Longtubes, Cutout & Stock Cam?

#22

Tech Resident

Let's use your analogy here for a second. A water garden hose. If you put a relatively large size hole(like a cut out in a exhaust pipe) in a water hose and there is a restriction on the outlet side like a half open or 3/4 open valve (this would be your muffler) and you turn on the water where would the water go FIRST? The water will go to the LEAST resistance which is the OPEN HOLE ie cut out. SO YOU ARE WRONG.

Remember, the exhaust gas here has two routes: the STRAIGHT route, which is through the I-pipe and into the muffler, and the route where it has to travel around a bend and out the cutout. If this was a y-merge, I'd agree with you, but it's not. Let me draw it out for you.

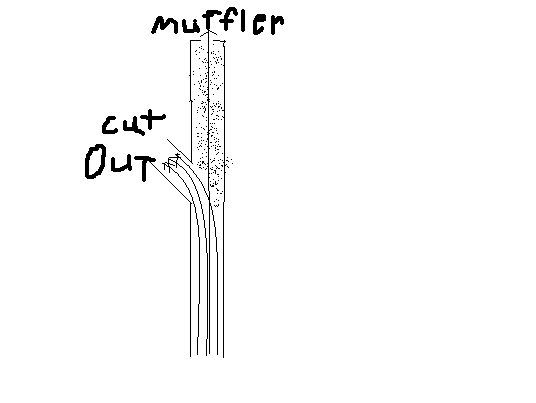

If the flow path was like this...:

...where the path to the muffler and the path to the cutout were split by an equal angle, then yes, most of the exhaust gas is going to follow the path of least resistance, and the more throttle you give it, the more exhaust is going to go through the cutout.

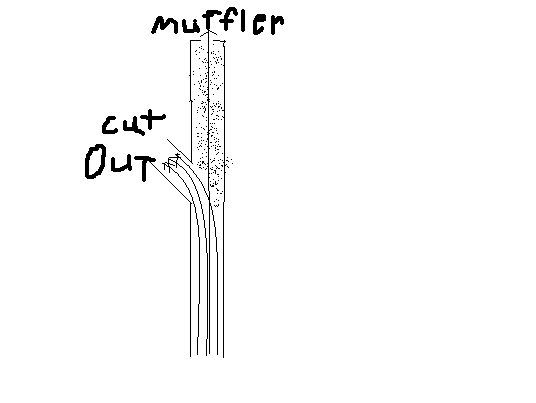

However, most setups DO NOT look like that. Most setups look like this:

In the majority of setups, in order for the gases to go out the cutout, they have to take an unnatural turn - they have to go off the main flow path. When the angle is like this, the cutout will expel the greatest PERCENTAGE of exhaust gas when the flow of exhaust gases are slowest - the gases will be moving at a low enough velocity to escape the main flow path and flow through the cutout.

Conversely, when the gases are moving very fast, the unnatural angle to take the cutout will become increasingly harder to take. It will be deviating from the main flow path.

These are NOT perfect scenarios. This isn't theory, this is real life. Again, you can use the simple hose trick to see what I mean. If you shoot a jet of water straight through the I-pipe, almost all the water will continue flowing completely straight out into the muffler. The faster the stream of water, the more will shoot into the muffler.

It's a lot easier to see with pictures. I can hear this effect plain as day on my setup. The more throttle I give it and the higher the RPM's climb, the more my exhaust sounds like my catback. The less throttle I give it, the more raw and "cutout-sounding" it is.

Now, this isn't to say that the cutout isn't expelling the MAJORITY of exhaust gases. The cutout may in fact be pulling more exhaust than the muffler. However, my point is, simply, that under more throttle, it's taking a smaller PERCENTAGE of the gas.

Last edited by ChocoTaco369; 01-05-2008 at 12:03 AM.

#24

Trunion King

iTrader: (16)

The main point of having a cut out is to become the MAIN FLOW PATH when is uncap because is it the LEAST resistance.

I see your point though but I don't think there is enough force from our engine that will push air with great magnitude that it will bypass the cutout completely and go through the muffler.

I see your point though but I don't think there is enough force from our engine that will push air with great magnitude that it will bypass the cutout completely and go through the muffler.

#26

Tech Resident

Have you ever watched exhaust soundclips? I've seen people start up their car and blow rocks across the driveway. There's plenty of exhaust velocity

To even further add to what I'm saying, if you've ever looked inside a cutout, it's not even fully opened. That 3" tubing is half blocked off. It IN REALITY looks more like this:

The whole back half is blocked off, and when you factor that in, it even more strongly designates the muffler as the main flow path.

In a perfect world where the angles are perfectly even between the flow paths, I'd agree with you 100%. However, pretty much no one that runs cutouts on this site are in that situation. They're in the situation I'm putting before you, which is actually one of the worst-case scenarios. It really minimizes the cutout's efficiency.

Not trying to bash you or anything. I just want you to see it from my perspective. I'm an engineering major, and the one thing I've learned is textbook definitions rarely hold water in real life. They are written based on ideal conditions, and when those ideal conditions are broken, they rarely hold up. The conditions users on this board see are far from ideal. The efficiency of cutouts are minimized in most people's setups on these boards. If you really want to maximize the efficiency of a cutout, you'd have to split the I-pipe into a y-style merge where an equal angle is present. You'd have to run one side to a muffler and run the other side open. That way, the path of least resistance will be followed to a maximum. Unfortunately, when you run a cutout on an angle and the muffler as a straight shot, it minimizes efficiency and you see minimal effects.

Last edited by ChocoTaco369; 01-05-2008 at 12:36 AM.

#27

11 Second Club

iTrader: (18)

One more thing though, guys. Cutouts installed on an LS1 generally let the muffler route wander off in an angle, while the open cutout route is straightforward right after the header. It's kinda like taco's model, only the "cutout" and the "muffler" labels would be reversed.

#28

Where are you getting this from? Any of these tests can be performed with a high pressure water hose. Take a straight piece of exhaust tube and put the cutout open on the bottom. Turn the hose on low. Most of the water is going to fall out of the cutout. Turn the hose on high pressure. Most of the water is going to go right over the cutout and out the back of the exhaust.

Exhaust gas is no different. You're the one that is completely wrong.

What is that supposed to mean? Are you trying to tell me 100% of the exhaust gas goes out the cutout?

Not to mention the main focus here is sound waves, not exhaust gas itself.

There is way more exhaust tone at WOT then there is at half throttle. WOT sounds mostly like my muffler, half throttle sounds like...well, nothing. Just raw noise.

You're trying to bring different laws of physics into this, mainly gravity. That analogy makes absolutely no sense. You can't use the force of gravity as a comparison to the effect of low and high pressure zones in exhaust gas.

I can sort of understand your logic, but it's completely incorrect. If there was the same amount of resistance through the cutout, AND through the catback, you would be correct, that most gas goes out the catback. This is not how it is though. Because the air "bundles up" in the catback and creates a higher pressure zone, there is more resistance to the air going in that section of the pipe, and more air comes out of the cutout as a result.

according to your logic, there should be fewer and fewer gains of HP and TQ the faster your engine is spinning, when in reality, it is the exact opposite. The higher your RPM's the more gain you receive over the comparable closed exhaust.

Originally Posted by ryanfx

Gas flows through the path of least resistance

EDIT: In addition, as I said, after looking at your picture of what a cutout is "supposed" to look like, your cutout is faulty. I can assure you my cutout was NOT blocked off like that. If your cutout truly looks like that, that's exactly why your car behaves differently.

Last edited by ryanfx; 01-05-2008 at 02:48 PM.

#29

12 Second Club

iTrader: (45)

Join Date: Dec 2006

Location: O'Hare

Posts: 526

Likes: 0

Received 0 Likes

on

0 Posts

to the OP: check out the multimedia section theres tons of vids/clips/info there!

oh and lt1s sound better ;-)

to the question of GAS dynamics: comparing a garden hose to an exhaust system is laughable. your an engineering major...you should know that velocity has a great impact on fluid dynamics AND gas dynamics. if you want a comparable experiment try this: take a straw. take a thick medical gauze pad and put it over the end. now cut a hole on the side of the straw and insert another straw in there in the manner that a cutout would be installed. now blow through the uncovered end of the straw. where does the air readily exit from?

i understand that there is air coming out of the catback. that is understandable. but compared to the air coming out of the cutout it is a negligible (and theoretically proportional) amount. this isn't an isolated system...of course the gases are going to follow a straight pipe. but not all of it. this is why the car is undoubtedly louder with a cutout rather than without a cutout. the noise is directly associated with the efficiency of existing exhaust. if that last comment isn't true than there is no reason why a freer flowing exhaust tends to be louder than a factory muffler specifically designed to restrict flow in order to reduce noise.

btw: unless your accomplished in your field the idea of "majoring in something" has no logical impact on the validity of your argument. in fact...its a logical fallacy.

oh and lt1s sound better ;-)

to the question of GAS dynamics: comparing a garden hose to an exhaust system is laughable. your an engineering major...you should know that velocity has a great impact on fluid dynamics AND gas dynamics. if you want a comparable experiment try this: take a straw. take a thick medical gauze pad and put it over the end. now cut a hole on the side of the straw and insert another straw in there in the manner that a cutout would be installed. now blow through the uncovered end of the straw. where does the air readily exit from?

i understand that there is air coming out of the catback. that is understandable. but compared to the air coming out of the cutout it is a negligible (and theoretically proportional) amount. this isn't an isolated system...of course the gases are going to follow a straight pipe. but not all of it. this is why the car is undoubtedly louder with a cutout rather than without a cutout. the noise is directly associated with the efficiency of existing exhaust. if that last comment isn't true than there is no reason why a freer flowing exhaust tends to be louder than a factory muffler specifically designed to restrict flow in order to reduce noise.

btw: unless your accomplished in your field the idea of "majoring in something" has no logical impact on the validity of your argument. in fact...its a logical fallacy.

#30

TECH Enthusiast

iTrader: (6)

Join Date: Oct 2005

Location: College Station/La Porte, TX

Posts: 669

Likes: 0

Received 0 Likes

on

0 Posts

Choco, im gonna have to disagree with you on this. You are not thinking about the resistance the exhaust gas is facing due to the more restrictive muffler. Let me illustrate with a pic, since you seem to like them so much...

The small dots represent the back pressure build up due to the restrictive muffler. With this pressure, more of the exhaust gas flow will be directed out the cutout, because there is NO restriction and NO back pressure. It's not a matter of the exhaust gas not wanting to turn a corner to go out the cutout, it is just a simple matter of the exhaust gas escaping the easiest way. If you drop a marble through a tube filled with syrup and another marble through a tube filled with water, which one would get to the end first? The marble that fell through the water, why? Because there is less resistance. Same for escaping exhaust gas, it will take the path with least amount of resistance.

I do agree that this theory in the real world wouldn't stand up perfectly, not all the gas will flow out of the cutout and yes I know cutouts aren't as efficient as everyone makes them out to be. But when you say the closer to wide open throttle, the more gas will flow out of the muffler and less out of the cutout, you aren't thinking about the increased back pressure once again. Yes, more gas will flow out of the muffler but even more will flow out of the cutout.

And for what it's worth, im an engineering major as well...

The small dots represent the back pressure build up due to the restrictive muffler. With this pressure, more of the exhaust gas flow will be directed out the cutout, because there is NO restriction and NO back pressure. It's not a matter of the exhaust gas not wanting to turn a corner to go out the cutout, it is just a simple matter of the exhaust gas escaping the easiest way. If you drop a marble through a tube filled with syrup and another marble through a tube filled with water, which one would get to the end first? The marble that fell through the water, why? Because there is less resistance. Same for escaping exhaust gas, it will take the path with least amount of resistance.

I do agree that this theory in the real world wouldn't stand up perfectly, not all the gas will flow out of the cutout and yes I know cutouts aren't as efficient as everyone makes them out to be. But when you say the closer to wide open throttle, the more gas will flow out of the muffler and less out of the cutout, you aren't thinking about the increased back pressure once again. Yes, more gas will flow out of the muffler but even more will flow out of the cutout.

And for what it's worth, im an engineering major as well...

#31

Tech Resident

The force of gravity isn't an issue here. Cutouts are typically horizonal to the I-pipe. They're not underneath the I-pipe, therefore, this isn't an issue of gravity. Shoot high pressure water through the I-pipe and little will exit the cutout. The higher the pressure, the less will exit. Why? Because the cutout is off to an angle vs. the main flow path. The faster the exhaust gases move, the harder it will be for the exhaust gases to make the turn it takes to exit the cutout.

I can sort of understand your logic, but it's completely incorrect. If there was the same amount of resistance through the cutout, AND through the catback, you would be correct, that most gas goes out the catback. This is not how it is though. Because the air "bundles up" in the catback and creates a higher pressure zone, there is more resistance to the air going in that section of the pipe, and more air comes out of the cutout as a result.

If you put the cutout in the I-pipe, the horsepower increase will be PROPORTIONATELY LESS than if you put the cutout after the header collectors. It's all percentages, not static numbers. You're not understanding what I'm really saying.

EDIT: In addition, as I said, after looking at your picture of what a cutout is "supposed" to look like, your cutout is faulty. I can assure you my cutout was NOT blocked off like that. If your cutout truly looks like that, that's exactly why your car behaves differently.

#32

Tech Resident

TLUZLS1, your diagram is fatally flawed. Your diagram, while making sense in a perfect world, has no place in the real world. Exhaust gas isn't magically pulled outside the cutout.

When a cutout is placed in the I-pipe, by design, the exit out of the cutout is NOT the main flow path. The main flow path is straight out to the muffler. In order for the gases to be pulled out of the cutout, the force has to be greater than than the force pulling the exhaust gases straight. The exhaust gases act like a freight train on rails, and the rails are going straight. In order to pull the "train" of exhaust gases out the cutout, the force has to be great enough to bend the "rails" to make the "train" turn a corner. This doesn't magically happen.

It's important to note that the faster the exhaust travels, the more force is required to change the flow path of the exhaust gas. This is my entire point - the faster the exhaust velocity, the more force is required to pull the exhaust gas out the cutout.

It makes perfect sense. You just have to sit back and think about it. Flow mechanics aren't all black and white. Different things happen in different situations. A cutout in the I-pipe has a completely different set of rules than a cutout at the end of each header collector.

In short, your drawing isn't a valid representation of a real-world setup.

It's also important to note that the freer flowing the muffler is, the more force is going to be necessary to pull the exhaust gas out the cutout. A Corsa muffler, in my case, is one of the best flowing mufflers on the market. It takes a lot more force to make that exhaust go out the cutout than, say, a stock catback, because the "path of least resistance" has proportionally much LESS resistance than on a not-so-free-flowing setup.

When a cutout is placed in the I-pipe, by design, the exit out of the cutout is NOT the main flow path. The main flow path is straight out to the muffler. In order for the gases to be pulled out of the cutout, the force has to be greater than than the force pulling the exhaust gases straight. The exhaust gases act like a freight train on rails, and the rails are going straight. In order to pull the "train" of exhaust gases out the cutout, the force has to be great enough to bend the "rails" to make the "train" turn a corner. This doesn't magically happen.

It's important to note that the faster the exhaust travels, the more force is required to change the flow path of the exhaust gas. This is my entire point - the faster the exhaust velocity, the more force is required to pull the exhaust gas out the cutout.

It makes perfect sense. You just have to sit back and think about it. Flow mechanics aren't all black and white. Different things happen in different situations. A cutout in the I-pipe has a completely different set of rules than a cutout at the end of each header collector.

In short, your drawing isn't a valid representation of a real-world setup.

It's also important to note that the freer flowing the muffler is, the more force is going to be necessary to pull the exhaust gas out the cutout. A Corsa muffler, in my case, is one of the best flowing mufflers on the market. It takes a lot more force to make that exhaust go out the cutout than, say, a stock catback, because the "path of least resistance" has proportionally much LESS resistance than on a not-so-free-flowing setup.

#33

12 Second Club

iTrader: (20)

This is what it sounds like with a baby cam and no cats, lt's, and a Magnaflow!

View Video on FQuick

View Video on FQuick

AND this at WOT!

View Video on FQuick

View Video on FQuick

View Video on FQuick

View Video on FQuickAND this at WOT!

View Video on FQuick

View Video on FQuick

#35

Tech Resident

That's the point I'm trying to make - the majority of people here don't follow the generalized rule. There are exceptions, and in the case of most F-body owners, the exceptions to the rule are in the majority.

#36

Where are you getting this from? Any of these tests can be performed with a high pressure water hose. Take a straight piece of exhaust tube and put the cutout open on the bottom. Turn the hose on low. Most of the water is going to fall out of the cutout. Turn the hose on high pressure. Most of the water is going to go right over the cutout and out the back of the exhaust.

Last edited by ryanfx; 01-06-2008 at 01:17 AM.

#37

Tech Resident

LOL. Trigger, Shawno and myself can jump in, let's do it. Are you waiting for the cam swap to put your headers on? We can throw on the LTs on in like 6 hours or less if you have a Y-pipe with your headers.

LOL. Trigger, Shawno and myself can jump in, let's do it. Are you waiting for the cam swap to put your headers on? We can throw on the LTs on in like 6 hours or less if you have a Y-pipe with your headers.