Engine back from machine shop, some concern...

#22

Moderator

iTrader: (20)

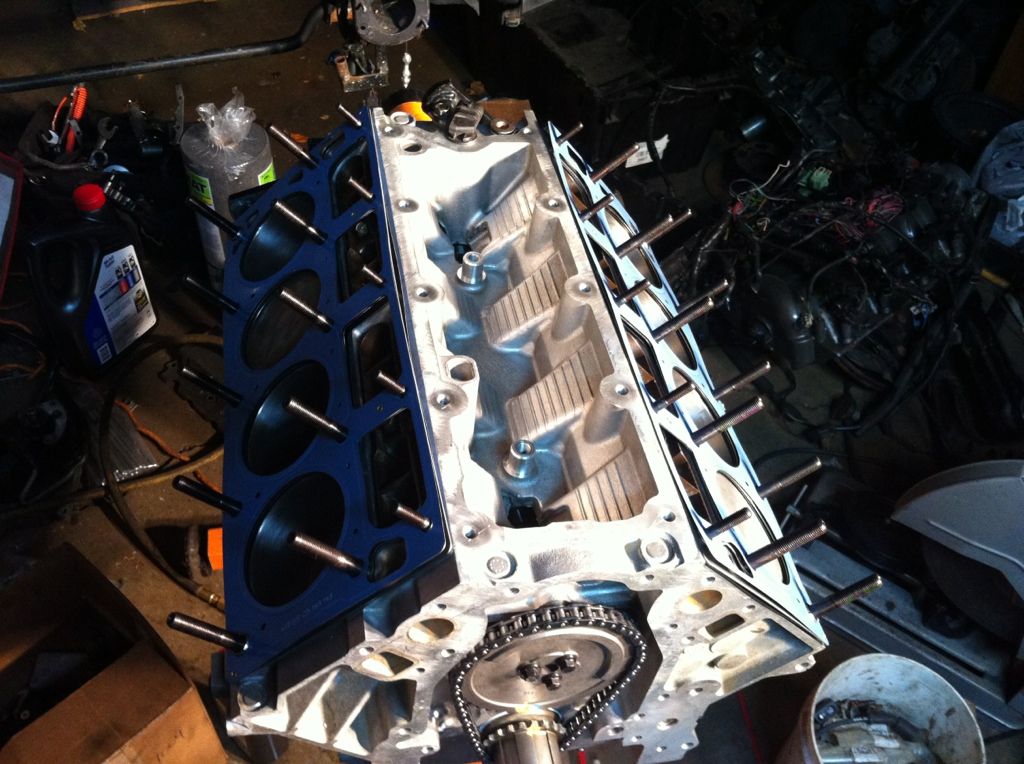

He stopped by last night to tear it down and show me why he moved it one tooth over. Installing the cam "dot to dot" then measures at 126degrees instead of the 110 that its supposed to be at when installed and degreed to the crank. Moving the cam gear one tooth over set the cam to roughly 109/110 degrees with the crank, which is what the cam is labeled and measured at.

Besides physical proof showing tdc and the cams degree during revolution, what makes it wrong besides a dot to dot being incorrect? Ive spoken with texas speed and hes speaking with them today as well to see what the issue could be.

Besides physical proof showing tdc and the cams degree during revolution, what makes it wrong besides a dot to dot being incorrect? Ive spoken with texas speed and hes speaking with them today as well to see what the issue could be.

#24

Thanks for the posts guys. I called him back to recheck his work, we also called texas speed while he was there. All the info they could give was that they use comp cam products and it "didnt sound right". I wouldve preferred a much more in depth reason but, oh well i guess. He remeasured the engine timing again and stood there a bit baffled then said, "im pretty sure its right". That alone showed me that he wasnt 100% sure of his work. Before he left, i also made him reinstall the main caps correct. *smacks forhead* I also reset the time to dot to dot and rolled it over a few times to insure it was ok. Ill likely fire it up tonight.

Last edited by Tony Nichols; 12-12-2012 at 08:49 AM.

#27

11 Second Club

iTrader: (1)

Torquing down fasteners distorts the block, studs and bolts distort the block differently because a bolt has a twisting pull to it where a stud's pull is more linear. Due to this the best way to treat an engine is to do all machining with the type of fastener it will use in service. The factory machined it for bolts, I would only use bolts unless the block is bored/honed oversized with torque plates and studs.

Used to be a time when torque plates were a special "race" sort of treatment but they are standard production use on engines for a long time now, torquing a plate over the bore allows the metal to be distorted as it would be when the head is bolted on.

If you used new pistons and had it bored .005 over with the studs and torque plates, great.

If this guy reused stock pistons no boring and went along with changing from bolts to studs without making you aware it is just more evidence that he should stick to 1970s stuff.

To be clear though this would be a quality of workman ship issue, it wont blowup the engine or anything, the ring seal would just not be as good as it could have been.

Used to be a time when torque plates were a special "race" sort of treatment but they are standard production use on engines for a long time now, torquing a plate over the bore allows the metal to be distorted as it would be when the head is bolted on.

If you used new pistons and had it bored .005 over with the studs and torque plates, great.

If this guy reused stock pistons no boring and went along with changing from bolts to studs without making you aware it is just more evidence that he should stick to 1970s stuff.

To be clear though this would be a quality of workman ship issue, it wont blowup the engine or anything, the ring seal would just not be as good as it could have been.

#30

11 Second Club

iTrader: (1)

who said you "can't" use studs?

I explained why it is not ideal to swap fastener types without remachining, if you have some technical explanation to refute that then by all means enlighten us.

If torquing fasteners didn't affect the block then things like torque plates would not be used and we could use ARP rodbolts without resizing rods etc.

I explained why it is not ideal to swap fastener types without remachining, if you have some technical explanation to refute that then by all means enlighten us.

If torquing fasteners didn't affect the block then things like torque plates would not be used and we could use ARP rodbolts without resizing rods etc.

#31

who said you "can't" use studs?

I explained why it is not ideal to swap fastener types without remachining, if you have some technical explanation to refute that then by all means enlighten us.

If torquing fasteners didn't affect the block then things like torque plates would not be used and we could use ARP rodbolts without resizing rods etc.

I explained why it is not ideal to swap fastener types without remachining, if you have some technical explanation to refute that then by all means enlighten us.

If torquing fasteners didn't affect the block then things like torque plates would not be used and we could use ARP rodbolts without resizing rods etc.

Take a look at an LSx deck tho. 1st look how far away the bolt holes are from the cylinder, 2nd look and see that the holes are seperated from the cylinder wall by a water jacket. Not saying they won't distort, but doesn look like a high probabilty. Because I dont have proof, some research on the net, will confirm alot of people would agree an Aluminum LS block would not be affected by a torque plate. My question is directed back as to prove your supporting evidence.

EDIT: Also keep in mind, the torque is different from using ARP bolts vs OEM TTY....Nobody had reported a problem from my search and TONS have switched over.

Last edited by badazz81z28; 12-12-2012 at 01:51 PM.

#32

Launching!

iTrader: (16)

Join Date: Apr 2007

Location: Harrisburg PA

Posts: 241

Likes: 0

Received 0 Likes

on

0 Posts

one important piece of data missing here... is what installed intake centerline are you asking him to put your LS6 cam in at?

It could very well need a tooth skip on the cam gear. If the degree wheel and dial indicator were used properly...it doesn't lie or make assumptions.

GM cams have strange centerlines and wide splits compared to Comp cams.

I will say though if I were using a stock GM LS6 cam however, I would just stick it in dot to dot and call it a day. I wouldn't even have degreed it

It could very well need a tooth skip on the cam gear. If the degree wheel and dial indicator were used properly...it doesn't lie or make assumptions.

GM cams have strange centerlines and wide splits compared to Comp cams.

I will say though if I were using a stock GM LS6 cam however, I would just stick it in dot to dot and call it a day. I wouldn't even have degreed it

#33

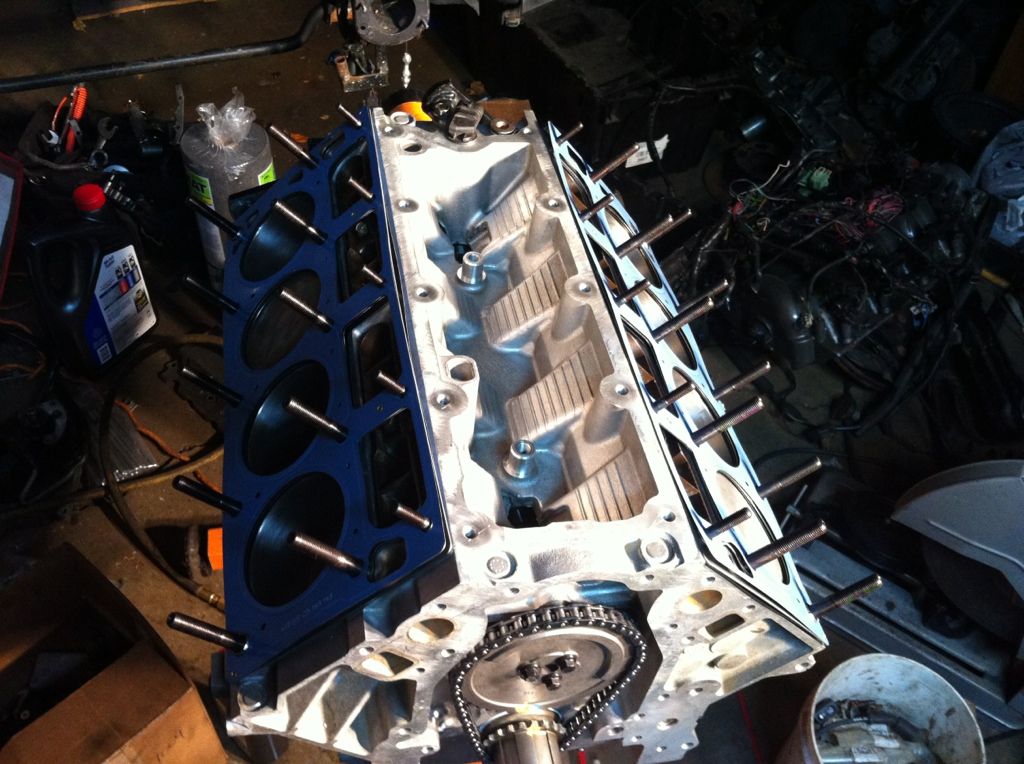

I literally brought him the block, new rods, crank, reused the pistons, new rings, honed, cleaned the block, brand new cam, brand new valves, brand new springs, new crank pulley, new crank bolt, new lifters, new gaskets all around, and all the specs for everything either in their original packages or from GM directly. I paid him to do the head work and assemble just the shortblock. His measuring and assembly was based on him being an engine builder, as i am not, i dont do it for a living and dont have the machinery.

As far as the stud kit goes, i called ARP, Texas Speed, a couple of the local machine shops, and a local speed shop, they all said that theres nothing wrong with installing studs and that theyre just hand tightened then the heads are torqued on top. I used a digital ac delco and snap torque wrench to assemble the rest of the engine.

As far as the stud kit goes, i called ARP, Texas Speed, a couple of the local machine shops, and a local speed shop, they all said that theres nothing wrong with installing studs and that theyre just hand tightened then the heads are torqued on top. I used a digital ac delco and snap torque wrench to assemble the rest of the engine.