Twin turbo 5.3L in a Lexus Is300...sounds fun right?

#1

On The Tree

Thread Starter

iTrader: (6)

Join Date: May 2007

Posts: 112

Likes: 0

Received 0 Likes

on

0 Posts

Some of you may have seen my other threads or past builds. I figured this build deserved to be in the forced induction forum so here we go.

In late 2009 I built the first ever LS1 powered Lexus Is300. Coming from the background of big turbo Supras and Mr2s the idea of building a Turbo Ls powered car was on my mind from the beginning. In December of 2013 I found a rare Is300 model without a sunroof. I've always had a hard on for hardtop cars. From here I decided to make this my master project. Using all my knowledge from past builds and pushing to better educate myself in suspension geometry. The planning begins.

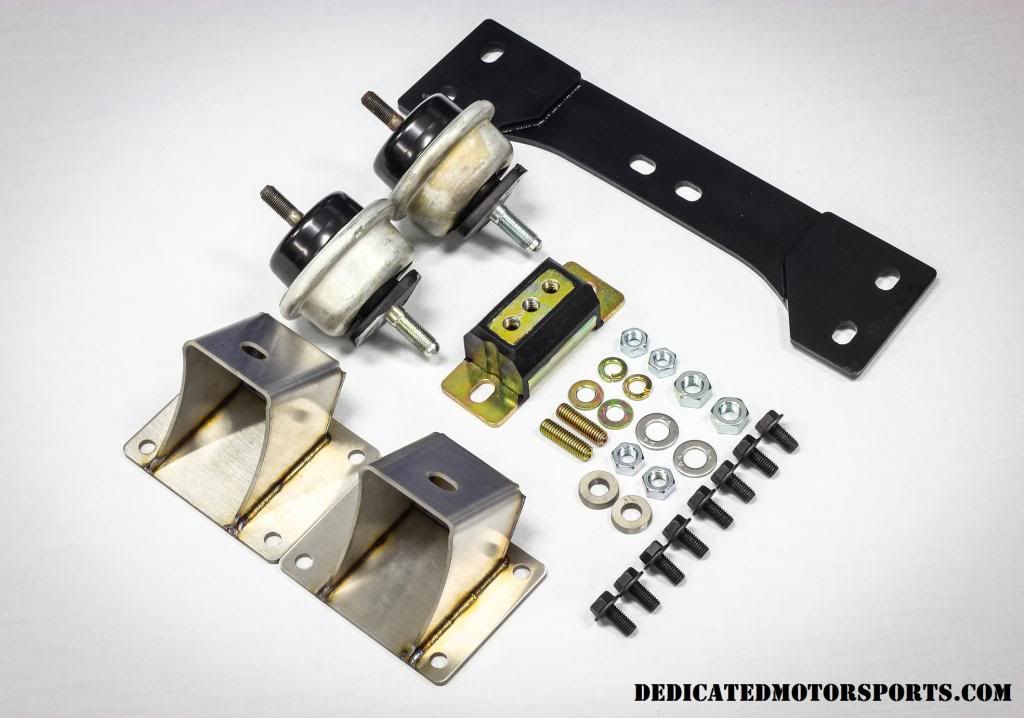

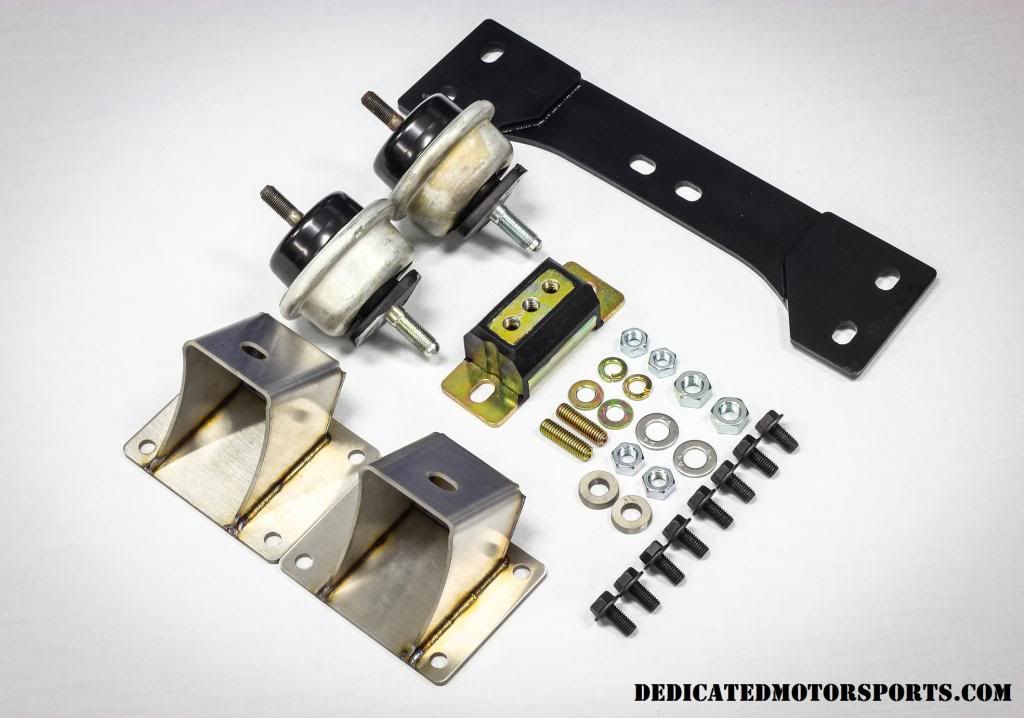

The easy part was fitting the engine in the chassis using my very own dedicatedmotorosports.com engine mount kit. From there I started the fabrication and mock up using a junkyard engine from my buddy Mike Morris of MAKK performance.

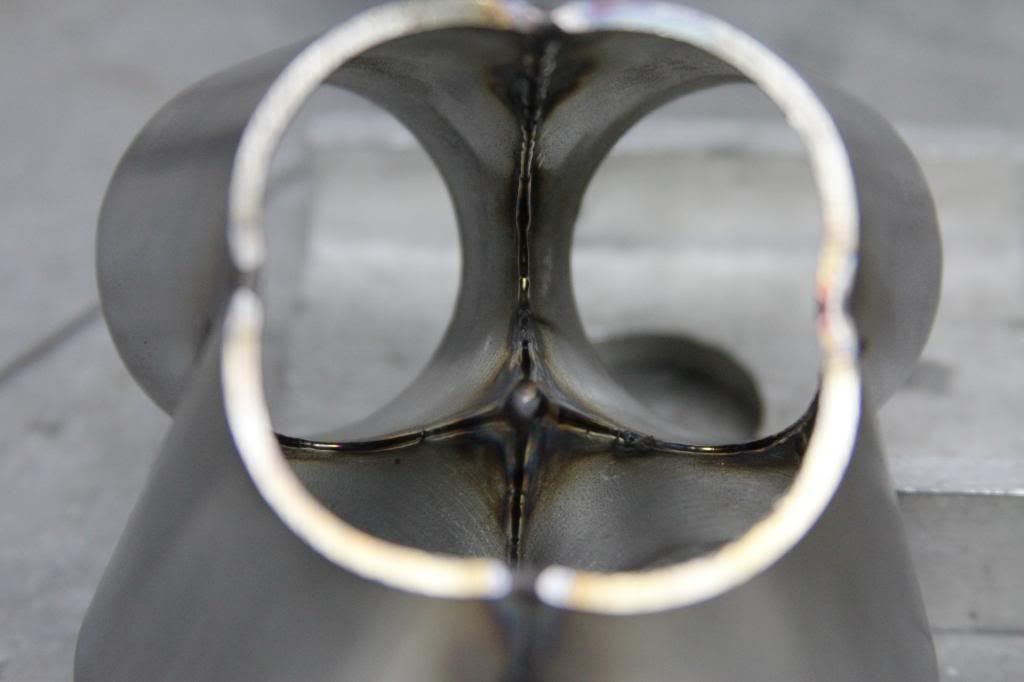

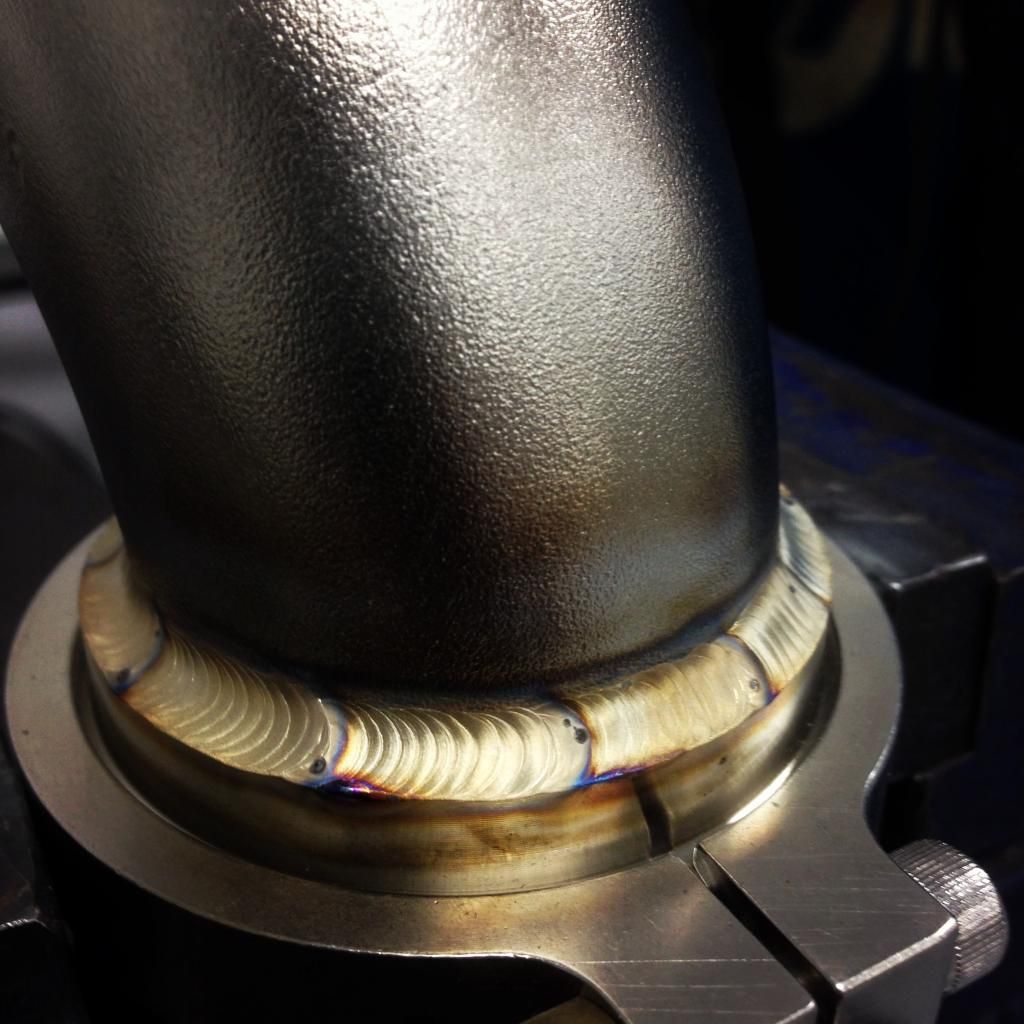

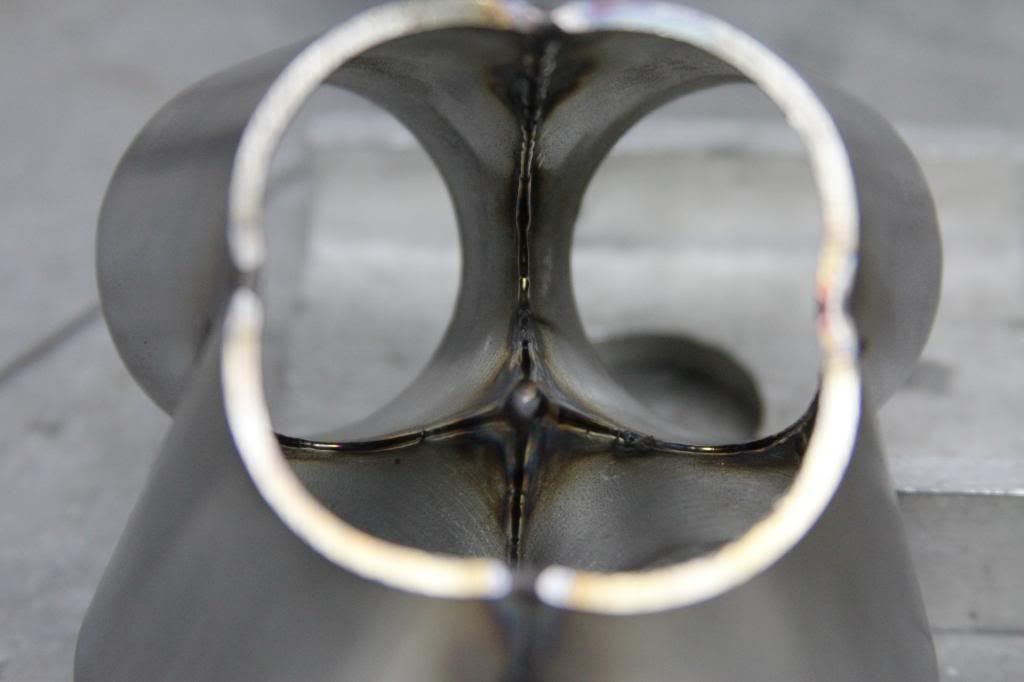

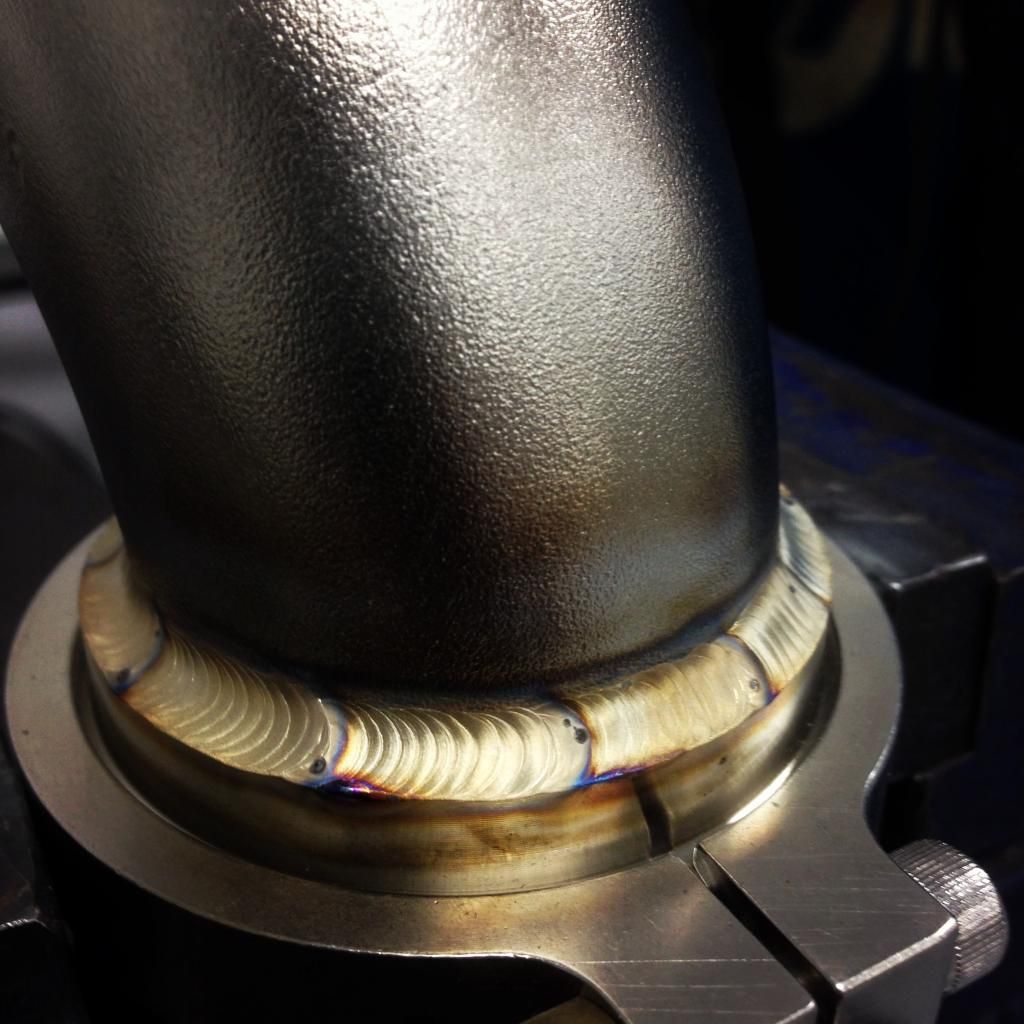

A pair of Percision 6266's with the V-band housings will provide positive inlet pressure for the beast. A lot of time went into the fabrication process. Everything always takes longer than it seems...even for a well rounded fabricator. I chose to build the turbo manifolds out of schedule 10 stainless for heat retention and cracking resistance. Hand made from start to finish.

A pair of 3 inch downpipes finishes off the exhaust for now.

When fabricating an intercooler choosing a quality core is the key to high efficiency cooling. I chose a pair of Garrett cores I've used on pass GTR intercooler builds.

Fender exit wastegate dumps

Engine:

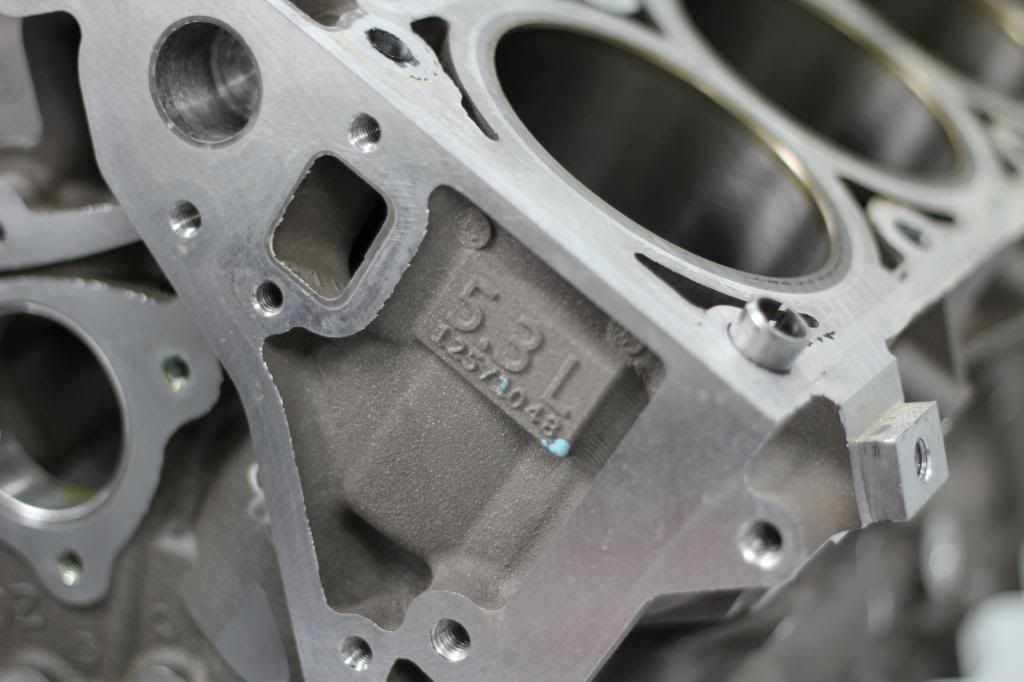

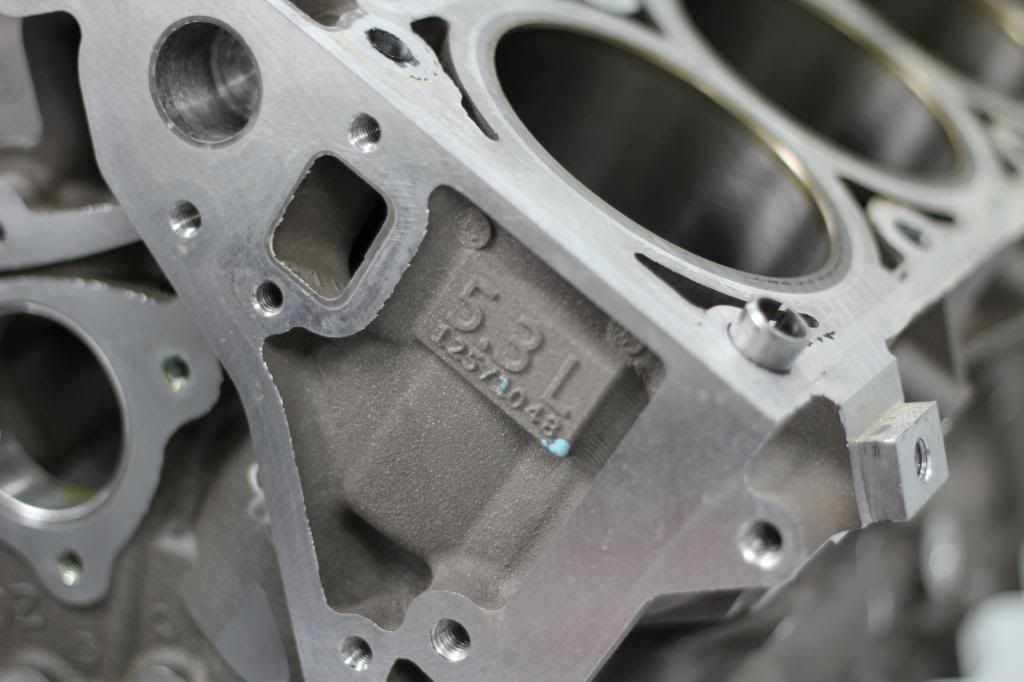

I had my mind set on using an aluminum block. The added 80-90 lbs of a iron block on the nose was not an option for me. After a great deal of research I stumbled upon the LC9 5.3 Liter engine found in the 2012 Gm trucks. Gm introduced a new casting procedure with strong webbing between the crank deck and cylinders. I was also set on using a small cube engine, the 5.3L will keep the compressor/turbine efficiency relationship of the twin 6266 turbos right where I want them. Since I'm running E85 I chosse the Wiseco Junkyard Dogg pistons with a 11.1 compression height and a set of Scat rods with the arp 2000 rod bolts. A pair of trick flow 205cc 5.3 heads will top it off. The cam is a custom grind from Geoff at Engine Power Systems this guy knows his cams. I turned the block and parts over to Watt Bigham of Watt's machine shop in Lavon Texas. This guy is a true artist and knows the Ls platform very well. After Watt had his way with the short block I proceeded with the final assembly.

In late 2009 I built the first ever LS1 powered Lexus Is300. Coming from the background of big turbo Supras and Mr2s the idea of building a Turbo Ls powered car was on my mind from the beginning. In December of 2013 I found a rare Is300 model without a sunroof. I've always had a hard on for hardtop cars. From here I decided to make this my master project. Using all my knowledge from past builds and pushing to better educate myself in suspension geometry. The planning begins.

The easy part was fitting the engine in the chassis using my very own dedicatedmotorosports.com engine mount kit. From there I started the fabrication and mock up using a junkyard engine from my buddy Mike Morris of MAKK performance.

A pair of Percision 6266's with the V-band housings will provide positive inlet pressure for the beast. A lot of time went into the fabrication process. Everything always takes longer than it seems...even for a well rounded fabricator. I chose to build the turbo manifolds out of schedule 10 stainless for heat retention and cracking resistance. Hand made from start to finish.

A pair of 3 inch downpipes finishes off the exhaust for now.

When fabricating an intercooler choosing a quality core is the key to high efficiency cooling. I chose a pair of Garrett cores I've used on pass GTR intercooler builds.

Fender exit wastegate dumps

Engine:

I had my mind set on using an aluminum block. The added 80-90 lbs of a iron block on the nose was not an option for me. After a great deal of research I stumbled upon the LC9 5.3 Liter engine found in the 2012 Gm trucks. Gm introduced a new casting procedure with strong webbing between the crank deck and cylinders. I was also set on using a small cube engine, the 5.3L will keep the compressor/turbine efficiency relationship of the twin 6266 turbos right where I want them. Since I'm running E85 I chosse the Wiseco Junkyard Dogg pistons with a 11.1 compression height and a set of Scat rods with the arp 2000 rod bolts. A pair of trick flow 205cc 5.3 heads will top it off. The cam is a custom grind from Geoff at Engine Power Systems this guy knows his cams. I turned the block and parts over to Watt Bigham of Watt's machine shop in Lavon Texas. This guy is a true artist and knows the Ls platform very well. After Watt had his way with the short block I proceeded with the final assembly.

Last edited by ATSMATT; 03-23-2014 at 03:53 PM.

#2

On The Tree

Thread Starter

iTrader: (6)

Join Date: May 2007

Posts: 112

Likes: 0

Received 0 Likes

on

0 Posts

I'll step away from the engine and turbo stuff for a moment at talk about the chassis and drive train. The Lexus Is300 isn't known for the ability to fit large tire or hold big power but will a little engineering I plan to change all that.

I started by picking a tire size. The mickey Thompson 275/60/15 radial pro. Followed by hours of measuring and calculating wheel offsets. Once I determined my wheel size I placed the order and frantically awaited delivery as the pressure of TX2k14 coming was beginning to sink in.

After a some serious rolling and a little cutting of the outer inner fender they fit. I didn't stop here tho. I know this car should squat hard and deflect the tire a bit. So the cutting continues...

Squatin hard still with good clearance in the key spots for tire growth. Obviously the bumper will require some trimming.

After rolling the **** out of these fenders I noticed they would stretch more in some places and pull in other spots. So I decided to just cut off nearly an inch of the fender lip. This is how it sits. I wont be using this rear bumper but I did some practice cuts to see what it might take.

To give you and idea of how much material I removed.

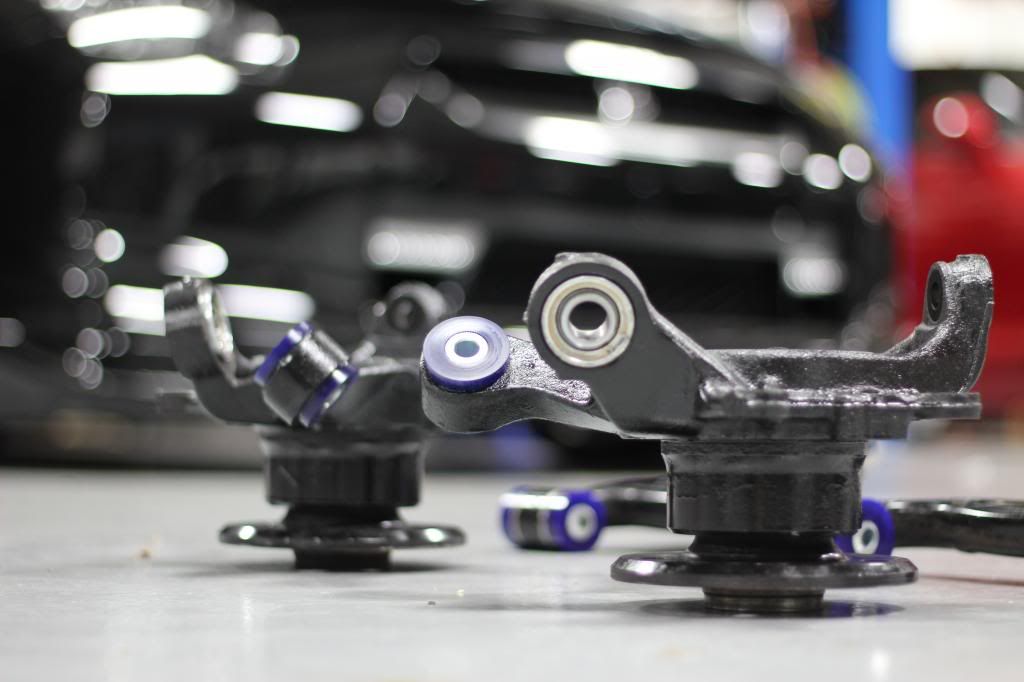

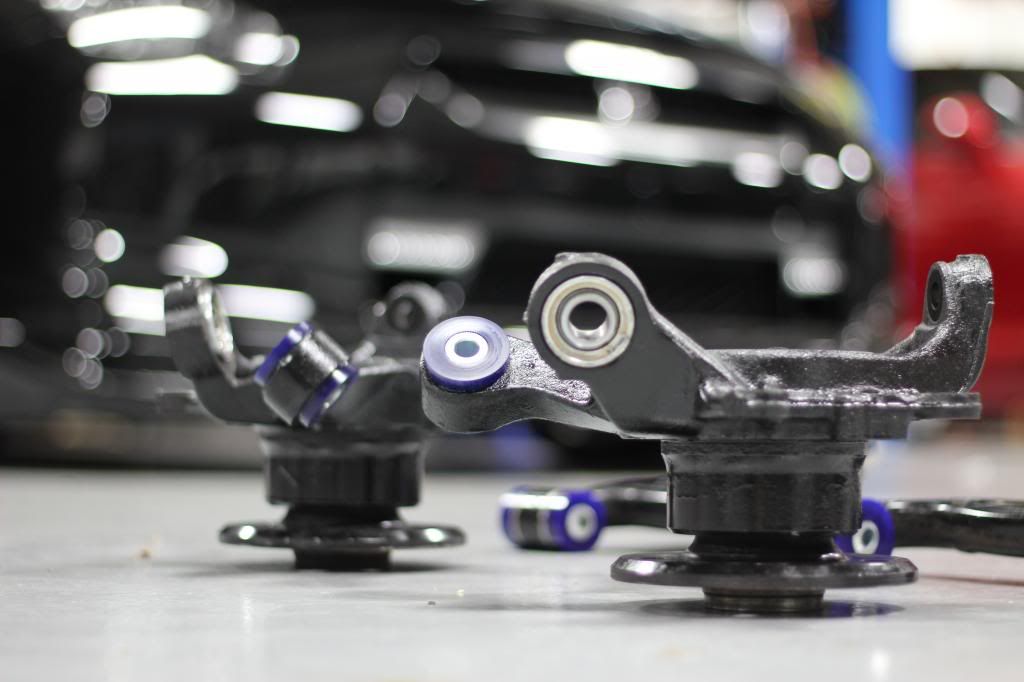

In order to correct the camber/toe sweep I had to engineer and fab up some new lower control arms. I also purchased nearly every bushing and aftermarket suspension component Fig's engineering makes.

This weekend I'll be focusing on my suspension and more tire fitment. Big thanks to Mike over at figsprops.com for all these well engineered pieces. If you're even considering building a lexus you'll need to visit his site. New parts are added all the time.

And it starts I did a really terrible job taking pictures this time. I might be able to snap a few of the inner fender work. It involved a torch, air hammer and a 12 pound sledge.

Some of these bushings are a bit of a pain to remove I suggest an air hammer and hydraulic press.

A couple bushings installed with the perfect back drop.

[/QUOTE]

[/QUOTE]

Lets face it the puny Lexus diff would never hold up to the 1000ft lbs of torque I plan to throw its way. I decided to contact our friends over at The Driveshaft shop for a universal Ford 9inch diff. From here I fabricated my own differential mounting points and sent DSS specs for the driveshaft/axle lengths. Dss is an awesome company to deal with. Great communication and very high quality components.

As you could imagine I ended up with a wicked stance.

I started by picking a tire size. The mickey Thompson 275/60/15 radial pro. Followed by hours of measuring and calculating wheel offsets. Once I determined my wheel size I placed the order and frantically awaited delivery as the pressure of TX2k14 coming was beginning to sink in.

After a some serious rolling and a little cutting of the outer inner fender they fit. I didn't stop here tho. I know this car should squat hard and deflect the tire a bit. So the cutting continues...

Squatin hard still with good clearance in the key spots for tire growth. Obviously the bumper will require some trimming.

After rolling the **** out of these fenders I noticed they would stretch more in some places and pull in other spots. So I decided to just cut off nearly an inch of the fender lip. This is how it sits. I wont be using this rear bumper but I did some practice cuts to see what it might take.

To give you and idea of how much material I removed.

In order to correct the camber/toe sweep I had to engineer and fab up some new lower control arms. I also purchased nearly every bushing and aftermarket suspension component Fig's engineering makes.

This weekend I'll be focusing on my suspension and more tire fitment. Big thanks to Mike over at figsprops.com for all these well engineered pieces. If you're even considering building a lexus you'll need to visit his site. New parts are added all the time.

And it starts I did a really terrible job taking pictures this time. I might be able to snap a few of the inner fender work. It involved a torch, air hammer and a 12 pound sledge.

Some of these bushings are a bit of a pain to remove I suggest an air hammer and hydraulic press.

A couple bushings installed with the perfect back drop.

[/QUOTE]

[/QUOTE]Lets face it the puny Lexus diff would never hold up to the 1000ft lbs of torque I plan to throw its way. I decided to contact our friends over at The Driveshaft shop for a universal Ford 9inch diff. From here I fabricated my own differential mounting points and sent DSS specs for the driveshaft/axle lengths. Dss is an awesome company to deal with. Great communication and very high quality components.

As you could imagine I ended up with a wicked stance.

Last edited by ATSMATT; 03-23-2014 at 03:56 PM.

#3

On The Tree

Thread Starter

iTrader: (6)

Join Date: May 2007

Posts: 112

Likes: 0

Received 0 Likes

on

0 Posts

Some of you may be wondering how I plan to feed this beast. Nothing but the best for this build. I work for T1 Race Development/Injector Dynamics so I opted for the the new ID exclusive 1300cc injectors and a Motec M150 ECU, Motec LTCD NTK lambda and the Motec CR125 dash.

Purchasing an expensive and well engineered ECU is worthless unless you have a wiring harness of equal quality tying it all together. For this I consulted Joel Levy at Racespec for one of his top notch mill spec harnesses.

The dash is just the cherry on top for this build. Tony Palo really stepped up my game with this one.

The fuel pump chosen for this project is the Aeromotive Gyro rotor unit. Its really surprising no one makes a kit for this fuel pump. With a little engineering and a mess of metal off the mill I had my pump mounted.

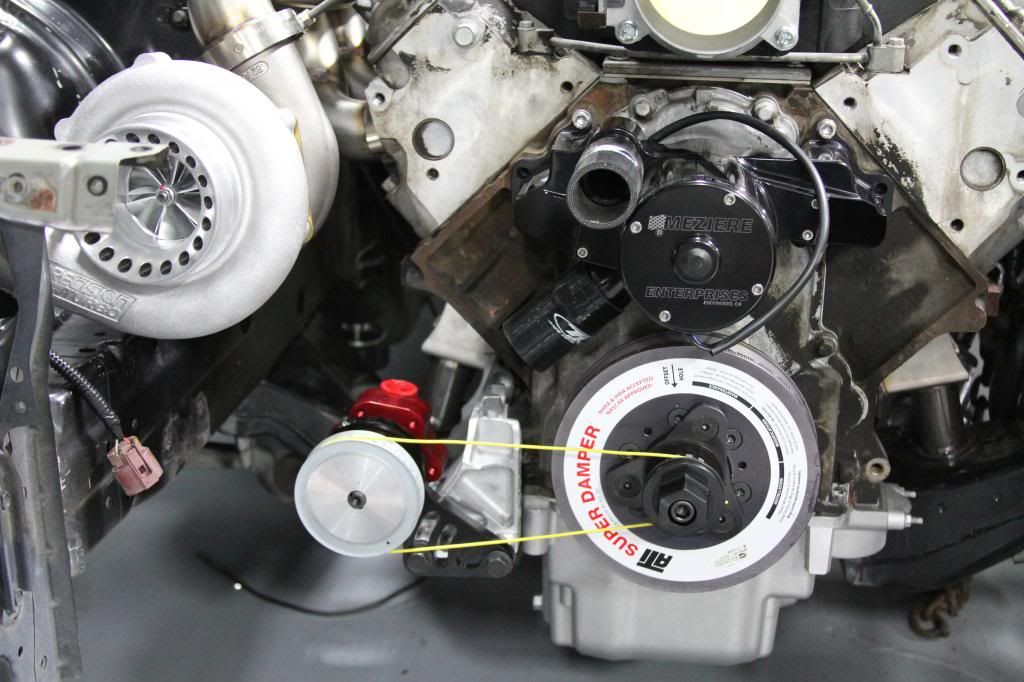

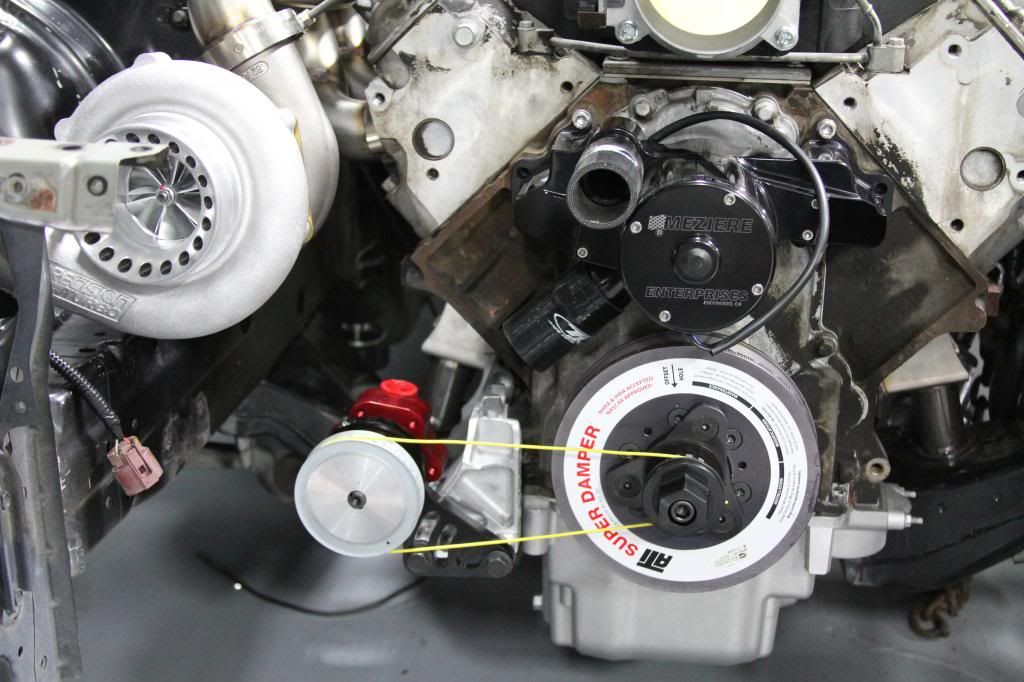

I called up Peterson Fluid Sytems for one of there muilty piece gear mandrels. Since all drive mandrels are made for big blocks this one required some machining on the shop lathe.

It was a long road with many sleepless nights for this picture.

Purchasing an expensive and well engineered ECU is worthless unless you have a wiring harness of equal quality tying it all together. For this I consulted Joel Levy at Racespec for one of his top notch mill spec harnesses.

The dash is just the cherry on top for this build. Tony Palo really stepped up my game with this one.

The fuel pump chosen for this project is the Aeromotive Gyro rotor unit. Its really surprising no one makes a kit for this fuel pump. With a little engineering and a mess of metal off the mill I had my pump mounted.

I called up Peterson Fluid Sytems for one of there muilty piece gear mandrels. Since all drive mandrels are made for big blocks this one required some machining on the shop lathe.

It was a long road with many sleepless nights for this picture.

Last edited by ATSMATT; 03-23-2014 at 07:34 PM.

Trending Topics

#12

On The Tree

Thread Starter

iTrader: (6)

Join Date: May 2007

Posts: 112

Likes: 0

Received 0 Likes

on

0 Posts

You're right Rod Millen and Chip Foose teamed up to build an Is300 with the 4.3L 3uz-fe engine and the supra 6 speed Getrag transmission.

I've updated my last post. I'll probably continue adding pics and I go through them.

Matt

I've updated my last post. I'll probably continue adding pics and I go through them.

Matt

#18

On The Tree

Thread Starter

iTrader: (6)

Join Date: May 2007

Posts: 112

Likes: 0

Received 0 Likes

on

0 Posts

I work full time for T1 Race development as the shop foreman , fabricator, GTR engine specialist. I also sell the LS swap parts in my spare time under Dedicated Motorsports.

This car was built in my spare time at T1's facility