Lean spike as I enter PE (and knock retard) any way to combat this?

#1

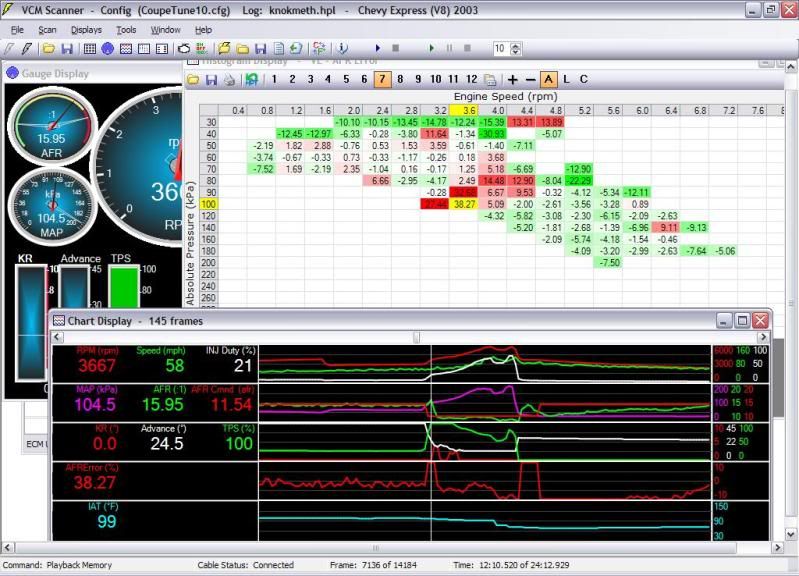

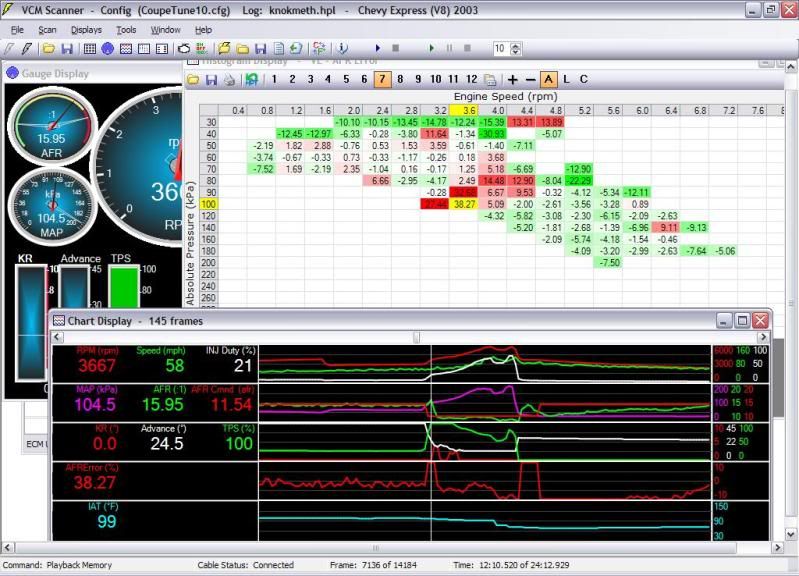

Not sure what is going on with my tune. If I punch it from a roll it goes very lean right off the bat (~100kpa), then corrects but knocks. If I actually tuned it how it "wants" me to based on AFR error my 90 and 100kpa regions would be crazy (I actually tried it and the car experiences a huge stutter as it dumps way too much fuel).

I am trying to figure out how I can combat this sudden lean spike that I am getting right after I punch it. I did some reading and saw where some folks said adjust transient fueling rate but I don't see that in my HPTuners.

Any turbo guys out there experience anything like this? The car is a cam only LQ9 w/Borg Warner S475 bolted to a TH350

Here is a graph, things to not are AFR, KR, TPS, etc. You can see the ~30% lean error in the histogram.

I am trying to figure out how I can combat this sudden lean spike that I am getting right after I punch it. I did some reading and saw where some folks said adjust transient fueling rate but I don't see that in my HPTuners.

Any turbo guys out there experience anything like this? The car is a cam only LQ9 w/Borg Warner S475 bolted to a TH350

Here is a graph, things to not are AFR, KR, TPS, etc. You can see the ~30% lean error in the histogram.

#2

Formerly 4mulaJoe

iTrader: (11)

Join Date: Nov 2001

Location: hou

Posts: 2,763

Likes: 0

Received 0 Likes

on

0 Posts

I haven't gotten a chance to really test it much on my car, but my twin 62/65's spool fast, and it was breaking up. I change the boost enrichment table to come in at 80kpa. This way you start commanding your boost AFR right before hitting boost. It may not be ideal for spool, etc, but I am betting it works.

#4

TECH Fanatic

iTrader: (12)

Join Date: Jun 2007

Location: earth

Posts: 1,438

Likes: 0

Received 0 Likes

on

0 Posts

interesting. could be injector offset data or something maybe? transient fueling should be under the fueling control tab. what happens if you only correct by half the amount in the ve? are you running boost referenced fuel regulator and flat lined IFR table?

i didnt run into any problems like that tuning my setup with the 2bar.

just curious why does your afr error table have such poor resolution jumping 20 kpa in boost regions?

i didnt run into any problems like that tuning my setup with the 2bar.

just curious why does your afr error table have such poor resolution jumping 20 kpa in boost regions?

#5

interesting. could be injector offset data or something maybe? transient fueling should be under the fueling control tab. what happens if you only correct by half the amount in the ve? are you running boost referenced fuel regulator and flat lined IFR table?

i didnt run into any problems like that tuning my setup with the 2bar.

just curious why does your afr error table have such poor resolution jumping 20 kpa in boost regions?

i didnt run into any problems like that tuning my setup with the 2bar.

just curious why does your afr error table have such poor resolution jumping 20 kpa in boost regions?

I have tried to "tune" around that lean spike but the huge "bump" in the VE table that occurs if I go adding 20%+ to those single cells causes a huge hiccup.

#6

TECH Fanatic

iTrader: (12)

Join Date: Jun 2007

Location: earth

Posts: 1,438

Likes: 0

Received 0 Likes

on

0 Posts

with a boost/vacuum referenced regulator i do believe your IFR table is supposed to be flatlined as the fuel pressure and intake manifold pressure differential should always be the equal. The ifr tables are scaled with stock fuel systems because the regulator in the tank is not referenced.

what im getting at is that obviously your fuel system is adequate and the computer is commanding the afr you want but the correct amount of fuel isnt being delivered perhaps because of incorrect data.. The IFR table only goes to 100kpa or 0kpa vacuum and thats where your having this issue. perhaps some numbers are just not correct. What do your injector pulse widths look like when this happens? does the problem only happen during certain RPM ranges or will it do it at any rpm when it goes to 100kpa?

what im getting at is that obviously your fuel system is adequate and the computer is commanding the afr you want but the correct amount of fuel isnt being delivered perhaps because of incorrect data.. The IFR table only goes to 100kpa or 0kpa vacuum and thats where your having this issue. perhaps some numbers are just not correct. What do your injector pulse widths look like when this happens? does the problem only happen during certain RPM ranges or will it do it at any rpm when it goes to 100kpa?

Last edited by got-a-ls1; 02-16-2012 at 12:44 PM.

#7

with a boost/vacuum referenced regulator i do believe your IFR table is supposed to be flatlined as the fuel pressure and intake manifold pressure differential should always be the equal. The ifr tables are scaled with stock fuel systems because the regulator in the tank is not referenced.

what im getting at is that obviously your fuel system is adequate and the computer is commanding the afr you want but the correct amount of fuel isnt being delivered perhaps because of incorrect data.. The IFR table only goes to 100kpa or 0kpa vacuum and thats where your having this issue. perhaps some numbers are just not correct. What do your injector pulse widths look like when this happens? does the problem only happen during certain RPM ranges or will it do it at any rpm when it goes to 100kpa?

what im getting at is that obviously your fuel system is adequate and the computer is commanding the afr you want but the correct amount of fuel isnt being delivered perhaps because of incorrect data.. The IFR table only goes to 100kpa or 0kpa vacuum and thats where your having this issue. perhaps some numbers are just not correct. What do your injector pulse widths look like when this happens? does the problem only happen during certain RPM ranges or will it do it at any rpm when it goes to 100kpa?

Could this cause the lean spike?

Trending Topics

#8

TECH Fanatic

iTrader: (12)

Join Date: Jun 2007

Location: earth

Posts: 1,438

Likes: 0

Received 0 Likes

on

0 Posts

if the injectors are not flowing what the computer thinks they are flowing then i can see it causing lean, or even rich depending on how the numbers are skewed. Like i said in the first post as well it could be the injector offsets as well as that is a kpa referenced

i dont run a referenced regulator so i cant say for sure 100% ive just always seen people with a referenced regulator have a flat IFR.

i dont run a referenced regulator so i cant say for sure 100% ive just always seen people with a referenced regulator have a flat IFR.

#11

I am confused after looking at the table again.

So at 0kpa of vacuum (i.e. 100kpa MAP, where I am getting the lean spike), it believes my injectors are 79.7lb injectors (very close to the 80lbs they are). I am having trouble understanding why it'd spray less fuel as it believes the injectors are smaller then they actually are. Is the issue the transient areas where it believes the injectors are "smaller" (to make up for the lack of vacuum) as the fuel pressure rises to overcome that exact same issue?

So when I punch it and the vacuum goes from ~50kpa to 0kpa the computer compensates for the fuel being "sucked" out by the vacuum to it no longer being "sucked" out anymore by using the IFR table which states that the injector in a sense got smaller, at the same time the FPR has increased the fuel pressure as the car went from vacuum to atmospheric pressure (thus making the injector push more fuel). Both of these conditions seem like they'd cause a super fat mix under transient conditions, not a lean spike.

So at 0kpa of vacuum (i.e. 100kpa MAP, where I am getting the lean spike), it believes my injectors are 79.7lb injectors (very close to the 80lbs they are). I am having trouble understanding why it'd spray less fuel as it believes the injectors are smaller then they actually are. Is the issue the transient areas where it believes the injectors are "smaller" (to make up for the lack of vacuum) as the fuel pressure rises to overcome that exact same issue?

So when I punch it and the vacuum goes from ~50kpa to 0kpa the computer compensates for the fuel being "sucked" out by the vacuum to it no longer being "sucked" out anymore by using the IFR table which states that the injector in a sense got smaller, at the same time the FPR has increased the fuel pressure as the car went from vacuum to atmospheric pressure (thus making the injector push more fuel). Both of these conditions seem like they'd cause a super fat mix under transient conditions, not a lean spike.

#13

TECH Enthusiast

Join Date: Jan 2004

Location: New Zealand

Posts: 608

Likes: 0

Received 0 Likes

on

0 Posts

If you have a sloped injector flow rate table, it is not set up for a boost ref fuel reg.

Rrising rate, boost ref, fuel reg sould have a flat injector flow rate table.

Rrising rate, boost ref, fuel reg sould have a flat injector flow rate table.

#15

This is correct, but what we haven't been able to figure out is why I would get a lean vs. rich spike. If it believes the injectors are smaller then they actually are (thus increasing the pulses) and the pressure is rising why wouldn't it go rich vs. lean?

#16

9 Second Club

iTrader: (10)

First you need to setup your injectors to have the correct data. When you give it a quick blip of throttle this is called transient response. If it goes lean you need to adjust the transiet response fuel table until it richens up. Go to fuel > transient > fuel to wall impact factor, try doubling the 80-100 kpa cells in the coolant temp ranges you're in. Start off by doubling the values and go from there until it's dialed in.

#17

First you need to setup your injectors to have the correct data. When you give it a quick blip of throttle this is called transient response. If it goes lean you need to adjust the transiet response fuel table until it richens up. Go to fuel > transient > fuel to wall impact factor, try doubling the 80-100 kpa cells in the coolant temp ranges you're in. Start off by doubling the values and go from there until it's dialed in.

#19

Formerly 4mulaJoe

iTrader: (11)

Join Date: Nov 2001

Location: hou

Posts: 2,763

Likes: 0

Received 0 Likes

on

0 Posts

The boost enrichment settings take over as you get into boost since it is the richer of the 2 normally. Notice how I told it to start at 80kpa just before the turbos spool.

You should have a constant flow rate for a boost referenced fuel system, but you could probably get away with it not being so if you dialed the VE in correctly.

That graph also kinda looks like you just have too much timing where the turbos spool up in the lower RPM. Log dyn cyl air so you can see what it is where this knock is happening. Lower it at least to what you are running where there is no knock, fix the issue, and then move on. There is no much room for error on stock pistons. Don't give it much timing until everything seems 100%.

#20

9 Second Club

iTrader: (10)

You need to update to a 01-02 fbody operating system if you don't have the transient tables. It's very simple to do but it will require 4 credits. Do not use boost enrichment for your main fueling as this table does not react as quickly as pe fueling. Boost enrichment is designed for an overboost situation for safety.