ARP Head Stud Instructions

#1

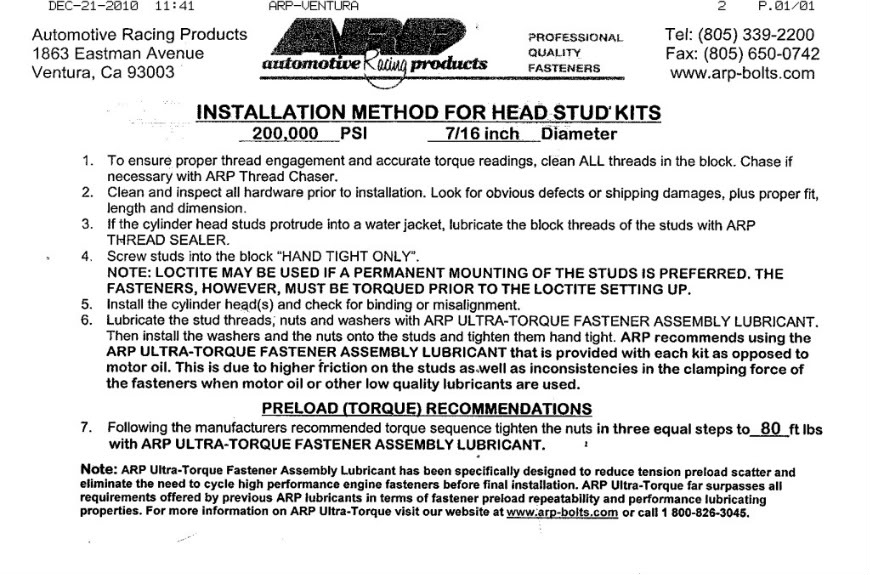

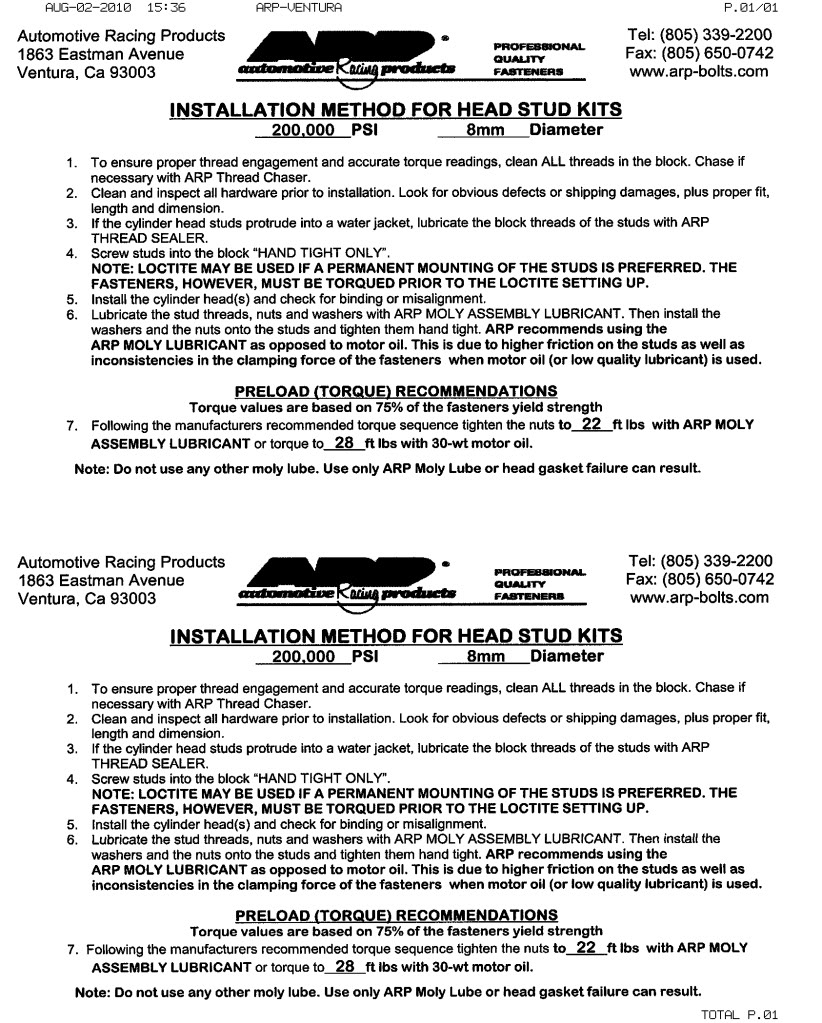

I'm seeing inconsistencies with ARP instructions. I was told the torque for the nuts is 80ftlbs, but someone a while ago said the torque was less for an Aluminum block. Does anyone have their instructions handy?

ARP website doesnt have specific instructions for 234-4317, they seem to be general.

ARP website doesnt have specific instructions for 234-4317, they seem to be general.

#2

TECH Junkie

iTrader: (2)

Join Date: Jan 2006

Location: Fort Wayne, IN

Posts: 3,776

Likes: 0

Received 0 Likes

on

0 Posts

I'm seeing inconsistencies with ARP instructions. I was told the torque for the nuts is 80ftlbs, but someone a while ago said the torque was less for an Aluminum block. Does anyone have their instructions handy?

ARP website doesnt have specific instructions for 234-4317, they seem to be general.

ARP website doesnt have specific instructions for 234-4317, they seem to be general.

#4

TECH Junkie

iTrader: (11)

I'm seeing inconsistencies with ARP instructions. I was told the torque for the nuts is 80ftlbs, but someone a while ago said the torque was less for an Aluminum block. Does anyone have their instructions handy?

ARP website doesnt have specific instructions for 234-4317, they seem to be general.

ARP website doesnt have specific instructions for 234-4317, they seem to be general.

#7

I torqued a stud to 80lb and stripped a thread in my block a few months ago and had to order that Kent Moore repair kit. I had spent 2 days prior cleaning those threads in the block.

I have only my studs torqued to 72lbs ft.

I have only my studs torqued to 72lbs ft.

Last edited by 427LS7HCI; 04-24-2012 at 02:47 PM.

Trending Topics

#10

ModSquad

iTrader: (6)

If you cleaned those threads with a tap, verses a cleanup tool, you were removing metal. 2 days worth of cleaning...yikes.

#11

My sole purpose for purchasing the Studs were to aviod a stripped thread inicident, but it stripped anyway

Last edited by 427LS7HCI; 04-25-2012 at 10:57 AM.

#12

I used a vaccum with a straw on the end to suck the coolant out the holes, then I used an air compressor to blow out the holes, then I used twisted papers towels to clean the bolt holes, then I used a .45 bore caliber brush to clean the holes, then I blew them out with compressed air again and then I ran a chaser down each hole. I used a flashlight while cleaning to make sure there was absolutely no crud in there, in which I was very meticulous and the entire process was very time consuming as I spent 2 days (4hrs each day) cleaning those bolt holes.