Starting an Lq4 build

#101

TECH Enthusiast

Thread Starter

iTrader: (7)

Join Date: Jan 2011

Location: Longbeach, CA

Posts: 590

Likes: 0

Received 0 Likes

on

0 Posts

Ah the holiday season... when every bill is due, gas is more expensive, and travel is at an all time high.

I usually like to make things worse around this time of year as well because it's the time of year I start looking at big ticket items.. cars, houses.. my camaro was purchased in march of last year, after looking from around now until then, to find one in my price range.

this year i'm looking at building a shop. 24x25, 12' legs, 2 10x10 doors, 12 ga steel metal building. This will cost a pretty penny and I don't even know if it's possible yet. As such, the LQ4 is on a bit of a back burner until I get some final costs/feasibility analysis completed on this shop.

If I do get the shop put in, I can do the motor swap in house most likely, as I'll have more room height wise. I'd also like to get a 4 post hydraulic lift, which would make this MUCH easier to do myself.. but I don't know that this project can be on hold that long.

Next major purchases for the motor are gonna be an ls6 valley plate, new gasket, lifters and trays, and maybe heads.. depends on a LOT of factors.

I usually like to make things worse around this time of year as well because it's the time of year I start looking at big ticket items.. cars, houses.. my camaro was purchased in march of last year, after looking from around now until then, to find one in my price range.

this year i'm looking at building a shop. 24x25, 12' legs, 2 10x10 doors, 12 ga steel metal building. This will cost a pretty penny and I don't even know if it's possible yet. As such, the LQ4 is on a bit of a back burner until I get some final costs/feasibility analysis completed on this shop.

If I do get the shop put in, I can do the motor swap in house most likely, as I'll have more room height wise. I'd also like to get a 4 post hydraulic lift, which would make this MUCH easier to do myself.. but I don't know that this project can be on hold that long.

Next major purchases for the motor are gonna be an ls6 valley plate, new gasket, lifters and trays, and maybe heads.. depends on a LOT of factors.

#104

10 Second Club

Keep seeing these L92/LS3 heads ....where to get them complete ?

Just put my name on an LQ4...was at machine shop for "approx" quote today on doing the machining.

Going to be a carbed set-up....want 550+ and 10's :o

Following closely

Just put my name on an LQ4...was at machine shop for "approx" quote today on doing the machining.

Going to be a carbed set-up....want 550+ and 10's :o

Following closely

#105

TECH Enthusiast

Thread Starter

iTrader: (7)

Join Date: Jan 2011

Location: Longbeach, CA

Posts: 590

Likes: 0

Received 0 Likes

on

0 Posts

A thought occurs..

if I run TSP's stage 3 LS6 heads and this 233/239 cam on the "stock" dished pistons, will I run into clearance issues and have to flycut? I already have the cam so I hate to back down now, I SUPPOSE one of the shops around here could do that, but no idea what it'd cost.

if I run TSP's stage 3 LS6 heads and this 233/239 cam on the "stock" dished pistons, will I run into clearance issues and have to flycut? I already have the cam so I hate to back down now, I SUPPOSE one of the shops around here could do that, but no idea what it'd cost.

#106

TECH Fanatic

iTrader: (24)

A common misconception is that the dish on an lq4 piston allows better ptv clearance. However the outer edge of the piston that is not dished will come into contact with stock valves the same as a flat top piston.

I believe the problem with ptv clearance with the stg 3 prc's is the larger intake valve. I think you'll be running real close with that cam if there is no milling. If they are milled, you might have problems. If the engine is on the stand, it's. It hard at all to flycut. I had to cut the intake side on my lq4 and it only took about an hour and a half. Search for a thread called "flycutting on the cheap" or something like that.

I believe the problem with ptv clearance with the stg 3 prc's is the larger intake valve. I think you'll be running real close with that cam if there is no milling. If they are milled, you might have problems. If the engine is on the stand, it's. It hard at all to flycut. I had to cut the intake side on my lq4 and it only took about an hour and a half. Search for a thread called "flycutting on the cheap" or something like that.

#107

TECH Enthusiast

Thread Starter

iTrader: (7)

Join Date: Jan 2011

Location: Longbeach, CA

Posts: 590

Likes: 0

Received 0 Likes

on

0 Posts

I don't trust myself to do such things. If it needs it, I'll need to buy all the components first yea? heads lifters rockers pushrods, then, if it needs it, take it to a machine shop to have it done?

kind of annoying... but I have to get the compression up to make any reasonable power with this motor.

I will need to mill the heads to get the compression up. These dished pistons are really hurting this project I think, but it's not practical to do anything about that.

kind of annoying... but I have to get the compression up to make any reasonable power with this motor.

I will need to mill the heads to get the compression up. These dished pistons are really hurting this project I think, but it's not practical to do anything about that.

#108

TECH Enthusiast

Thread Starter

iTrader: (7)

Join Date: Jan 2011

Location: Longbeach, CA

Posts: 590

Likes: 0

Received 0 Likes

on

0 Posts

Yea, sounds like it will need flycutting if I'm going to go with TSP's stage 3 LS6 head.

I shoulda sucked it up and paid the ~$2500 for an LQ9. These dished pistons are the bane of my existence.

Either way, I've contacted a shop to see what they charge for having the pistons flycut. I'm not even sure how you do that on an LQ4 since the valve relief will have to be right around where the dish curve is located. It could be a tricky cut. Anyone have a pic of a flycut dished piston?

It doesn't sound like going with anything that DOESN'T require flycutting will meet my power goals either. Seemed like TSP wasn't even sure even with the stage 3 Ls6 heads that it'd get 400 to the wheels.. but I'm not sure what more I can do without going into the bottom end to beef it up.

I shoulda sucked it up and paid the ~$2500 for an LQ9. These dished pistons are the bane of my existence.

Either way, I've contacted a shop to see what they charge for having the pistons flycut. I'm not even sure how you do that on an LQ4 since the valve relief will have to be right around where the dish curve is located. It could be a tricky cut. Anyone have a pic of a flycut dished piston?

It doesn't sound like going with anything that DOESN'T require flycutting will meet my power goals either. Seemed like TSP wasn't even sure even with the stage 3 Ls6 heads that it'd get 400 to the wheels.. but I'm not sure what more I can do without going into the bottom end to beef it up.

#109

TECH Fanatic

iTrader: (24)

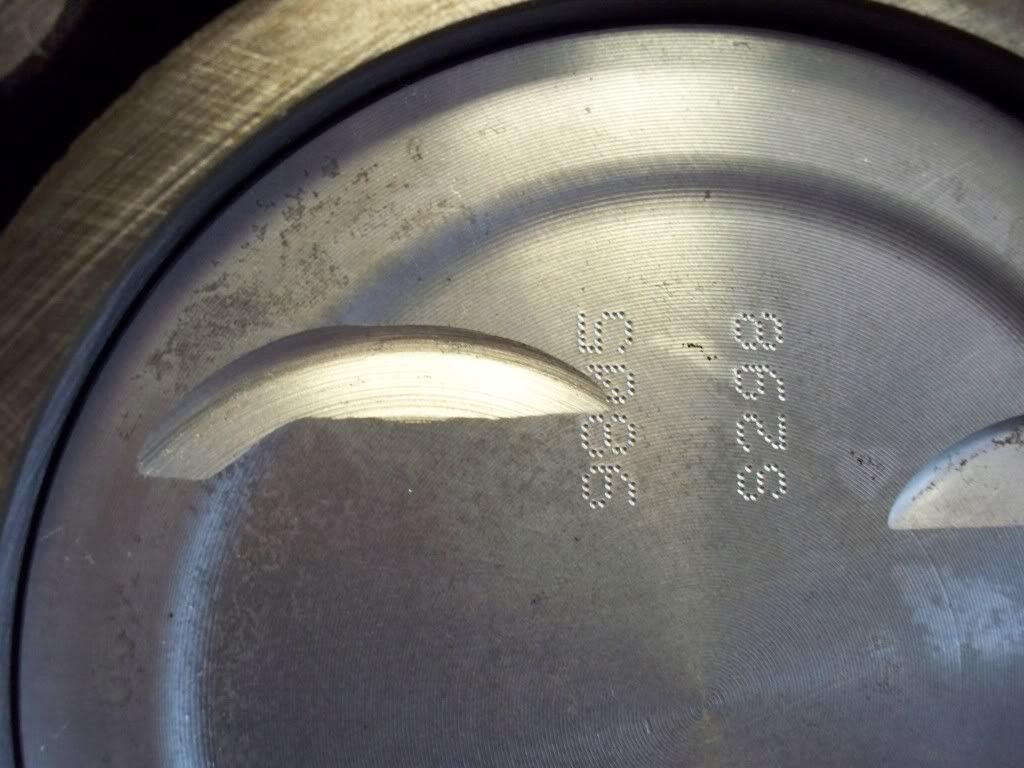

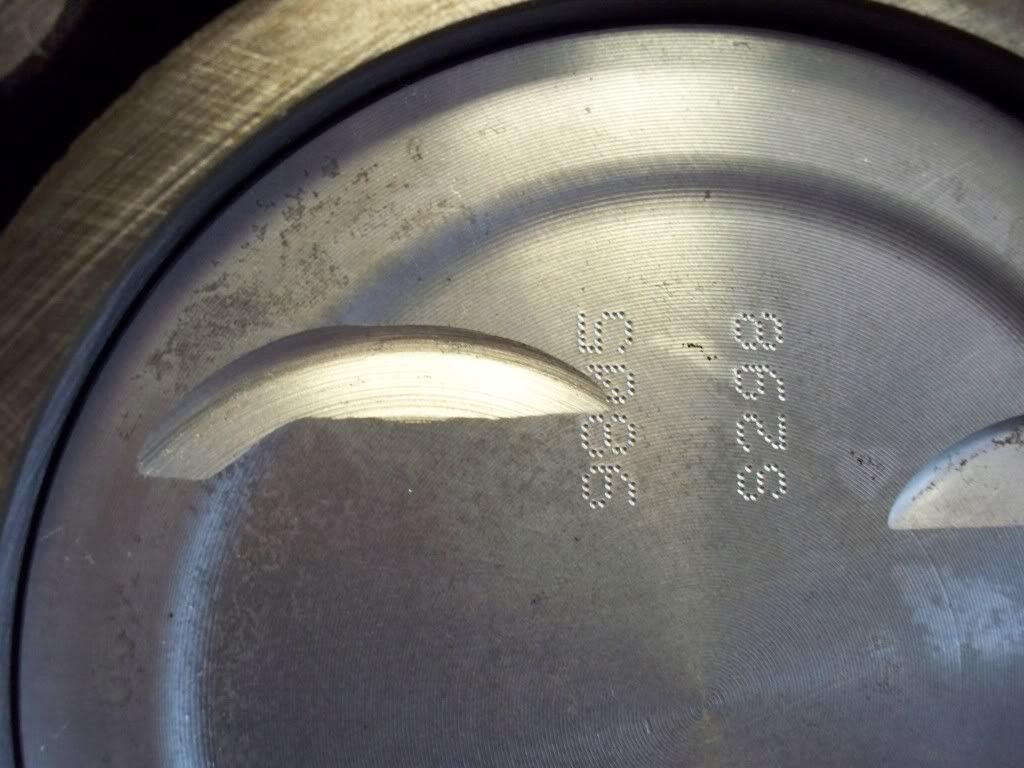

Here's a pic of mine that I did.

I just bought a 2.08 intake valve and used a junk '98 head. I put the valve in the head, snugged up 4 bolts around the piston I was working on (taped everything up), and placed adhesive backed sandpaper on the valve. Use a lock ring and tighten it above the valve seal the distance you want to cut into the piston (use feeler gauge). Then put an electric drill on the valve and drilled away until the lock ring hit the valve seal.

I just bought a 2.08 intake valve and used a junk '98 head. I put the valve in the head, snugged up 4 bolts around the piston I was working on (taped everything up), and placed adhesive backed sandpaper on the valve. Use a lock ring and tighten it above the valve seal the distance you want to cut into the piston (use feeler gauge). Then put an electric drill on the valve and drilled away until the lock ring hit the valve seal.

#110

TECH Enthusiast

Thread Starter

iTrader: (7)

Join Date: Jan 2011

Location: Longbeach, CA

Posts: 590

Likes: 0

Received 0 Likes

on

0 Posts

yea, I was just re-reading your thread. 799s? Aren't those Ls6 heads? are they stock?

I spotted a guy in for sale claiming 420WHP on a cam only LQ4. (232/234 even.. not that aggressive.)

https://ls1tech.com/forums/vehicle-c...s-mods-sc.html

that guy.

He's claiming 11.0 with a 75 shot, the cynical side of me doesn't believe one bit of it.

I was leaning toward the Ls6 stage 3 heads by TSP, got a friend pushing me to 5.3s.. says it's better for midrange, since the car will be 99.99999999999999% street driving.

not sure yet what to do.

got a quick response from the guys at HPS, flycutting isn't that expensive, so if it's needed, and they do it right, it's perfectly find if it's required.

I spotted a guy in for sale claiming 420WHP on a cam only LQ4. (232/234 even.. not that aggressive.)

https://ls1tech.com/forums/vehicle-c...s-mods-sc.html

that guy.

He's claiming 11.0 with a 75 shot, the cynical side of me doesn't believe one bit of it.

I was leaning toward the Ls6 stage 3 heads by TSP, got a friend pushing me to 5.3s.. says it's better for midrange, since the car will be 99.99999999999999% street driving.

not sure yet what to do.

got a quick response from the guys at HPS, flycutting isn't that expensive, so if it's needed, and they do it right, it's perfectly find if it's required.

#111

TECH Fanatic

iTrader: (24)

799's are the same as 243's. Mine are stock, but milled .030. I can see 420whp on a happy dyno with a light drivetrain (even though his is an auto). But at 420whp....he should be trapping 121mph without the nitrous. 11.0 with that 60' and a 75 shot sounds about right. I've done 11.8@117, and that's with a high 1.6, and I still can get a little more out of her. A 75 shot would definitely put me close to 11.0's.

#114

TECH Enthusiast

Thread Starter

iTrader: (7)

Join Date: Jan 2011

Location: Longbeach, CA

Posts: 590

Likes: 0

Received 0 Likes

on

0 Posts

well I'm also running a bit larger piston since the engine is bored over .020, but.. isn't yours as well? I know you had it rebuilt.

The compression numbers I've gotten on this motor have varied a good bit from everyone else's calculations.. mainly cos I don't think we really know the dish on these pistons.. and I lack the brains to find out myself. I wish I had flat tops tbh.. but it's VERY costly at this point to do that...and probably won't make a huge difference in power to validate the $2-3k worth of work it would take to do it. is 20-30whp worth $2-3k to re-do the bottom end of this engine? I think it'd just slow me down on getting this thing done tbh.

The compression numbers I've gotten on this motor have varied a good bit from everyone else's calculations.. mainly cos I don't think we really know the dish on these pistons.. and I lack the brains to find out myself. I wish I had flat tops tbh.. but it's VERY costly at this point to do that...and probably won't make a huge difference in power to validate the $2-3k worth of work it would take to do it. is 20-30whp worth $2-3k to re-do the bottom end of this engine? I think it'd just slow me down on getting this thing done tbh.

#115

TECH Enthusiast

Thread Starter

iTrader: (7)

Join Date: Jan 2011

Location: Longbeach, CA

Posts: 590

Likes: 0

Received 0 Likes

on

0 Posts

http://texas-speed.com/p-1163-prc-22...der-heads.aspx

I suppose those are also a possibility.

I have 2 parts of this equation already.

A "stock" Lq4 bottom end machined .020 over, ~40k miles of life already sucked out of it from a cab n chassis truck from acworth GA

a TSP 233/239 cam with just over .650" lift (iirc..) and 114 LSA

The final part of this equation is the top end, heads, intake, injectors, TB. It's easy to just say I'll throw a fast 102/102 combo at it, but I want to do whats' best for my application, so I'm not really counting this, tho it is the default at the moment. injectors.. I have no idea what to do there.

So heads are the next important desicion.. they're really the make or break at this point I suppose, and are the part that requires the most planning, especially now that I already have the cam.

If I have to have the flycutting done, whatever.. all I need is a junk tire and some ratchet straps to take it down the road to have that done, so that's not a deal breaker thankfully.

My thoughts SHOULD be in every decision on this build about application. Where will I be using this car the most?

well.. 99% of my driving is 0-35mph.

but aside from that the takeaway is that this is a street car, so most of my power needs to be in a usable range... no 7000rpm peak performance numbers.

I was thinking about, for longevity.. asking the tuner to set a 5800-6200 rpm redline on the tune to prevent it from damaging itself should my foot "accidentally" become very heavy on a few occasions. I don't know that this "stock" rotating assembly with so much wear on it can take reving any higher than that.

I suppose those are also a possibility.

I have 2 parts of this equation already.

A "stock" Lq4 bottom end machined .020 over, ~40k miles of life already sucked out of it from a cab n chassis truck from acworth GA

a TSP 233/239 cam with just over .650" lift (iirc..) and 114 LSA

The final part of this equation is the top end, heads, intake, injectors, TB. It's easy to just say I'll throw a fast 102/102 combo at it, but I want to do whats' best for my application, so I'm not really counting this, tho it is the default at the moment. injectors.. I have no idea what to do there.

So heads are the next important desicion.. they're really the make or break at this point I suppose, and are the part that requires the most planning, especially now that I already have the cam.

If I have to have the flycutting done, whatever.. all I need is a junk tire and some ratchet straps to take it down the road to have that done, so that's not a deal breaker thankfully.

My thoughts SHOULD be in every decision on this build about application. Where will I be using this car the most?

well.. 99% of my driving is 0-35mph.

but aside from that the takeaway is that this is a street car, so most of my power needs to be in a usable range... no 7000rpm peak performance numbers.

I was thinking about, for longevity.. asking the tuner to set a 5800-6200 rpm redline on the tune to prevent it from damaging itself should my foot "accidentally" become very heavy on a few occasions. I don't know that this "stock" rotating assembly with so much wear on it can take reving any higher than that.

#116

TECH Fanatic

iTrader: (24)

Those are nice heads but I don't think you need them for what you want. To keep budget and longetivity in mind, just stick with 799 heads. Even if you don't get them milled, they'll put you at about stock ls1 compression ratio of 10:1. Get a decent size cam in the mid/low 230's, and I'm sure you'd hit your goal of 400. I basically put down 400whp, but that was through a heavy, heavy drivetrain and an engine with only 50 miles.

Just don't over think things!

Just don't over think things!

#117

Teching In

iTrader: (2)

Join Date: Sep 2010

Location: Wilkes-Barre PA

Posts: 8

Likes: 0

Received 0 Likes

on

0 Posts

Glad to hear you are back on track with the LQ4 build. I'm am currently working on my own build with the same block for my 89 IROC. Taking the short block to the machine shop to have them hot tank and go over everything before final assembly. I went with the TSP torquer V2 cam and PRC stage 2.5 5.3 heads that were just delivered today (my own Christmas presents). My build is on a slight budget, but don't want to cut any corners. I've learned that you get what you pay for and patience over the past few months has given me a chance to get a lot of great deals both here on tech and ebay. Wish you luck with the rest of your build and will check in to see how you are making out.

#118

TECH Enthusiast

Thread Starter

iTrader: (7)

Join Date: Jan 2011

Location: Longbeach, CA

Posts: 590

Likes: 0

Received 0 Likes

on

0 Posts

Yea, I'm on the fence with heads.

I want ot make sure I get the best bang out of this, and not necessarily "for the buck." 5.3 heads are pretty cheap. I think TSP's stage 2.5 heads are around $1300, the Ls6 stage 3s are about $1900, and the PRC 255s are about $3k.

The way I look at it, I want 400whp to be the floor, not necessarily the target. I'll be happy with 400, but more happy with 420,450, 480 etc.

One thing a friend of mine has mentioned is port velocity. If you run too large an intake you risk having your torque curve moved much higher. Since i'm going to daily drive the car, I want to keep it 3-4k range, so I will need to lean toward a smaller valve I'd think for that reason. When I get the money, I'll call up TSP and see what they have to say on the topic as well. Certainly, they're not the final authority on engines, but I trust their opinion, especially since I'll probably be buying from them and the cam came from them.

I weas reading a thread earlier, a guy ran PRC 255s, a fast 102/102 combo on his 346. He was pulling 447whp iirc. Not bad, but he seemed disappointed. The consensus from other members was the port velocity issue and the fact that he was basically going "too big" on the top end. Given, I have a bit more motor here than he did, but it's still no monster.

I want ot make sure I get the best bang out of this, and not necessarily "for the buck." 5.3 heads are pretty cheap. I think TSP's stage 2.5 heads are around $1300, the Ls6 stage 3s are about $1900, and the PRC 255s are about $3k.

The way I look at it, I want 400whp to be the floor, not necessarily the target. I'll be happy with 400, but more happy with 420,450, 480 etc.

One thing a friend of mine has mentioned is port velocity. If you run too large an intake you risk having your torque curve moved much higher. Since i'm going to daily drive the car, I want to keep it 3-4k range, so I will need to lean toward a smaller valve I'd think for that reason. When I get the money, I'll call up TSP and see what they have to say on the topic as well. Certainly, they're not the final authority on engines, but I trust their opinion, especially since I'll probably be buying from them and the cam came from them.

I weas reading a thread earlier, a guy ran PRC 255s, a fast 102/102 combo on his 346. He was pulling 447whp iirc. Not bad, but he seemed disappointed. The consensus from other members was the port velocity issue and the fact that he was basically going "too big" on the top end. Given, I have a bit more motor here than he did, but it's still no monster.

#119

TECH Enthusiast

Thread Starter

iTrader: (7)

Join Date: Jan 2011

Location: Longbeach, CA

Posts: 590

Likes: 0

Received 0 Likes

on

0 Posts

Just spoke with TSP on the topic of heads. They had recommended the PRC237s as the "best choice" head for this application.

@ 62CC chambers he was estimating just squeaking past 400whp out of this. I'm not sure what's holding this configuration back. Not that I'm really looking for more, just trying to use this as an opportunity to learn if nothing else in breaking the 400whp mark. 400 is a floor, certainly not a ceiling. If I can only achieve the minimum I have much to learn.

When trying to peg down what the limiting factor in this motor's case was, I didn't really get a definite answer. Obviously, the engine is limited by what kind of forces the rotating assembly can tolerate, but bottom end strength is not what I'm talking about in this case. I mean.. what factor in my configuration is wrong? What prevents this from being a 450,500,600hp motor? Can that even be done @ 11 compression and 4" bore?

I'll know in a few days how soon the heads are coming. If things don't work out as I anticipated I will probably just go ahead and get my lifters and trays, my valley tray and cover for an ls6 pvc setup, and just leave it at that and tackle heads later.

@ 62CC chambers he was estimating just squeaking past 400whp out of this. I'm not sure what's holding this configuration back. Not that I'm really looking for more, just trying to use this as an opportunity to learn if nothing else in breaking the 400whp mark. 400 is a floor, certainly not a ceiling. If I can only achieve the minimum I have much to learn.

When trying to peg down what the limiting factor in this motor's case was, I didn't really get a definite answer. Obviously, the engine is limited by what kind of forces the rotating assembly can tolerate, but bottom end strength is not what I'm talking about in this case. I mean.. what factor in my configuration is wrong? What prevents this from being a 450,500,600hp motor? Can that even be done @ 11 compression and 4" bore?

I'll know in a few days how soon the heads are coming. If things don't work out as I anticipated I will probably just go ahead and get my lifters and trays, my valley tray and cover for an ls6 pvc setup, and just leave it at that and tackle heads later.

#120

Launching!

iTrader: (1)

Join Date: Apr 2011

Location: Adamsville Tennessee

Posts: 231

Likes: 0

Received 0 Likes

on

0 Posts

My .02, Determine whether you really need this much HP. I for one decided to go turbo on my lq4. I have forged pistons, connecting rods with a stock crank that has been balanced. I didn't think about how much hp I would want I just wanted it bad a$$. If I could go back and start over I would have just put new mains in, rod bolts and cam, head swap. Oh and ls6 intake. The lq4/9 are great engines by themselves! If i was in your shoes I'd just put a good valve train set-up on it and call it done, and replace the mains and call it done. A good tune and you should see near 400 IMO. I'm still in the stages of finishing mine I figure another year because I set my goals so high and parts are so expensive. Plus mine is going into an old car.

Just my .02 lol, If i would have spent the money that I used in my engine elsewhere in my car, I'd probably be driving it now instead of daydreaming about it!!

Good luck with whatever you decide to do!

Just my .02 lol, If i would have spent the money that I used in my engine elsewhere in my car, I'd probably be driving it now instead of daydreaming about it!!

Good luck with whatever you decide to do!