GM head bolt question

#1

11 Second Club

Thread Starter

iTrader: (7)

Join Date: Dec 2007

Location: South Shore, NS

Posts: 216

Likes: 0

Received 0 Likes

on

0 Posts

So I just installed my heads this morning and got them all torqued as per instructions.

through my FAST back on and went to tighten it down and all the bolts went in fine and then the last bolt wouldn't start. hmmm... pulled the intake off and the PO snapped a bolt in the head from his manifold (Now learn a shop did, not the PO himself; we are trying to work this out currently).

So now I need to pull the head so I can get the busted bolt out of the head as I don't forsee the manifold sealing without it. Duh

So since I have torqued the stock GM bolts once when I pull them out are they now garbage? Same with the MLS GM gasket I used?

through my FAST back on and went to tighten it down and all the bolts went in fine and then the last bolt wouldn't start. hmmm... pulled the intake off and the PO snapped a bolt in the head from his manifold (Now learn a shop did, not the PO himself; we are trying to work this out currently).

So now I need to pull the head so I can get the busted bolt out of the head as I don't forsee the manifold sealing without it. Duh

So since I have torqued the stock GM bolts once when I pull them out are they now garbage? Same with the MLS GM gasket I used?

#2

Staging Lane

iTrader: (2)

Join Date: Aug 2010

Location: Quebec

Posts: 64

Likes: 0

Received 0 Likes

on

0 Posts

the bolts are torque to yield so unfortionatly no you can not reuse them , some people will say you can but for what they cost it is not worth it , have them sent from summit you will get them fast for 46 bucks but not till monday or tuesday , think about it 46 bucks compared to what you have already invested , i am not sure about the gasket , can you not get the bolt out without removing the head , i have used bolt exstactors with alot of sucess but it is probably broke down deep , do you know a good welder because there are speacial pieces of rod that you can arc weld to the bolt and then use that as leverage to unscrew never used one but they exist , good luck Eric

#4

TECH Addict

iTrader: (8)

Get a small drill bit and drill a hole in the bolt.. then get an "easy out" and screw it in the hole and it should back right out. Easy as pie.

an "Easy out" is a reverse fluted drill bit sort of. They make really small ones you can get at an auto parts store for a couple bucks.

an "Easy out" is a reverse fluted drill bit sort of. They make really small ones you can get at an auto parts store for a couple bucks.

#6

I've had good luck welding a nub on the existing bolt high enough to weld a nut to. works better when you have a bit more room, like the exhuast stuff. If it doesn't work the first time, its usually clean enough to do it the second time. A tap after the nut is welded on usually helps crack it free if its seized normally. The heat from welding seems to help as well, just wait for it to cool back down before trying to turn it off. If its been bottomed out and then snapped it may be more difficult.

#7

Staging Lane

iTrader: (2)

Join Date: Aug 2010

Location: Quebec

Posts: 64

Likes: 0

Received 0 Likes

on

0 Posts

Get a small drill bit and drill a hole in the bolt.. then get an "easy out" and screw it in the hole and it should back right out. Easy as pie.

an "Easy out" is a reverse fluted drill bit sort of. They make really small ones you can get at an auto parts store for a couple bucks.

an "Easy out" is a reverse fluted drill bit sort of. They make really small ones you can get at an auto parts store for a couple bucks.

Trending Topics

#8

TECH Senior Member

iTrader: (4)

I would pull the head. You will need new bolts and "maybe" a new gasket (although I would personally replace the gasket). If you try and do this on the car and the drill wanders your threads are toast. Also, any chips fall right on the lifters, not exactly where you want them. You may find that the remains of the bolt are sticking out the other side and you can remove it from the bottom of the head. If not, either use a drill press or a machine shop.

#9

I like using reverse drill bits when ever I can. usually if its a bolt that will come out easy during the drilling it will back out. also get a center punch befor you drill.. this helps for so many reasons!

one if you need an easy out your turning on center this helps on larger bolts from twisting the easyout and snapping a hardened part in a bolt you cant get out

also if you find you need to drill out the bolt all the way your leaving a nice centered hole to retap or install a new thread (timesert or helicoil)

one if you need an easy out your turning on center this helps on larger bolts from twisting the easyout and snapping a hardened part in a bolt you cant get out

also if you find you need to drill out the bolt all the way your leaving a nice centered hole to retap or install a new thread (timesert or helicoil)

#10

You can try to use a small punch and tap in direction to remove i am a gm tech and have done this many time also you could try trimming a chisel and tap that around . If that doesnt work go to local auto parts store and get an easy out kit . Remember to use duct tape to cover ports for debris . And definatlely chase the threads with a tap and or helicoil once you get the bolt out .

Oh and center punch before you drill into broken bolt . No need to pull cylinder head you will be wasting your time and money if you do and no do not weld onto it the aluminum will melt first from the heat and you will have a bigger problem .

Oh and center punch before you drill into broken bolt . No need to pull cylinder head you will be wasting your time and money if you do and no do not weld onto it the aluminum will melt first from the heat and you will have a bigger problem .

#11

TECH Senior Member

iTrader: (4)

You can try to use a small punch and tap in direction to remove i am a gm tech and have done this many time also you could try trimming a chisel and tap that around . If that doesnt work go to local auto parts store and get an easy out kit . Remember to use duct tape to cover ports for debris . And definatlely chase the threads with a tap and or helicoil once you get the bolt out .

Oh and center punch before you drill into broken bolt . No need to pull cylinder head you will be wasting your time and money if you do and no do not weld onto it the aluminum will melt first from the heat and you will have a bigger problem .

Oh and center punch before you drill into broken bolt . No need to pull cylinder head you will be wasting your time and money if you do and no do not weld onto it the aluminum will melt first from the heat and you will have a bigger problem .

#12

Staging Lane

iTrader: (2)

Join Date: Aug 2010

Location: Quebec

Posts: 64

Likes: 0

Received 0 Likes

on

0 Posts

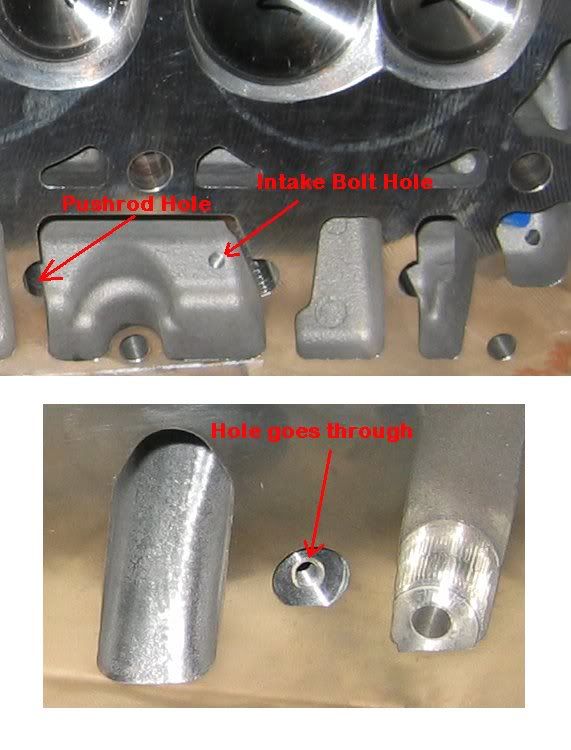

If your correct and these holes do fall into the lifters then he should not do this , never noticed this , so the threaded holes go completely through the head , unless it comes out very clean with no damage to the threads i would remove the head , Eric

#14

Staging Lane

iTrader: (2)

Join Date: Aug 2010

Location: Quebec

Posts: 64

Likes: 0

Received 0 Likes

on

0 Posts

Nice pictures, so he will have to take his head off if he cant get it out clean , i wonder how does a intake bolt break when taking it out are they not only torqued to 90in pounds , Eric

#15

TECH Apprentice

iTrader: (1)

Join Date: Jan 2010

Location: Arlington, TX

Posts: 350

Likes: 0

Received 0 Likes

on

0 Posts

The bolts are supposed to be one time use. Some people have reused them but with my luck I wouldnt. Other companies make bolts that are reuseable and very close in price to the GM bolts. Look at what ARP offers. Pretty sure they make bolts are reuseble. Even if they cost double the GM bolts, you save money in the long run not have to buy more bolts next time you take the heads off.

#17

You can try to use a small punch and tap in direction to remove i am a gm tech and have done this many time also you could try trimming a chisel and tap that around . If that doesnt work go to local auto parts store and get an easy out kit . Remember to use duct tape to cover ports for debris . And definatlely chase the threads with a tap and or helicoil once you get the bolt out .

Oh and center punch before you drill into broken bolt . No need to pull cylinder head you will be wasting your time and money if you do and no do not weld onto it the aluminum will melt first from the heat and you will have a bigger problem .

Oh and center punch before you drill into broken bolt . No need to pull cylinder head you will be wasting your time and money if you do and no do not weld onto it the aluminum will melt first from the heat and you will have a bigger problem .

X2 on the center-punch before drilling. Easy outs don't work when they are grabbing the hole you're trying to remove the bolt from.

X2 on the not pulling the head either. Rag in ports (all of them) and tape over the rag. Don't forget them in there. Shop-vac everything before installing intake.

#19

I even checked a stock head. All of them go right through.

I even checked a stock head. All of them go right through. Again, see if you have access to a welder. Just make sure everything is covered up. I've done this to bigger bolts stuck in aluminum, you won't melt it. Just build up a bunch of small tack welds so that you have a "shaft" to weld a small nut to from the inside.

That, or the trick mentioned in the 2nd post.