Rebuilding 210K Mile LQ4 - Have a couple questions

#1

I am swapping a 2001 LQ4 into a 1970 Chevelle. I have been keeping a build thread on the Team Chevelle forums but I figured I could get better LSX related answers here.

The motor has 210,000 miles on it so I am doing a full rebuild. The machine shop is cleaning and honing the motor and doing the valve seats on the heads. (There is almost no detectable ridge on the cylinder walls even after that many miles which is simply amazing to me.) I have been looking at Rock Auto for all of the gaskets and bearings because they seem to have the best prices. I just have a few questions about a couple parts. I know that most of the gaskets are supposed to be reusable but I figure after 200k miles it's a pretty good idea to replace them, right?

1. Does Fel-Pro make decent gaskets for LS engines?

2. How are Clevite's main, rod, and cam bearings? I have heard that certain aftermarket bearings don't have as tight of clearances as the factory bearings which causes low oil pressure. Is this something I should be worried about?

3. I do not plan on revving this engine past 6500 rpm (actually it will probably rarely see anything past 5500) so I don't see a reason to upgrade the rod bolts. However, since the motor has such high mileage, should I be worried about the rod bolts being stressed or worn?

4. Is anyone familiar with DNJ Engine Components? Their piston rings are half the price of the Sealed Power rings but are they the same quality?

Thats all I can think of for now but I am sure I will have further questions. If anyone is interested in seeing my progress, my build thread can be seen here: http://www.chevelles.com/forums/showthread.php?t=346452

Thank you,

David

The motor has 210,000 miles on it so I am doing a full rebuild. The machine shop is cleaning and honing the motor and doing the valve seats on the heads. (There is almost no detectable ridge on the cylinder walls even after that many miles which is simply amazing to me.) I have been looking at Rock Auto for all of the gaskets and bearings because they seem to have the best prices. I just have a few questions about a couple parts. I know that most of the gaskets are supposed to be reusable but I figure after 200k miles it's a pretty good idea to replace them, right?

1. Does Fel-Pro make decent gaskets for LS engines?

2. How are Clevite's main, rod, and cam bearings? I have heard that certain aftermarket bearings don't have as tight of clearances as the factory bearings which causes low oil pressure. Is this something I should be worried about?

3. I do not plan on revving this engine past 6500 rpm (actually it will probably rarely see anything past 5500) so I don't see a reason to upgrade the rod bolts. However, since the motor has such high mileage, should I be worried about the rod bolts being stressed or worn?

4. Is anyone familiar with DNJ Engine Components? Their piston rings are half the price of the Sealed Power rings but are they the same quality?

Thats all I can think of for now but I am sure I will have further questions. If anyone is interested in seeing my progress, my build thread can be seen here: http://www.chevelles.com/forums/showthread.php?t=346452

Thank you,

David

Trending Topics

#9

I ended up getting the cam bearings for the machine shop, although I can't remember what brand they are now haha. I am going to order most of the parts tonight since northern auto parts has a 12% off sale. I am going with Clevite 77 bearings, Mahle rings, and mostly Fel-pro gaskets. I do still have a couple questions though.

I never got a response to my question about the stock rod bolts being fatigued after 210k miles. I would like to know if that is something I should worry about.

The machinist told me that he did not have to grind the crankshaft down because it was still within spec. I am going to plasti-gauge the clearances anyway when I assemble the motor. As long as the clearances are on the tight side of the acceptable range, I am just going to use a new stock melling oil pump. However, if the clearances are on the looser side, I am going to get a high pressure/volume oil pump to make up for that. Does that sound like a decent plan?

Thanks again,

David

I never got a response to my question about the stock rod bolts being fatigued after 210k miles. I would like to know if that is something I should worry about.

The machinist told me that he did not have to grind the crankshaft down because it was still within spec. I am going to plasti-gauge the clearances anyway when I assemble the motor. As long as the clearances are on the tight side of the acceptable range, I am just going to use a new stock melling oil pump. However, if the clearances are on the looser side, I am going to get a high pressure/volume oil pump to make up for that. Does that sound like a decent plan?

Thanks again,

David

#10

TECH Enthusiast

iTrader: (17)

for the rod bolts since it wont see high RPM's it not really neccessary. But for piece of mind I would. I mean your going threw all this trouble to rebuild it why not spend another

$90 and get piece of mind and not have to worry about anything. Rod bolts are one of the weakest points in a LS motor in my book exspecially if its going to see any kind of High RPM's. So yes in my book

$90 and get piece of mind and not have to worry about anything. Rod bolts are one of the weakest points in a LS motor in my book exspecially if its going to see any kind of High RPM's. So yes in my book

#11

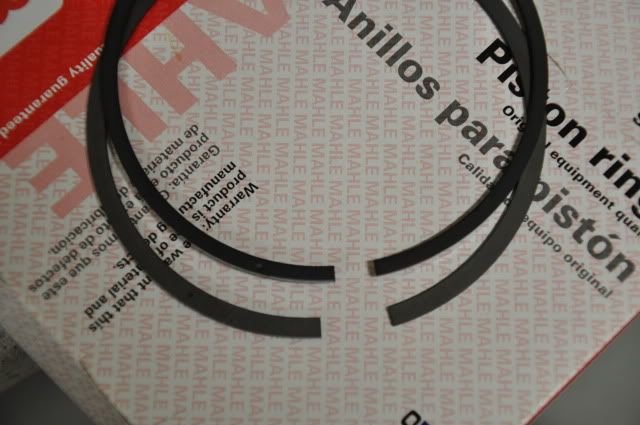

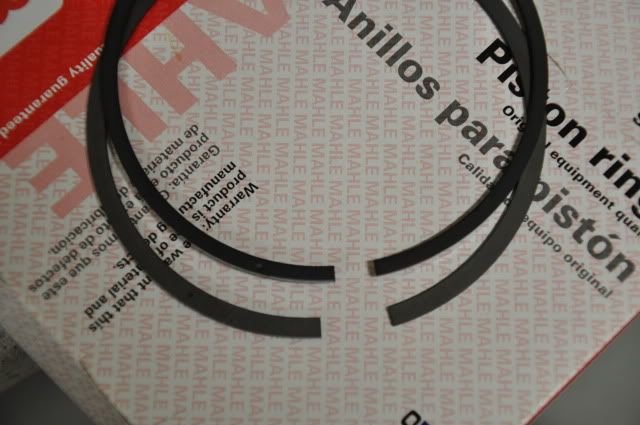

I got all of the parts for the engine. I ended up getting Mahle piston rings but they didn't say which ones were for the first and second position. Does anyone know which is which? The dark one in the second pic has small bevels on the top and bottom of the inside face. The wider, lighter one has a larger bevel on the bottom. Also, what is the recommended orientation for the gaps? Usually it seems like the compression rings are 180 degrees apart.

#12

TECH Fanatic

iTrader: (8)

Join Date: Nov 2009

Location: phx the cactus patch

Posts: 1,095

Likes: 0

Received 13 Likes

on

13 Posts

It appears that none of those compression rings is chrome plated . Usually the top narrower compression ring is chrome plated in these LS based engines . You're rod bolts will work just fine . Have You measured the piston to bore with a feeler gauge . I'd be surprised if it was still in specs as there is only .001" of wear until out of specs . With that many miles I'm pretty sure You're cylinders have worn maybe .003 which even though the pistons may be almost the same size as they were new , the cylinder walls most likely are'nt . Good luck

#13

11 Second Club

iTrader: (2)

The ring with a bevel on the bottom only (small dot on top side) WILL be the

secondary compression ring which I locate @ 6 o'clock (bottom or EX. side)

of the piston....then put primary gap @ 12 o'clock (top or IN. side) away

from spark plug. Also make sure bores are thoroughly clean before assembly

and lightly dampen the skirts, rings, and bores with dexron for break-in.

secondary compression ring which I locate @ 6 o'clock (bottom or EX. side)

of the piston....then put primary gap @ 12 o'clock (top or IN. side) away

from spark plug. Also make sure bores are thoroughly clean before assembly

and lightly dampen the skirts, rings, and bores with dexron for break-in.

#14

Moderator

iTrader: (20)

I never got a response to my question about the stock rod bolts being fatigued after 210k miles. I would like to know if that is something I should worry about.

The machinist told me that he did not have to grind the crankshaft down because it was still within spec. I am going to plasti-gauge the clearances anyway when I assemble the motor. As long as the clearances are on the tight side of the acceptable range, I am just going to use a new stock melling oil pump. However, if the clearances are on the looser side, I am going to get a high pressure/volume oil pump to make up for that. Does that sound like a decent plan?

Thanks again,

David

The machinist told me that he did not have to grind the crankshaft down because it was still within spec. I am going to plasti-gauge the clearances anyway when I assemble the motor. As long as the clearances are on the tight side of the acceptable range, I am just going to use a new stock melling oil pump. However, if the clearances are on the looser side, I am going to get a high pressure/volume oil pump to make up for that. Does that sound like a decent plan?

Thanks again,

David

The clearances, though, I would prefer to set to the looser side of the spec. You can run into trouble a lot faster with too tight of a bearing clearance than too loose. Clevite recommends .001" of clearance per 1" of shaft diameter as a safe starting point, and adding .0005" for an extra margin of safety.

Also, I haven't used Clevites in some time, but I rememeber them always being extra tight on the #3 main bearing.

#15

The ring with a bevel on the bottom only (small dot on top side) WILL be the

secondary compression ring which I locate @ 6 o'clock (bottom or EX. side)

of the piston....then put primary gap @ 12 o'clock (top or IN. side) away

from spark plug. Also make sure bores are thoroughly clean before assembly

and lightly dampen the skirts, rings, and bores with dexron for break-in.

secondary compression ring which I locate @ 6 o'clock (bottom or EX. side)

of the piston....then put primary gap @ 12 o'clock (top or IN. side) away

from spark plug. Also make sure bores are thoroughly clean before assembly

and lightly dampen the skirts, rings, and bores with dexron for break-in.

Also, by dextron do you mean automatic transmission fluid?

Last edited by dlabooda; 09-18-2011 at 09:07 PM.

#16

I installed the cam and the timing chain. I ordered a new LS2 chain and there seems to be a lot of slack. Most people say that it is normal but after rotating the crankshaft a few times, the timing marks don't line up anymore. Is there a method to installing the chain so that there is no slack on the side that is being pulled on?

#17

11 Second Club

iTrader: (2)

Yes on trans fluid...has natural detergents yet lubes during break in

Also the replacement chain does have some slop because the GM robots

were unable to install on new engines when they were tighter. Since it is

a true single roller design, once it's operating and bathed in oil it tightens

slightly....no worries

#18

I've gotten the rotating assembly done and one head installed. The other head gasket looked like it had been installed before so I sent it back to have it exchanged. A picked a Comp cams rocker trunion bearing upgrade kit and I had a quick question before I installed the kit.

Should I be concerned about any excessive wear on the rockers or push rods because of the high mileage? I included a picture of one of the rockers but I am not sure if that would help any.

Should I be concerned about any excessive wear on the rockers or push rods because of the high mileage? I included a picture of one of the rockers but I am not sure if that would help any.

#19

TECH Enthusiast

iTrader: (11)

Join Date: Aug 2009

Location: Michigan

Posts: 749

Likes: 0

Received 0 Likes

on

0 Posts

just curious, did you get this all together? How did those Mahle rings work out for you? Need much filing?

And also curious how much cylinder wear there was at that mileage, did you ever compare it to piston size?

And also curious how much cylinder wear there was at that mileage, did you ever compare it to piston size?

#20

The machinist never gave me any numbers but he did say they were well within spec. I could still see 80% of the factory cross hatching when I tore into it and those marks are not deep at all to begin with.