Turbo bolts question.

#1

Teching In

Thread Starter

Hey guys, I checked some FAQ and searched, so I could have over looked this...

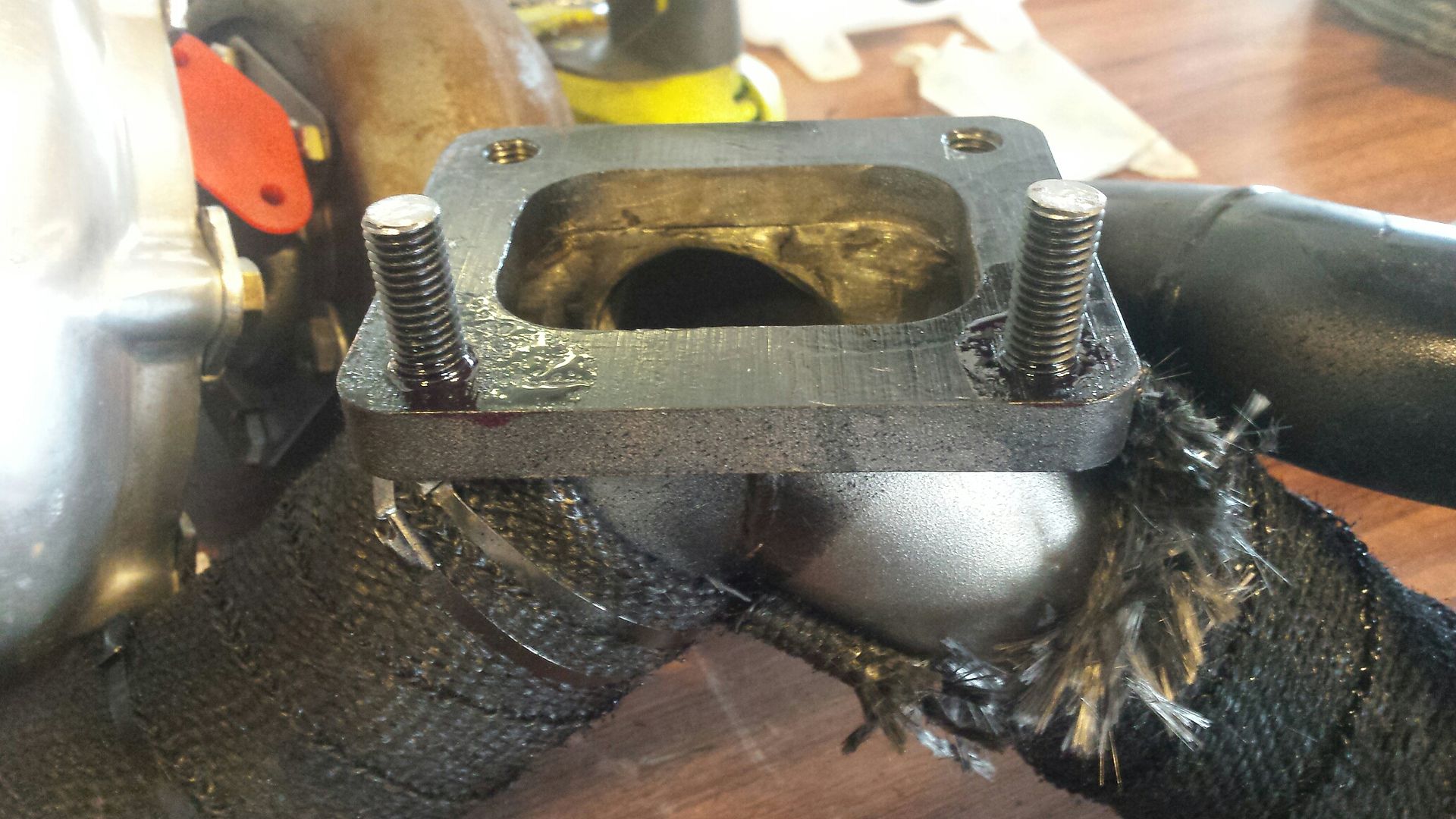

Im running a log style manifold w/ a T4 flange and a VS racing billet 78/75 turbo. What bolt size and length is typically used to attach the turbo to the manifold? Also, does anyone know the size for attaching the oil feed and drain flanges to the turbo?

Thanks!

Im running a log style manifold w/ a T4 flange and a VS racing billet 78/75 turbo. What bolt size and length is typically used to attach the turbo to the manifold? Also, does anyone know the size for attaching the oil feed and drain flanges to the turbo?

Thanks!

#3

Banned

iTrader: (1)

search for something like "10mm T3 & T4 Turbo M10 Inconel Stud Hardware Kit"

"Stud torque spec: 38 Nm +/- 3 Nm

Nut torque spec: Low Limit: 60 Nm / Upper Limit: 130 Nm (95 ft/lbs) after snug tighten to 30 Nm (in sequence)

By using 1.5 (standard pitch) on the manifold side and 1.25 (fine pitch) on the turbo side, the standard pitch thread will stay put in the manifold while the fine pitch 1.25 inconel nut will be easy to remove without dislodging/unthreading the stud from the flange. This works perfectly with your existing turbo manifolds which typically use 3/8-16 hardware (the old industry standard) – all you need to do is run a 10mm x 1.5 tap through the old 3/8-16 threads to chase them and it works perfectly."

"Stud torque spec: 38 Nm +/- 3 Nm

Nut torque spec: Low Limit: 60 Nm / Upper Limit: 130 Nm (95 ft/lbs) after snug tighten to 30 Nm (in sequence)

By using 1.5 (standard pitch) on the manifold side and 1.25 (fine pitch) on the turbo side, the standard pitch thread will stay put in the manifold while the fine pitch 1.25 inconel nut will be easy to remove without dislodging/unthreading the stud from the flange. This works perfectly with your existing turbo manifolds which typically use 3/8-16 hardware (the old industry standard) – all you need to do is run a 10mm x 1.5 tap through the old 3/8-16 threads to chase them and it works perfectly."

#5

Kingtalon - seems a little over kill using inconel doesn’t it?

OP - if your on a budget slap some anti-seize on some zinc 3/8 bolts with either all metal lock nuts or flanged nuts with serrations on them or use some nordlock washers on some smooth flanged nuts.

OP - if your on a budget slap some anti-seize on some zinc 3/8 bolts with either all metal lock nuts or flanged nuts with serrations on them or use some nordlock washers on some smooth flanged nuts.

Trending Topics

#10

9 Second Club

Use plain and simple mild steel.

Stainless is a **** if it catches and galls up and you need to cut anything free. There should be almost no stress on those bolts at all other than holding the turbo from moving which for 4 bolts....is no work at all.

A locking style nut is always a good idea though, interference style.

as for inconel bolts.....wise the **** up.

Stainless is a **** if it catches and galls up and you need to cut anything free. There should be almost no stress on those bolts at all other than holding the turbo from moving which for 4 bolts....is no work at all.

A locking style nut is always a good idea though, interference style.

as for inconel bolts.....wise the **** up.

#12

Banned

iTrader: (1)

$50 is nothing. I don't see why its such a big deal, using high quality fasteners, I prefer to overkill wherever possible.

I want 100k out of them and I don't need to worry 8 years down the road. I know somebody patching up cracks in their 10 year old mild steel setup.

Not trying to be that guy.

I want 100k out of them and I don't need to worry 8 years down the road. I know somebody patching up cracks in their 10 year old mild steel setup.

Not trying to be that guy.

#14

#15

FormerVendor

iTrader: (1)

Join Date: Nov 2008

Location: Santa Ana, CA. USA

Posts: 2,157

Likes: 0

Received 16 Likes

on

16 Posts

HI ALL, MY first Pantera Twin Turbo KIT included head/manifold EX STUDS AND

ALL S/S hardware. (circa 1973)

The Exhaust studs were 3/8" coarse on the head with the manifold size of 3/8" fine.

The HOT side used "long shank" 3/8" 24 bolt/nut of stainless steel, common grade, to connect the Snail to the Manifold.

AL bolts/nuts/studs were coated with Jet Nut in the thread area.

THIS bit of "tech" is STANDARD for an A/P mechanic.

My customers report to this day, no problems with bolt breakage.

SO I ASK : What material is your head/manifold stud and size ?

Lance

ALL S/S hardware. (circa 1973)

The Exhaust studs were 3/8" coarse on the head with the manifold size of 3/8" fine.

The HOT side used "long shank" 3/8" 24 bolt/nut of stainless steel, common grade, to connect the Snail to the Manifold.

AL bolts/nuts/studs were coated with Jet Nut in the thread area.

THIS bit of "tech" is STANDARD for an A/P mechanic.

My customers report to this day, no problems with bolt breakage.

SO I ASK : What material is your head/manifold stud and size ?

Lance

#17

9 Second Club

And not one single OEM fitment use inconel for their bolts, and their vehicles will do more miles than anything you ever dream of building.

#19

9 Second Club

And as for longevity etc...I'm sure pretty much every user here doesnt give a damn about a single build lasting for 200k...which regular steel bolts will do anyway.

Because who here would actually build it once and never touch it again for 200k....100k....50k !! None, everyone is always continually modifying and making changes.

This isnt a forum for cars that are never touched or modified.

Because who here would actually build it once and never touch it again for 200k....100k....50k !! None, everyone is always continually modifying and making changes.

This isnt a forum for cars that are never touched or modified.