KYTP GT-88 Truck Manifold 408ci Build w/Pics

#61

12 Second Club

Thread Starter

iTrader: (9)

Join Date: Jun 2006

Location: Grand Forks, North Dakota

Posts: 1,051

Likes: 0

Received 0 Likes

on

0 Posts

Well in June we had worked most the bugs out besides the high boost backfire. On a pull it backfired bad and the oil pressure went to zero. We dropped the oil and found lots of bearing flakes. I took a few months off, i needed it. We tore it apart this weekend and found the main bearings were toast and the thrust bearing had worn significantly, even causing the crank to rub on the block.

I am pretty confident this was the cause of the backfire, crank walking from the crank sensor on high boost. Not sure what is causing the walk, could be the converter i suppose. Yank PY 3400, a nice piece.

You can see where the crank rubbed on the block.

Thrust bearing

I am pretty confident this was the cause of the backfire, crank walking from the crank sensor on high boost. Not sure what is causing the walk, could be the converter i suppose. Yank PY 3400, a nice piece.

You can see where the crank rubbed on the block.

Thrust bearing

#64

12 Second Club

Thread Starter

iTrader: (9)

Join Date: Jun 2006

Location: Grand Forks, North Dakota

Posts: 1,051

Likes: 0

Received 0 Likes

on

0 Posts

So long story short not sure what caused the failure.

#65

Make sure to flush that GT88. Even though in theory the oil is suppose to be filtered make sure you check the oil drain pipe for flakes as well. The bearings in those turbos and the CHRA oils are machined very tight clearance for oil passage. We use pretty small oil holes to feed the bearings to keep pressure up, so trash can block them.

#67

12 Second Club

Thread Starter

iTrader: (9)

Join Date: Jun 2006

Location: Grand Forks, North Dakota

Posts: 1,051

Likes: 0

Received 0 Likes

on

0 Posts

Interesting that happened to you tho....

The crank got all hot and rubbed against the block for you as well, or a lot less damage?

Last edited by nahasapeemapetalon; 08-15-2011 at 09:12 PM.

#68

TECH Fanatic

iTrader: (2)

it rubbed the block, not quite as deep as yours but a good half as deep at least. you could hear metal/metal when it was idling and lost all oil pressure. Just so happens it did it about 2 blocks from my shop so I just drove it there. IMHO you shouldnt be running a PY anymore with the weight and power you are making, time to step it up to a higher quality piece.

#70

TECH Enthusiast

iTrader: (4)

Join Date: Apr 2008

Location: Home town Clive,IA current town FORT BENNING GEORGIA

Posts: 525

Likes: 0

Received 0 Likes

on

0 Posts

Can we have alittle more detail on you going to the track, like possibly posting up a video or slip? Did you leave on a trans-brake or two step?

Not to sound rude but i was expecting a little more from this car with all of those supporting mods. i figured you could easily be into the 9's the reason.

Not to sound rude but i was expecting a little more from this car with all of those supporting mods. i figured you could easily be into the 9's the reason.

#71

12 Second Club

Thread Starter

iTrader: (9)

Join Date: Jun 2006

Location: Grand Forks, North Dakota

Posts: 1,051

Likes: 0

Received 0 Likes

on

0 Posts

It sounds like they think the block will be salvageable and welding and recutting the crank would be reused for about 400 or so. If they put together the short block they would want to rehone and put new rings in it. He thought if I put it together it might be ok with existing rings.

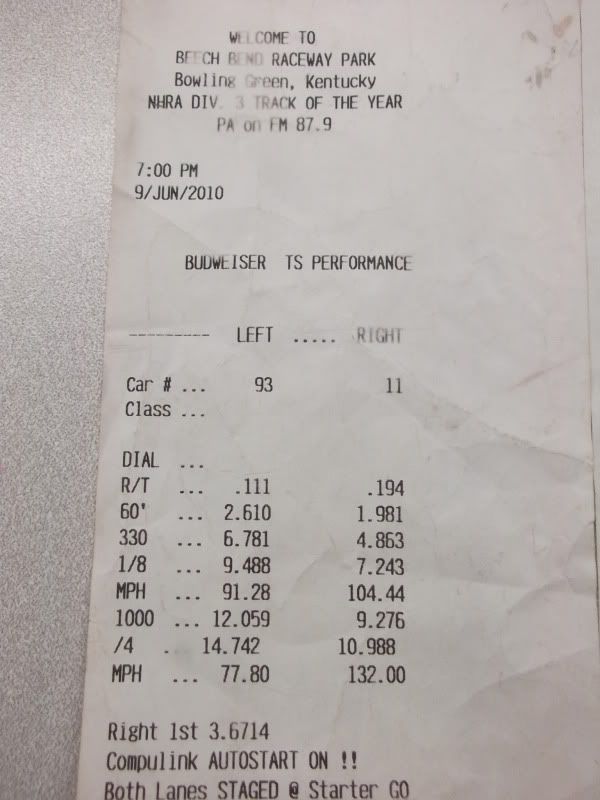

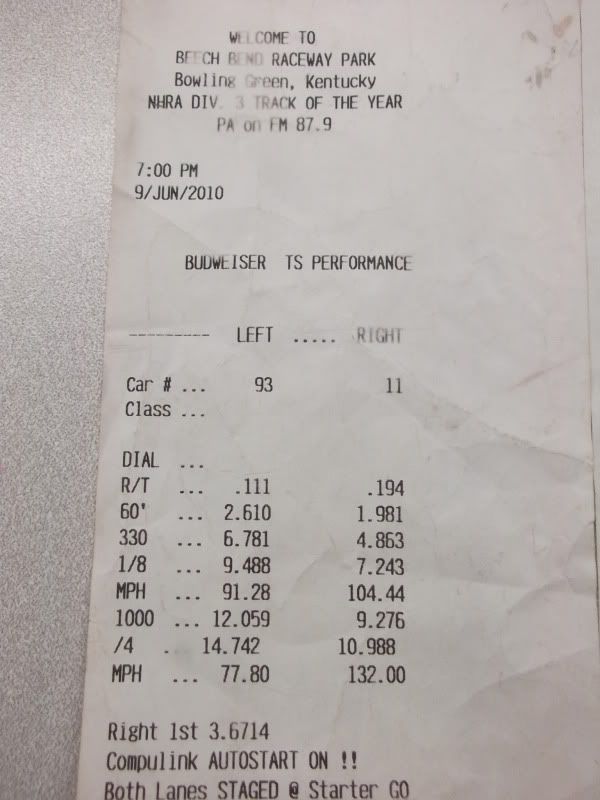

Here is my best drag radial time to date with this setup, didnt have N20 to spool so the 60' was horrible. Just left off the foot brake. This was on power tour in Bowling Green in 2010, it was 95 IIRC, i was happy with it.

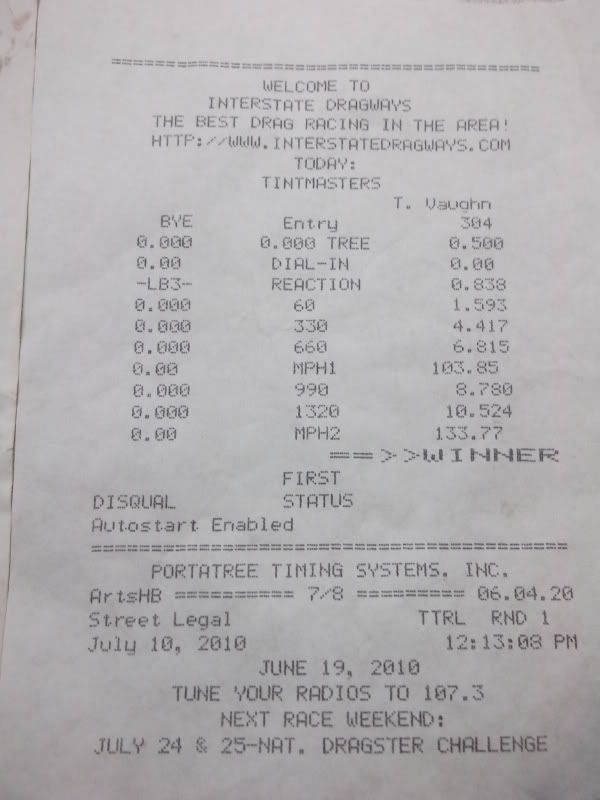

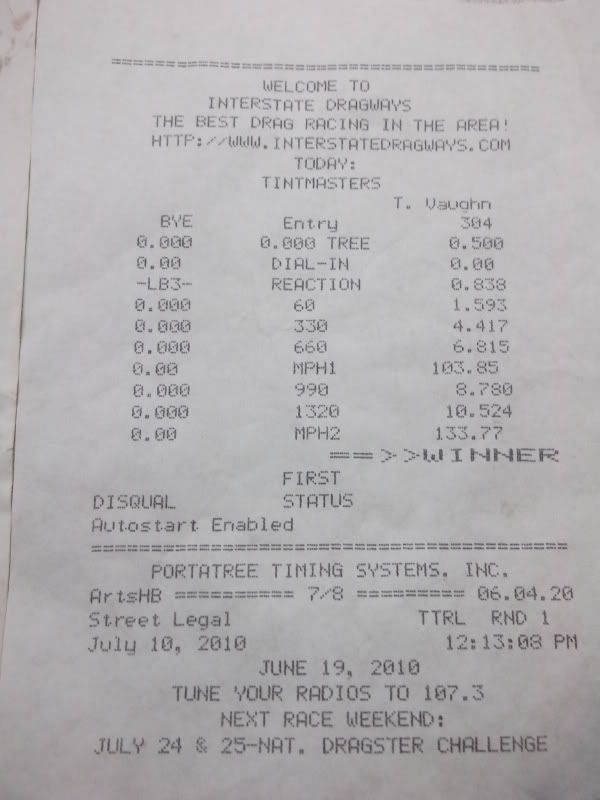

Here is the best with slicks so far with the turbo setup, ran N20 through first gear to get going. I think I was at about 14-15lbs.

I just leave on the foot brake with a n20 shot to get me going. I usually cut 1.5 60 foots. I think the car could squeak out a high 9 with everything working, the weight kills me. 4280 lbs is heavy!

Can we have alittle more detail on you going to the track, like possibly posting up a video or slip? Did you leave on a trans-brake or two step?

Not to sound rude but i was expecting a little more from this car with all of those supporting mods. i figured you could easily be into the 9's the reason.

Not to sound rude but i was expecting a little more from this car with all of those supporting mods. i figured you could easily be into the 9's the reason.

Here is the best with slicks so far with the turbo setup, ran N20 through first gear to get going. I think I was at about 14-15lbs.

I just leave on the foot brake with a n20 shot to get me going. I usually cut 1.5 60 foots. I think the car could squeak out a high 9 with everything working, the weight kills me. 4280 lbs is heavy!

Last edited by nahasapeemapetalon; 10-11-2011 at 08:08 AM.

#72

12 Second Club

Thread Starter

iTrader: (9)

Join Date: Jun 2006

Location: Grand Forks, North Dakota

Posts: 1,051

Likes: 0

Received 0 Likes

on

0 Posts

I never updated this, last summer right before the motor took a dump i put a new alternator kit on from modular turbo.

My mid 90's suburban alternator wasnt doing the job, voltage was always really low and my belt alignment wasnt very great.

I got a 145A truck alternator and used this Modular Turbo bracket. I have nasty nate fuel rails and just had to replace the passenger front rail fuel fitting with an NPT 90 to hose end fitting.

The bracket was well put together, seems really sturdy. Nice adjustable tensioner. No more belt squeal. So far so good.

I probably didnt need to modify the alternator back plastic cover but chose to for possible belt tightening.

The belt sent was 72", ended up buying a master pro belt that was 70-7/8" long.

14.0Volts FTW!!

My mid 90's suburban alternator wasnt doing the job, voltage was always really low and my belt alignment wasnt very great.

I got a 145A truck alternator and used this Modular Turbo bracket. I have nasty nate fuel rails and just had to replace the passenger front rail fuel fitting with an NPT 90 to hose end fitting.

The bracket was well put together, seems really sturdy. Nice adjustable tensioner. No more belt squeal. So far so good.

I probably didnt need to modify the alternator back plastic cover but chose to for possible belt tightening.

The belt sent was 72", ended up buying a master pro belt that was 70-7/8" long.

14.0Volts FTW!!

Last edited by nahasapeemapetalon; 03-05-2012 at 07:38 AM.

#73

12 Second Club

Thread Starter

iTrader: (9)

Join Date: Jun 2006

Location: Grand Forks, North Dakota

Posts: 1,051

Likes: 0

Received 0 Likes

on

0 Posts

So after a long down time from the thrust bearing problem and talking to people who have seen this we are pretty confident that high pressure within the torque converter caused excess pressure being applied to the crank. We had the converter feed passage tapped and restricted to limit this pressure and had it dyno’d on a transmission dyno to monitor these pressures.

So here is some progress with My Build Version 2.0

Ordered a new "LS4" hi volume oil pump from a dealership online

P/N:12612289

Here is a picture of the "LS4" pump (on left) and a ls6 pump (on right).

LS4 Pump Gerotor on left and LS6 Gerotor on right. You can see the LS4 gerotor is thicker, it is larger in diameter as well.

LS4 pump, green high lighter to show what material we removed and smoothed.

Inlet Before

Inlet After

Outlet Before

Outlet After

So here is some progress with My Build Version 2.0

Ordered a new "LS4" hi volume oil pump from a dealership online

P/N:12612289

Here is a picture of the "LS4" pump (on left) and a ls6 pump (on right).

LS4 Pump Gerotor on left and LS6 Gerotor on right. You can see the LS4 gerotor is thicker, it is larger in diameter as well.

LS4 pump, green high lighter to show what material we removed and smoothed.

Inlet Before

Inlet After

Outlet Before

Outlet After

#76

12 Second Club

Thread Starter

iTrader: (9)

Join Date: Jun 2006

Location: Grand Forks, North Dakota

Posts: 1,051

Likes: 0

Received 0 Likes

on

0 Posts

Here is the update:

Found the cam had some chips on a lobe so I had Pat G spec me out one.

Cam Specs: 231/231 .598/.598 115LSA +4 Comp HUC lobes

Purchased it through Geoff at Engine Power Systems.

Had the engine rebuilt (new bearings, reused rings) and new 24 tooth reluctor wheel on the Callies crank. Mine was cracked so it needed replacement.

I sent the turbo in and had it inspected and they said it needed to be rebuilt.

Three weeks ago I got everything together and running. Under some boost it BACKFIRED and shut off. It would not start. All over again I thought. After further inspection the timing was sketchy. We removed the crank sensor and looked in at the reluctor wheel. 24x wheels are two piece design riveted together. It had separated

Had to take it all out again. My builder was awesome and took it apart and I ordered a one piece LME billet 24 tooth reluctor wheel and had it tack welded in two spots (1/2" long) on the crank. Got the motor back in this weekend and took it for a spin!

More to come soon....

Found the cam had some chips on a lobe so I had Pat G spec me out one.

Cam Specs: 231/231 .598/.598 115LSA +4 Comp HUC lobes

Purchased it through Geoff at Engine Power Systems.

Had the engine rebuilt (new bearings, reused rings) and new 24 tooth reluctor wheel on the Callies crank. Mine was cracked so it needed replacement.

I sent the turbo in and had it inspected and they said it needed to be rebuilt.

Three weeks ago I got everything together and running. Under some boost it BACKFIRED and shut off. It would not start. All over again I thought. After further inspection the timing was sketchy. We removed the crank sensor and looked in at the reluctor wheel. 24x wheels are two piece design riveted together. It had separated

Had to take it all out again. My builder was awesome and took it apart and I ordered a one piece LME billet 24 tooth reluctor wheel and had it tack welded in two spots (1/2" long) on the crank. Got the motor back in this weekend and took it for a spin!

More to come soon....

#80

12 Second Club

Thread Starter

iTrader: (9)

Join Date: Jun 2006

Location: Grand Forks, North Dakota

Posts: 1,051

Likes: 0

Received 0 Likes

on

0 Posts

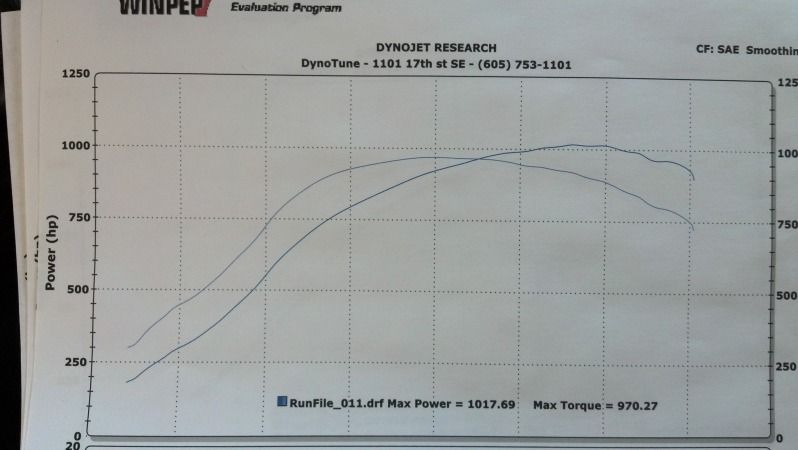

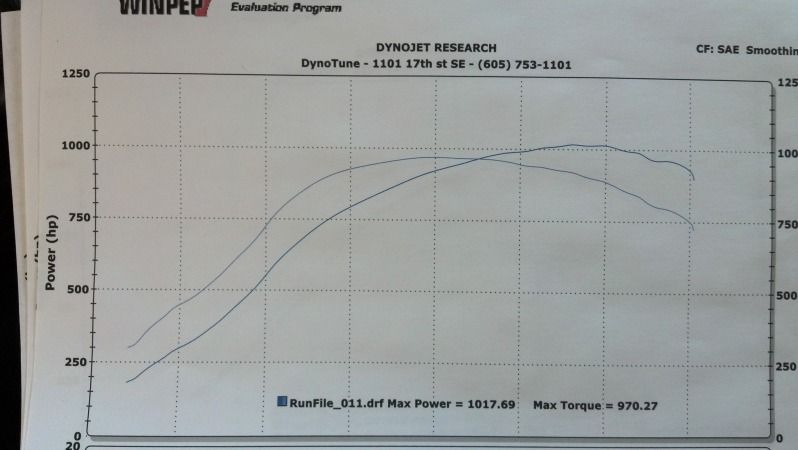

I dyno'd yesterday in Watertown SD. I made 1017/970 at 20lbs. Made more than I expected. This was on E85 with the verter locked. I will post up more pictures later, i let off at 6500. My base boost numbers were 675/728 at just over 8 lbs.