Thinking about switching cams

#21

Super Hulk Smash

iTrader: (7)

Attention to detail is my old standby mantra:

XE-R and LSK lobes that are used by many vendors in their shelf cams are hard on a valvetrain. If you understand that and accept the fact that you need to design the rest of the system to account for this, you can run XE-R lobes - and I'd NEVER run them with beehives. LSK I'd never advocate for a true street car, even one that sees the strip, unless you were willing to check things ever 3-5k miles. However, if you're just adding **** into a shopping cart on a vendor's site.

STOP.

LSK and XE-R lobes beat a valvetrain up pretty good. Running LS7 lifters, 5/16" pushrods, heavy stainless valves, stock rockers, and aggressive springs to try and control those crazy lobes and heavy valves = failure somewhere down the line as things degrade over time. What fails? Rockers fail, lifters fail, springs can bind and break, or cams can become galled and take out a lifter. Why is that happening? ****-poor matched components.

With an aggressive cam lobe you generally get "loft" where a lifter will actually come off the cam for a brief moment and then get slammed back down on the cam as the valvesprings try to keep the system together. The more spring pressure you put on the system, the less likely loft is to happen, but it happens because of weak pushrods that flex and allow some spring pressure to be lost and the lifter to take flight. The problem is the lifter comes crashing back down and that can damage the lifter, cam, pushrod, or beat on the rockers and cause them to fail. It usually doesn't happen right away. But after 5-10k miles, you see the issues. As you increase the spring pressure trying to control everything, you put more stress on the rockers, pushrods, and lifters. It just becomes a problem that escalates.

How do you avoid this? First, get an endurance type lobe. Comp has them in LXL, HUC, Xtreme RPM. EPS has them as well with their proprietary lobes. Ed Curtis has his own lobes that work. Brian Tooley sells versions of his cams using these lobes too. You might give up a few HP at the top end with more endurance specific profiles, but you gain a lot of stability which can be worth HP and certainly longevity.

When spec'ing out a system take into consideration the two sides of the fulcrum on the rocker: valve side and lifter side. Lifter side, you want stout pushrods like 11/32nds or better, quality lifters designed to take aftermarket valvespring pressures, and endurance cam lobes that won't beat a system to ****.

On the valve side, a lighter valve is easier to control and requires less valve spring. And less spring is usually lighter as well, which just adds to the overall goodness of the system. A lightweight rocker is also important (the GM rocker is the lightest and one of the strongest - keep it).

When you combine lightweight over the valve with strength on the lifter side all with an endurance lobe profile, you end up with a pretty well engineered system.

My valvetrain is setup like that. Lightweight turned-down LS3 valves are 83g vs the stock LS1 100g and 110g for most aftermarket valves. The rockers are stock w/upgraded trunions. The valvesprings are Custom PAC 1900 with Ti retainers which have 150lbs seat pressure but only 400 open to be stock rocker friendly. I went with Manton 11/32 pushrods to eliminate flex and Morel 5206 lifters, because they are billet bodies with oversize rollers to create more surface area contact with the camshaft. And lastly, I have an EPS lobed cam that was ground on a Cam Motion billet core to ensure valvetrain stability. It costs more to do it this way and may require talking to several vendors. But if you're doing the work yourself, it'll be worth it.

And always, always, set up your valvetrain correctly! Degree your cam, check pushrod length for preload, check wipe pattern on the valve, and ensure adequate piston-to-valve clearance. Any of those could be off and it would hurt power at best or destroy the engine at worse.

XE-R and LSK lobes that are used by many vendors in their shelf cams are hard on a valvetrain. If you understand that and accept the fact that you need to design the rest of the system to account for this, you can run XE-R lobes - and I'd NEVER run them with beehives. LSK I'd never advocate for a true street car, even one that sees the strip, unless you were willing to check things ever 3-5k miles. However, if you're just adding **** into a shopping cart on a vendor's site.

STOP.

LSK and XE-R lobes beat a valvetrain up pretty good. Running LS7 lifters, 5/16" pushrods, heavy stainless valves, stock rockers, and aggressive springs to try and control those crazy lobes and heavy valves = failure somewhere down the line as things degrade over time. What fails? Rockers fail, lifters fail, springs can bind and break, or cams can become galled and take out a lifter. Why is that happening? ****-poor matched components.

With an aggressive cam lobe you generally get "loft" where a lifter will actually come off the cam for a brief moment and then get slammed back down on the cam as the valvesprings try to keep the system together. The more spring pressure you put on the system, the less likely loft is to happen, but it happens because of weak pushrods that flex and allow some spring pressure to be lost and the lifter to take flight. The problem is the lifter comes crashing back down and that can damage the lifter, cam, pushrod, or beat on the rockers and cause them to fail. It usually doesn't happen right away. But after 5-10k miles, you see the issues. As you increase the spring pressure trying to control everything, you put more stress on the rockers, pushrods, and lifters. It just becomes a problem that escalates.

How do you avoid this? First, get an endurance type lobe. Comp has them in LXL, HUC, Xtreme RPM. EPS has them as well with their proprietary lobes. Ed Curtis has his own lobes that work. Brian Tooley sells versions of his cams using these lobes too. You might give up a few HP at the top end with more endurance specific profiles, but you gain a lot of stability which can be worth HP and certainly longevity.

When spec'ing out a system take into consideration the two sides of the fulcrum on the rocker: valve side and lifter side. Lifter side, you want stout pushrods like 11/32nds or better, quality lifters designed to take aftermarket valvespring pressures, and endurance cam lobes that won't beat a system to ****.

On the valve side, a lighter valve is easier to control and requires less valve spring. And less spring is usually lighter as well, which just adds to the overall goodness of the system. A lightweight rocker is also important (the GM rocker is the lightest and one of the strongest - keep it).

When you combine lightweight over the valve with strength on the lifter side all with an endurance lobe profile, you end up with a pretty well engineered system.

My valvetrain is setup like that. Lightweight turned-down LS3 valves are 83g vs the stock LS1 100g and 110g for most aftermarket valves. The rockers are stock w/upgraded trunions. The valvesprings are Custom PAC 1900 with Ti retainers which have 150lbs seat pressure but only 400 open to be stock rocker friendly. I went with Manton 11/32 pushrods to eliminate flex and Morel 5206 lifters, because they are billet bodies with oversize rollers to create more surface area contact with the camshaft. And lastly, I have an EPS lobed cam that was ground on a Cam Motion billet core to ensure valvetrain stability. It costs more to do it this way and may require talking to several vendors. But if you're doing the work yourself, it'll be worth it.

And always, always, set up your valvetrain correctly! Degree your cam, check pushrod length for preload, check wipe pattern on the valve, and ensure adequate piston-to-valve clearance. Any of those could be off and it would hurt power at best or destroy the engine at worse.

#22

FormerVendor

iTrader: (3)

I would look into our SNS Stage 2 camshaft. With TEA CNC ported 243's, Fast 92, ORY and a Borla cat-back it made 462rwhp/433rwtq. With a good tune it's a very drivable camshaft that performs extremely well across the board.

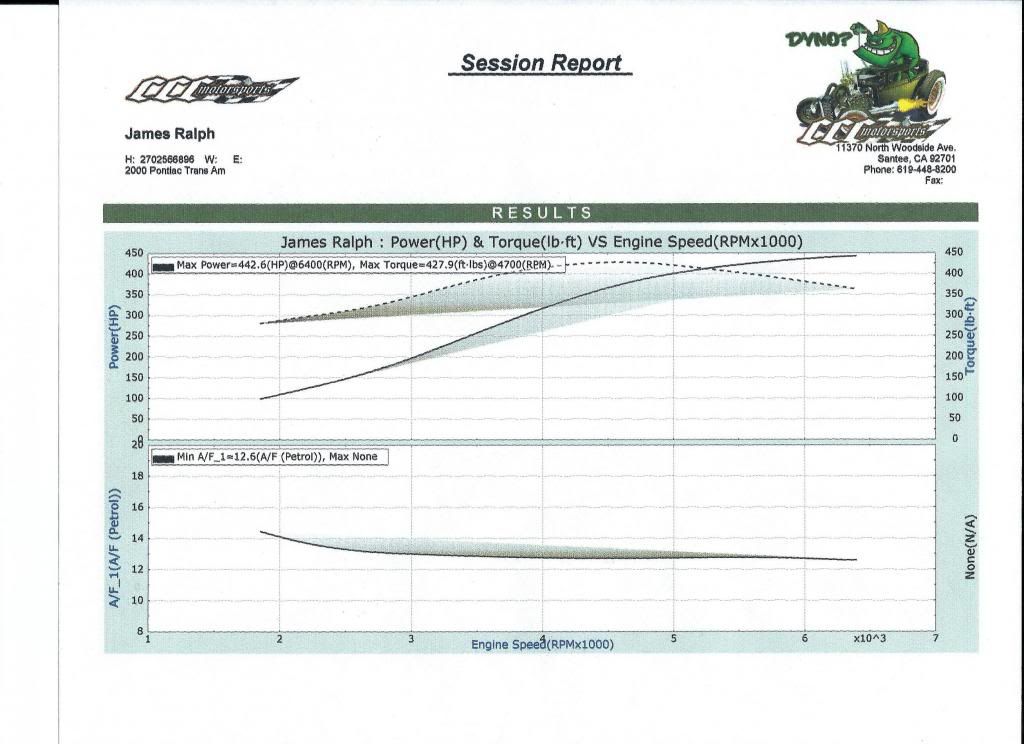

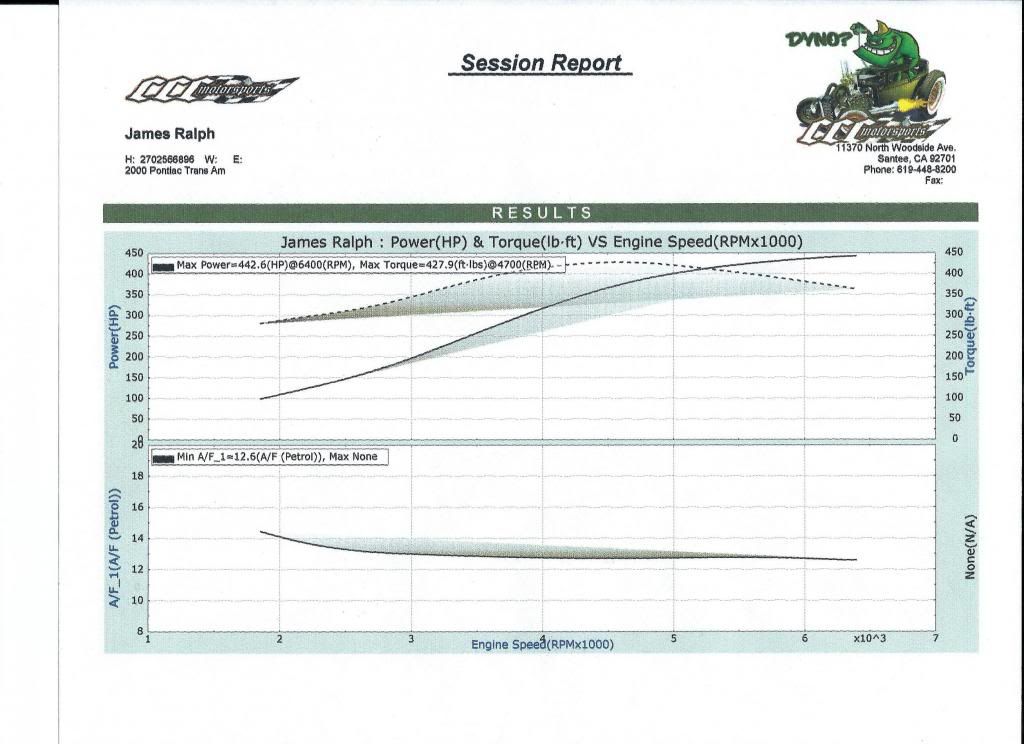

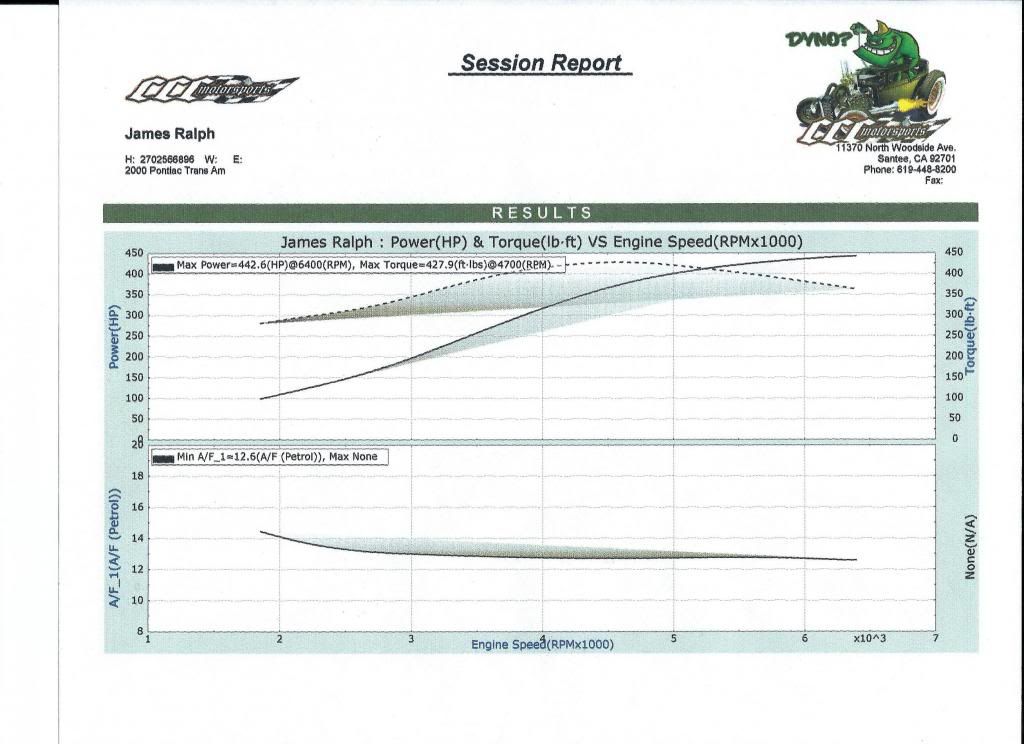

Here is a Mustang Dyno Graph of said car that made 462/433 at a later date on a Dyno Jet that I feel is still pretty stingy. Note the torque it makes under the curve while still pulling to 6500rpm where it would of kept going all the way to 7000rpm. It hasn't even peaked yet on this graph. With the right valve event's even a 227 degree duration intake lobe can carry to 7000rpm as shown here.

Your car being a six speed you will enjoy this torque much more than you would a "max effort" grind. Most "max effort cams" aside from my own, Ed's and Brian's(that I know for a fact) don't grind any intake center line advance into the camshaft. Or they don't grind enough. What this does with the large intake durations being used, is it closes the intake valve very late. With the intake manifold we are limited to with OEM style intakes, this makes for a huge loss in torque under 4500rpm. Only to gain a fraction of that back up top. With a 6 speed car that doesn't have at least a 4.10-4.30 rear gear and isn't willing to side step the clutch at 6500rpm at the track to run a good time, shouldn't consider a "max effort camshaft".

Last edited by Sales@Tick; 07-02-2013 at 09:44 AM.

#23

TECH Fanatic

iTrader: (9)

Join Date: Apr 2012

Location: Georgetown, Tx

Posts: 1,053

Likes: 0

Received 0 Likes

on

0 Posts

Sooner Brad, you've received some GREAT advice from some guys that really know there stuff. Take advantage of it. Setup and Goal are key, along w/ reliability. The guys here are helping you build a reliable setup if you follow their guidence. Ultimately, you will be better off planning your build using the cams and lobes suggested above. You'll make good power, and have a reliable setup "If" you use any of the cams suggested by Jake Fusion. Big hitters on this forum spoke, take their advice!

#24

10 Second Club

Thread Starter

iTrader: (15)

Join Date: Mar 2013

Location: Broken Arrow, OK

Posts: 337

Likes: 0

Received 0 Likes

on

0 Posts

See, putting a huge cam in with stock gears and differential will result in a badly matched combo that will suck below 4000+rpm and it will not yield good performance.

What are your differential gears? Pick a cam that will work well with those.

I bet you want it to sound mean, for that you do not need big durations you need overlap. If I were you I would look into about 9* overlap or so. Plenty for the street.

After all, is your car going to be driven? Or you just want a high dyno number to talk about and park it?

What are your differential gears? Pick a cam that will work well with those.

I bet you want it to sound mean, for that you do not need big durations you need overlap. If I were you I would look into about 9* overlap or so. Plenty for the street.

After all, is your car going to be driven? Or you just want a high dyno number to talk about and park it?

#25

10 Second Club

Thread Starter

iTrader: (15)

Join Date: Mar 2013

Location: Broken Arrow, OK

Posts: 337

Likes: 0

Received 0 Likes

on

0 Posts

Attention to detail is my old standby mantra:

XE-R and LSK lobes that are used by many vendors in their shelf cams are hard on a valvetrain. If you understand that and accept the fact that you need to design the rest of the system to account for this, you can run XE-R lobes - and I'd NEVER run them with beehives. LSK I'd never advocate for a true street car, even one that sees the strip, unless you were willing to check things ever 3-5k miles. However, if you're just adding **** into a shopping cart on a vendor's site.

STOP.

LSK and XE-R lobes beat a valvetrain up pretty good. Running LS7 lifters, 5/16" pushrods, heavy stainless valves, stock rockers, and aggressive springs to try and control those crazy lobes and heavy valves = failure somewhere down the line as things degrade over time. What fails? Rockers fail, lifters fail, springs can bind and break, or cams can become galled and take out a lifter. Why is that happening? ****-poor matched components.

With an aggressive cam lobe you generally get "loft" where a lifter will actually come off the cam for a brief moment and then get slammed back down on the cam as the valvesprings try to keep the system together. The more spring pressure you put on the system, the less likely loft is to happen, but it happens because of weak pushrods that flex and allow some spring pressure to be lost and the lifter to take flight. The problem is the lifter comes crashing back down and that can damage the lifter, cam, pushrod, or beat on the rockers and cause them to fail. It usually doesn't happen right away. But after 5-10k miles, you see the issues. As you increase the spring pressure trying to control everything, you put more stress on the rockers, pushrods, and lifters. It just becomes a problem that escalates.

How do you avoid this? First, get an endurance type lobe. Comp has them in LXL, HUC, Xtreme RPM. EPS has them as well with their proprietary lobes. Ed Curtis has his own lobes that work. Brian Tooley sells versions of his cams using these lobes too. You might give up a few HP at the top end with more endurance specific profiles, but you gain a lot of stability which can be worth HP and certainly longevity.

When spec'ing out a system take into consideration the two sides of the fulcrum on the rocker: valve side and lifter side. Lifter side, you want stout pushrods like 11/32nds or better, quality lifters designed to take aftermarket valvespring pressures, and endurance cam lobes that won't beat a system to ****.

On the valve side, a lighter valve is easier to control and requires less valve spring. And less spring is usually lighter as well, which just adds to the overall goodness of the system. A lightweight rocker is also important (the GM rocker is the lightest and one of the strongest - keep it).

When you combine lightweight over the valve with strength on the lifter side all with an endurance lobe profile, you end up with a pretty well engineered system.

My valvetrain is setup like that. Lightweight turned-down LS3 valves are 83g vs the stock LS1 100g and 110g for most aftermarket valves. The rockers are stock w/upgraded trunions. The valvesprings are Custom PAC 1900 with Ti retainers which have 150lbs seat pressure but only 400 open to be stock rocker friendly. I went with Manton 11/32 pushrods to eliminate flex and Morel 5206 lifters, because they are billet bodies with oversize rollers to create more surface area contact with the camshaft. And lastly, I have an EPS lobed cam that was ground on a Cam Motion billet core to ensure valvetrain stability. It costs more to do it this way and may require talking to several vendors. But if you're doing the work yourself, it'll be worth it.

And always, always, set up your valvetrain correctly! Degree your cam, check pushrod length for preload, check wipe pattern on the valve, and ensure adequate piston-to-valve clearance. Any of those could be off and it would hurt power at best or destroy the engine at worse.

XE-R and LSK lobes that are used by many vendors in their shelf cams are hard on a valvetrain. If you understand that and accept the fact that you need to design the rest of the system to account for this, you can run XE-R lobes - and I'd NEVER run them with beehives. LSK I'd never advocate for a true street car, even one that sees the strip, unless you were willing to check things ever 3-5k miles. However, if you're just adding **** into a shopping cart on a vendor's site.

STOP.

LSK and XE-R lobes beat a valvetrain up pretty good. Running LS7 lifters, 5/16" pushrods, heavy stainless valves, stock rockers, and aggressive springs to try and control those crazy lobes and heavy valves = failure somewhere down the line as things degrade over time. What fails? Rockers fail, lifters fail, springs can bind and break, or cams can become galled and take out a lifter. Why is that happening? ****-poor matched components.

With an aggressive cam lobe you generally get "loft" where a lifter will actually come off the cam for a brief moment and then get slammed back down on the cam as the valvesprings try to keep the system together. The more spring pressure you put on the system, the less likely loft is to happen, but it happens because of weak pushrods that flex and allow some spring pressure to be lost and the lifter to take flight. The problem is the lifter comes crashing back down and that can damage the lifter, cam, pushrod, or beat on the rockers and cause them to fail. It usually doesn't happen right away. But after 5-10k miles, you see the issues. As you increase the spring pressure trying to control everything, you put more stress on the rockers, pushrods, and lifters. It just becomes a problem that escalates.

How do you avoid this? First, get an endurance type lobe. Comp has them in LXL, HUC, Xtreme RPM. EPS has them as well with their proprietary lobes. Ed Curtis has his own lobes that work. Brian Tooley sells versions of his cams using these lobes too. You might give up a few HP at the top end with more endurance specific profiles, but you gain a lot of stability which can be worth HP and certainly longevity.

When spec'ing out a system take into consideration the two sides of the fulcrum on the rocker: valve side and lifter side. Lifter side, you want stout pushrods like 11/32nds or better, quality lifters designed to take aftermarket valvespring pressures, and endurance cam lobes that won't beat a system to ****.

On the valve side, a lighter valve is easier to control and requires less valve spring. And less spring is usually lighter as well, which just adds to the overall goodness of the system. A lightweight rocker is also important (the GM rocker is the lightest and one of the strongest - keep it).

When you combine lightweight over the valve with strength on the lifter side all with an endurance lobe profile, you end up with a pretty well engineered system.

My valvetrain is setup like that. Lightweight turned-down LS3 valves are 83g vs the stock LS1 100g and 110g for most aftermarket valves. The rockers are stock w/upgraded trunions. The valvesprings are Custom PAC 1900 with Ti retainers which have 150lbs seat pressure but only 400 open to be stock rocker friendly. I went with Manton 11/32 pushrods to eliminate flex and Morel 5206 lifters, because they are billet bodies with oversize rollers to create more surface area contact with the camshaft. And lastly, I have an EPS lobed cam that was ground on a Cam Motion billet core to ensure valvetrain stability. It costs more to do it this way and may require talking to several vendors. But if you're doing the work yourself, it'll be worth it.

And always, always, set up your valvetrain correctly! Degree your cam, check pushrod length for preload, check wipe pattern on the valve, and ensure adequate piston-to-valve clearance. Any of those could be off and it would hurt power at best or destroy the engine at worse.

#26

10 Second Club

Thread Starter

iTrader: (15)

Join Date: Mar 2013

Location: Broken Arrow, OK

Posts: 337

Likes: 0

Received 0 Likes

on

0 Posts

I believe it made 444rwtq.

I would look into our SNS Stage 2 camshaft. With TEA CNC ported 243's, Fast 92, ORY and a Borla cat-back it made 462rwhp/433rwtq. With a good tune it's a very drivable camshaft that performs extremely well across the board.

Here is a Mustang Dyno Graph of said car that made 462/433 at a later date on a Dyno Jet that I feel is still pretty stingy. Note the torque it makes under the curve while still pulling to 6500rpm where it would of kept going all the way to 7000rpm. It hasn't even peaked yet on this graph. With the right valve event's even a 227 degree duration intake lobe can carry to 7000rpm as shown here.

Your car being a six speed you will enjoy this torque much more than you would a "max effort" grind. Most "max effort cams" aside from my own, Ed's and Brian's(that I know for a fact) don't grind any intake center line advance into the camshaft. Or they don't grind enough. What this does with the large intake durations being used, is it closes the intake valve very late. With the intake manifold we are limited to with OEM style intakes, this makes for a huge loss in torque under 4500rpm. Only to gain a fraction of that back up top. With a 6 speed car that doesn't have at least a 4.10-4.30 rear gear and isn't willing to side step the clutch at 6500rpm at the track to run a good time, shouldn't consider a "max effort camshaft".

I would look into our SNS Stage 2 camshaft. With TEA CNC ported 243's, Fast 92, ORY and a Borla cat-back it made 462rwhp/433rwtq. With a good tune it's a very drivable camshaft that performs extremely well across the board.

Here is a Mustang Dyno Graph of said car that made 462/433 at a later date on a Dyno Jet that I feel is still pretty stingy. Note the torque it makes under the curve while still pulling to 6500rpm where it would of kept going all the way to 7000rpm. It hasn't even peaked yet on this graph. With the right valve event's even a 227 degree duration intake lobe can carry to 7000rpm as shown here.

Your car being a six speed you will enjoy this torque much more than you would a "max effort" grind. Most "max effort cams" aside from my own, Ed's and Brian's(that I know for a fact) don't grind any intake center line advance into the camshaft. Or they don't grind enough. What this does with the large intake durations being used, is it closes the intake valve very late. With the intake manifold we are limited to with OEM style intakes, this makes for a huge loss in torque under 4500rpm. Only to gain a fraction of that back up top. With a 6 speed car that doesn't have at least a 4.10-4.30 rear gear and isn't willing to side step the clutch at 6500rpm at the track to run a good time, shouldn't consider a "max effort camshaft".

#27

12 Second Club

iTrader: (10)

Join Date: Jan 2007

Location: Charleston, SC

Posts: 226

Likes: 0

Received 0 Likes

on

0 Posts

I made 446/426 to the wheels with my COMP XR281HR. 228/230 .571/.573 112. Not even close to aggressive compared to some of the cams listed here and my compression was low. Using off the shelf AFR205s, unmodified FAST90/90, and 1 3/4 Pacesetters.

#28

10 Second Club

Thread Starter

iTrader: (15)

Join Date: Mar 2013

Location: Broken Arrow, OK

Posts: 337

Likes: 0

Received 0 Likes

on

0 Posts

^Nice

I've also been seeing a lot of the "bigger" cams have a much higher hp than tq number. Is that a sacrifice for having an extreme cam? I feel like I would rather have a closer set of numbers like whitedevil or the number martin posted.

I've also been seeing a lot of the "bigger" cams have a much higher hp than tq number. Is that a sacrifice for having an extreme cam? I feel like I would rather have a closer set of numbers like whitedevil or the number martin posted.

#29

TECH Senior Member

227/235 111+2 LSA,

9* overlap so nice lope, 42.5 IVC for 6300 rpm peak (6600>6800rpm shifts), equidistant IVO/EVC from TDC (will carry nicely after peak); will work well with 3.42:1 diff.

Something in that range to work with the mods you already have.

9* overlap so nice lope, 42.5 IVC for 6300 rpm peak (6600>6800rpm shifts), equidistant IVO/EVC from TDC (will carry nicely after peak); will work well with 3.42:1 diff.

Something in that range to work with the mods you already have.

#31

12 Second Club

iTrader: (10)

Join Date: Jan 2007

Location: Charleston, SC

Posts: 226

Likes: 0

Received 0 Likes

on

0 Posts

Whatever you do, just make sure you don't overlook your DCR like I did. I didn't account for my 4cc valve pockets and cam timing so my DCR was weak. Still made great power but left a LOT on the table. Also cheap headers and older intake held me back. We will see how this revision goes...I'm pretty excited.

As far as your situation, I wouldn't hesitate to use a bigger cam than I did, but don't think smaller ones won't put up some numbers. Pay the most attention to your heads. That goes for money too, since heads are where you make your money anyways. Start there and work away from it. Whatever application you want, get the heads there, then get the cam that will go with it. I'd advise working with a pro, since messing with heads is a big deal.

As far as your situation, I wouldn't hesitate to use a bigger cam than I did, but don't think smaller ones won't put up some numbers. Pay the most attention to your heads. That goes for money too, since heads are where you make your money anyways. Start there and work away from it. Whatever application you want, get the heads there, then get the cam that will go with it. I'd advise working with a pro, since messing with heads is a big deal.

#33

12 Second Club

iTrader: (10)

Join Date: Jan 2007

Location: Charleston, SC

Posts: 226

Likes: 0

Received 0 Likes

on

0 Posts

And also remember there are a million factors that can affect the numbers. I had a 6 speed with a heavy clutch, 3.73 gears, heavy wheels, 10 bolt...the list goes on forever. As long as it's in a ball park range then you can turn your attention to how fast it goes in the real world.

#34

TECH Senior Member

#35

10 Second Club

Thread Starter

iTrader: (15)

Join Date: Mar 2013

Location: Broken Arrow, OK

Posts: 337

Likes: 0

Received 0 Likes

on

0 Posts

Good to know. Im only taking it to 6k right now. And she's running pretty healty so I may try to take it up a bit. With the cam you suggested earlier do you think a good set of 243s would do? I haven't heard otherwise.

#36

Super Hulk Smash

iTrader: (7)

You're doing fine shifting at 6k now because you have the stock cam. With any of the cams listed here, you're going to be a lot faster shifting 6600+ or more.

Btw, thanks 427zm for the kind words. I'm just a shadetree mechanic who wants everyone to have a well sorted setup.

Btw, thanks 427zm for the kind words. I'm just a shadetree mechanic who wants everyone to have a well sorted setup.

#39

10 Second Club

Thread Starter

iTrader: (15)

Join Date: Mar 2013

Location: Broken Arrow, OK

Posts: 337

Likes: 0

Received 0 Likes

on

0 Posts

Sooner Brad, you've received some GREAT advice from some guys that really know there stuff. Take advantage of it. Setup and Goal are key, along w/ reliability. The guys here are helping you build a reliable setup if you follow their guidence. Ultimately, you will be better off planning your build using the cams and lobes suggested above. You'll make good power, and have a reliable setup "If" you use any of the cams suggested by Jake Fusion. Big hitters on this forum spoke, take their advice!

Thanks to all you guys.