Ud Pulley Install Helppppp!!!! Please!!!

#1

TECH Addict

Thread Starter

iTrader: (29)

Join Date: Apr 2005

Location: Margate, FL

Posts: 2,269

Likes: 0

Received 0 Likes

on

0 Posts

i got my March UD pulley from Thunder Racing today, nice looking product!

Anyway

Got the old crank off with a breaker bar, and then a pulley puller...cool so far

Now the problem....i lubed up the new pulley and placed it on the crank...however, i cant get it far enough on to thread the bolt...WHAT NOW?!?!?!? How do i get it on the crank far enough to strt the bolt??

HELP!

thanks

Anyway

Got the old crank off with a breaker bar, and then a pulley puller...cool so far

Now the problem....i lubed up the new pulley and placed it on the crank...however, i cant get it far enough on to thread the bolt...WHAT NOW?!?!?!? How do i get it on the crank far enough to strt the bolt??

HELP!

thanks

#2

Search the topic and you go buy a longer bolt. The old threads have length diameter and pitch. Buy the new bolt to suck it on far enough to get the stock bolt started.

#4

TECH Fanatic

iTrader: (2)

Join Date: Jul 2004

Location: Greensburg,PA

Posts: 1,882

Likes: 0

Received 0 Likes

on

0 Posts

he is right, also I got a bolt down at the hardware store, just take you crank bolt there and get one, get a thick washer as well to get it started. once started, USE YOUR OLD CRANK BOLT TO TIGHTEN IT DOWN. then install as par howtols1.com

#5

UNDER PRESSURE MOD

iTrader: (19)

Be careful to not strip the threads in the crank because you will be in a world of hurt then.

I would search and you'll find people selling a hardened steel rod / bearing / nut combination that will pull the balancer on. That's the right way to do this so that you don't risk trashing the threads in your crank, if you're not sure, take the 5 minutes to search for "stripped crank threads" and see how often it happens.

Trust me, nothing is a worse feeling than tightening down a bolt and it either snaps, or gets easy and you know you just stripped out the threads.

I would search and you'll find people selling a hardened steel rod / bearing / nut combination that will pull the balancer on. That's the right way to do this so that you don't risk trashing the threads in your crank, if you're not sure, take the 5 minutes to search for "stripped crank threads" and see how often it happens.

Trust me, nothing is a worse feeling than tightening down a bolt and it either snaps, or gets easy and you know you just stripped out the threads.

#6

The Install Tool that The Alchemist was talking about:

https://ls1tech.com/forums/showthrea...Pulley+Install

The size of bolt:

https://ls1tech.com/forums/showthrea...Pulley+Install

Make sure you get a large washer that rest on the pulley and won't bend to much.

For the Torque specs. go to www.ls1howto.com and look up a cam and valve spring install.

https://ls1tech.com/forums/showthrea...Pulley+Install

The size of bolt:

https://ls1tech.com/forums/showthrea...Pulley+Install

Make sure you get a large washer that rest on the pulley and won't bend to much.

For the Torque specs. go to www.ls1howto.com and look up a cam and valve spring install.

#7

TECH Addict

iTrader: (1)

The bolt you need to buy is 120mmX16mmX2mm. Push the pulley on with this bolt until the longer bolt bottoms out. Now finish using the NEW OEM bolt you purchased. Be sure the pulley is straight and square as you start it on. If the pulley isn't moving a little bit every time you turn the longer bolt or if it gets hard to turn the bolt STOP! Once you get the longer bolt to bottom out your past the problem area.

Trending Topics

#9

SSU's Drunk Typing Whore

iTrader: (47)

Join Date: Jan 2004

Posts: 4,609

Likes: 0

Received 0 Likes

on

0 Posts

I was not thinking enough and used the stock bolt to put mine on...no problems but I was kicking myself in the *** though big time.

Its always best to use a longer bolt to get the pulley started.

Its always best to use a longer bolt to get the pulley started.

#11

TECH Addict

iTrader: (1)

A long threaded rod is really the way to go as DaddySS mention, but I got the 120mm bolt for $3 and have used it with success a bunch of times. You'd be surprised how much thread purchase you get with a bolt 120mm long. With the stock bolt you get only a few threads at first, but with the longer bolt you have an additional 17mm(3/4") of thread purchase. That's enough to walk that pulley on even if it is an interference fit.

#12

TECH Addict

Thread Starter

iTrader: (29)

Join Date: Apr 2005

Location: Margate, FL

Posts: 2,269

Likes: 0

Received 0 Likes

on

0 Posts

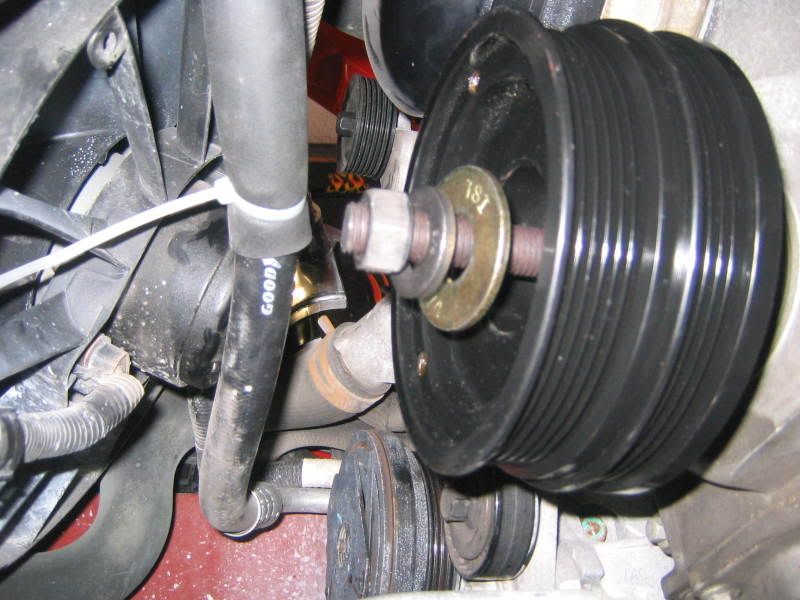

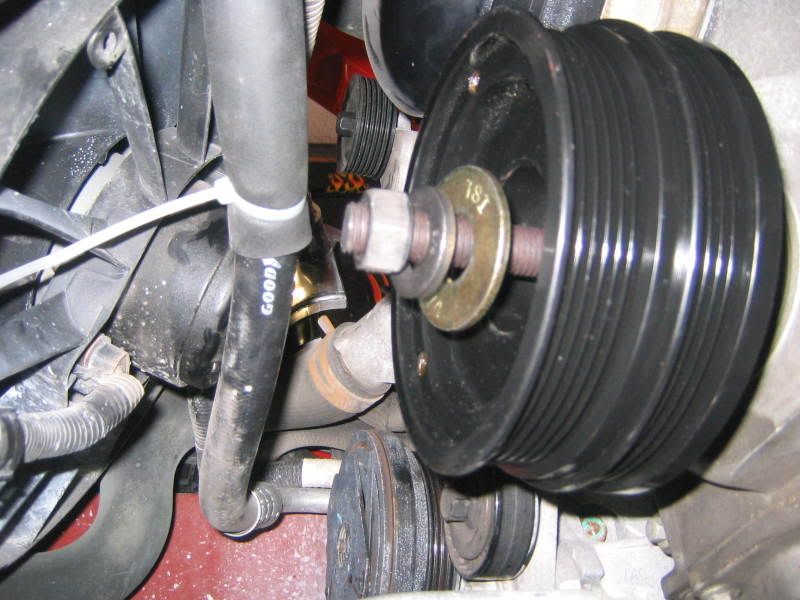

SUCCESS, I went out and bought a threaded rod, cut it to 7", got a nut, and two washers (hardened)...screwed the rod into the crank, placed pulley over rod, tightened nut and watched the pulley slide right on the crank..here are some pics, put belts back on and car runs fine, I need a tune however, I just installed LT's as well...so I havent noticed gains yet, hopefull with the tune itll really make the most out of my mods!!! THANKS TO ALL WHO CHIMED IN!!! A+ advice!

Here are some pics!

Here are some pics!

#19

TECH Addict

Thread Starter

iTrader: (29)

Join Date: Apr 2005

Location: Margate, FL

Posts: 2,269

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by eallanboggs

One advantage to the threaded rod method is that you don't have to be so concerned about keeping the crank from turning while you're installing the pulley. I'm sure it has a tendency to rotate, but not nearly as much as when you use the long bolt method.

Thanks to everyone again...i HIGHLY recommened this process when installing an UD pulley!