Twin 67/66 Lazy...Help

#1

I'm trying to figure out what might cause these turbos to be so lazy..

here is the motor combo:

LSX 427

9.75.1 CR (-18cc dish piston)

BTR stage 3 turbo cam (off the shelf)

GMPP LSX heads

low mount twin 67/66 with .96AR

Before we get to far into this I have already checked for boost leaks..

If I target 23PSI i'm not seeing it till 6100 RPM, I would think with my engine size these turbos would spool rather quickly.

I'm at a lose and really not sure why these little turbos are lazy.

Any help would be great!

here is the motor combo:

LSX 427

9.75.1 CR (-18cc dish piston)

BTR stage 3 turbo cam (off the shelf)

GMPP LSX heads

low mount twin 67/66 with .96AR

Before we get to far into this I have already checked for boost leaks..

If I target 23PSI i'm not seeing it till 6100 RPM, I would think with my engine size these turbos would spool rather quickly.

I'm at a lose and really not sure why these little turbos are lazy.

Any help would be great!

#2

9 Second Club

Well you clearly have a leak somewhere. Whether that's pre-turbine or on the cold/boost side...up to you to find it.

they should not be lazy on a 427

Presumably your gates return into the main exhaust so you cannot hear them leaking ?

they should not be lazy on a 427

Presumably your gates return into the main exhaust so you cannot hear them leaking ?

#4

9 Second Club

Well with such sparse detail, only checking for leaks will yield any info.

You dont state when it starts to make any boost, what means of boost control you're using and how it's configured, potential tuning issues ? How does it feel off boost ?

Are the gates even opening then ? Or are they properly sealed as they should be ?

Details, we cannot see what's going on.

You dont state when it starts to make any boost, what means of boost control you're using and how it's configured, potential tuning issues ? How does it feel off boost ?

Are the gates even opening then ? Or are they properly sealed as they should be ?

Details, we cannot see what's going on.

#5

Well with such sparse detail, only checking for leaks will yield any info.

You dont state when it starts to make any boost, what means of boost control you're using and how it's configured, potential tuning issues ? How does it feel off boost ?

Are the gates even opening then ? Or are they properly sealed as they should be ?

Details, we cannot see what's going on.

You dont state when it starts to make any boost, what means of boost control you're using and how it's configured, potential tuning issues ? How does it feel off boost ?

Are the gates even opening then ? Or are they properly sealed as they should be ?

Details, we cannot see what's going on.

off boost the car feels great. Any suggestion on how you might do a boost leak test?

#6

9 Second Club

that doesnt give any detail on how you have boost controlo configured.

Nor mention of what type of gates, what springs, general layout.

To test for leaks best way is remove the rockers, plug up both turbo compressor inlets and then pressurise the entire inlet system, ideally with a smoke machine.

That way you're testing the entire system right to the inlet valves. A lesser test would just be to the throttle body, again plugging the pipework, and much easier and probably sufficient.

Just search boost leak test on youtube, there are dozens of videos with various options.

Although with the rockers removed, it also allows you to do a good leak test on the exhaust side too.

Nor mention of what type of gates, what springs, general layout.

To test for leaks best way is remove the rockers, plug up both turbo compressor inlets and then pressurise the entire inlet system, ideally with a smoke machine.

That way you're testing the entire system right to the inlet valves. A lesser test would just be to the throttle body, again plugging the pipework, and much easier and probably sufficient.

Just search boost leak test on youtube, there are dozens of videos with various options.

Although with the rockers removed, it also allows you to do a good leak test on the exhaust side too.

#7

that doesnt give any detail on how you have boost controlo configured.

Nor mention of what type of gates, what springs, general layout.

To test for leaks best way is remove the rockers, plug up both turbo compressor inlets and then pressurise the entire inlet system, ideally with a smoke machine.

That way you're testing the entire system right to the inlet valves. A lesser test would just be to the throttle body, again plugging the pipework, and much easier and probably sufficient.

Just search boost leak test on youtube, there are dozens of videos with various options.

Although with the rockers removed, it also allows you to do a good leak test on the exhaust side too.

Nor mention of what type of gates, what springs, general layout.

To test for leaks best way is remove the rockers, plug up both turbo compressor inlets and then pressurise the entire inlet system, ideally with a smoke machine.

That way you're testing the entire system right to the inlet valves. A lesser test would just be to the throttle body, again plugging the pipework, and much easier and probably sufficient.

Just search boost leak test on youtube, there are dozens of videos with various options.

Although with the rockers removed, it also allows you to do a good leak test on the exhaust side too.

What do you mean when you ask how the boost controller is configured?

Trending Topics

#8

9 Second Club

Are you blowing into top chamber, bottom chamber, where is pressure source taken from ? bla bla bla.

Although if the gates are actually closed, it may be a moot point at the minute...assuming they are closed which you would hear if the gates vent to atmos and they were not closed.

But a pressure test would be a starting point assuming all the obvious things are ok.

Although if the gates are actually closed, it may be a moot point at the minute...assuming they are closed which you would hear if the gates vent to atmos and they were not closed.

But a pressure test would be a starting point assuming all the obvious things are ok.

#10

Are you blowing into top chamber, bottom chamber, where is pressure source taken from ? bla bla bla.

Although if the gates are actually closed, it may be a moot point at the minute...assuming they are closed which you would hear if the gates vent to atmos and they were not closed.

But a pressure test would be a starting point assuming all the obvious things are ok.

Although if the gates are actually closed, it may be a moot point at the minute...assuming they are closed which you would hear if the gates vent to atmos and they were not closed.

But a pressure test would be a starting point assuming all the obvious things are ok.

In your opinion with my engine combo when should these tubos be full spool?

#11

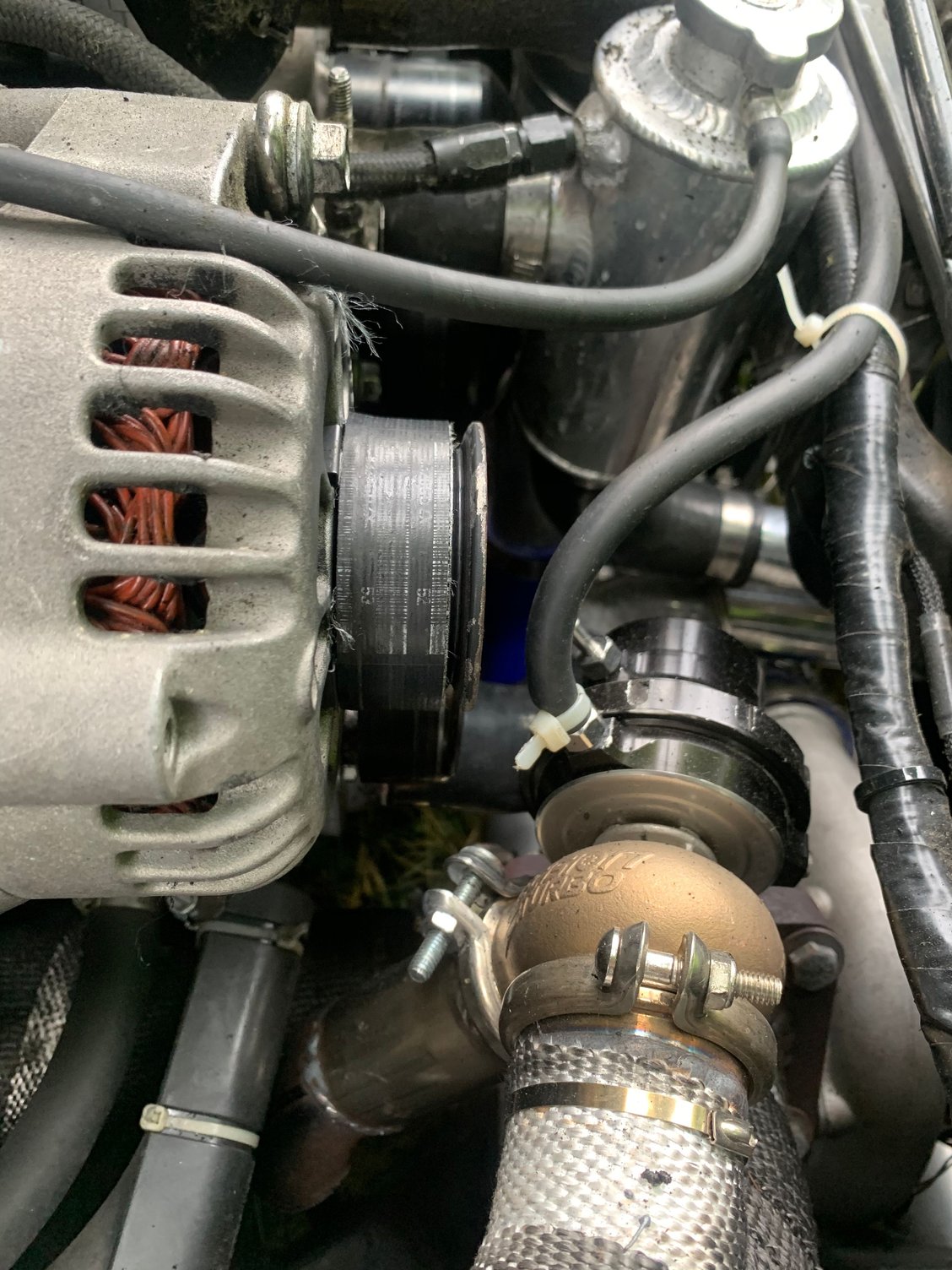

ignore my belt, using this pic cause shows wastegate line...

hook vacuum line from Pressure only source, TB to turbo on the nipple closest to valve like in picture. The furthest away nipple should vent open. This way boost is just pushing onto the diaphragm whole time and opens as boost builds up to spring pressure. This pushes against the spring pressure

when using an electronic controller you will T into the top nipple also so boost will keep the valve closed until the moment you want it open. So boost will go against the springs pressure through bottom nipple AND be boost will come into top nipple to ADD to the spring pressure.

Logically thinking, you have 10lb spring and put just boost into bottom nipple closest the valve. You boost pressure is working against the spring to open the diaphragm. As you hit 7psi youíll start cracking the valve open and at 10psi itíll be wide open.

now with the EBC, your applying boost to the bottom nipple like above so it works against spring pressure, however your also applying boost to the top nipple which pushing with the springs to hold valve closed. This way you do not start opening at 7psi on a 10psi spring cause boost is also pushing valve shut. Then whenever you set the EBC it will cut off the boost to the top nipple which allows the valve to fly open.

thereís alittle more details than that in there but itís as basic as I could think to explain it. Thatís how an EBC can adjust the curve of your boost cause itíll hold WG shut and not crack open to slowly bleed some boost.

in your case, you should just run it like my picture is and get your true reading of motor/turbo/tune setup to see your real boost curve and not an artificial one by an EBC. After you solve your issue then hook up the ENC and play with duty cycle etc.

#13

9 Second Club

With a 427 and unless the turbo's were scrap, I'd have thought you'd have plenty of boost sub 4k.

#16

9 Second Club

Never used them, but Chinese turbos wouldn't be my first port of call, although they do seem to be popular and give good results for many.

Some of them do look quite good visually though.

Some of them do look quite good visually though.

#17

TECH Apprentice

iTrader: (3)

I'm running a set of VS Racing 69/73 on a 370" motor and they do extremely well. A couple buddies are also running them with great results and no issues. I'm almost wondering if the large motor and small turbos if its high backpressure opening the gates early. Have you checked boost pressure at the compressor vs at the intake ?

#18

8 Second Club

iTrader: (4)

Place some thick paper over the WG exhaust outlets. Have a buddy or you get on the trans brake, 2 step, whatever. Just make boost. Or try to. Ensure the WG's are staying closed. Have any timing maps handy? Who tuned it? What fuel?

I'd try pulling the top and bottom WG lines off completely. Plug them and see if boost comes in noticeably quicker. Obviously don't stay in it and over boost it. (might set over-boost protection if you feel you won't be able to let off)

Next common leak area is the blow off valve(s).

I'd try pulling the top and bottom WG lines off completely. Plug them and see if boost comes in noticeably quicker. Obviously don't stay in it and over boost it. (might set over-boost protection if you feel you won't be able to let off)

Next common leak area is the blow off valve(s).

#20

8 Second Club

iTrader: (4)

Depends on the rest of the setup and if you know what to listen for. I think we assume a lot about owners, some may have little to no experience. I don't hear diddly out of mine and they are both vented. They are 4 inches from 2 open 3" dumps however! They could be "cracked" open or not seated properly in the valve cup. I've seen the valve cups not installed numerous times as well. Yet to see one of the cheapie gates that sealed well out of the box, some much worse than others. Sounds like he used good parts, so hopefully that isn't the case. Also if there's say a 16th gap all around, the sound will never change. "Leaky" will just sounds "normal". Just something good to verify IMO.