Question about adequate crankcase ventilation?

#1

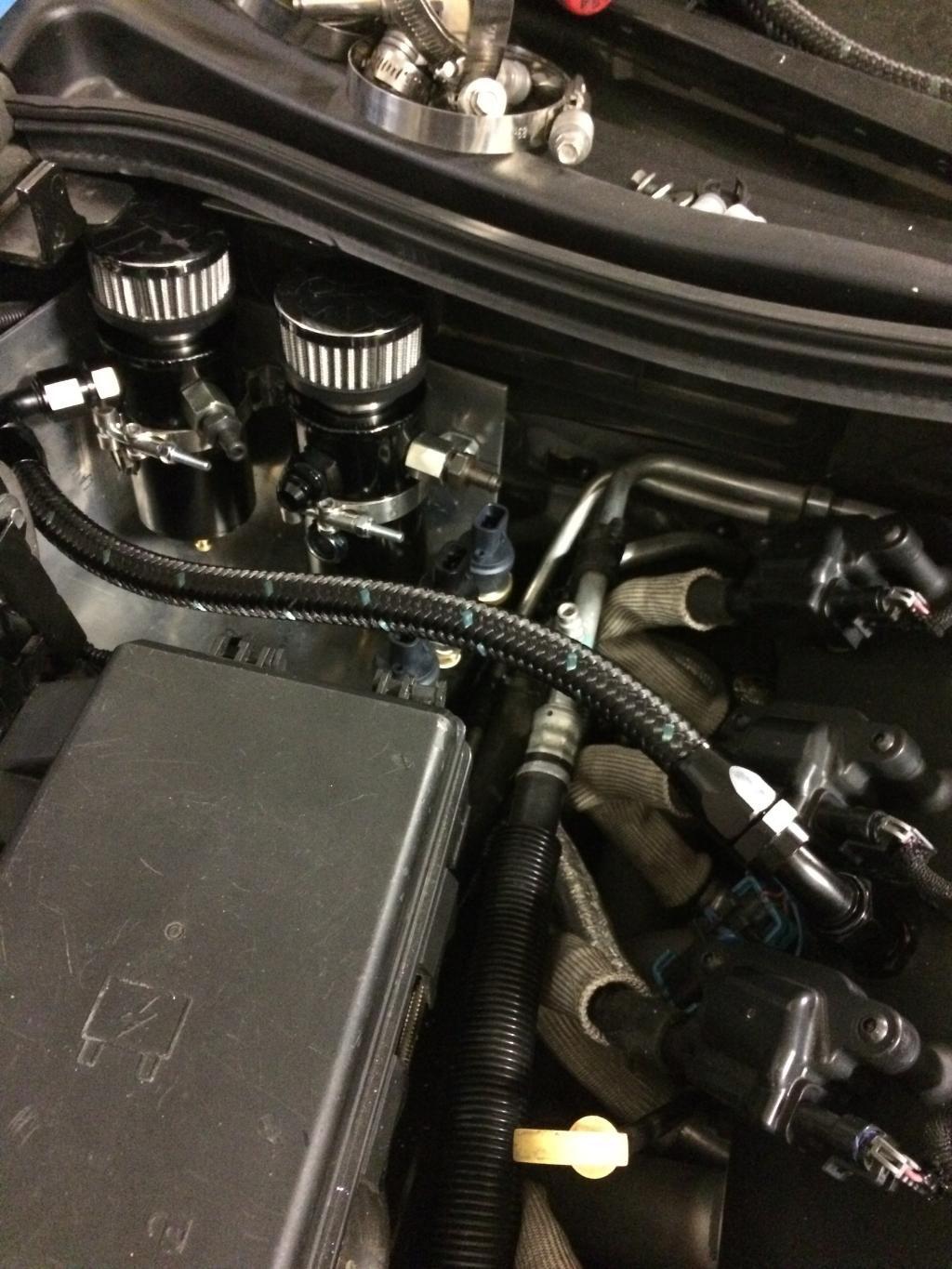

I am doing the final assembly of a iron block 346 motor. I am using aftermarket valve covers to clear the Pro Magnum roller rocker arms. I have a PCV valve installed at the rear of the driver side cover. That's it. Should I add a breather on the other side? I have a catch can and one way valve for the PCV. Boost will be modest at around 9 pounds. Street motor. Thanks

#2

TECH Regular

I use breathers on both stock vakve covers same motor u have but I am installing the mighty mouse catch can soon. Originally I was going to use my down pipe to pull draft and burn it all out thathe way but don't want an oily residue on my bumper or oil sprayed on the track even tho it's a street car do u have a pic of your valve covers

#3

Banned

iTrader: (1)

First you will want to pressure test both the crankcase, and the intake air pathways. Fill the intake pathway (from the turbo compressor all the way to the engine) with whatever boost pressure (typically 15psi~) you intend to run to make sure it holds that pressure. While it holds the pressure, pull the dipstick tube and make sure there is minimal crankcase pressure, no real flow from the crankcase.

Then, do the same thing for the crankcase, but with minimal pressure, usually 1psi max. The idea is, find all the leaks in the crankcase. Once you find all the "holes" you can design a proper PCV system. In other words, you assume right now you have a fresh air feed, and a pcv valve, and that is it. However, you may find that during your pressure test, there are other "holes" like a leaky dipstick tube. Which absolutely does count. There can other holes also. you want to seal up all of the holes, except for the fresh air inlet, which is typically on one valve cover, and feeds from the post-air filter, pre-compressor tract. This is fresh air into the crankcase pathway, every engine needs at least one of these. The other "hole" is the pcv valve, which is the crankcase dirty air outlet into the intake tract of the breathing engine (or exhaust drawn setup, or vacuum pump setup, etc...) the idea is, one allows fresh air in, one allows filthy air out. On a turbo setup, since boost will shut the PCV valve, you also need to verify this actually happens: pressure test the pcv valve to make sure it fully shuts and holds the boost you intend to run, many will leak and this will cause crankcase pressure issues. Then, also for turbo setups, you will wish to angle/design/fabricate the fresh air crankcase inlet (remember the one that was post air filter, pre-compressor?) such that, during boost, it will allow a vacuum to pull on the crankcase (opposite of what it does during off-boost situations) since there is no PCV valve on that line the air can go either way. You can adjust the air filter style to accommodate this vacuum. Ideally for healthy street driven daily driver turbocharger setups that see 100k+ mileage you will want to install a gauge which reads in inches of water ("H2O) from 0 to 32" of H2O and watch that during boost there is at least 2 to 10" of H2O vacuum pressure on that line, this is your crankcase pressure during boost and by keeping it at a slight vacuum you will keep the engine clean and healthy, as the slight vacuum tends to keep oil in the engine and keep it from pressing out on the oil seals (like front and rear main for example). It also is an indicator of bottom end health. You can be sure that when the vacuum suddenly disappears and there is now a positive pressure in the crankcase, you have a big problem that need immediate attention. In other words, it is a very important, highly undervalued diagnostic indication of the condition of the rotating assembly and it's associated oil control faculty.

Then, do the same thing for the crankcase, but with minimal pressure, usually 1psi max. The idea is, find all the leaks in the crankcase. Once you find all the "holes" you can design a proper PCV system. In other words, you assume right now you have a fresh air feed, and a pcv valve, and that is it. However, you may find that during your pressure test, there are other "holes" like a leaky dipstick tube. Which absolutely does count. There can other holes also. you want to seal up all of the holes, except for the fresh air inlet, which is typically on one valve cover, and feeds from the post-air filter, pre-compressor tract. This is fresh air into the crankcase pathway, every engine needs at least one of these. The other "hole" is the pcv valve, which is the crankcase dirty air outlet into the intake tract of the breathing engine (or exhaust drawn setup, or vacuum pump setup, etc...) the idea is, one allows fresh air in, one allows filthy air out. On a turbo setup, since boost will shut the PCV valve, you also need to verify this actually happens: pressure test the pcv valve to make sure it fully shuts and holds the boost you intend to run, many will leak and this will cause crankcase pressure issues. Then, also for turbo setups, you will wish to angle/design/fabricate the fresh air crankcase inlet (remember the one that was post air filter, pre-compressor?) such that, during boost, it will allow a vacuum to pull on the crankcase (opposite of what it does during off-boost situations) since there is no PCV valve on that line the air can go either way. You can adjust the air filter style to accommodate this vacuum. Ideally for healthy street driven daily driver turbocharger setups that see 100k+ mileage you will want to install a gauge which reads in inches of water ("H2O) from 0 to 32" of H2O and watch that during boost there is at least 2 to 10" of H2O vacuum pressure on that line, this is your crankcase pressure during boost and by keeping it at a slight vacuum you will keep the engine clean and healthy, as the slight vacuum tends to keep oil in the engine and keep it from pressing out on the oil seals (like front and rear main for example). It also is an indicator of bottom end health. You can be sure that when the vacuum suddenly disappears and there is now a positive pressure in the crankcase, you have a big problem that need immediate attention. In other words, it is a very important, highly undervalued diagnostic indication of the condition of the rotating assembly and it's associated oil control faculty.

#7

Banned

iTrader: (1)

My pressure test on my own personal LS engine is coming up soon, couple days, and like all of the other details I have posted in my thread I will take pictures to minimize the words by using actual pics of the process to make it easy to understand and follow. It is not hard to do, but it is hard to explain without pics. Sorry about the wall of text I know people don't like reading all the time online, this supposed to be a chill place to relax, not a study hall. Still the info is important and pertinent, very powerful way of monitoring engine health and ensuring optimal performance.

Trending Topics

#8

all the ECS and A&A supercharged vettes just run a single breather on one side and I'm not sure what point that becomes an issue but lots of those guys running 700whp. It's so easy to do though so I put dual 10 AN lines with one off each side and zero issues at 900whp in 1/2 mile. might mouse solutions sells a trick filter PCV setup that just threads into the oil fill spout so I added that also

#9

Banned

iTrader: (1)

all the ECS and A&A supercharged vettes just run a single breather on one side and I'm not sure what point that becomes an issue but lots of those guys running 700whp. It's so easy to do though so I put dual 10 AN lines with one off each side and zero issues at 900whp in 1/2 mile. might mouse solutions sells a trick filter PCV setup that just threads into the oil fill spout so I added that also

we desire a (variable) vacuum in the crankcase all the time for those reasons outlined; there is often an issue with how to go about doing this. I would explain more but I think I hit the reader's limit...

#10

TECH Apprentice

Just install a Mighty Mouse system as per Davids instructions for your setup, and know that you wont have problems. Ive seen blown out seals with most other, and especially, home brewed solutions.

#12

TECH Apprentice

#13

The initial question might be, what crankcase pressure should be considered too high? I would imagine some seals only need 15 psi to get pushed out. I'd think 3-5psi might be considered max allowable. An old worn out motor (rings not holding under boost) likely can create some serious crankcase pressure. In summary, above max suggested, time to increase ventilation.

#14

this is basically what I did also but with one catch can.

i was just thinking the filter setup could be easy way to add more venting, but it's so easy to just weld a 10 AN bung onto the other valve cover i don't see why anyone wouldn't just do that and make sure there is more than enough venting

#15

TECH Apprentice

The initial question might be, what crankcase pressure should be considered too high? I would imagine some seals only need 15 psi to get pushed out. I'd think 3-5psi might be considered max allowable. An old worn out motor (rings not holding under boost) likely can create some serious crankcase pressure. In summary, above max suggested, time to increase ventilation.

#16

Banned

iTrader: (1)

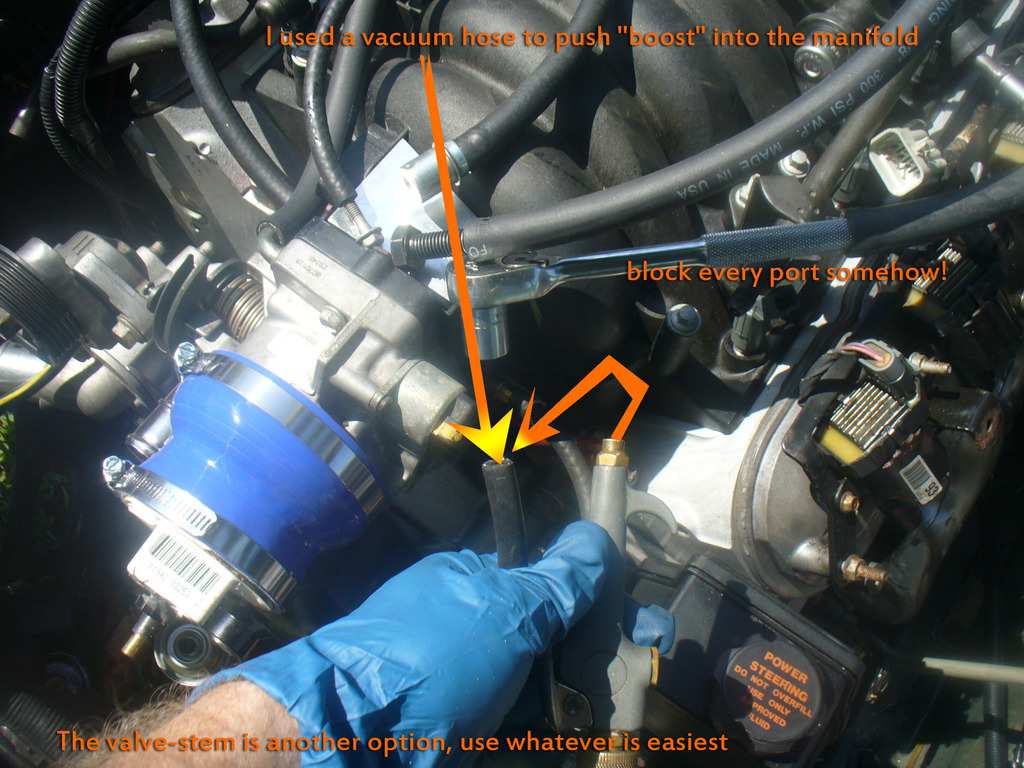

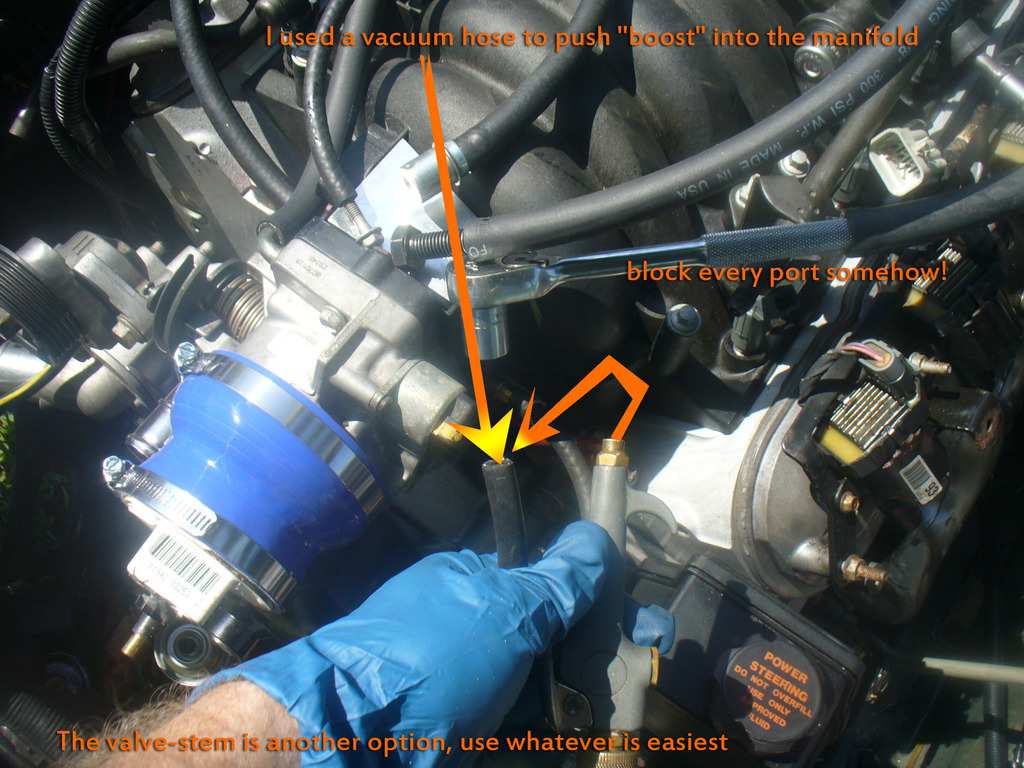

As promised here are some pics and a video of a couple pressure test methods.

When the engine is running, you can't hear what is going on. That is why you need to shut the engine off, and use a very quiet air hose (turn off that compressor!) to fill the air path with pressure and find all of the leaks. This is NOT an optional test; every forced induction setup NEEDS to be pressure tested, there are always leaks to find.

Video:

I just realized I never mentioned that a leaking PCV valve was NO GOOD. They should not leak like that! You need to test your PCV to make sure it seals up tight when there is boost in the manifold, or it will send boost right into the crankcase.

When the engine is running, you can't hear what is going on. That is why you need to shut the engine off, and use a very quiet air hose (turn off that compressor!) to fill the air path with pressure and find all of the leaks. This is NOT an optional test; every forced induction setup NEEDS to be pressure tested, there are always leaks to find.

Video:

I just realized I never mentioned that a leaking PCV valve was NO GOOD. They should not leak like that! You need to test your PCV to make sure it seals up tight when there is boost in the manifold, or it will send boost right into the crankcase.

Last edited by kingtal0n; 04-12-2017 at 02:49 PM.