Can I degree my cam w/o the proper length pushrods?

#1

Teching In

Thread Starter

iTrader: (2)

Join Date: Sep 2005

Location: Long Beach, CA

Posts: 38

Likes: 0

Received 0 Likes

on

0 Posts

I'm in the middle of a heads & cam install and I still need to measure my push rod length and then degree the cam. Once I get the push rods measured, it's going to be a few days before the new one arrive and I'm wondering if I can degree the cam using either the stock push rods (which may be the wrong length) or my push rod length checker.

I haven't looked over the instructions on how to degree the cam in awhile so I'm not sure how that goes down. I do have a pair of checker springs on the heads right now.

I haven't looked over the instructions on how to degree the cam in awhile so I'm not sure how that goes down. I do have a pair of checker springs on the heads right now.

#3

Teching In

Thread Starter

iTrader: (2)

Join Date: Sep 2005

Location: Long Beach, CA

Posts: 38

Likes: 0

Received 0 Likes

on

0 Posts

Thanks! I couldn't remember if that was how it was done. I was about to put my new Cloyes hex-a-just cam gears on and then read how to degree the cam, but then I got worrying that I wouldn't be able to degree it without the push rods.

#4

12 Second Club

iTrader: (49)

WRONG information.

I wanna see you try to get the dial indicator down to reach the lifter without a pushrod. You can use any length pushrod, you are measuring the movement of the lifter on the cam lobe. Thats why you reset your dial indicator.

Make sure the lifter is on the cam's base circle. Put the pushrod in the solid lifter cup, then set your dial on the tip of the pushrod in the oil hole at the angle.

I wanna see you try to get the dial indicator down to reach the lifter without a pushrod. You can use any length pushrod, you are measuring the movement of the lifter on the cam lobe. Thats why you reset your dial indicator.

Make sure the lifter is on the cam's base circle. Put the pushrod in the solid lifter cup, then set your dial on the tip of the pushrod in the oil hole at the angle.

#5

TECH Fanatic

#6

TECH Senior Member

iTrader: (4)

WRONG information.

I wanna see you try to get the dial indicator down to reach the lifter without a pushrod. You can use any length pushrod, you are measuring the movement of the lifter on the cam lobe. Thats why you reset your dial indicator.

Make sure the lifter is on the cam's base circle. Put the pushrod in the solid lifter cup, then set your dial on the tip of the pushrod in the oil hole at the angle.

I wanna see you try to get the dial indicator down to reach the lifter without a pushrod. You can use any length pushrod, you are measuring the movement of the lifter on the cam lobe. Thats why you reset your dial indicator.

Make sure the lifter is on the cam's base circle. Put the pushrod in the solid lifter cup, then set your dial on the tip of the pushrod in the oil hole at the angle.

Trending Topics

#9

On The Tree

Join Date: Jul 2013

Location: Augusta, GA

Posts: 132

Likes: 0

Received 0 Likes

on

0 Posts

WRONG information.

I wanna see you try to get the dial indicator down to reach the lifter without a pushrod. You can use any length pushrod, you are measuring the movement of the lifter on the cam lobe. Thats why you reset your dial indicator.

Make sure the lifter is on the cam's base circle. Put the pushrod in the solid lifter cup, then set your dial on the tip of the pushrod in the oil hole at the angle.

I wanna see you try to get the dial indicator down to reach the lifter without a pushrod. You can use any length pushrod, you are measuring the movement of the lifter on the cam lobe. Thats why you reset your dial indicator.

Make sure the lifter is on the cam's base circle. Put the pushrod in the solid lifter cup, then set your dial on the tip of the pushrod in the oil hole at the angle.

#10

TECH Enthusiast

Join Date: Feb 2007

Location: Raleigh, NC

Posts: 625

Likes: 0

Received 0 Likes

on

0 Posts

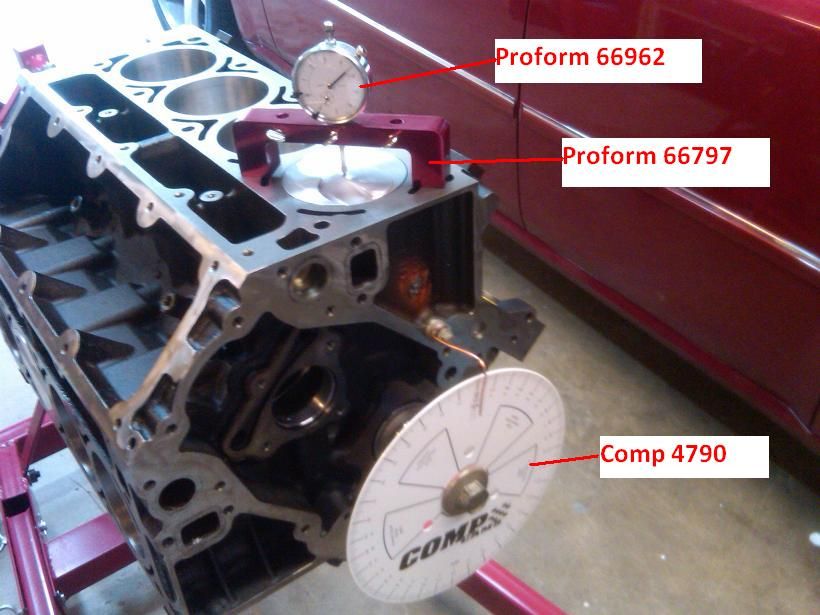

If the heads are still on the motor, you can use a piston stop to find TDC. You just need to install the piston stop, rotate the crank until the piston hits the piston stop, and set the zero on the timing wheel. From there, rotate the engine backwards until you hit the stop a second time, and take a reading from the degree wheel. TDC is half whatever the degree wheel reading is.

Remove piston stop and rotate engine to the calculated TDC value. Reset zero on the degree wheel pointer.

You can make a piston stop out of an old spark plug and bolt. Pictures here:

https://ls1tech.com/forums/generatio...l#post17541521

Remove piston stop and rotate engine to the calculated TDC value. Reset zero on the degree wheel pointer.

You can make a piston stop out of an old spark plug and bolt. Pictures here:

https://ls1tech.com/forums/generatio...l#post17541521

#11

TECH Fanatic

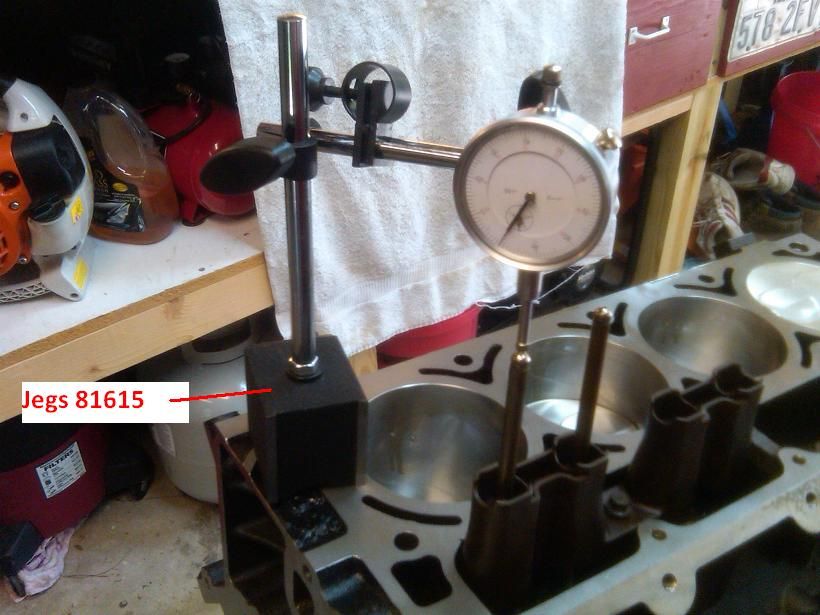

When measuring the closing side of the lobe, the lifter can get hung up in the lifter bore because the force from the dial indicator pushing it back down is so small. With a pushrod, you have plenty of space to grab the pushrod and push the lifter back down to resume contact with the cam lobe.

Also, the oem pushrods have a perfect cup at the top for holding the dial indicator probe. The other end of the pushrod is a natural fit with the lifter obviously.

Its like anything else, there are plenty of ways to get it done right. Very interested to see your pictures that you mentioned.