Forged LS3 preliminary numbers 722ftlb @ 4,500rpm by Rick @ Synergy

#1

TECH Enthusiast

Thread Starter

Join Date: Dec 2001

Location: Dublin, CA

Posts: 548

Likes: 0

Received 0 Likes

on

0 Posts

Custom cam and Mafless 2bar (like SD) tuning by Rick @ Synergy

Edit: SD tune, not like SD tune

Valve job and springs set by Angie @ Daves Engine Machining, Precision TIG welding of weld-on fittings on the LS2 fuel rails by Dave

Tips and tricks by Andy @ A and A Corvette

Forged LS3 by Bruce @ Powrmax.com

DIY dual pump fuel system, head porting, and engine install by me

722ftlb @ 4,500rpm

710ftlb @ 5,400rpm

And that is on his unforgiving Dynopak dyno.

Next, fix belt slip that starts at 5,400rpm (big crank pulley?). Also figure out why the Vigilante 10.5" 3-disk converter is slipping by 600rpm.

Edit: Not a 3-disk converter, it turned out to be a single disk

LS3 block and heads, 9:1cr, DIY ported heads, Diamond pistons, Manley stainless intake valves, Comp 921 springs, stock LS3 rockers (should do the Harlan Sharp bearings), LS7 lifters, MTI 7.4" pushrods, Synergy custom cam ~224/.610", DIY dual fuel pumps and 1/2" fuel lines, Aeromotive fuel filter and regulator, L76 intake (mild port with advice from Angie @ D.E.M.), RC engineering 75lb injectors, LS2 throttle body, D1SC 8-rib, A&A stage 2 8-rib bracket and modded v1.0 FMIC, Turbohoses hard pipes, TPIS/Melrose (unsure now) headers and cats, Ti mufflers.

I wasted some time and money on two other vendors before I found great vendors.

Edit: SD tune, not like SD tune

Valve job and springs set by Angie @ Daves Engine Machining, Precision TIG welding of weld-on fittings on the LS2 fuel rails by Dave

Tips and tricks by Andy @ A and A Corvette

Forged LS3 by Bruce @ Powrmax.com

DIY dual pump fuel system, head porting, and engine install by me

722ftlb @ 4,500rpm

710ftlb @ 5,400rpm

And that is on his unforgiving Dynopak dyno.

Next, fix belt slip that starts at 5,400rpm (big crank pulley?). Also figure out why the Vigilante 10.5" 3-disk converter is slipping by 600rpm.

Edit: Not a 3-disk converter, it turned out to be a single disk

LS3 block and heads, 9:1cr, DIY ported heads, Diamond pistons, Manley stainless intake valves, Comp 921 springs, stock LS3 rockers (should do the Harlan Sharp bearings), LS7 lifters, MTI 7.4" pushrods, Synergy custom cam ~224/.610", DIY dual fuel pumps and 1/2" fuel lines, Aeromotive fuel filter and regulator, L76 intake (mild port with advice from Angie @ D.E.M.), RC engineering 75lb injectors, LS2 throttle body, D1SC 8-rib, A&A stage 2 8-rib bracket and modded v1.0 FMIC, Turbohoses hard pipes, TPIS/Melrose (unsure now) headers and cats, Ti mufflers.

I wasted some time and money on two other vendors before I found great vendors.

Last edited by blu00rdstr; 09-16-2008 at 11:06 PM. Reason: Toned down the dyno numbers

#3

TECH Enthusiast

Thread Starter

Join Date: Dec 2001

Location: Dublin, CA

Posts: 548

Likes: 0

Received 0 Likes

on

0 Posts

What's a track?

VetteMagic is up at the Sacramento Track on Sunday. Not enough time to get the belt slip fixed (8" crank pulley?), get a mondo or race valve, and figure out the 600rpm converter slippage. I'd love to make a run before I got kicked off (it's a convertible).

http://www.nccacorvettes.org/080607-..._final_web.pdf

VetteMagic is up at the Sacramento Track on Sunday. Not enough time to get the belt slip fixed (8" crank pulley?), get a mondo or race valve, and figure out the 600rpm converter slippage. I'd love to make a run before I got kicked off (it's a convertible).

http://www.nccacorvettes.org/080607-..._final_web.pdf

#6

TECH Enthusiast

Thread Starter

Join Date: Dec 2001

Location: Dublin, CA

Posts: 548

Likes: 0

Received 0 Likes

on

0 Posts

I did the install in my driveway, drove it enough to find leaks and get gas, and had the car flatbedded to Synergy.

Last edited by blu00rdstr; 06-04-2008 at 03:17 PM.

#7

TECH Enthusiast

Thread Starter

Join Date: Dec 2001

Location: Dublin, CA

Posts: 548

Likes: 0

Received 0 Likes

on

0 Posts

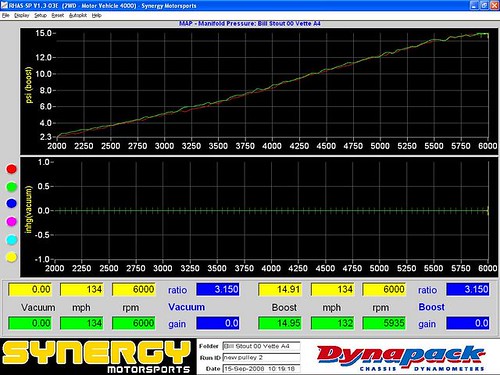

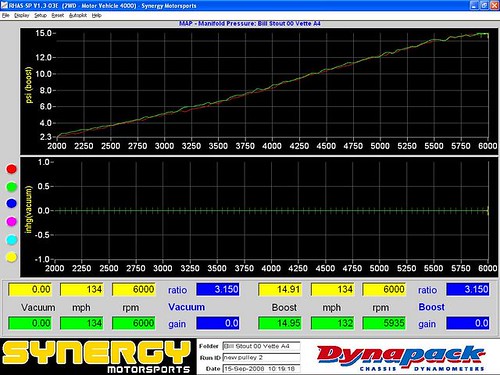

I swapped in a 3.85" pulley, so now it is down to a more reasonable 650rwtq/660rwhp. I kinda miss that 735rwtq peak figure we hit after my initial post. Spun tires on demand. Made a nice raspy exhaust sound at throttle. There was too much converter slip to use the 3.2" pulley which earlier hit 14psi at 4,500rpm (if the belt held it would hit 26psi according to Rick). Rick also nixed my request to use a restrictor plate to keep the boost down at higher rpm, as I'd have go through the motor again way too early.

Excellent cam design and tuning work by Rick @ Synergy as usual, the car drives smooth as a baby. The idle is more aggressive than before, but it's not exactly a lumpy cam idle. With a 3.85" 8-rib reichard pulley the boost is steady and smooth with no slippage at all. I'm not used to that.

The engine RPM in the graphs are off by 1000 rpm at the peak due to converter slippage.

The PI Vigilante single-disk converter is slipping by 1,000rpm, that'll affect the dyno results somehow (reads rpm from the hubs and calculates HP from rpm). So I'm in the market for a multi-disk low stall Vigilante, and after that a 3.5" or 3.6" 8-rib reichard pulley.

Excellent cam design and tuning work by Rick @ Synergy as usual, the car drives smooth as a baby. The idle is more aggressive than before, but it's not exactly a lumpy cam idle. With a 3.85" 8-rib reichard pulley the boost is steady and smooth with no slippage at all. I'm not used to that.

The engine RPM in the graphs are off by 1000 rpm at the peak due to converter slippage.

The PI Vigilante single-disk converter is slipping by 1,000rpm, that'll affect the dyno results somehow (reads rpm from the hubs and calculates HP from rpm). So I'm in the market for a multi-disk low stall Vigilante, and after that a 3.5" or 3.6" 8-rib reichard pulley.

Last edited by blu00rdstr; 09-15-2008 at 10:48 PM.

Trending Topics

#9

12 Second Club

iTrader: (6)

Join Date: Jun 2004

Location: Ft. Irwin, California (But Virginia is home)

Posts: 1,501

Likes: 0

Received 7 Likes

on

1 Post

Custom cam and Mafless 2bar (like SD) tuning by Rick @ Synergy

Valve job and springs set by Angie @ Daves Engine Machining, Precision TIG welding of weld-on fittings on the LS2 fuel rails by Dave

Tips and tricks by Andy @ A and A Corvette

Forged LS3 by Bruce @ Powrmax.com

DIY dual pump fuel system, head porting, and engine install by me

722ftlb @ 4,500rpm

710ftlb @ 5,400rpm

And that is on his unforgiving Dynopak dyno.

Next, fix belt slip that starts at 5,400rpm (big crank pulley?). Also figure out why the Vigilante 10.5" 3-disk converter is slipping by 600rpm.

LS3 block and heads, 9:1cr, DIY ported heads, Diamond pistons, Manley stainless intake valves, Comp 921 springs, stock LS3 rockers (should do the Harlan Sharp bearings), LS7 lifters, MTI 7.4" pushrods, Synergy custom cam ~224/.610", DIY dual fuel pumps and 1/2" fuel lines, Aeromotive fuel filter and regulator, L76 intake (mild port with advice from Angie @ D.E.M.), RC engineering 75lb injectors, LS2 throttle body, D1SC 8-rib, A&A stage 2 8-rib bracket and modded v1.0 FMIC, Turbohoses hard pipes, TPIS/Melrose (unsure now) headers and cats, Ti mufflers.

I wasted some time and money on two other vendors before I found great vendors.

Valve job and springs set by Angie @ Daves Engine Machining, Precision TIG welding of weld-on fittings on the LS2 fuel rails by Dave

Tips and tricks by Andy @ A and A Corvette

Forged LS3 by Bruce @ Powrmax.com

DIY dual pump fuel system, head porting, and engine install by me

722ftlb @ 4,500rpm

710ftlb @ 5,400rpm

And that is on his unforgiving Dynopak dyno.

Next, fix belt slip that starts at 5,400rpm (big crank pulley?). Also figure out why the Vigilante 10.5" 3-disk converter is slipping by 600rpm.

LS3 block and heads, 9:1cr, DIY ported heads, Diamond pistons, Manley stainless intake valves, Comp 921 springs, stock LS3 rockers (should do the Harlan Sharp bearings), LS7 lifters, MTI 7.4" pushrods, Synergy custom cam ~224/.610", DIY dual fuel pumps and 1/2" fuel lines, Aeromotive fuel filter and regulator, L76 intake (mild port with advice from Angie @ D.E.M.), RC engineering 75lb injectors, LS2 throttle body, D1SC 8-rib, A&A stage 2 8-rib bracket and modded v1.0 FMIC, Turbohoses hard pipes, TPIS/Melrose (unsure now) headers and cats, Ti mufflers.

I wasted some time and money on two other vendors before I found great vendors.

Why do you call MAFless "like SD". If the car has a MAP sensor +IAT being used w/out a MAF.....isn't that SD?

#11

TECH Veteran

iTrader: (1)

Custom cam and Mafless 2bar (like SD) tuning by Rick @ Synergy

Valve job and springs set by Angie @ Daves Engine Machining, Precision TIG welding of weld-on fittings on the LS2 fuel rails by Dave

Tips and tricks by Andy @ A and A Corvette

Forged LS3 by Bruce @ Powrmax.com

DIY dual pump fuel system, head porting, and engine install by me

722ftlb @ 4,500rpm

710ftlb @ 5,400rpm

And that is on his unforgiving Dynopak dyno.

Next, fix belt slip that starts at 5,400rpm (big crank pulley?). Also figure out why the Vigilante 10.5" 3-disk converter is slipping by 600rpm.

LS3 block and heads, 9:1cr, DIY ported heads, Diamond pistons, Manley stainless intake valves, Comp 921 springs, stock LS3 rockers (should do the Harlan Sharp bearings), LS7 lifters, MTI 7.4" pushrods, Synergy custom cam ~224/.610", DIY dual fuel pumps and 1/2" fuel lines, Aeromotive fuel filter and regulator, L76 intake (mild port with advice from Angie @ D.E.M.), RC engineering 75lb injectors, LS2 throttle body, D1SC 8-rib, A&A stage 2 8-rib bracket and modded v1.0 FMIC, Turbohoses hard pipes, TPIS/Melrose (unsure now) headers and cats, Ti mufflers.

I wasted some time and money on two other vendors before I found great vendors.

Valve job and springs set by Angie @ Daves Engine Machining, Precision TIG welding of weld-on fittings on the LS2 fuel rails by Dave

Tips and tricks by Andy @ A and A Corvette

Forged LS3 by Bruce @ Powrmax.com

DIY dual pump fuel system, head porting, and engine install by me

722ftlb @ 4,500rpm

710ftlb @ 5,400rpm

And that is on his unforgiving Dynopak dyno.

Next, fix belt slip that starts at 5,400rpm (big crank pulley?). Also figure out why the Vigilante 10.5" 3-disk converter is slipping by 600rpm.

LS3 block and heads, 9:1cr, DIY ported heads, Diamond pistons, Manley stainless intake valves, Comp 921 springs, stock LS3 rockers (should do the Harlan Sharp bearings), LS7 lifters, MTI 7.4" pushrods, Synergy custom cam ~224/.610", DIY dual fuel pumps and 1/2" fuel lines, Aeromotive fuel filter and regulator, L76 intake (mild port with advice from Angie @ D.E.M.), RC engineering 75lb injectors, LS2 throttle body, D1SC 8-rib, A&A stage 2 8-rib bracket and modded v1.0 FMIC, Turbohoses hard pipes, TPIS/Melrose (unsure now) headers and cats, Ti mufflers.

I wasted some time and money on two other vendors before I found great vendors.

#12

TECH Enthusiast

Thread Starter

Join Date: Dec 2001

Location: Dublin, CA

Posts: 548

Likes: 0

Received 0 Likes

on

0 Posts

The motor has a stock bore LS3 aluminum block and LS3 heads.

There was a long pause between initial tune and final tune because we were waiting on a neighboring shop to lathe out a larger crank pulley, but both Rick and I got tired of hearing 'it'll be done in two weeks'.

Initially Rick suggested a MAF + SD tune with a 2bar MAP which is like an SD tune with benefits. I felt the 3.5" MAF was a restrictor in a 4" pipe, especially when I had to use a hose section as a shim around the MAF so the larger outer hose could compress down. I asked Rick to pull the MAF, and I kept calling it an SD like tune, but it is an SD tune. Rick tells me I have to live with the P0103 MAF frequency code it throws (I thought it could be programmed out). Also without a MAF the fuel consumption calculation is way off, and the PCM thinks I'm averaging 12mpg.

The converter is a single-disk. I thought I bought a triple, but Rick pointed out those go for $900, and if I paid $600 I have a single-disk.

I believe Rick locked the converter but it was still slipping by 1,000 rpm. The dynapack measures hub rpm not from an impedance pickup, so no hero numbers. I was very interested in how the curves would look, where the peak torque would be for the LS3 heads/L76 manifold would end up, and what rpm the horsepower would fall off. With such great initial torque numbers I was looking forward to the final results of the motor combo, but the converter and pulley combo is holding it back.

On the road it flys, but it's not violent. It'll fishtail merging on the freeway, and the throttle needs to be feathered on the streets, but it's not a sudden peak of power. The boost on the street is less than what's on the dyno. If I can see 4-5 psi more, I think that'll bring it back to that violent edge that I like.

There was a long pause between initial tune and final tune because we were waiting on a neighboring shop to lathe out a larger crank pulley, but both Rick and I got tired of hearing 'it'll be done in two weeks'.

Initially Rick suggested a MAF + SD tune with a 2bar MAP which is like an SD tune with benefits. I felt the 3.5" MAF was a restrictor in a 4" pipe, especially when I had to use a hose section as a shim around the MAF so the larger outer hose could compress down. I asked Rick to pull the MAF, and I kept calling it an SD like tune, but it is an SD tune. Rick tells me I have to live with the P0103 MAF frequency code it throws (I thought it could be programmed out). Also without a MAF the fuel consumption calculation is way off, and the PCM thinks I'm averaging 12mpg.

The converter is a single-disk. I thought I bought a triple, but Rick pointed out those go for $900, and if I paid $600 I have a single-disk.

I believe Rick locked the converter but it was still slipping by 1,000 rpm. The dynapack measures hub rpm not from an impedance pickup, so no hero numbers. I was very interested in how the curves would look, where the peak torque would be for the LS3 heads/L76 manifold would end up, and what rpm the horsepower would fall off. With such great initial torque numbers I was looking forward to the final results of the motor combo, but the converter and pulley combo is holding it back.

On the road it flys, but it's not violent. It'll fishtail merging on the freeway, and the throttle needs to be feathered on the streets, but it's not a sudden peak of power. The boost on the street is less than what's on the dyno. If I can see 4-5 psi more, I think that'll bring it back to that violent edge that I like.

Are you using a stock stroke length crank in the block?

Are you using a stock stroke length crank in the block?