Building a junkyard 9" compared to 8.8

#25

LS1Tech Premium Sponsor

iTrader: (5)

PM sent to you as well..

Might just have to do a group buy here and hook all you guys up at once or something.

Looking at this picture here I can explain better what you will be getting.

Items will be raw just bare laser cut items that will need to be welded together.

Panhard bar bracket assembly

Spring perch

Lca relocation bracket assembly

sway bar mounts

If you choose to do the torque arm package that includes all hardware and weld on tabs you will be getting these items.

Torque arm long or short of your choice

Bolt in cross member to suit your needs, short will have drive shaft loop

Pivot link

All heim joints and adjusters including nuts bolts and bushing for the pivot link

If anyone has any questions just shoot me a PM.

Might just have to do a group buy here and hook all you guys up at once or something.

Looking at this picture here I can explain better what you will be getting.

Items will be raw just bare laser cut items that will need to be welded together.

Panhard bar bracket assembly

Spring perch

Lca relocation bracket assembly

sway bar mounts

If you choose to do the torque arm package that includes all hardware and weld on tabs you will be getting these items.

Torque arm long or short of your choice

Bolt in cross member to suit your needs, short will have drive shaft loop

Pivot link

All heim joints and adjusters including nuts bolts and bushing for the pivot link

If anyone has any questions just shoot me a PM.

#27

I found 3 today at my local pull-a-part. They have a set price of $100.00. All 3 were in 69-70 ford trucks and all the same width. Someone had pulled the tags off them so I dont know what the gear ratios are. I found this on the web and am guessing its from the backing plate flange.

1957-1972 Ford pickup 9-inch housing width: 56"

Whats the 4th gen width backing plate flange to flange?

I am picking up an extra 7.5 for $100.00 to cut everything off of while I am there. I found a Firebird that looked pretty clean underneath, no rusty bolts, so I am going to pull the rear out of it.

1957-1972 Ford pickup 9-inch housing width: 56"

Whats the 4th gen width backing plate flange to flange?

I am picking up an extra 7.5 for $100.00 to cut everything off of while I am there. I found a Firebird that looked pretty clean underneath, no rusty bolts, so I am going to pull the rear out of it.

#29

TECH Enthusiast

iTrader: (8)

Join Date: Mar 2005

Location: Phoenix AZ

Posts: 686

Likes: 0

Received 0 Likes

on

0 Posts

You could run rims with less back spacing and use the narrower rear. The stock rear runs 7.5 inches of back spacing so if you were 3.5" narrower total you could run 5.5 BS on both sides and be good (if the 1/4" extra clears ok).

#30

I would like to run the stock rims for now, I just checked their web site and they have a few trucks that fall in the right year range, so I will just have to look and see what they have. The have an Antique section and that is where I found the 3 I found today. They have a few early 80's models that are supose to have the right length in there. I will just have to look.

#31

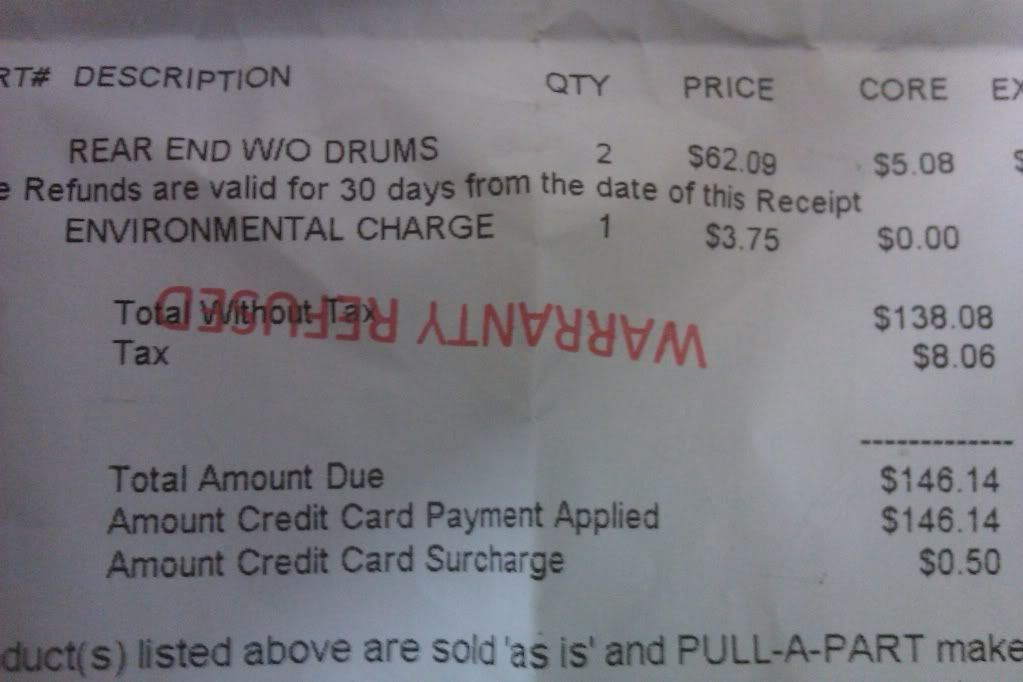

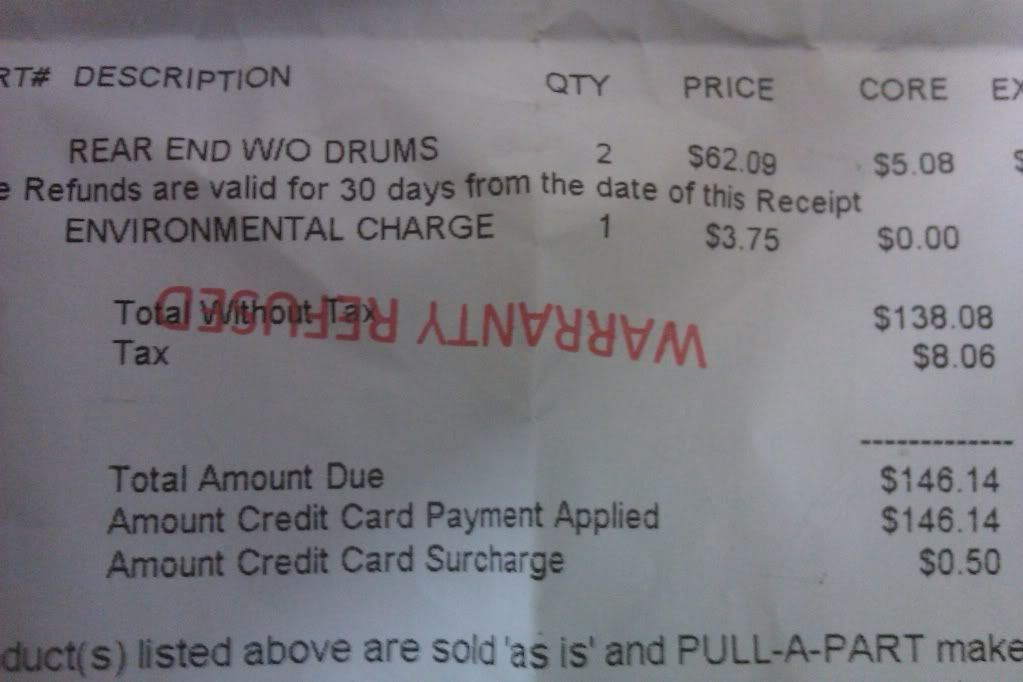

Check out what I scored today got both of them for 146.00! I thought they were going to be 100.00 a piece. It looks it might be a pain to cut the bracket off the 7.5, if its too much trouble I will buy the MWC brackets. The 9 is out of a 73 ford f100 ford truck. The 73 to around 86 trucks are the right length for the 4th gen, they are just a little wider about 3/4 to 7/8. The early ones seem to have the big wheel bearings. The later ones had smaller wheel bearings and 29 spline axels. Mine has the large outer wheel bearings and 31 spline axels. For anyone wanting to look for one of these, you can tell if it has the large bearings by looking at the ends of the tubes. If the tube is the same width all the way to the backing plate then its a big bearing, if it tapers at the end then its the smaller one. This one doesnt have the posi nor the gear I want so I will have to deal with that.

Last edited by 96lt4c4; 12-20-2010 at 08:36 AM. Reason: Spline count is 31

#35

Is there a trick to counting splines. I counted them last night but was counting the top of the spline not the inside or 'V". I looked at this site last night for some prices and they are saying the rear should have 28 spline axels. I recounted this morning and counting the "V" or root of the spline I get 31.

http://www.accuautoparts.com/axleinfo.jsp?sr=1

For some reason this site does not start showing the 31 spline until 75. Maybe the yard had the year on the truck wrong or someone had changed the rear on the truck at some point.

http://www.accuautoparts.com/axleinfo.jsp?sr=1

For some reason this site does not start showing the 31 spline until 75. Maybe the yard had the year on the truck wrong or someone had changed the rear on the truck at some point.

Last edited by 96lt4c4; 12-20-2010 at 09:36 AM.

#37

Thanks for the heads up, I have been doing research on making the the ls1 brakes work. I am either going to have to buy Moser housing ends or weld the holes up on the Ford ends and redrill for the LS1 7.5" patern. Also the ford brake backspacing is different then the chevy so I will have to address that somehow. I have read that the ford is 2.5" and the chevy is 2.75". But I havent measured to confirm that yet.

#38

TECH Enthusiast

iTrader: (4)

Thanks for the heads up, I have been doing research on making the the ls1 brakes work. I am either going to have to buy Moser housing ends or weld the holes up on the Ford ends and redrill for the LS1 7.5" patern. Also the ford brake backspacing is different then the chevy so I will have to address that somehow. I have read that the ford is 2.5" and the chevy is 2.75". But I havent measured to confirm that yet.

#39

9 Second Club

iTrader: (9)

Join Date: Jan 2007

Location: Pittsburgh

Posts: 793

Likes: 0

Received 0 Likes

on

0 Posts

nice i just built one for someone a couple months ago. kinda wished would have known about the brackt package from midwest. i used stock brackets but had to be trimmed down a bit though.

also i used the moser housing ends setup for GM brakes. real nice peices and made it simple. just watch the heat from welding it pulls the housing a good bit

also i used the moser housing ends setup for GM brakes. real nice peices and made it simple. just watch the heat from welding it pulls the housing a good bit

#40

nice i just built one for someone a couple months ago. kinda wished would have known about the brackt package from midwest. i used stock brackets but had to be trimmed down a bit though.

also i used the moser housing ends setup for GM brakes. real nice peices and made it simple. just watch the heat from welding it pulls the housing a good bit

also i used the moser housing ends setup for GM brakes. real nice peices and made it simple. just watch the heat from welding it pulls the housing a good bit

How do these work? Do you cut the factory ford ends off and weld these on? They show a couple differnet ends on their site that have the chevy pattern. Not sure which ones I would need.

Also did you use the stock axels or buy new. Just trying to figure out hoe to make the brake backspacing work.