effective to make a little picture. Maybe that will work better than my words.

Install:

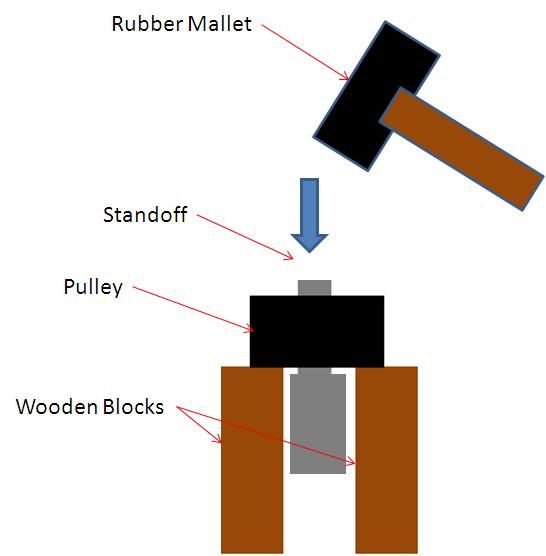

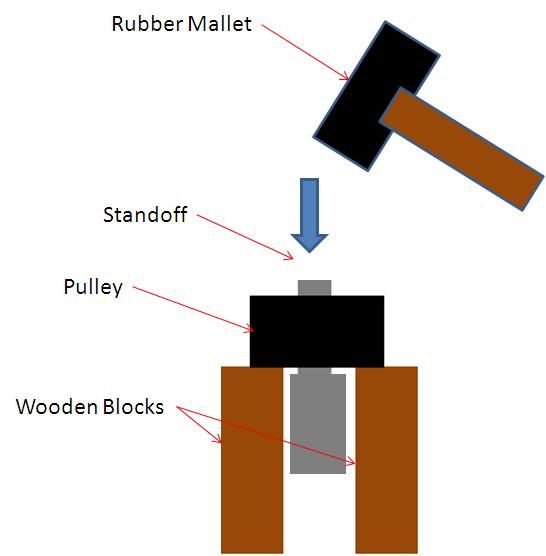

Remove:

*If you don't have a rubber mallet, use a hammer and a block of wood where it contacts the standoff.. That is- put a block of wood on top of the standoff so there is no metal to metal contact. If you STILL can't figure out how to install and remove the pulley after reading this, you should NOT be working on your own car!

Install:

Remove:

*If you don't have a rubber mallet, use a hammer and a block of wood where it contacts the standoff.. That is- put a block of wood on top of the standoff so there is no metal to metal contact. If you STILL can't figure out how to install and remove the pulley after reading this, you should NOT be working on your own car!

#276

TECH Regular

iTrader: (9)

You don't want to put a side load on the bearings like that. You need to apply pressure to the race that the shaft is going into if you are working with a press fit. This means the side of the inside ring is what would need the load during the press. By supporting the outside of the bearing and hammering into the inside you risk unseating the ball bearings inside from the groove, or deforming them which would cause a failure. If the bearing seizes your best case scenario is a broken belt and needing a new pulley and likely shaft given the press fit will twist the aluminum, worst case the pulley separates from the bearing and you damage the bracket too.

You should instead machine the shaft as a slip fit and use side clamping to retain the bearing in place once it is all bolted together. This is the method used by the OEM's and myself, sandwiching the bearing on both sides and bolting it down. This is easier to replace, and less chance of incorrect installation leading to bearing failure.

You should instead machine the shaft as a slip fit and use side clamping to retain the bearing in place once it is all bolted together. This is the method used by the OEM's and myself, sandwiching the bearing on both sides and bolting it down. This is easier to replace, and less chance of incorrect installation leading to bearing failure.

#277

It is not an interference fit. There should be .001" of clearance. The ID of the bearings are 17mm = .669". The shaft is .668". Maybe that clearance is a tad tight, but there should not be more side load on the bearings than what they can handle just to tap the pulley on. Again, I'll reiterate: this is what I did, and this is what has been working for me. No one has to do it the way I did it. If anyone wants the fitment to be looser, they can machine their standoff down some more.

#278

TECH Regular

iTrader: (9)

.001 is a press fit, that's all I'm saying, that is a tight fit, especially since often when you call for .668 you can end up plus or minus that number pretty easily. If you end up over by even a thousanth of an inch you're hosed. Even .667 is a tight slip fit.

You're right if you get it going in straight the first shot you can tap it in if it is the right size, but I'm just saying you need to be careful. Anyone who is having trouble getting the shaft in, shouldn't just try and force it on with a hammer, the first thing to do is measure the shaft and make sure it is the right diameter.

If it is close you can freeze the shaft and that might gain someone whose shaft is tight enough wiggle room to get it to go on easier.

You're right if you get it going in straight the first shot you can tap it in if it is the right size, but I'm just saying you need to be careful. Anyone who is having trouble getting the shaft in, shouldn't just try and force it on with a hammer, the first thing to do is measure the shaft and make sure it is the right diameter.

If it is close you can freeze the shaft and that might gain someone whose shaft is tight enough wiggle room to get it to go on easier.

#279

Yes, you are correct, it is a press fit. I did not say it was not a press fit, I said it was not an interference fit. Infact, in the drawing I made, it even specifies that its a press fit. I know my standoff was machined to .6680 because I measured it. I guess anyone else who has had theirs done should do the same. I did not put tolerances on my drawing. Maybe I should have, but again, I did not make the drawing initially for intentions of being mass produced by a company machining them. I could have, but I am not getting paid for it, and I already had mine made.

Having stated all that, radial bearings can take *some* side load. They are designed to take axial and shear loading while in use, but some side loading is always accounted for exactly for installation. A press would be ideal for install, but not all people have that. If someone had a big C-clamp that could work as well. Impact loading stresses can often typically double that of static loading. However, I doubt that tapping it on with a rubber mallet would be too bad if the fit is not an interference fit.

Having stated all that, radial bearings can take *some* side load. They are designed to take axial and shear loading while in use, but some side loading is always accounted for exactly for installation. A press would be ideal for install, but not all people have that. If someone had a big C-clamp that could work as well. Impact loading stresses can often typically double that of static loading. However, I doubt that tapping it on with a rubber mallet would be too bad if the fit is not an interference fit.