100 Mile Motor Help

#1

I have a GM crate LS6 engine with upgrades. The engine has about 100 miles on it. The heads and cam were bought about a year ago. The mail order tune was last fall. The car has low miles due to final assembly after paint. It would start at the turn of a key and ran good. I was cruising through my neighbor hood at 30-40 mph. A loud metallic clatter and loss of power.

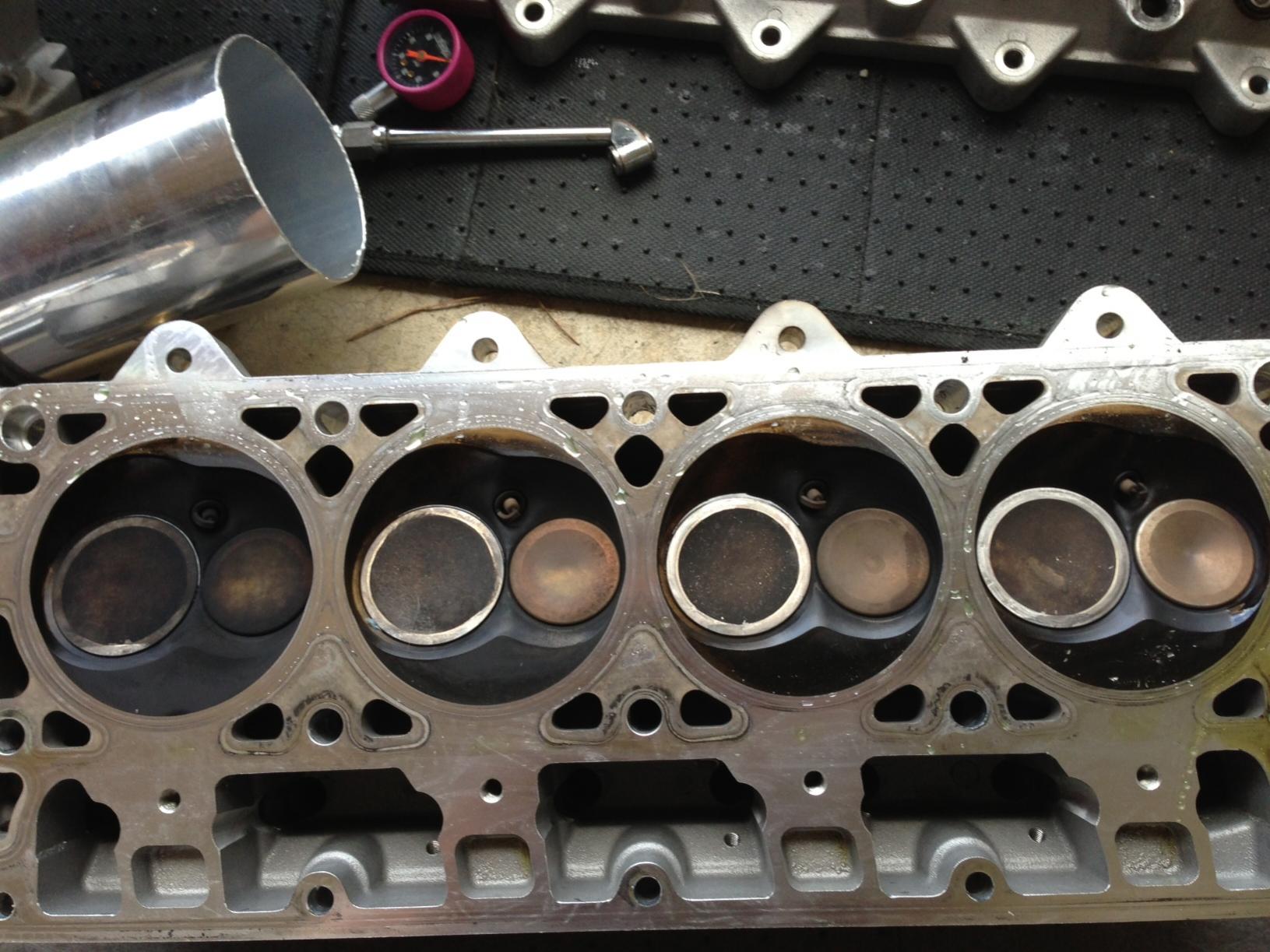

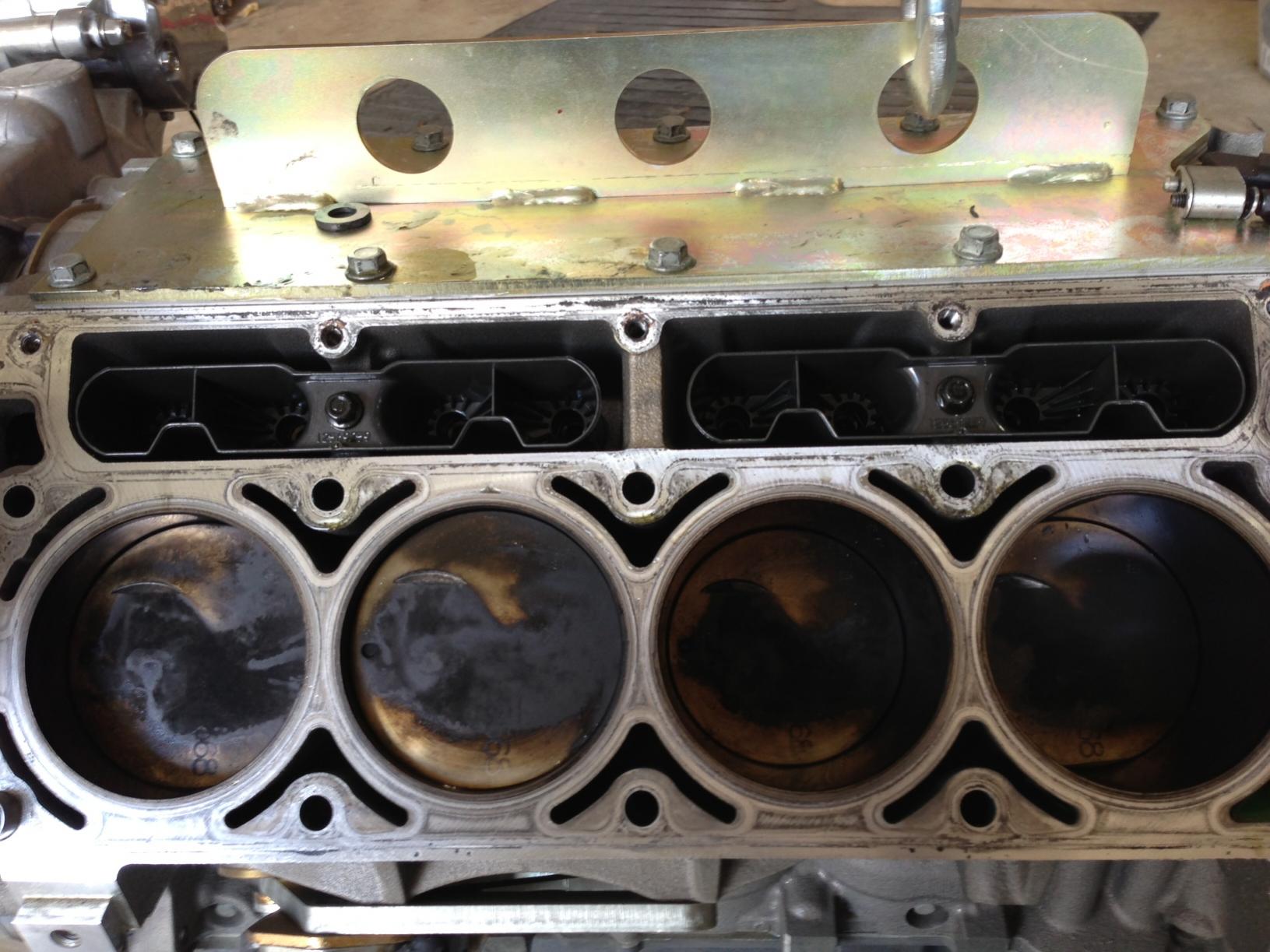

After partial disassembly, here are the pictures and damage. The push rod was broken into 3 pieces. The valve keeper was still in place. The valve head was snapped at the head and is wedged into the chamber.

1) Any thoughts on cause?

2) Does the engine need to be torn down and all bearings replaced along with the piston, rod and 1 set of bearings?

Here are the components:

GM crate engine LS6

TSP/PRC 227 Heads w .675 lift springs

TSP Tsunami cam

TSP mail order Tune

Cometic .041 MLS head gaskets

Edelbrock 90mm TB

Edelbrock Pro Flo intake

Comp Cams Magnum push rods

Stock lifters

Stock oil pump

After partial disassembly, here are the pictures and damage. The push rod was broken into 3 pieces. The valve keeper was still in place. The valve head was snapped at the head and is wedged into the chamber.

1) Any thoughts on cause?

2) Does the engine need to be torn down and all bearings replaced along with the piston, rod and 1 set of bearings?

Here are the components:

GM crate engine LS6

TSP/PRC 227 Heads w .675 lift springs

TSP Tsunami cam

TSP mail order Tune

Cometic .041 MLS head gaskets

Edelbrock 90mm TB

Edelbrock Pro Flo intake

Comp Cams Magnum push rods

Stock lifters

Stock oil pump

#2

12 Second Club

iTrader: (4)

Piston looks to have a hole in it! That will need to be replaced. Did a valve spring break? It may have droped the valve and what your seeing is what happened after the piston shoved it back up in the head and pounded the crap outta it. Sorry this happened man for whatever the cause was but this looks to be a major rebuild. Take it all to a machine shop and see what they can do for you.

#4

TECH Resident

iTrader: (4)

I'd be really curious about the ptv clearance running that big of a cam with the cometic gaskets and stock flat top style pistons without valve reliefs. Depending on your deck height you could theoretically have been as much as 0.010" out of the hole at TDC. Was ptv measured when you/whoever installed the new cam? Any signs of contact in any of the other cylinders?

#9

The heads were not milled. They were off the shelf PRC 227 from Texas Speed. The chambers are 62cc. All of the parts were ordered based on their recommendation. The cam was chosen because of the lack of PTV clearance issues unlike the higher risk with the MS3 and MS4 cams.

All of the other cylinders on this side look perfect as well as the head. I will mount the head tomorrow and double check the PTV after the engine is out. I will also check 1-7 cylinders.

Thanks for input all.

TT

All of the other cylinders on this side look perfect as well as the head. I will mount the head tomorrow and double check the PTV after the engine is out. I will also check 1-7 cylinders.

Thanks for input all.

TT

#12

TECH Addict

iTrader: (88)

well PTV should have been checked because the piston can come out of the hole 0-.010 and add that to the .040 cometic gaskets and you can have a problem without valve reliefs...

But if they suggested it then it doesnt seem it was PTV clearance only because Texas speed does alot of combos and they have probably seen and heard of every combo on the ls1 engine with their products and thats why they are comfortable telling people over the phone which pushrods to run without checking length, and that a certain cam won't have PTV clearance problems with the suggested head....

but even still it should have been checked that way when this happend you would know right away that its not pushrod length or PTV clearance because you made sure it was spot on...

keep us posted on what you find, the heads look to be done and un repairable... the cylinder walls look ok from the pic but a machine shop will tell you whats up when you get there..

#14

I pulled the motor today and started disassembly. All the other chamber, cylinders and head look normal. I will pick up a couple of solid lifters tomorrow and measure PTV. The rod bearing and journal look great.

Can I replace the piston, rod and bearing only? Do need to tear the entire assembly down, clean, inspect, replace all bearings?

Can I replace the piston, rod and bearing only? Do need to tear the entire assembly down, clean, inspect, replace all bearings?

#15

TECH Resident

iTrader: (4)

so they did fly cut for the intake valves....I wonder with what size cutter? Did these come with the motor or did you / someone else do it with your cam install?

It's kinda hard to tell by your pictures, but it looks like you're having radial interference issues. If you look closely at the top of the fly cut and the perimeter of your valves, it almost looks like a freshly machined surface. If the one fly cut on the piston that failed wasn't cut as deep as the others, it could explain why that one failed while the others didn't. In addition to using an indicator, I'd also use the clay method to check ptv so you can have a look at your radial clearances.

It's kinda hard to tell by your pictures, but it looks like you're having radial interference issues. If you look closely at the top of the fly cut and the perimeter of your valves, it almost looks like a freshly machined surface. If the one fly cut on the piston that failed wasn't cut as deep as the others, it could explain why that one failed while the others didn't. In addition to using an indicator, I'd also use the clay method to check ptv so you can have a look at your radial clearances.

#17

That's MISTER MODERATOR

iTrader: (9)

Valves hit the pistons. No carbon build up in a crescent pattern on the pistons and every intake valve's perimeter is shiny-no carbon. Valves rotate as they do their thing.

I'd strip the block and have that cylinder sonic checked & magnafluxed, have the crank magnafluxed and don't even bother checking the rod, just replace it. Have ALL the intake valves checked for straightness. I'd outright replace them as we see they all hit.

Re-build the block and certainly check the PTV clearance.

Coulda been worse, broken rod, crank, block or all three.

I'd strip the block and have that cylinder sonic checked & magnafluxed, have the crank magnafluxed and don't even bother checking the rod, just replace it. Have ALL the intake valves checked for straightness. I'd outright replace them as we see they all hit.

Re-build the block and certainly check the PTV clearance.

Coulda been worse, broken rod, crank, block or all three.

#18

TECH Addict

iTrader: (88)

Valves hit the pistons. No carbon build up in a crescent pattern on the pistons and every intake valve's perimeter is shiny-no carbon. Valves rotate as they do their thing.

I'd strip the block and have that cylinder sonic checked & magnafluxed, have the crank magnafluxed and don't even bother checking the rod, just replace it. Have ALL the intake valves checked for straightness. I'd outright replace them as we see they all hit.

Re-build the block and certainly check the PTV clearance.

Coulda been worse, broken rod, crank, block or all three.

I'd strip the block and have that cylinder sonic checked & magnafluxed, have the crank magnafluxed and don't even bother checking the rod, just replace it. Have ALL the intake valves checked for straightness. I'd outright replace them as we see they all hit.

Re-build the block and certainly check the PTV clearance.

Coulda been worse, broken rod, crank, block or all three.