9" housing end blue prints?

#1

12 Second Club

Thread Starter

Join Date: Feb 2006

Location: Catlettsburg, Ky

Posts: 876

Likes: 0

Received 0 Likes

on

0 Posts

I'm FINALLY getting the ball rolling on my 8.8" build ( picked up an explorer 8.8 with 4.10's and trac lok with disc brakes for $150)

Now, I plan on making my own 9" housing ends, but I can't seem to find any prints on the Internet for one. Any help fellas?

Also curious how you fabricators know how wide to make the rearend from housing end to housing end based off of what the wheel mount surface to wheel Mount surface distance is?

I don't wanna order axles until I know how long they have to be, won't know that until I measure the housing. Lol so I'm stuck at the moment.

Now, I plan on making my own 9" housing ends, but I can't seem to find any prints on the Internet for one. Any help fellas?

Also curious how you fabricators know how wide to make the rearend from housing end to housing end based off of what the wheel mount surface to wheel Mount surface distance is?

I don't wanna order axles until I know how long they have to be, won't know that until I measure the housing. Lol so I'm stuck at the moment.

#3

12 Second Club

Thread Starter

Join Date: Feb 2006

Location: Catlettsburg, Ky

Posts: 876

Likes: 0

Received 0 Likes

on

0 Posts

Yes, that's exactly what I'm wanting to make.

Why would I buy something that I can make myself? I'm making all the bracketry for the rearend myself. I'm completely retubing the housing as well

Why would I buy something that I can make myself? I'm making all the bracketry for the rearend myself. I'm completely retubing the housing as well

#6

12 Second Club

Thread Starter

Join Date: Feb 2006

Location: Catlettsburg, Ky

Posts: 876

Likes: 0

Received 0 Likes

on

0 Posts

I imagine it's no where near $80, as I know exactly how long it takes to make, and what 1018 material costs for the job.

Luckily I have a friend with a 9" housing that I can get the bore diameters and depths off of, so this won't be an issue any longer. I'm fairly confident no one makes a 9" housing end for a 3 1/4" tube anyway.

Trending Topics

#8

FormerVendor

iTrader: (9)

I'm FINALLY getting the ball rolling on my 8.8" build ( picked up an explorer 8.8 with 4.10's and trac lok with disc brakes for $150)

Now, I plan on making my own 9" housing ends, but I can't seem to find any prints on the Internet for one. Any help fellas?

Also curious how you fabricators know how wide to make the rearend from housing end to housing end based off of what the wheel mount surface to wheel Mount surface distance is?

I don't wanna order axles until I know how long they have to be, won't know that until I measure the housing. Lol so I'm stuck at the moment.

Now, I plan on making my own 9" housing ends, but I can't seem to find any prints on the Internet for one. Any help fellas?

Also curious how you fabricators know how wide to make the rearend from housing end to housing end based off of what the wheel mount surface to wheel Mount surface distance is?

I don't wanna order axles until I know how long they have to be, won't know that until I measure the housing. Lol so I'm stuck at the moment.

Carl

#10

12 Second Club

iTrader: (91)

How much do you think quick performance has in a set of their $80 housing ends?

I imagine it's no where near $80, as I know exactly how long it takes to make, and what 1018 material costs for the job.

Luckily I have a friend with a 9" housing that I can get the bore diameters and depths off of, so this won't be an issue any longer. I'm fairly confident no one makes a 9" housing end for a 3 1/4" tube anyway.

I imagine it's no where near $80, as I know exactly how long it takes to make, and what 1018 material costs for the job.

Luckily I have a friend with a 9" housing that I can get the bore diameters and depths off of, so this won't be an issue any longer. I'm fairly confident no one makes a 9" housing end for a 3 1/4" tube anyway.

What is your estimate for what you will spend to make them? Just curious.

#12

12 Second Club

Thread Starter

Join Date: Feb 2006

Location: Catlettsburg, Ky

Posts: 876

Likes: 0

Received 0 Likes

on

0 Posts

Fringe Benefit of working at a shop that has a drop pile that's free for the taking, and a boss that builds hotrods as well.

As soon as I finish the CAD drawings, the burn table operator is going to burn out all the brackets I need for my LCA's, PHR, shocks and spring perches.

Just last week I made a two sets of sbc to LSx motor mount adapters. 1 for the bosses '52 Chevy with a 5.3, one for myself. shop material, their machine, on the clock.

So yeah. T&M costs are low. REAL low...

#13

12 Second Club

Thread Starter

Join Date: Feb 2006

Location: Catlettsburg, Ky

Posts: 876

Likes: 0

Received 0 Likes

on

0 Posts

There's actually two people in here that I plan to buy parts from:

Carl @ CRP, and Hiltsy855.

I've checked out your torque arm mount that a friend bought from you, and I have to say, as easily as it could be duplicated I WILL NOT copy your design on my own, Simply because you did the R&D to make a solid product that works, and aren't trying to **** the eye ***** out of the prospective buyer.

Carl, I will send you a pm as soon as I have the information you need.

Hiltsy, Ill PayPal you a payment for your product as soon as I get to a computer.

Thank you both for your contributions to this online tech forum.

#15

FormerVendor

iTrader: (9)

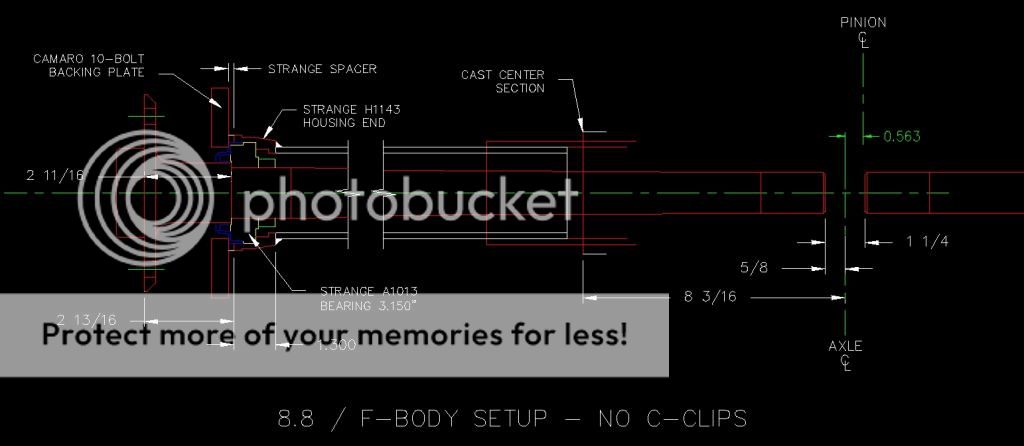

Good find Hiltsy, this might help as well,

http://centralracingparts.com/index....product_id=745

and this...

http://centralracingparts.com/index....formation_id=9

Carl

http://centralracingparts.com/index....product_id=745

and this...

http://centralracingparts.com/index....formation_id=9

Carl

#19

$0

Fringe Benefit of working at a shop that has a drop pile that's free for the taking, and a boss that builds hotrods as well.

As soon as I finish the CAD drawings, the burn table operator is going to burn out all the brackets I need for my LCA's, PHR, shocks and spring perches.

Just last week I made a two sets of sbc to LSx motor mount adapters. 1 for the bosses '52 Chevy with a 5.3, one for myself. shop material, their machine, on the clock.

So yeah. T&M costs are low. REAL low...

Fringe Benefit of working at a shop that has a drop pile that's free for the taking, and a boss that builds hotrods as well.

As soon as I finish the CAD drawings, the burn table operator is going to burn out all the brackets I need for my LCA's, PHR, shocks and spring perches.

Just last week I made a two sets of sbc to LSx motor mount adapters. 1 for the bosses '52 Chevy with a 5.3, one for myself. shop material, their machine, on the clock.

So yeah. T&M costs are low. REAL low...

I have a machine shop at my disposal too, but my bosses are dicks!