e85 switch

#1

On The Tree

Thread Starter

Join Date: Sep 2005

Location: FLORIDA

Posts: 103

Likes: 0

Received 0 Likes

on

0 Posts

I made the switch from pump gas to e85 on my street driven "1/2 mile" procharged aluminum LS2 this weekend at the Ocala airport and starting with the first pass on it saw radiator pressure increase up until I blew a radiator hose on the last pass and had to put it on the trailer.

Graphs all look good, no detonation... Im running ARP studs and cometic gaskets ( 0.040 ) and 8:1 compression... was at 20 lbs of boost when I blew the last hose...

BOTTOM end is fine !! I really dont want to switch blocks to steel... Is the problem ? ... the aluminum block threads arent strong enough to keep the studs planted ? Would it help to " time cert" new 1/2 threads into the aluminum block and then put studs into that ?

or would that be a waste of time ?

Graphs all look good, no detonation... Im running ARP studs and cometic gaskets ( 0.040 ) and 8:1 compression... was at 20 lbs of boost when I blew the last hose...

BOTTOM end is fine !! I really dont want to switch blocks to steel... Is the problem ? ... the aluminum block threads arent strong enough to keep the studs planted ? Would it help to " time cert" new 1/2 threads into the aluminum block and then put studs into that ?

or would that be a waste of time ?

#3

On The Tree

Thread Starter

Join Date: Sep 2005

Location: FLORIDA

Posts: 103

Likes: 0

Received 0 Likes

on

0 Posts

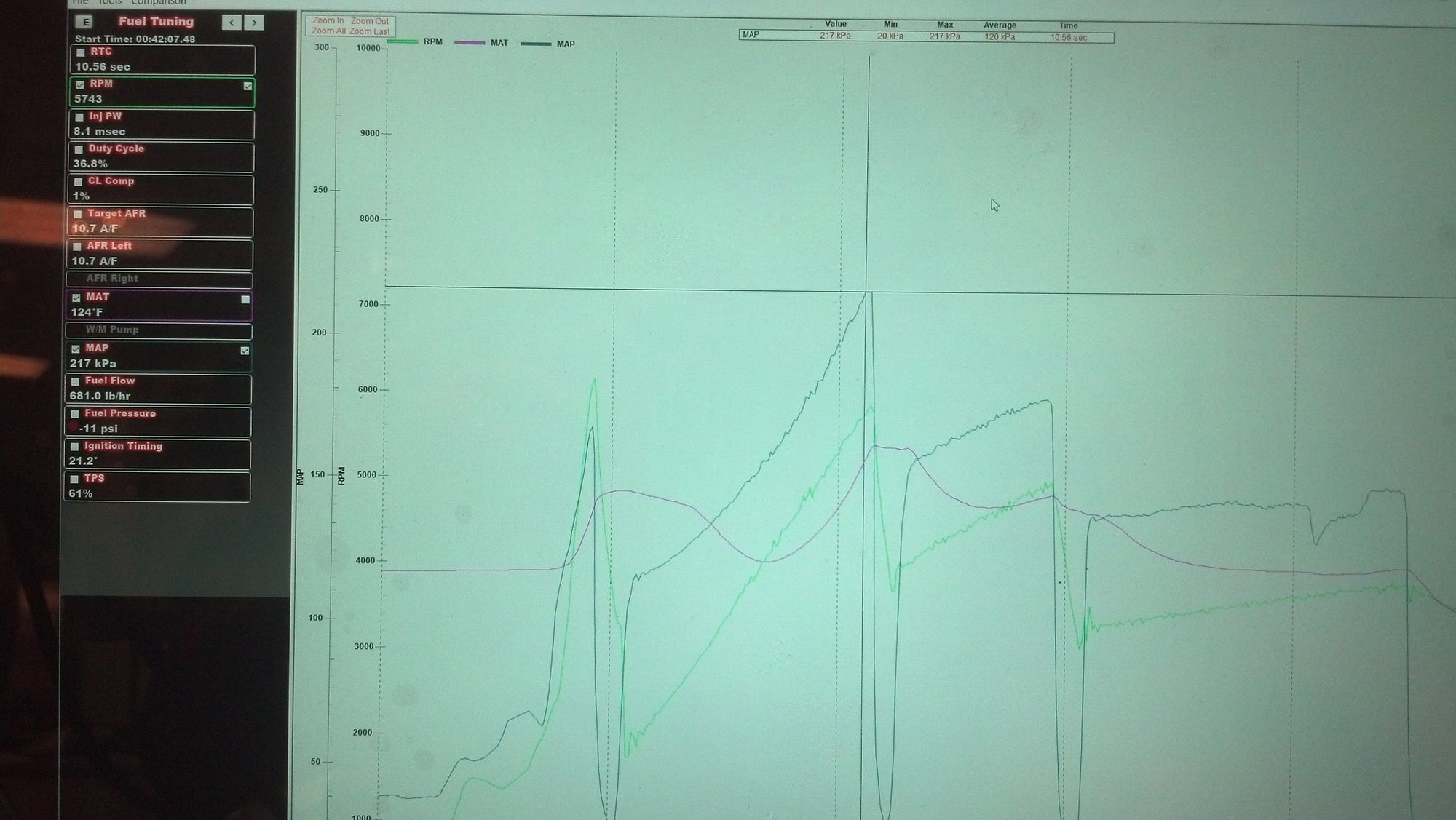

the rpm graph looks smooth... no dips like it would be detonating... but I have serious coolant pressure... oil looks fine on the dipstick so I dont think the block is cracked. the black line is my TPS... ( you can see when the radiator blows , it hits my windshield and scared me into diping my TPS when I was in top gear half way through ) My timing is in the RED... is that too much ? AFR is purple/pink. MAP is blue RPM is neon green

So can I just send the heads out to get o-ringed somewhere ? should I "time cert " the block threads for a better hold ? or drain the coolant, jack up the car on one side at a time and pour hard block in ??? whats my best bet ??

#4

8 Second Club

iTrader: (4)

How do the plugs look? What plugs do you run? IAT’s? Cam specs? Are you spraying any water/meth?

You need to pull the heads and install new gaskets if you pressurized the radiator. They never seal the same after they lift. Can you run the LS9 OEM gasket with your bore? What did you torque the HG to? Which cometic gasket? Did you surface the heads/block to the suggested RA finish?

E85 doesn’t register knock/detonation like pump and race gas. It jumps straight into pre-ignition and breaks things. You get little to no warning. Very similar to methanol tunes.

25* is *generally* a lot of timing for 20lbs… For comparison I run 12-13* on E85 intercooled at 20lbs. My alum 5.3 held the heads down just fine with china head studs at 26+lbs…Until I bumped the timing from 15* to 17*. Which blew the HG and pressurized the rad just like you. The alum threads are not weak/neither is the block. Always start low on timing… like 9-10*. Then bump a degree and check the plugs.

You need to pull the heads and install new gaskets if you pressurized the radiator. They never seal the same after they lift. Can you run the LS9 OEM gasket with your bore? What did you torque the HG to? Which cometic gasket? Did you surface the heads/block to the suggested RA finish?

E85 doesn’t register knock/detonation like pump and race gas. It jumps straight into pre-ignition and breaks things. You get little to no warning. Very similar to methanol tunes.

25* is *generally* a lot of timing for 20lbs… For comparison I run 12-13* on E85 intercooled at 20lbs. My alum 5.3 held the heads down just fine with china head studs at 26+lbs…Until I bumped the timing from 15* to 17*. Which blew the HG and pressurized the rad just like you. The alum threads are not weak/neither is the block. Always start low on timing… like 9-10*. Then bump a degree and check the plugs.

Last edited by Forcefed86; 01-25-2016 at 09:55 AM.

#5

Restricted User

That's a lot of timing. I've never ran more than 18 degrees on E85. These engine generally take tons of abuse until you get greedy with timing. Id bet you wouldn't lose a huge amount of power dropping that by 8 degrees or so, but cylinder pressures would go way down.

#6

On The Tree

Thread Starter

Join Date: Sep 2005

Location: FLORIDA

Posts: 103

Likes: 0

Received 0 Likes

on

0 Posts

Im running meth injection... here is what my temperature graph looks like.

Cam is the street lingfelter blower cam.

It is the stainless multilayer cometic gaskets ... 0.040 thickenss, new block and heads were resurfaced before bolted them down .. I think at 80 flbls. ( been about 5 years ago)

car is only 2500 lbs... so its not alot of weight to push either....

I was running pump gas fine and when I switched blowers to this f3r and hit 15 lbs of boost at 4000 rpm, decided to switch to e85. The boost in the graph was only at 63 % throttle... so Im not quite where its going to be yet and not sure what i can do to make it where I can get more runs out of it before rebuilding ....

I can switch gaskets to whatever ... just not sure if o-ringing should be an option ? I read that there is some kind of ISKY tool that will oring the block ? and then run a copper gasket ? is that hard ? or a good option ?

I didnt even pull the plugs yet...DOH...

#7

I've used the Isky O-ringing tool. Works pretty decent.

it helps control fire ring damage caused by detonation but if it is severe enough it will still let the gasket go. I went probably 3yrs after I o-ringed a 302 Block until one day I over ran the MAF tune past 70lb/min & it let go on the big end. Even with the o-rings it still ended up spitting coolant out from between the block & head.

If the head is lifting enough, o-ringed doesn't stop it entirely.

Add: That happened running 114 Octane... But I was already pushing ~1725 EGT on the big end...

it helps control fire ring damage caused by detonation but if it is severe enough it will still let the gasket go. I went probably 3yrs after I o-ringed a 302 Block until one day I over ran the MAF tune past 70lb/min & it let go on the big end. Even with the o-rings it still ended up spitting coolant out from between the block & head.

If the head is lifting enough, o-ringed doesn't stop it entirely.

Add: That happened running 114 Octane... But I was already pushing ~1725 EGT on the big end...

Last edited by gtfoxy; 01-25-2016 at 10:13 AM.

Trending Topics

#9

8 Second Club

iTrader: (4)

If your IAT sensor is down stream of the meth injection it skews the IAT tempo readings to the point of uselessness. You have no idea what the actual charge temps are when it’s spraying. Meth/water injection is great don’t get me wrong. I have it on all my setups. But you shouldn’t ever tune by a saturated IAT sensor. Trust me your actual charge temps are nowhere near that cool.

Was the block/head surfaced to 50RA or finer? Or just “surfaced”? If not that’s most likely an issue as well. My cometics were always picky, nothing like the LS9 gasket. If you’re bore isn’t too large to run an LS9 gasket I’d highly suggest it. I torqued my std diameter ARP studs to 85ftlb. I’ve run 30+lbs without head sealing issues. O-rings work great with copper gaskets. Just a matter of time money, that’s up to you. I think an LS9 gasket with a proper tune should be more than fine at 20ish lbs.

8:1 Compression is super low. My 8.6:1 5.3 liked about 17*. Where my 10:1 stuff doesn’t like more than 12-14* @ 25ish lbs. This was also not a supercharged setup and was using a neg. overlap @ .050 cam. I know a lot of times the SC setups run a high duration cam where you’re bleeding off a ton of cyl pressure, so you can get away with much higher timing numbers… Do you have the actual cam card with the specs on it for us?

Learning to read plugs and doing it often is the best tuning method for any alky fueled car. Start low on timing and work your way up slowly watching plugs. If you know how to read them, it’s very hard to hurt the engine tuning this way. Most (including me) don’t do it nearly as often as they should.

Was the block/head surfaced to 50RA or finer? Or just “surfaced”? If not that’s most likely an issue as well. My cometics were always picky, nothing like the LS9 gasket. If you’re bore isn’t too large to run an LS9 gasket I’d highly suggest it. I torqued my std diameter ARP studs to 85ftlb. I’ve run 30+lbs without head sealing issues. O-rings work great with copper gaskets. Just a matter of time money, that’s up to you. I think an LS9 gasket with a proper tune should be more than fine at 20ish lbs.

8:1 Compression is super low. My 8.6:1 5.3 liked about 17*. Where my 10:1 stuff doesn’t like more than 12-14* @ 25ish lbs. This was also not a supercharged setup and was using a neg. overlap @ .050 cam. I know a lot of times the SC setups run a high duration cam where you’re bleeding off a ton of cyl pressure, so you can get away with much higher timing numbers… Do you have the actual cam card with the specs on it for us?

Learning to read plugs and doing it often is the best tuning method for any alky fueled car. Start low on timing and work your way up slowly watching plugs. If you know how to read them, it’s very hard to hurt the engine tuning this way. Most (including me) don’t do it nearly as often as they should.

#10

On The Tree

Thread Starter

Join Date: Sep 2005

Location: FLORIDA

Posts: 103

Likes: 0

Received 0 Likes

on

0 Posts

211/230 @.050 valve lift and .558/.552 lift with 1.7 rockers and a 122.5 centerline.

I believe its that one.

If not down stream, how do you measure IAT on a methanol engine ?

I believe its that one.

If not down stream, how do you measure IAT on a methanol engine ?

#11

8 Second Club

iTrader: (4)

I wouldn’t run anywhere near that timing with that cam. Subtracting 5* isn’t enough. As soon as you make positive boost you should be in the 14* range. Then get a plug reading and go from there. It will be slower for sure, I’m not suggesting you leave it there. Just get a baseline and read the plugs from there. What plugs are you running? You need to run a new set just before your pass, then shut down as quickly as possible after to get a good read.

Tough to answer your question without getting long winded, how much fluid do you inject? 100% meth? The small amounts of meth most inject don’t have a large effect on IAT’s like the companies want you to believe. They help most in the CC by upping octane and pulling heat there. I prefer to know my actual charge temps to tune by. My IAT sensor is just after the IC. I spray my meth at the TB. This way I get my actual charge temps post IC that aren’t skewed by false aux injection saturating the sensor. If you’re spraying pre-compressor you don’t have a lot of choice. Just put the IAT sensor as far away as possible. Are you intercooled as well?

Tough to answer your question without getting long winded, how much fluid do you inject? 100% meth? The small amounts of meth most inject don’t have a large effect on IAT’s like the companies want you to believe. They help most in the CC by upping octane and pulling heat there. I prefer to know my actual charge temps to tune by. My IAT sensor is just after the IC. I spray my meth at the TB. This way I get my actual charge temps post IC that aren’t skewed by false aux injection saturating the sensor. If you’re spraying pre-compressor you don’t have a lot of choice. Just put the IAT sensor as far away as possible. Are you intercooled as well?

#13

There was a guy posted not long ago that was running 24* of timing but IDR the set-up entirely but IIRC it was a turbo.

#15

On The Tree

Thread Starter

Join Date: Sep 2005

Location: FLORIDA

Posts: 103

Likes: 0

Received 0 Likes

on

0 Posts

im using the 35% windshield wiper fluid (-20) for methanol injection.... my sensor is too close to my nozzle ... the more you mention it... you are right .

its the snow kit .. one nozzle.. i will be adding another nozzle... no intercooler.

its the snow kit .. one nozzle.. i will be adding another nozzle... no intercooler.

Last edited by monsterchevylizzard; 01-25-2016 at 01:40 PM.

#17

TECH Fanatic

You cant truly read a plug unless you shut it down immediate after a WOT run.

Its simply too much timing. E85 will not show knock- it will juts be "all good" on the tune and sling a rod!

Move the Meth nozzle post IAT, put some head gaskets on there and RIP it. No way you need an O ring with 20 psi on any turbo with a good tune. T66 or single 101, it should be fine. Dont over complicate the repair.

Its simply too much timing. E85 will not show knock- it will juts be "all good" on the tune and sling a rod!

Move the Meth nozzle post IAT, put some head gaskets on there and RIP it. No way you need an O ring with 20 psi on any turbo with a good tune. T66 or single 101, it should be fine. Dont over complicate the repair.

#20

8 Second Club

iTrader: (3)

I'm not real convinced the Cometics are the best choice. We lost a set not even being agressive.

Surface finish on the heads and block are important. If you can see the machine marks, its too coarse.

I thinks it's best not to touch the block. GM does a great job there.

I actually had my heads lapped smooth.

Then ran the LS9 gasket.

Hearing that E85 doesn't show detonation is a first for me.

Given that you are doing long pulls, much harder on parts than us 1/4 milers, I agree that you need to cut the timing back and try again. Power goes up when you get it right.

Timing = power is only correct at the sweet spot.

Sounds like a fun ride!

Surface finish on the heads and block are important. If you can see the machine marks, its too coarse.

I thinks it's best not to touch the block. GM does a great job there.

I actually had my heads lapped smooth.

Then ran the LS9 gasket.

Hearing that E85 doesn't show detonation is a first for me.

Given that you are doing long pulls, much harder on parts than us 1/4 milers, I agree that you need to cut the timing back and try again. Power goes up when you get it right.

Timing = power is only correct at the sweet spot.

Sounds like a fun ride!