Home Porter Pics, NO CNCs

#21

TECH Senior Member

iTrader: (28)

Heres a 241 set I did, stock VJ put down some good numbers on my car.

put down some good numbers on my car.

https://ls1tech.com/forums/generatio...ted-heads.html

I did a set of 243s, I sent out to airflowdevolpe on here. I'll be getting back this week with a bitchen VJ. so far with a quick blend they went 3xx

I have some in progress work to them still really tight, with good VJ they be larger but will use it.

put down some good numbers on my car.

put down some good numbers on my car.https://ls1tech.com/forums/generatio...ted-heads.html

I did a set of 243s, I sent out to airflowdevolpe on here. I'll be getting back this week with a bitchen VJ. so far with a quick blend they went 3xx

I have some in progress work to them still really tight, with good VJ they be larger but will use it.

Last edited by studderin; 09-01-2009 at 08:46 PM.

#22

11 Second Club

iTrader: (20)

Join Date: Oct 2006

Location: Virginia

Posts: 3,131

Likes: 0

Received 0 Likes

on

0 Posts

I suppose if you know nothing about engineering, it's easy to believe it's possible to cut 8 intake ports and 8 exhaust ports by eye with any sort of precision.

Makita...

We use pneumatic tools, ace. Try getting any kind of RPM from an electric motor. And that's only for final finish with a very fine abrasive. CNC does the cutting, and it does every port to exactly the same spec.

If you knew anything about engines, you'd know variation in port flow characteristics is not a good thing.

Makita...

We use pneumatic tools, ace. Try getting any kind of RPM from an electric motor. And that's only for final finish with a very fine abrasive. CNC does the cutting, and it does every port to exactly the same spec.

If you knew anything about engines, you'd know variation in port flow characteristics is not a good thing.

actually all my cutting is done pnuematic and my finishing is by electric.....

wish i had enough hair left to grow a mullet....

#23

TECH Fanatic

iTrader: (1)

Join Date: Nov 2007

Location: NJ

Posts: 1,193

Likes: 0

Received 0 Likes

on

0 Posts

Not picking on any here but the pic of the ported heads suck. I cant see if the shape of the port are any good. But i can see that the finish and way the alum was cut could cause issues with fuel dropping out. plus weird pressure spikes in the air flow path.

The time need to do a good port job on a set of head by a pro is a min of like 25 hours and can go up to 80 hours for one set. I worked with a flow bench and worked with a top level head porter. Many heads are throw out before they have a finished port which it then casted and copyed and slowly refined

The time need to do a good port job on a set of head by a pro is a min of like 25 hours and can go up to 80 hours for one set. I worked with a flow bench and worked with a top level head porter. Many heads are throw out before they have a finished port which it then casted and copyed and slowly refined

#24

11 Second Club

iTrader: (20)

Join Date: Oct 2006

Location: Virginia

Posts: 3,131

Likes: 0

Received 0 Likes

on

0 Posts

Not picking on any here but the pic of the ported heads suck. I cant see if the shape of the port is any good. But i can see that the finish and way the alum was cut could cause issues with fuel dropping out. plus weird pressure spikes in the air flow path.

The time need to do a good port job on a set of head by a pro is a min of like 25 hours and can go up to 80 hours for one set. I worked with a flow bench and worked with a top level head porter. Many heads are throw out before they have a finished port which it then casted and copyed and slowly refined

The time need to do a good port job on a set of head by a pro is a min of like 25 hours and can go up to 80 hours for one set. I worked with a flow bench and worked with a top level head porter. Many heads are throw out before they have a finished port which it then casted and copyed and slowly refined

#25

9 Second Club

iTrader: (17)

Sorry for jumping on the other guy, but I posted what the OP wanted to see and (mostly). And like I said..it's know it alls like him that ruin this site.

#26

#27

9 Second Club

iTrader: (17)

Like I said they are crappy pictures and they aren't "hogged out". It is actually very minimal porting and keeping the radius. If I had better pictures you would be able to see that. Also the intake runner was just polished and blended the little "hump".

Too bad some people are scared to take chances and actually learn something, sorry I don't have $2,000 to sink in a nice set of heads either...maybe one day.

The car still runs and runs good

Too bad some people are scared to take chances and actually learn something, sorry I don't have $2,000 to sink in a nice set of heads either...maybe one day.

The car still runs and runs good

#28

TECH Fanatic

iTrader: (1)

Join Date: Nov 2007

Location: NJ

Posts: 1,193

Likes: 0

Received 0 Likes

on

0 Posts

It's people like that who ruin LS1 Tech who think they know 100% of everything. Those are pictures of the unfinished smoothing and blending btw. I never got pictures of them completely finished.

Sorry for jumping on the other guy, but I posted what the OP wanted to see and (mostly). And like I said..it's know it alls like him that ruin this site.

Sorry for jumping on the other guy, but I posted what the OP wanted to see and (mostly). And like I said..it's know it alls like him that ruin this site.

In a few spot you would have to blend metal back on to the head to make it flow right ?

Stock heads= work good

Stock heads with blending and valve jobs= better

Very very very very light home porting with above Almost no change in shape= littler bit better

Home ported heads maybe look like there helping but 99% of the time. there was no gain or a lost of gain for work done to head = not good

#29

Moderator

iTrader: (11)

Join Date: Mar 2002

Location: East Central Florida

Posts: 12,604

Likes: 0

Received 6 Likes

on

6 Posts

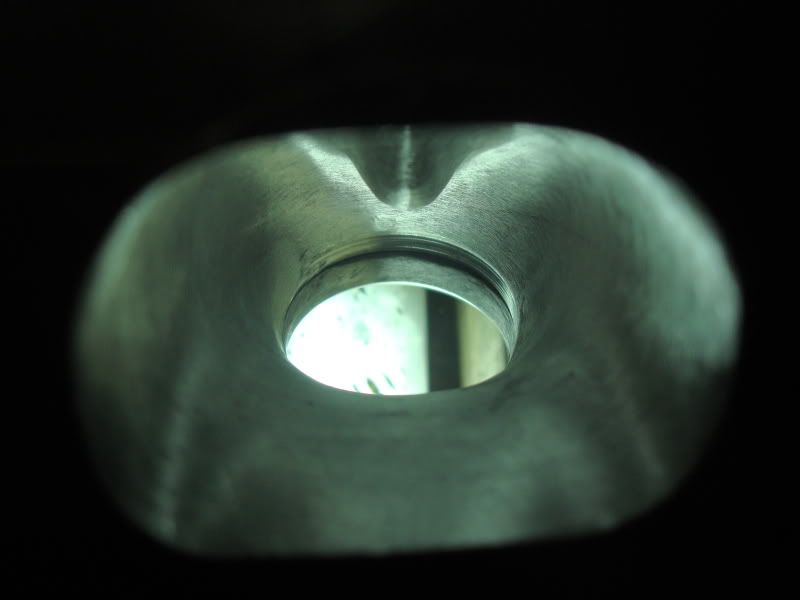

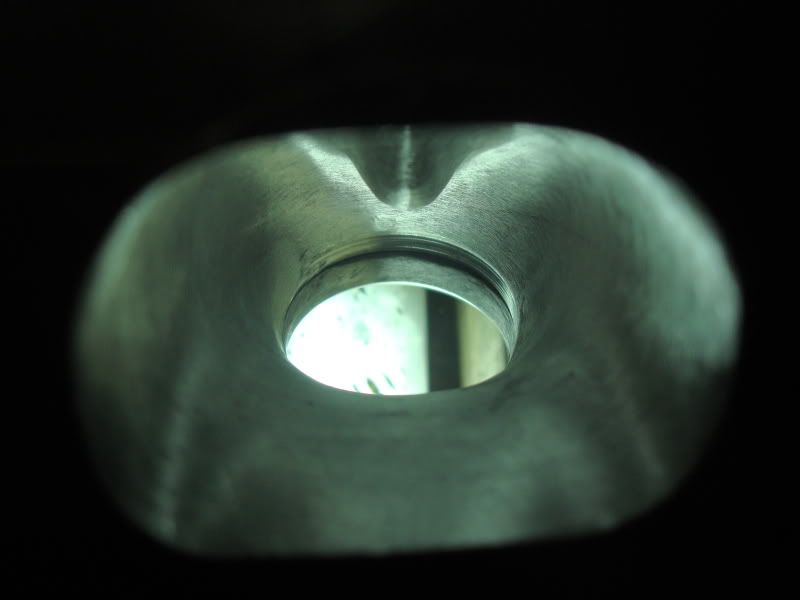

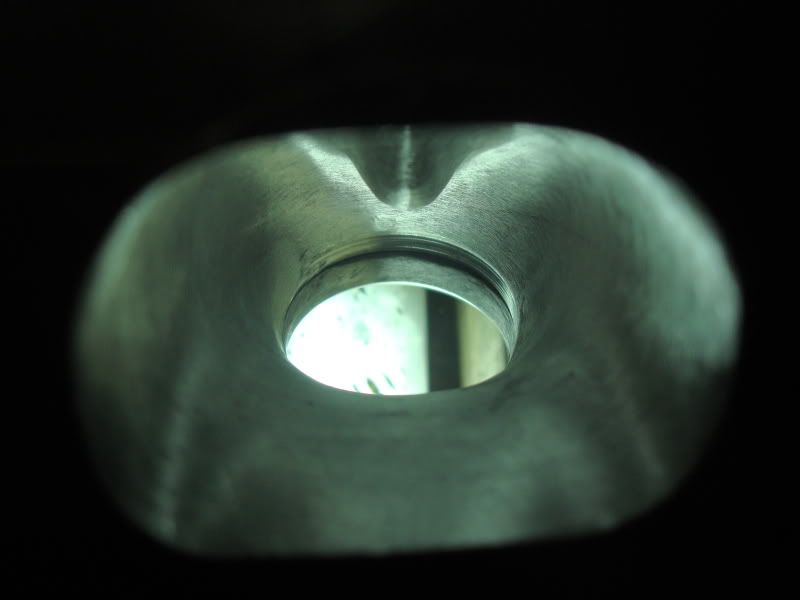

I didn't bother taking any pictures of my home-porting session. I did not

go too crazy; I blended the underside of the valve seat taking out any

"sharps" with the backside of a ball burr. The valve guides I only blended,

didn't knife-edge them and avoided taking out any bushing bronze at all.

I think I knocked down the swirl ramp. I port matched to the gaskets for

intake (Professional Products was kind enough to send me a couple of

gaskets, before I had even bought the manifold) and exhaust. I polished

the chambers but did not remove any material beyond the rough.

Being as I did it only by eye and by "best guess" I saw no use in trying

to document it. All I wanted was to get rid of stupid, and keep things

uniform hole to hole.

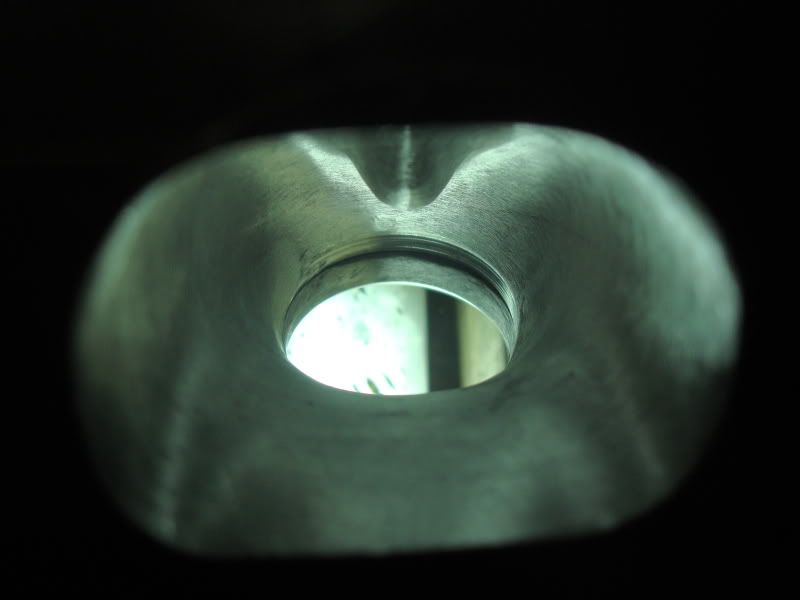

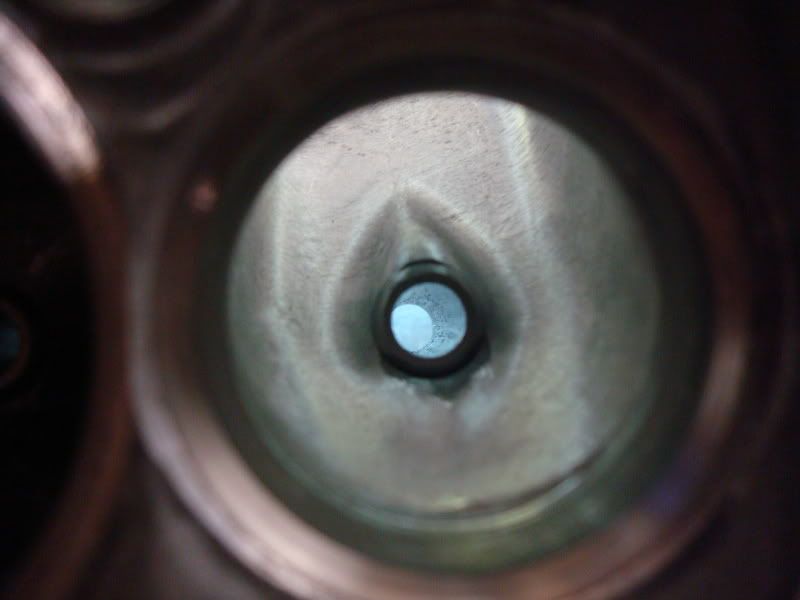

But here are some pics you may find useful. In preparing for the job, I

took the chop saw to a junk 317 head (presuming they were a fair model

of what to expect the 243 internals to be) and took pics of the cross

sections. Maybe it will help someone avoid "striking oil".

go too crazy; I blended the underside of the valve seat taking out any

"sharps" with the backside of a ball burr. The valve guides I only blended,

didn't knife-edge them and avoided taking out any bushing bronze at all.

I think I knocked down the swirl ramp. I port matched to the gaskets for

intake (Professional Products was kind enough to send me a couple of

gaskets, before I had even bought the manifold) and exhaust. I polished

the chambers but did not remove any material beyond the rough.

Being as I did it only by eye and by "best guess" I saw no use in trying

to document it. All I wanted was to get rid of stupid, and keep things

uniform hole to hole.

But here are some pics you may find useful. In preparing for the job, I

took the chop saw to a junk 317 head (presuming they were a fair model

of what to expect the 243 internals to be) and took pics of the cross

sections. Maybe it will help someone avoid "striking oil".

#30

LSX Mechanic

iTrader: (89)

It's people like that who ruin LS1 Tech who think they know 100% of everything. Those are pictures of the unfinished smoothing and blending btw. I never got pictures of them completely finished.

Sorry for jumping on the other guy, but I posted what the OP wanted to see and (mostly). And like I said..it's know it alls like him that ruin this site.

Sorry for jumping on the other guy, but I posted what the OP wanted to see and (mostly). And like I said..it's know it alls like him that ruin this site.

I was actually trying to be nice about your hack job and gave you props for trying. It's not people acting like "know it alls". But anybody who knows anything about porting, knows that those pictures you posted are a porting disaster. No offense.

If you like them, then I guess that's all that matters.

#31

9 Second Club

iTrader: (17)

Actually Junior, I provide technical information for people on this site every day, for free. And have been doing so for 8 years. Someone please stop me now, I'm ruining the site!!

I was actually trying to be nice about your hack job and gave you props for trying. It's not people acting like "know it alls". But anybody who knows anything about porting, knows that those pictures you posted are a porting disaster. No offense.

If you like them, then I guess that's all that matters.

I was actually trying to be nice about your hack job and gave you props for trying. It's not people acting like "know it alls". But anybody who knows anything about porting, knows that those pictures you posted are a porting disaster. No offense.

If you like them, then I guess that's all that matters.

I'm done with this thread, especially since I'm some dumbass 18 year old apparently. Looks to me like some people should actually read a whole post instead of skimming through things too quickly.

The bowls look very similar to the pictures that Studderin posted once they were actually ready to be bolted on the engine, but people apparently want to keep thinking I just stuck the damn things on the car as they look in the pictures.

Last edited by StreetSilverado; 09-02-2009 at 12:36 AM.

#32

Hate to throw my.02 in this but there is a diff between turning wrenches and porting. Just like everything the right tools are needed and at first its best to blend and smooth it out than to dig in. Need to get a feel for the cutting and how much/where to remove. It's best to try them on those 98 heads no one wants and get a couple ports flowed.

I'm NO expert but I will say I did it this way and I got nice results. I did them on my LT1 heads and put down 390rwhp on a 350 stock bottom end just h/c. would've been more if I didn't have valve float at 6k.

Thing is we are all hot rodders or some of us. If we didn't tinker nothing would get done or invented. Just can't think that DIY heads will be on a 10 sec car. Nice little street car, yeah...and knowing you did it all, priceless.

I'm NO expert but I will say I did it this way and I got nice results. I did them on my LT1 heads and put down 390rwhp on a 350 stock bottom end just h/c. would've been more if I didn't have valve float at 6k.

Thing is we are all hot rodders or some of us. If we didn't tinker nothing would get done or invented. Just can't think that DIY heads will be on a 10 sec car. Nice little street car, yeah...and knowing you did it all, priceless.

#33

TECH Fanatic

iTrader: (5)

Join Date: Sep 2008

Location: Salem/Keizer

Posts: 1,120

Likes: 0

Received 0 Likes

on

0 Posts

oh noezzzzzzzz!!!!no one ever ported heads without a flowbench.....you guys act like head porting is some black magic that only wizards and warlocks are capable of doing.....

its like these pro's were born with a big makita in there hand......but us that know better set back and laugh at all the others who dont.....

its like these pro's were born with a big makita in there hand......but us that know better set back and laugh at all the others who dont.....

Laugh at what? Lack of accurate cylinder balance because you have no way to accurately measure cfm at a given lift? Or for that matter even worrying about intake charge velocity and swirl attributes around the back of the valve?

It would be way too easy to "hog it out and get 'em big", but QUALITY performance porting ...like it or not... IS a bit of an art.....an art derived from experience. It starts with being able to MEASURE results (good and bad), and learn from mistakes made and modify your approach. I've seen various smaller-port heads flow more on a bench than some other large-port heads. It just goes to prove that "just because it's a bigger port, it doesn't mean it's better..."

For that very reason, EVERY performance cylinder head shop that is worth it's salt has a flow bench. They don't guess. Ever.

Last edited by salemetro; 09-02-2009 at 01:56 AM.

#34

Banned

iTrader: (1)

I have a cheap 1200 dollar shopvac powered flow bench run by a laptop.

I have pitot tubes.

I have an adjustable speed electric mikita grinder.

I have carbides, cartridge rolls, stones, and fap wheels.

I have read everything I could get my hands on and still am not done. SBC and LSX related both.

I have been minorly involved in discussions with top head porters.

I have a math AND art background.

If you have the tools, you should have no problem improving flow on a set of heads. My suggestion would be to "map" the runner. Test it as stock. Then during testing, check the airflow with the pitot tube. Make notes. Shape the area that the pitot tube suggests needs to be looked at (how it's related is what you have to figure out). Then map the runner again after a few changes. The measurements mean something. Again, you should be able to figure out what and why. Then check airflow again. The head will tell you when to stop, either by getting into a water jacket, or um... other ways. When you are satisfied, you get the valve job needed for the heads and for their use. Again, this is not free info but if you're smart you can figure it out.

I guess this post wasn't really that helpful.. but those who know rarely tell, and those who tell rarely know.

Someone smart once told me, to be a good head porter, you need to be 1) A little OCD, **** retentive. 2) Good hand- eye coordination. 3) knowledge of math and physics. 4) See shapes well 5) Having a good ear when testing 6) Have an addictive personality.

I want to add a 7th though.. 7) Being able to "see" with your fingertips.

I have pitot tubes.

I have an adjustable speed electric mikita grinder.

I have carbides, cartridge rolls, stones, and fap wheels.

I have read everything I could get my hands on and still am not done. SBC and LSX related both.

I have been minorly involved in discussions with top head porters.

I have a math AND art background.

If you have the tools, you should have no problem improving flow on a set of heads. My suggestion would be to "map" the runner. Test it as stock. Then during testing, check the airflow with the pitot tube. Make notes. Shape the area that the pitot tube suggests needs to be looked at (how it's related is what you have to figure out). Then map the runner again after a few changes. The measurements mean something. Again, you should be able to figure out what and why. Then check airflow again. The head will tell you when to stop, either by getting into a water jacket, or um... other ways. When you are satisfied, you get the valve job needed for the heads and for their use. Again, this is not free info but if you're smart you can figure it out.

I guess this post wasn't really that helpful.. but those who know rarely tell, and those who tell rarely know.

Someone smart once told me, to be a good head porter, you need to be 1) A little OCD, **** retentive. 2) Good hand- eye coordination. 3) knowledge of math and physics. 4) See shapes well 5) Having a good ear when testing 6) Have an addictive personality.

I want to add a 7th though.. 7) Being able to "see" with your fingertips.

#35

TECH Senior Member

iTrader: (42)

QUOTE FROM OP

I am well aware they are 2 different animals. But like I said this is not my first go around porting and cleaning up heads. I am not a pro, nor am I some kid in mom&dads basement with a dremel.The whole idea of this thread was to get some ideas about what guys are doing as an alternative to cncing.If you don't have any thing constructive to post then stay the PHUCH OUT of the thread!!!!

Being an internet tough guy is hardly what I would call being positive so lets get back to the subject at hand sir. You missed my point completely... I always say more power to anyone who does things on their own....that is what hot rodding is all about ... but the only way that you will know if you made any gains or loses is by checking the flow of the finished head...other wise your are just guessing as to wether you have any positive results...I said that it sounded like the OP was getting ready to phuch up a set of heads because that is what most inexperienced people do when they get the cutting tool in their hands...I wished the OP good luck too .... and I say again to please have his work flowed so we can see the results...technology has progressed to where we have CNC which can duplicate each port...I am very interested in seeing how close our would be porter can do in duplicating his own work on each port of the head ... my TEA heads flow 316 cubic feet of air on the intake side @ .600 lift ..... that is a good flowing head ... I've been hot rodding since the early 60s and I would never assume that I could duplicate that kind of flow in 8 different intake ports and chambers...I applaud his desire to learn a new skill but I have serious doubts on his final results....anyway used stock LS1 heads are cheep...good luck and please let us know how they flow.

PS Hay OP I have a set of stock LS1 heads for sale PM me if your interested.

I am well aware they are 2 different animals. But like I said this is not my first go around porting and cleaning up heads. I am not a pro, nor am I some kid in mom&dads basement with a dremel.The whole idea of this thread was to get some ideas about what guys are doing as an alternative to cncing.If you don't have any thing constructive to post then stay the PHUCH OUT of the thread!!!!

Being an internet tough guy is hardly what I would call being positive so lets get back to the subject at hand sir. You missed my point completely... I always say more power to anyone who does things on their own....that is what hot rodding is all about ... but the only way that you will know if you made any gains or loses is by checking the flow of the finished head...other wise your are just guessing as to wether you have any positive results...I said that it sounded like the OP was getting ready to phuch up a set of heads because that is what most inexperienced people do when they get the cutting tool in their hands...I wished the OP good luck too .... and I say again to please have his work flowed so we can see the results...technology has progressed to where we have CNC which can duplicate each port...I am very interested in seeing how close our would be porter can do in duplicating his own work on each port of the head ... my TEA heads flow 316 cubic feet of air on the intake side @ .600 lift ..... that is a good flowing head ... I've been hot rodding since the early 60s and I would never assume that I could duplicate that kind of flow in 8 different intake ports and chambers...I applaud his desire to learn a new skill but I have serious doubts on his final results....anyway used stock LS1 heads are cheep...good luck and please let us know how they flow.

PS Hay OP I have a set of stock LS1 heads for sale PM me if your interested.

Last edited by slt200mph; 09-02-2009 at 08:55 AM.

#36

The OP may screw up his heads but I say more power to him for thinking he can do it. Most members of LS1tech have others do there mods for them and then they become experts by osmosis or something. I am not excusing crappy work that was shown here but I applaud his enthusiasm.

#37

Staging Lane

iTrader: (10)

Join Date: Jul 2008

Location: Ingleside IL

Posts: 76

Likes: 0

Received 0 Likes

on

0 Posts

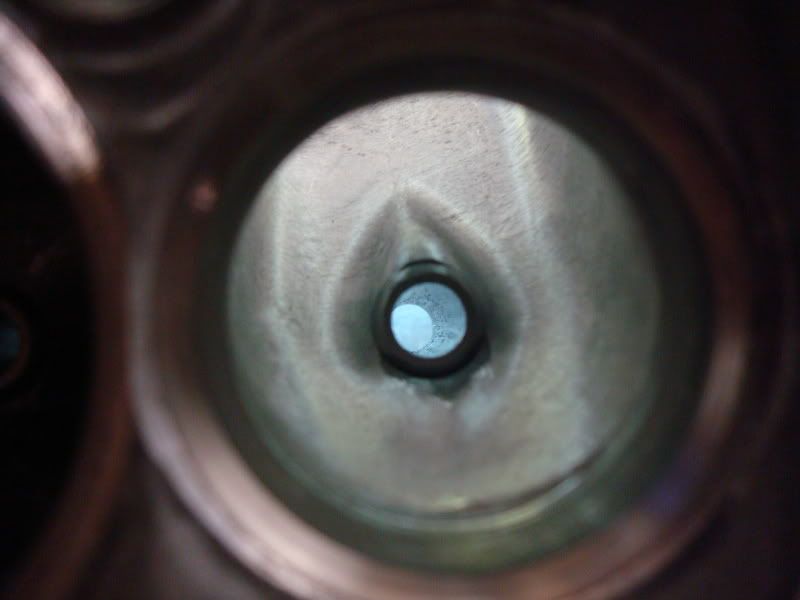

I thought I had more uploaded but dont. Here is a exhaust runner I did on mine, I did the intake but dont have any pics uploaded. I took the pic at a strange angle so it may look goofy but I do plan on having them flow tested and checked out before I run them.

#38

TECH Senior Member

iTrader: (127)

i agree that a valve upgrade with 2.02, corresponding vj,backcut and blend of bowl, valve throat area. is the best option for a basic street head.

its what i have in my car, it works, very well. and does not cut out any real metal out of the heads. besides what ever the cartridge rolls remove to acheive the valve diameter %

its what i have in my car, it works, very well. and does not cut out any real metal out of the heads. besides what ever the cartridge rolls remove to acheive the valve diameter %

#39

TECH Fanatic

iTrader: (10)

Join Date: Oct 2007

Location: plainfield,IL

Posts: 1,389

Likes: 0

Received 0 Likes

on

0 Posts

wow....so many ppl think they know soooooo much, **** that **** is annoying. i ported my own heads, and with only a dremel and slower speed drill....at first you doubt your self but after a while i looked back....at 25+ hours of work and the heads looked great Now i know NOTHING MORE THEN THE NEXT IDIOT but **** i tryed and they put out. i just wanna see the ******* that says someones going to destroy there heads by home porting, and show me one person that has ever hurt there heads by porting...im sure there has been but ITS NOT COMMIN...