Driveline/Pinion Angle and Vibration HELP

#1

TECH Resident

Thread Starter

iTrader: (12)

Join Date: Sep 2004

Location: Newhall, CA

Posts: 782

Likes: 0

Received 0 Likes

on

0 Posts

Basically I have been fighting a vibration since I installed my moser 9", adjustable torque arm, torque arm relocation bracket/trans crossmember, poly motor mounts, 3.5" PST aluminum driveshaft. I believe it to be the driveline/pinion angle. I still have not been able to get it right so today I measured all the angles so that you LS1tech expert engineer/mechanic know it alls can calculate it for me and tell me what to do  . Basically (if you cant tell from my sarcasm) I'm about ready to blow my car to pieces with lots of explosives so help me please

. Basically (if you cant tell from my sarcasm) I'm about ready to blow my car to pieces with lots of explosives so help me please

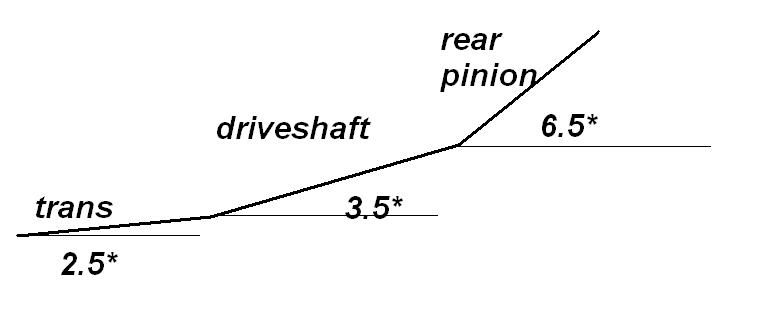

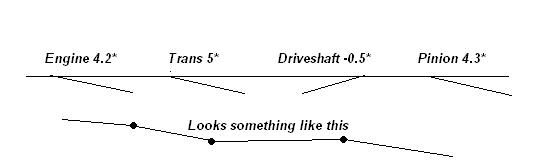

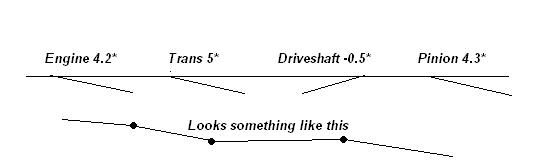

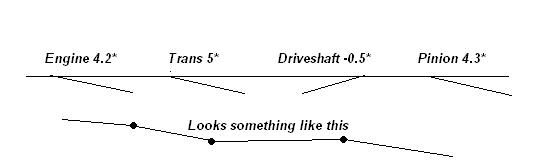

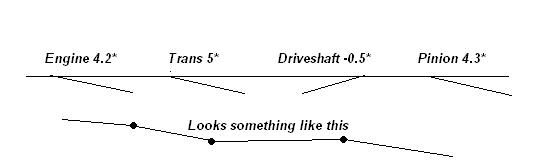

btw I have gone through every other possibility (wheels/tires/brakes/ujoints/crank pulley/clutch/etc) It starts at 60mph and gets worse the higher speed I go and is much worse when I am coasting as compared to when I am on the gas. Here is a diagram that I drew up myself on the angles for which I have measured.

The car was lifted by the rear axle, suspension loaded, rear end in the air, front on the ground.

And yes, I know its completely wrong. It was different before, but when I had an alignment done, I told the guy to set my pinion angle at -1 to -2 degrees just in case the planets aligned right and it fixed my problem, but of course it didn't.

I'll be here waiting

. Basically (if you cant tell from my sarcasm) I'm about ready to blow my car to pieces with lots of explosives so help me please

. Basically (if you cant tell from my sarcasm) I'm about ready to blow my car to pieces with lots of explosives so help me please

btw I have gone through every other possibility (wheels/tires/brakes/ujoints/crank pulley/clutch/etc) It starts at 60mph and gets worse the higher speed I go and is much worse when I am coasting as compared to when I am on the gas. Here is a diagram that I drew up myself on the angles for which I have measured.

The car was lifted by the rear axle, suspension loaded, rear end in the air, front on the ground.

And yes, I know its completely wrong. It was different before, but when I had an alignment done, I told the guy to set my pinion angle at -1 to -2 degrees just in case the planets aligned right and it fixed my problem, but of course it didn't.

I'll be here waiting

#2

OK, yeah, vibrations are a pain, but to set the car up correctly, the tires / suspension must be loaded and level - front to rear and left to right. Then, and only then, make your measurments... (BTW - I set my rear end to -3.5 degrees [which most 'experts' say to far too much] and could not be happier!)

However, I suspect your vibration may be due to your poly motor / engine mounts vs. the rear end / pinion angle setting.

Having said that, the only way to test this theory is to replace the engine's poly mounts with stock units then check for a vibration again; yeah sorry.

However, I suspect your vibration may be due to your poly motor / engine mounts vs. the rear end / pinion angle setting.

Having said that, the only way to test this theory is to replace the engine's poly mounts with stock units then check for a vibration again; yeah sorry.

Basically I have been fighting a vibration since I installed my moser 9", adjustable torque arm, torque arm relocation bracket/trans crossmember, poly motor mounts, 3.5" PST aluminum driveshaft. I believe it to be the driveline/pinion angle.

Here is a diagram that I drew up myself on the angles for which I have measured. The car was lifted by the rear axle, suspension loaded, rear end in the air, front on the ground.

And yes, I know its completely wrong. It was different before, but when I had an alignment done, I told the guy to set my pinion angle at -1 to -2 degrees just in case the planets aligned right and it fixed my problem, but of course it didn't.

Here is a diagram that I drew up myself on the angles for which I have measured. The car was lifted by the rear axle, suspension loaded, rear end in the air, front on the ground.

And yes, I know its completely wrong. It was different before, but when I had an alignment done, I told the guy to set my pinion angle at -1 to -2 degrees just in case the planets aligned right and it fixed my problem, but of course it didn't.

#3

TECH Resident

Thread Starter

iTrader: (12)

Join Date: Sep 2004

Location: Newhall, CA

Posts: 782

Likes: 0

Received 0 Likes

on

0 Posts

The suspension is loaded. Shouldn't it not really matter what angle the actual vehicle is at since we are only looking at the angle relation between all 3 parts and not their angular relation to the ground?

#4

11 Second Club

iTrader: (10)

Join Date: Apr 2007

Location: Central MA

Posts: 507

Likes: 0

Received 0 Likes

on

0 Posts

try reducing the pinion angle from 6.5 to around 2-2.5 and see how it is then. I know a few guys who actually have their pinions facing up slightly to stop the vibration. Their cars still hook ok too.. Its all trial and error I guess.

#5

TECH Resident

Thread Starter

iTrader: (12)

Join Date: Sep 2004

Location: Newhall, CA

Posts: 782

Likes: 0

Received 0 Likes

on

0 Posts

I pulled the driveshaft and the ujoints were shot after only 5-10 thousand miles. Had them replaced and adjusted the angle at 2.5*. The vibration is still there, however I noticed there is a lot of slop where the driveshaft goes into the back of the transmission. The vibration changed slightly.

#6

TECH Resident

Thread Starter

iTrader: (12)

Join Date: Sep 2004

Location: Newhall, CA

Posts: 782

Likes: 0

Received 0 Likes

on

0 Posts

I have replaced the rear tailshaft bushing twice now, I really dont want to do it again just to tear it up again. I'm really sick of the problems I've been having since putting the 9" in. I'm about ready to just go back to stock, IM SO SICK OF IT

#7

TECH Veteran

iTrader: (12)

Follow this procedure.

First go to Sears and buy the $25.00 magnetic digital angle finder that reads to the .1 of a degree. The one with the rotating needle is ****.

1. Put the front wheels on ramps or the front chassis on jackstands.

2. Put jackstands under the rear axle tubes.

3. Make sure the entire car is supported well and mostly level to the ground.

4. Place the angle finder (AF) on the front VERTICAL face of the harmonic balancer. Record the reading.

5. Place the AF on a VERTICAL surface on the rear end.

6. While adjusting the torque arm, set the AF to the exact same reading recorded in step 4. The crankshaft/tranny and pinion should now be perfectly parallel.

7. With the AF still on the rear end, again note the reading. Adjust the torque arm so the pinion yoke slowly rotates down toward the ground. You want to lower it 2 degrees compared to your original reading.

8. Tighten down the torque arm.

9. Drop it and dive it. You now have dead nuts on negative 2 degree pinion angle.

If the vibrations are still there, the drive shaft is out of balance. I have been down this road. I feel your pain. Follow these directions and wrap this bitch up.

First go to Sears and buy the $25.00 magnetic digital angle finder that reads to the .1 of a degree. The one with the rotating needle is ****.

1. Put the front wheels on ramps or the front chassis on jackstands.

2. Put jackstands under the rear axle tubes.

3. Make sure the entire car is supported well and mostly level to the ground.

4. Place the angle finder (AF) on the front VERTICAL face of the harmonic balancer. Record the reading.

5. Place the AF on a VERTICAL surface on the rear end.

6. While adjusting the torque arm, set the AF to the exact same reading recorded in step 4. The crankshaft/tranny and pinion should now be perfectly parallel.

7. With the AF still on the rear end, again note the reading. Adjust the torque arm so the pinion yoke slowly rotates down toward the ground. You want to lower it 2 degrees compared to your original reading.

8. Tighten down the torque arm.

9. Drop it and dive it. You now have dead nuts on negative 2 degree pinion angle.

If the vibrations are still there, the drive shaft is out of balance. I have been down this road. I feel your pain. Follow these directions and wrap this bitch up.

Trending Topics

#8

TECH Resident

Thread Starter

iTrader: (12)

Join Date: Sep 2004

Location: Newhall, CA

Posts: 782

Likes: 0

Received 0 Likes

on

0 Posts

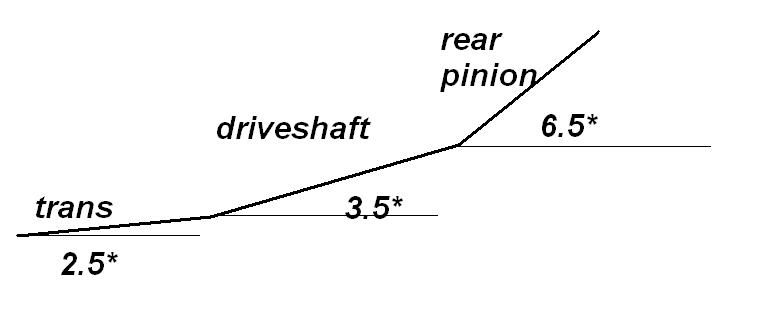

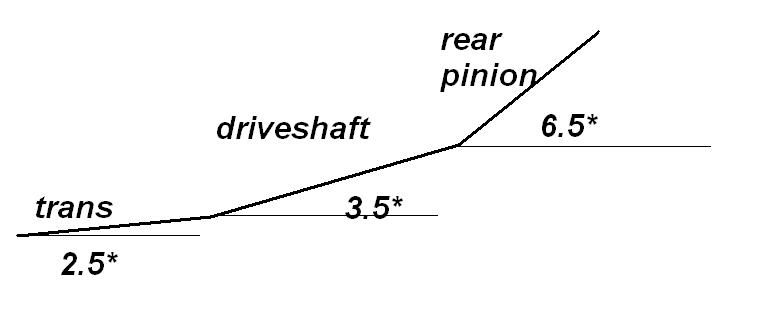

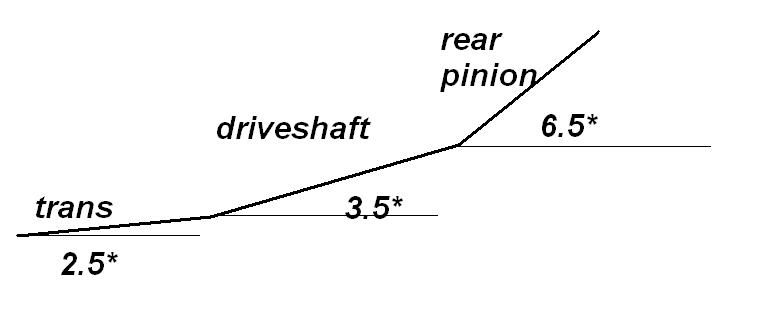

Alright, went and bought a digital angle finder, the cheapest one was 38 bucks, measures to 0.1* and remeasured all my angles. Here they are:

Looks like the trans tailshaft and front pulley are approximately 1* off from each other, not sure this is normal. Now when setting the rear pinion you're saying I should base it off the front pulley and should set it at a 6.2* angle correct? As of right now it is at a -0.1* angle according to the pulley and a +0.7* according to the tailshaft. Car is somewhat level now as both the front and rear are raised. Thanks for the help

Any possibility that I am going beyond the ujoint operating angles? Maybe I should consider shimming the rear of the transmission

Looks like the trans tailshaft and front pulley are approximately 1* off from each other, not sure this is normal. Now when setting the rear pinion you're saying I should base it off the front pulley and should set it at a 6.2* angle correct? As of right now it is at a -0.1* angle according to the pulley and a +0.7* according to the tailshaft. Car is somewhat level now as both the front and rear are raised. Thanks for the help

Any possibility that I am going beyond the ujoint operating angles? Maybe I should consider shimming the rear of the transmission

Last edited by Jimmard; 08-06-2009 at 03:39 AM.

#9

TECH Resident

Thread Starter

iTrader: (12)

Join Date: Sep 2004

Location: Newhall, CA

Posts: 782

Likes: 0

Received 0 Likes

on

0 Posts

I pulled the driveshaft and ran the car up to 80 or 90 real quick and shut it off, there was no vibration. Only a little fluid leaked out, but its good to know its nothing in front of the driveshaft.

#10

TECH Resident

Thread Starter

iTrader: (12)

Join Date: Sep 2004

Location: Newhall, CA

Posts: 782

Likes: 0

Received 0 Likes

on

0 Posts

After running the car with the driveshaft in while on jackstands, I notice a small puddle of fluid where the tailshaft bushing/seal is at, so I am sure the tailshaft bushing is completely shot. I will try to get all my angles correct, then pull the tailshaft off and have those parts replaced... again.

#11

TECH Veteran

iTrader: (12)

Alright, went and bought a digital angle finder, the cheapest one was 38 bucks, measures to 0.1* and remeasured all my angles. Here they are:

Looks like the trans tailshaft and front pulley are approximately 1* off from each other, not sure this is normal. Now when setting the rear pinion you're saying I should base it off the front pulley and should set it at a 6.2* angle correct? As of right now it is at a -0.1* angle according to the pulley and a +0.7* according to the tailshaft. Car is somewhat level now as both the front and rear are raised. Thanks for the help

Any possibility that I am going beyond the ujoint operating angles? Maybe I should consider shimming the rear of the transmission

Looks like the trans tailshaft and front pulley are approximately 1* off from each other, not sure this is normal. Now when setting the rear pinion you're saying I should base it off the front pulley and should set it at a 6.2* angle correct? As of right now it is at a -0.1* angle according to the pulley and a +0.7* according to the tailshaft. Car is somewhat level now as both the front and rear are raised. Thanks for the help

Any possibility that I am going beyond the ujoint operating angles? Maybe I should consider shimming the rear of the transmission

Once you have the exact same readings on the balancer and at the rearend, rotate the pinion yoke down toward the ground 1.5-2 degrees according to the AF. It will now be set.

Ideally you want 3 degrees or less operating angles on the u-joints for long life and less parasitic loss. If you have even 4 degrees (which I doubt you will) its no big deal. As long as both joints angles are equal or +/- 1 degree to each other, you will NOT have angle induced vibrations. Both u-joint angles being closer to equal trumps operating angle. I once ran 13 degree operatring angles on my Jeep Wrangler and had no vibes since they were 13 degrees on both ends.

I found on my 9" I had to raise the tranny 1/2" with spacers (off of the tranny mount) in order to get closer to equal angles on both joints. This did cause my operating angles to go about 2.5 degrees which is no big deal. The 9" has its pinion around 3/4" lower than the 12 bolt and 10 bolt so that has to be tweaked for optimum setup.

Last edited by wrd1972; 08-06-2009 at 12:39 PM.

#12

TECH Veteran

iTrader: (12)

After running the car with the driveshaft in while on jackstands, I notice a small puddle of fluid where the tailshaft bushing/seal is at, so I am sure the tailshaft bushing is completely shot. I will try to get all my angles correct, then pull the tailshaft off and have those parts replaced... again.

You might have the area just outside the seal but behind the dust cover filled with fluid. Put some miles on it before going after the bushing again.

#13

TECH Resident

Thread Starter

iTrader: (12)

Join Date: Sep 2004

Location: Newhall, CA

Posts: 782

Likes: 0

Received 0 Likes

on

0 Posts

Dont freakout over the tailshaft bushing yet. I found that when I had severe vibration it would cause fluid to leak out of the rear tranny seal. When the vibration was cured, no more leak.

You might have the area just outside the seal but behind the dust cover filled with fluid. Put some miles on it before going after the bushing again.

You might have the area just outside the seal but behind the dust cover filled with fluid. Put some miles on it before going after the bushing again.

#15

TECH Resident

Thread Starter

iTrader: (12)

Join Date: Sep 2004

Location: Newhall, CA

Posts: 782

Likes: 0

Received 0 Likes

on

0 Posts

Funny thing is, I pulled the rear out once before and had it looked at, and when I put it back in the vibration was 90% gone. Then the slave cylinder went bad, so I pulled the trans, replaced the slave, had to pull the torque arm to get the trans back in, and after putting it all back together it was vibrating again.

#16

11 Second Club

iTrader: (6)

im having a very similar problem. im hoping mine is a driveline angle issue. if its not its a worn out bearing in the trans or something.

if it changed when you took out/reinstalled the trans, i think you still have a drive line angle problem. try putting a washer or 2 under the trans mount

if it changed when you took out/reinstalled the trans, i think you still have a drive line angle problem. try putting a washer or 2 under the trans mount

#17

TECH Resident

Thread Starter

iTrader: (12)

Join Date: Sep 2004

Location: Newhall, CA

Posts: 782

Likes: 0

Received 0 Likes

on

0 Posts

im having a very similar problem. im hoping mine is a driveline angle issue. if its not its a worn out bearing in the trans or something.

if it changed when you took out/reinstalled the trans, i think you still have a drive line angle problem. try putting a washer or 2 under the trans mount

if it changed when you took out/reinstalled the trans, i think you still have a drive line angle problem. try putting a washer or 2 under the trans mount

#18

TECH Resident

Thread Starter

iTrader: (12)

Join Date: Sep 2004

Location: Newhall, CA

Posts: 782

Likes: 0

Received 0 Likes

on

0 Posts

Someone mentioned it could be the fact that 9" rear ends require a 1" longer driveshaft. I am using a stock length PST driveshaft. It was too short, but I used the lower control arms to move the rear axle forward a little bit. Could that be throwing off some geometry I am unaware of? Also there is about 1" of yoke showing out of the back of the tailshaft, is that any sort of problem?

#19

TECH Veteran

iTrader: (12)

Someone mentioned it could be the fact that 9" rear ends require a 1" longer driveshaft. I am using a stock length PST driveshaft. It was too short, but I used the lower control arms to move the rear axle forward a little bit. Could that be throwing off some geometry I am unaware of? Also there is about 1" of yoke showing out of the back of the tailshaft, is that any sort of problem?

#20

TECH Resident

Thread Starter

iTrader: (12)

Join Date: Sep 2004

Location: Newhall, CA

Posts: 782

Likes: 0

Received 0 Likes

on

0 Posts

Ok I called the company I bought the driveshaft from. PST closes at noon on fridays, so they are going to call me back on monday. Hopefully they can help me out and this vibration will come to an end. Thanks a lot for your help.