What to do with a 5.3

#1

Teching In

Thread Starter

iTrader: (2)

Join Date: Apr 2011

Location: Biloxi, MS

Posts: 9

Likes: 0

Received 0 Likes

on

0 Posts

I picked up a 5.3 long block for a decent price after I found a crack in my LS1 block. So now I have a complete 5.7L rotating assembly and a good 5.3L long block. I'm looking to build a decent running street engine for my 63 Impala. I plan on using fuel injection with a factory LS1 intake. Any suggestions on which way to go with this?

#3

Teching In

Thread Starter

iTrader: (2)

Join Date: Apr 2011

Location: Biloxi, MS

Posts: 9

Likes: 0

Received 0 Likes

on

0 Posts

Would the stock LS1 pistons and rods be worth using? I'd like to be able to add a single turbo on it later on. Is there a difference in the cc of 5.3L heads and 5.7L to produce an acceptable CR for 8-10lbs of boost?

#4

11 Second Club

iTrader: (6)

Join Date: Feb 2005

Location: middle of nowhere, Kansas

Posts: 1,309

Likes: 0

Received 2 Likes

on

2 Posts

The LS1 rotating assembly is pretty tough, although I would get ARP rod bolts. I would have no problem using the crank and rods for boost. You might consider forged pistons though. Then you could get ones with valve reliefs or a dish. As for combustion chambers, the 5.3 heads are 61cc and the LS1 heads are 66-67cc. I would not use either though. At least get 243 heads (LS6) which are 64cc.

#6

Teching In

Thread Starter

iTrader: (2)

Join Date: Apr 2011

Location: Biloxi, MS

Posts: 9

Likes: 0

Received 0 Likes

on

0 Posts

The pistons seem to be the weakest link in the LS motors from what I've read about them. I think that's the way I'm going to go with this. Might as well get the most out of what I have. At least I have the broken aluminum block to mock everything up with in the car, so that thing can still be somewhat useful.

#7

TECH Resident

iTrader: (12)

I picked up a 5.3 long block for a decent price after I found a crack in my LS1 block. So now I have a complete 5.7L rotating assembly and a good 5.3L long block. I'm looking to build a decent running street engine for my 63 Impala. I plan on using fuel injection with a factory LS1 intake. Any suggestions on which way to go with this?

Trending Topics

#8

Launching!

Join Date: May 2011

Location: Honey Brook, Pa.

Posts: 215

Likes: 0

Received 0 Likes

on

0 Posts

The easiest route might be to leave the 5.3 as is and get a set of 317 heads. They have the 243 ports but a 72cc chamber to lower the compression to 9.5. With 8-10 lbs. of boost on the street you'll be safe. Something to consider!! Larry.

#10

TECH Apprentice

iTrader: (21)

Join Date: Nov 2007

Location: Albuquerque, New Mexico

Posts: 398

Likes: 0

Received 0 Likes

on

0 Posts

Have the bore sonic checked as kossuth suggested and go LS1 bore. Don't use the used LS1 pistons on the fresh bore. Go forged pistons, have the rods resized with ARP bolts, the crank freshened and 72 cc heads. Then go ten pounds without worries. I personally hate to skimp on the bottom end. Just too much work to correct a big bang.

#13

Teching In

Thread Starter

iTrader: (2)

Join Date: Apr 2011

Location: Biloxi, MS

Posts: 9

Likes: 0

Received 0 Likes

on

0 Posts

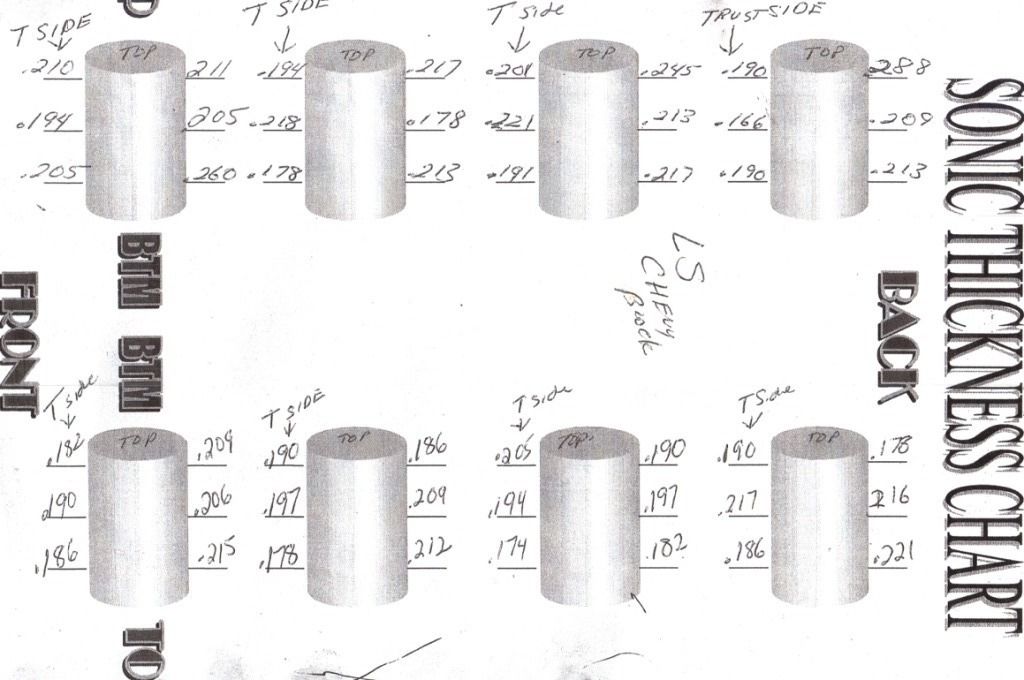

First things first if you are even thinking about building a 5.7 out of it you have got to get the bare block over to a machine well equipped machine shop and figure out if the bore is thick enough to bore it that far. Most are, but I would definately spend the money and make sure it would be ok to bore that far before I bought a single part to build it. It would suck to have the machinist punch through a unknowingly thin wall. It would suck even worse to have a really thin wall and have it collapse/buckle and punch a piston through everything ruining the whole motor.

#14

Teching In

Thread Starter

iTrader: (2)

Join Date: Apr 2011

Location: Biloxi, MS

Posts: 9

Likes: 0

Received 0 Likes

on

0 Posts

Have the bore sonic checked as kossuth suggested and go LS1 bore. Don't use the used LS1 pistons on the fresh bore. Go forged pistons, have the rods resized with ARP bolts, the crank freshened and 72 cc heads. Then go ten pounds without worries. I personally hate to skimp on the bottom end. Just too much work to correct a big bang.

#15

11 Second Club

iTrader: (6)

Join Date: Feb 2005

Location: middle of nowhere, Kansas

Posts: 1,309

Likes: 0

Received 2 Likes

on

2 Posts

I'd probably get Wiseco pistons from Texas Speed.

While having the cylinder walls sonic check is a good idea, the 5.3 block is plenty meaty and almost always will take an overbore to LS1 size. Core shift that was fairly common with the old school small blocks is virtually a thing of the past.

While having the cylinder walls sonic check is a good idea, the 5.3 block is plenty meaty and almost always will take an overbore to LS1 size. Core shift that was fairly common with the old school small blocks is virtually a thing of the past.

#16

TECH Resident

iTrader: (12)

I'd probably get Wiseco pistons from Texas Speed.

While having the cylinder walls sonic check is a good idea, the 5.3 block is plenty meaty and almost always will take an overbore to LS1 size. Core shift that was fairly common with the old school small blocks is virtually a thing of the past.

While having the cylinder walls sonic check is a good idea, the 5.3 block is plenty meaty and almost always will take an overbore to LS1 size. Core shift that was fairly common with the old school small blocks is virtually a thing of the past.

#17

TECH Resident

iTrader: (12)

Here is some good reading on sonic checking. They mention .140" as getting alittle thin. My machinist that checked the motor was comfortable going as thin as .125" being I wasnt boosting or spraying it, but I wasn't even close to that. http://www.popularhotrodding.com/tec...s/viewall.html

#18

11 Second Club

iTrader: (6)

Join Date: Feb 2005

Location: middle of nowhere, Kansas

Posts: 1,309

Likes: 0

Received 2 Likes

on

2 Posts

I said most were thick enough. You showed one example. Show me a hundred blocks with the majority failing. But yeah, I would not bore that block out .125". Again, it's a good idea to have the block sonic tested.