Adjusting Engine / Trans Tilt to get Proper Driveline Angles?

#1

I've recently replaced my stock 10-bolt w/ an S60 and am attempting to get the driveline angles setup. I have an adjustable TA that allows me to adjust the rear pinion angle to whatever I want. I've got the factory springs/shocks, but my ride height as measured right in front of the rear wheels increased by ~1/2-3/4" (I think this is due to the spring perches on the S60 being higher relative to the axle centerline due to the tube being slightly larger than the 10-bolt). The guidance I got and found was to set the angle of the rear pinion to the same angle as the engine/trans output shaft. On my rack w/ ~1.1 deg downward slope towards the rear, I was measuring ~6.0 deg down from horz (F-to-R) on the engine/trans (measuring on the front of the engine vibration damper), so I set the rear pinion (measured on the yoke flats) to the same 6.0 deg down from horz. (F-to-R). This is where I made the length measurements to order my custom driveshaft from MWC/Strange. I installed the shaft and found that the driveshaft was about 0.0 deg (level), resulting in a 6.0 deg operating angle for both front and rear U-joints (the engine/trans and pinion are parallel as is recommended)

During break-in, I noticed that I'm getting a vibration when I got much over 85 MPH. So, based on some other info I found that recommended the max U-joint operating angle of 4 deg, I went to install some shims under the trans mount to raise the tail-shaft up (to reduce the front U-joint operating angle) and discovered that the T56 trans is basically clamped between the trans crossmember and the trans tunnel: There is no way to raise the trans tail shaft since there is a rubber bumper on the top of the trans that is right against the peak of the tunnel (a few inches forward of the shifter), thus I'm stuck w/ the ~6.0 deg down (F-R) of the engine/trans angle.

So then I attempted to reduce the rear U-joint operating angle and got it down to 0.9 deg down (F-R), which lowered the rear of the driveshaft (now at 2.1 deg down F-R) which reduced the front U-joint operating angle to 3.9 deg and resulted in the rear operating angle of 1.2 deg. (the engine/trans and pinion are no longer parallel w/ a net angle of 5.1 deg) Took it for another spin and now the vibration doesn't start until ~90 MPH.

I'm working on another adjustment to attempt to get the U-joint operating angles closer to each other, however any attempt to do this will result in an increased angle between the engine/trans and pinion which seems to be a bad thing to do. It seems the only way to get the engine/trans and pinion angles parallel w/ U-joint angles < 3-4 deg is to raise the tailshaft of the trans, which seems to be impossible w/ how the T56 is clamped between the crossmember and tunnel.

Any advice on how to rectify this situation? I didn't think to make any measurements of the factory driveline before I pulled it to see what those angles are for comparison. Does anyone have measurements of a factory driveline? I've never had driveline vibration issues w/ the 10-bolt up to 120 MPH, so the factory was doing something different. I suppose it would be possible to raise the rear of the car with lift springs to lower the pinion WRT the engine/trans, but I don't want to look like old-school muscle car w/ slicks and skinnies. A higher CG is not the direction I want to go.

During break-in, I noticed that I'm getting a vibration when I got much over 85 MPH. So, based on some other info I found that recommended the max U-joint operating angle of 4 deg, I went to install some shims under the trans mount to raise the tail-shaft up (to reduce the front U-joint operating angle) and discovered that the T56 trans is basically clamped between the trans crossmember and the trans tunnel: There is no way to raise the trans tail shaft since there is a rubber bumper on the top of the trans that is right against the peak of the tunnel (a few inches forward of the shifter), thus I'm stuck w/ the ~6.0 deg down (F-R) of the engine/trans angle.

So then I attempted to reduce the rear U-joint operating angle and got it down to 0.9 deg down (F-R), which lowered the rear of the driveshaft (now at 2.1 deg down F-R) which reduced the front U-joint operating angle to 3.9 deg and resulted in the rear operating angle of 1.2 deg. (the engine/trans and pinion are no longer parallel w/ a net angle of 5.1 deg) Took it for another spin and now the vibration doesn't start until ~90 MPH.

I'm working on another adjustment to attempt to get the U-joint operating angles closer to each other, however any attempt to do this will result in an increased angle between the engine/trans and pinion which seems to be a bad thing to do. It seems the only way to get the engine/trans and pinion angles parallel w/ U-joint angles < 3-4 deg is to raise the tailshaft of the trans, which seems to be impossible w/ how the T56 is clamped between the crossmember and tunnel.

Any advice on how to rectify this situation? I didn't think to make any measurements of the factory driveline before I pulled it to see what those angles are for comparison. Does anyone have measurements of a factory driveline? I've never had driveline vibration issues w/ the 10-bolt up to 120 MPH, so the factory was doing something different. I suppose it would be possible to raise the rear of the car with lift springs to lower the pinion WRT the engine/trans, but I don't want to look like old-school muscle car w/ slicks and skinnies. A higher CG is not the direction I want to go.

#3

#4

On my rack w/ ~1.1 deg downward slope towards the rear, I was measuring ~6.0 deg down from horz (F-to-R) on the engine/trans (measuring on the front of the engine vibration damper)

When I installed the S60, I also installed a MWC TA which came w/ a new trans cross-member. When I installed that, I jacked under the trans to hold it up while I swapped the factory cross-member out w/ the new one. I wasn't really paying attention to the engine/trans angles at that time, and kept the same trans mount (rubber), which is bolted to the new trans cross-member without any shims. Everything seemed to line up the same way as w/ the original trans cross-member (no gaps between the cross-member and the floor-pan). It wasn't until I attempted to jack up the trans to install shims under the trans mount at the cross-member that I discovered the rubber bumper on the top of the trans being right up against the tunnel / floor-pan, leaving no room to install shims to raise the rear of the trans.

Is it possible that back in '99 when "grey-haired granny" in MI smacked me in the driver's door resulting in me jumping a curb could've buckled the floor-pan (F-R) such that the engine/trans is now pointed downward more than originally? I had the Pontiac dealership do the repairs (new door skin, front fender and rear quarter, new front LCA and a new rim or two) and as far as I know and can tell they got everything aligned back up (all panel and door gaps are as good as when it left the factory). Shortly after that I installed the KBDDSFCs which was welded in place w/ the car's weight on the suspension. I've never had any drive-line vibrations following that (although I've never gone faster than ~120 MPH in the car).

Last edited by JohnnyBs98WS6Rag; 08-31-2020 at 08:26 AM.

#5

In the meantime, I've entered all my data I've collected over ~13 different adjustments into a spreadsheet and plotted the UJ operating angles vs. pinion angle to see where to go. I think what I'm going to do is to use a SPL meter that I have to measure the vibration noise level at 5 MPH increments from 70-90 MPH as the pinion angle is adjusted in 0.5 deg increments to see if I can determine an optimum pinion angle that gives me minimum noise/vibration. Seems the pinion angle is the only adjustment I have at my disposal (dropping the trans to BFH the tunnel to allow me to jack up the rear of the trans is not in the cards..........at least not yet).

Thanks for the feedback!

#6

U joint angle is not supposed to be more than 3

Both u joint angles need to be within .5 degree of each other . You can use the TREMEC app

Or the spicer angle calc . I'm going thru the same **** . There is a place called driveshaftshop.com that makes a cv joint driveshaft . Supposed to fix .

Both u joint angles need to be within .5 degree of each other . You can use the TREMEC app

Or the spicer angle calc . I'm going thru the same **** . There is a place called driveshaftshop.com that makes a cv joint driveshaft . Supposed to fix .

#7

WTF is wrong with my car? Why is my engine/trans angled downward so much? Why is there no room in the tunnel to allow me to shim it up? NONE of that has anything to do w/ the S60. While I can't rule out the possibility, I can't believe my chassis/floor pan buckled from my '99 collision and my doors / top / seals are all still lined up perfectly. Can someone please measure their stock engine-trans / driveshaft / pinion / ground angles so I can determine if my car is whacked? Much appreciated.

Trending Topics

#11

Your S60 has nothing to do with your issues. The extra inch or so towards the front that the pinion is pushed is of little consequence.

Are your engine/tranny mounts new? Even so they could have buckled.

Are your engine/tranny mounts new? Even so they could have buckled.

#12

First, had you measured your stock drive shaft angle and pinion angle you would have calculated a 0 degrees TRUE pinion angle. This is how all cars come from the factory.

Originally Posted by [color=#222222

440_Stroker]Your S60 has nothing to do with your issues. The extra inch or so towards the front that the pinion is pushed is of little consequence.

Are your engine/tranny mounts new? Even so they could have buckled.

Today 02:52 PM

Are your engine/tranny mounts new? Even so they could have buckled.

Today 02:52 PM

Thanks for the feedback all, keep the ideas percolating. Sorry if my frustration is showing through in my earlier post. I do appreciate having this community for bouncing ideas off of. This blind squirrel will find a nut eventually.

Last edited by JohnnyBs98WS6Rag; 09-01-2020 at 07:45 PM.

#13

TECH Fanatic

iTrader: (11)

Thanks. I do question the validity of this though:

Seems like a pretty bold statement to me. In any case, as they define "true pinion angle" being the difference between the pinion and driveshaft angle, a 0 deg true pinion angle would result in a front UJ operating angle of ~4 deg. I'll try that next and then vary each direction to see if that's the sweet spot.

Agreed 100%. The engine and trans mounts are original (only have 21K mi on the car). However I doubt that's my issue, if the engine mounts had collapsed, the trans would be tilting less downward (F-R) and would help, not aggravate my situation. And if the trans mount collapsed, I'd have room to lift the tail of the trans up.

Thanks for the feedback all, keep the ideas percolating. Sorry if my frustration is showing through in my earlier post. I do appreciate having this community for bouncing ideas off of. This blind squirrel will find a nut eventually.

Seems like a pretty bold statement to me. In any case, as they define "true pinion angle" being the difference between the pinion and driveshaft angle, a 0 deg true pinion angle would result in a front UJ operating angle of ~4 deg. I'll try that next and then vary each direction to see if that's the sweet spot.

Agreed 100%. The engine and trans mounts are original (only have 21K mi on the car). However I doubt that's my issue, if the engine mounts had collapsed, the trans would be tilting less downward (F-R) and would help, not aggravate my situation. And if the trans mount collapsed, I'd have room to lift the tail of the trans up.

Thanks for the feedback all, keep the ideas percolating. Sorry if my frustration is showing through in my earlier post. I do appreciate having this community for bouncing ideas off of. This blind squirrel will find a nut eventually.

I went through something similar. I would recommend you use a real gauge and not your phone for the measurements. get an angle gauge for $5. take the driveshaft out. Here's my own thread where I got it resolved. see post #26. https://ls1tech.com/forums/gears-axl...ion-45mph.html

The following users liked this post:

Coy (12-09-2020)

#15

I went through something similar. I would recommend you use a real gauge and not your phone for the measurements. get an angle gauge for $5. take the driveshaft out. Here's my own thread where I got it resolved. see post #26. https://ls1tech.com/forums/gears-axl...ion-45mph.html

Thanks for the link, however the pinion yoke on my S60 has pockets for the UJ caps to sit in, eliminating the possibility of mounting the driveshaft off-center WRT the pinion yoke.

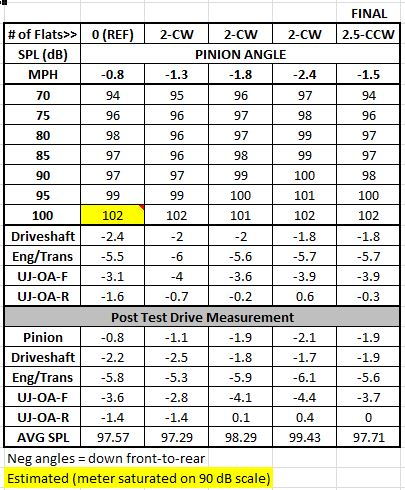

Since I'm locked into a fixed engine/trans angle, I'm left to trial-and-error. I'm in the process of collecting SPL data at 5 MPH increments from 70-100 MPH as I adjust the pinion angle every 2-flats of the adjustment hex (~0.5 deg). Once I complete this, I should know what pinion angle gives me the minimum vibration and will set it to that and live with it. I'll share the data here in case its helpful to someone.

#16

Moderator

iTrader: (4)

Join Date: Jul 2014

Location: My own internal universe

Posts: 10,446

Received 1,838 Likes

on

1,146 Posts

Maybe I missed it in the thread - are you measuring trans angle off the tail shaft housing or off the U joint? I find variability on the housing. I use a socket on the u joint cap to get the trans angle.

My TA from the factory had the DS is a broke-back configuration. Both angles matched but were on the same side of the DS. Trans was at 6, pinion at 2, 2 degree interior angles. That was years ago lol.

I shimmed under the trans to get to 4 degrees when I installed nine inch. Raised pinion to 3.5. DS angles at 2 and 1.5. Under load, pinion raises just a smidge and it is perfect.

My TA from the factory had the DS is a broke-back configuration. Both angles matched but were on the same side of the DS. Trans was at 6, pinion at 2, 2 degree interior angles. That was years ago lol.

I shimmed under the trans to get to 4 degrees when I installed nine inch. Raised pinion to 3.5. DS angles at 2 and 1.5. Under load, pinion raises just a smidge and it is perfect.

#17

Here's my data summary from my multiple measurements. After making the first 4 measurements, it was clear that I had passed through the sweet spot, so I backed off 2.5 flats of adjustment at the TA to get my final setting. At the starting point (-0.8 deg), it seems I had a vibration mode occurring around 80 MPH and another mode coming on at 100 MPH. Increasing the pinion angle made that lower mode disappear and further increases made the higher mode disappear, but overall vibration / noise started increasing. I dialed it back to a 1/2-flat past the prior adjustment and the result had the higher mode coming back but overall less noise < 100 MPH. I measured the driveline angles both after adjustment and after the test drive (some settling shows up in the data). Of course, in order to get the post-drive measurements, I had to unload the suspension to rotate the driveshaft and then sat it back down to get a decent pinion angle measurement, so that probably invalidated some of the settling of the suspension during the drive.

#18

Moderator

iTrader: (4)

Join Date: Jul 2014

Location: My own internal universe

Posts: 10,446

Received 1,838 Likes

on

1,146 Posts

T56.

You are not using a poly trans mount are you?

Also, long or short torque arm?

I found on the long torque arm, the car like about a two degree drop transmission vs rear. Short, it just liked then to be within a half degree.

I do not worry about the working angles of the DS. Just make them match

You are not using a poly trans mount are you?

Also, long or short torque arm?

I found on the long torque arm, the car like about a two degree drop transmission vs rear. Short, it just liked then to be within a half degree.

I do not worry about the working angles of the DS. Just make them match

#19

T56.

You are not using a poly trans mount are you?

Also, long or short torque arm?

I found on the long torque arm, the car like about a two degree drop transmission vs rear. Short, it just liked then to be within a half degree.

I do not worry about the working angles of the DS. Just make them match

You are not using a poly trans mount are you?

Also, long or short torque arm?

I found on the long torque arm, the car like about a two degree drop transmission vs rear. Short, it just liked then to be within a half degree.

I do not worry about the working angles of the DS. Just make them match